A case study by 3M explored the issues caused by sand production and tested their ceramic sand screen against a utility disrupted by this problem

Many factors such as the strength of a reservoir, cementation and reduction in pore pressure, fluid viscosity, and drawdown can all induce sand production. This can cause damage to downhole, subsea and surface equipment and can even lead to catastrophic failure. Production engineers across the industry have grappled with this potentially serious problem with solutions focused on reducing wellbore stress, improving consolidation, or transferring stress to some form of mechanical retention.

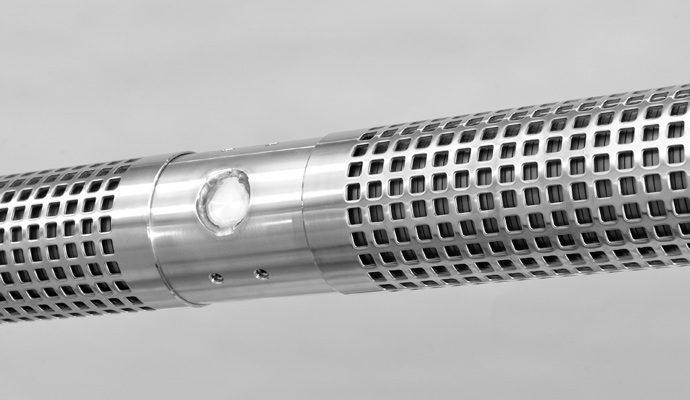

3M have recognised this issue, and have developed a ceramic sand screen as a solution. They have released a case study to test their product against a facility restricted by sand production:

The Challenge:

At a facility in the Caspian Sea, due to reservoir depletion, the operator was forced to restrict flow rate in order to achieve sand-free production. Without sand control already in place, the operator sought a cost-effective retrofit sand control solution to assure desired production rate in a high flux and impingement velocities environment.

The Solution:

The ceramic sand screen solution was speced-in to a given wellbore restriction and to set across the perforation zone using a rigless deployment technique. The coil tubing unit was utilised for wellbore clean out and subsequent deployment of the screen BHA in 2 runs.

The Results:

The case study demonstrated the applicability of ceramic sand screen as a stand-alone screen solution in unconsolidated, poorly sorted sand with nearly 30% fines content. The industry rule of thumb would have led to complaint sand control techniques adding complexity and cost. The operator achieved his goal of increasing production through a cost-effective retrofit solution deployed on coil tubing. Sand control was maintained at a higher drawdown so that within 5 days the equipment was paid back based on incremental oil production.

A strong collaboration and team effort between the operator, coil tubing service provider and 3M as a technology provider, enabled a cost-effective approach to achieve sand free production and unlocked the production potential from a challenging offshore oil producing well.

Visit https://multimedia.3m.com/mws/media/1903939O/3m-ceramic-san-screens.pdf to find out more.