Decom Engineering, a provider of green decommissioning solutions, has proved the capabilities of its ‘neutrally-buoyant’ Chopsaw on a North Sea decommissioning project.

Offshore contractor Allseas tasked Decom Engineering with designing a chopsaw specifically for the unique challenges posed by the conductor removal scope for the Brent Charlie platform decommissioning campaign. This required 40 well conductors to be cut at various water depths and needed the Chopsaw to be positioned and powered from a ROW subsea (with several cuts below the conductor guide-frame).

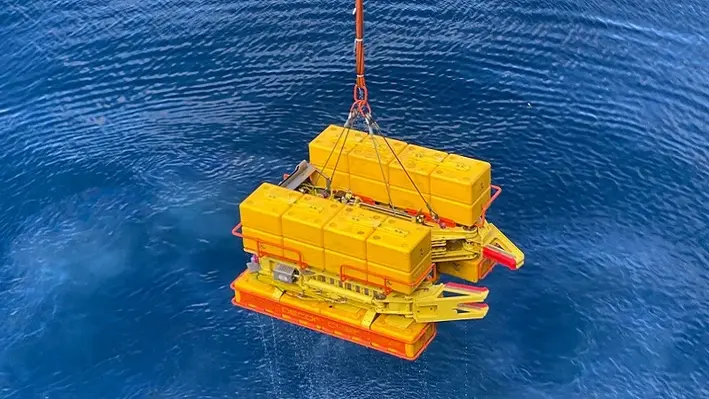

The tool, therefore, had to be neutrally buoyant in seawater, as well as being easily manoeuvrable with a single ROV. The Chopsaw width was also restricted to three metres due to the complexity of the conductor layout at the seabed.

"We successfully designed, manufactured, assembled, and tested the new Chopsaw within just six months, ready for offshore deployment from Allseas' heavy lift vessel Pioneering Spirit,” remarked Decom Engineering Managing Director, Sean Conway.

"The C1-32 Chopsaw has demonstrated its effectiveness in the field, completing numerous conductor cuts with an average cut time of approximately one hour. The tool's capability to perform multiple subsea cuts before needing to return to deck has saved both operational and vessel time.

"With the buoyancy functioning as designed and tested, the ROV was able to easily navigate the Chopsaw to and from each conductor, even at depths as shallow as 20 meters below sea level."

Complex cutting services

The C1-32 Chopsaw was engineered to cut conductors up to 32" outer diameter (OD), with a blade diameter of 2,100mm. Each of the 40 Brent Charlie conductors had an OD of 30 inches, consisting of both welded and Talon conductors, as well as some flexible risers.

With its neutrally buoyant design, the Chopsaw weighed approximately 6,700 kg in air but only about 50 kg in seawater, making it easily manoeuvrable by a ROV and allowing the tool to be flown into position and manoeuvred between conductors with precision.

To facilitate safe deployment and recovery, the Chopsaw was used in conjunction with a ‘deployment frame’ which allowed the tool to be quickly deployed to the correct subsea depth and safely through the splash zone. Once at the desired depth, the ROV connected the hot stabs, opened the clamps, and removed the tool from the frame.

“We have a strong relationship with Allseas, having worked for them on a previous North Sea platform removal project,” Conway concluded. “Completion of the Brent Charlie workscope further cements our credentials as a major provider of complex subsea conductor cutting services.

"Ongoing investment in R&D has been a critical factor in securing these projects and we will continue to invest and innovate so that our technologies remain as the market leader in cutting solutions."