Aker Solutions can now offer operators a Second Life Report on the raw materials a platform contributes to the circular economy as part of its decommissioning offering in light of the fact that 99% of a drilling platform can be recycled.

Aker Solutions can now offer operators a Second Life Report on the raw materials a platform contributes to the circular economy as part of its decommissioning offering in light of the fact that 99% of a drilling platform can be recycled.

The report spotlights the quantity of materials yielded in decommissioning work, and for topsides with heavy lift records, that leads to a lot of valuable raw materials. Maintaining more sustainable economic activity relies heavily on reusing as many materials as possible, as far less energy is used in the recovery of recycled materials than in the production of newer ones. Steel recovered offshore has many unique qualities and uses that can be capitalised on.

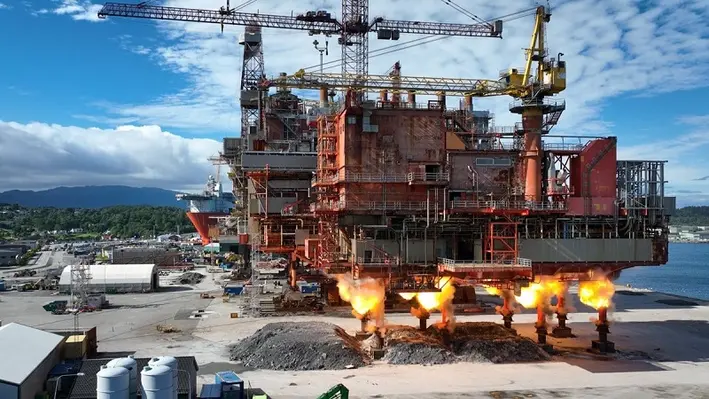

However, the process of rendering these huge structures into salvageable materials can be a brutal endeavour. For example, on its final journey, the drilling platform used in the Norwegian Valhall oil and gas field was carried on the Pioneering Spirit heavy lift vessel only to be left at the Aker Solution’s Stord yard in May 2022 as large machines waited to demolish it. The 6,700 ton platform was first stripped of all hazardous materials and electrical waste before it was levelled by explosives. This process, however, speeds up the demo and makes it safer by bringing down heavy structures to ground level, avoiding the need to work from height.

The original Valhall installations have produced over one billion barrels of oil equivalent since the field entered production in 1982, with two platforms having been recycled at the Stord yard, and a third will be decommissioned later this year. While the original structures will continue on as raw materials, Aker Solutions has aided Aker BP in extending the life of the remaining Valhall centre for an extra 40 years.

Aker Solutions has already accumulated a pipeline of orders for structural teardowns in the North Sea, and already have some 40,000 tons of recovered hulks awaiting dismantling and recycling at the Stord’s yard.