Following the article from Colin Beharie (“P&A: Are you absolutely sure it’s plugged?”), we got a significant amount of questions on well’s plugging/abandonment. In this article, I will try to answer as many as possible.

-

- How many plugs are we supposed to pump?

- Is cement the only material existing for well abandonment?

- Is there an international standard governing the decommissioning of wells?

- Are there differences when it comes to permanent or temporal abandonment?

These were some of the questions popping out from our readers.

I have organized our answers in three main areas:

-

- Requirements for plug and abandonment of an oil/gas well – Legislation and Job design

- Materials to be used

- Abandonment techniques (placement methods, etc. including some of the new technologies that are out there already).

The scope of the article is quite broad, so I’ll split it into three sections; one for each area.

The topic should be straightforward since well abandonment is an inevitable stage in the life of a well and one that should be as obvious as drilling and casing it, but it is not. So let’s get started.

REQUIREMENTS FOR PLUG & ABANDONMENT (LEGISLATION)

From a legislation perspective, at least for offshore wells, the 1958 Geneva Convention rules, and the 1982 Law of the Sea regulations are the accepted framework for removal and disposal of offshore structures. Obviously, regulating offshore structures, it doesn’t apply to land wells for which there is no universal international regulation nor standard.

That said, the specificity, significance and in general, the approach towards well abandonment and decommissioning vary significantly by country. While some countries, especially the major oil and gas hubs, such as the Gulf of Mexico (GoM) and the North Sea, possess a detailed and specific legislation dictating the do’s and don’ts of decommissioning a well, other countries, like Italy, Ukraine, Angola, and Australia, only go as far as setting the goals of the P&A operation. Also, essential niches for the industry, such as Venezuela, Oman, Egypt, and Russia, have no known legislation on this matter.

Two of the most highly-regulated areas for well abandonment and intervention are the GoM and the North Sea. In both areas, most fields are reaching the end of their productive lives and are made up of aging infrastructure. These long-life producing regions that once pioneered offshore drilling are, under pressure. The public opinion focuses on environmental concerns and the official regulatory agencies actively intervening, getting ready to plug and abandon (P&A) a substantial number of wells in the next few years.

In the UK sector of the North Sea, (according to Abshire, Desai, Mueller, Paulsen, Robertson & Solheim, Oilfield Review, 2012 ) it was estimated that more than 500 structures with about 3,000 wells were slated for permanent abandonment as soon as possible. In the Norwegian sector, more than 350 platforms and more than 3,700 wells must be permanently abandoned. Additionally, there are more than 200 structures slated for decommissioning offshore the Netherlands, Denmark, Ireland, Spain, and Germany.

Globally, (according to Smith, Olstad & Segura, Offshore 71, 2011 ) an estimated 20,000 offshore idle wells have been identified for abandonment, with 60% located in GoM. Some of the GoM wells have been idle for five years or longer. The “Idle Iron” regulation (NTL No. 2010-N05) states that if a GoM well has not been productive for three or more years, the operator must put forward a plan, including a timeframe and methodology, to abandon it.

This proliferation of present and future P&A lead local regulatory bodies in these regions to set leading edge legislation that serves as an example to the industry and establishes “best practices” worldwide.

In the GoM, (regulated by the federal government’s Bureau of Safety and Environmental Enforcement) the “Idle Iron” regulations and guidelines for nonproducing wells were introduced in October 2010. They aim to provide some clarity about the required standards and outcomes expected from oil and gas companies as part of an abandonment philosophy.

The website of the Cornell Law School ( https://www.law.cornell.edu/cfr/text/30/250.1715) offers (for free) an excellent summary of the “Code of Federal Regulation,” title 30, Chapter II, Subchapter B, part 250, subpart Q, section 250.1715. This summary contains specifications on the length and location of barriers in the well and points towards the use of tools such as bridge plugs, retainers, baskets or cement as a barrier:

Source: 30 CFR 250.1715 (Legal Information Institute, 2015)

In the North Sea, regulated in the UK by the government’s Health and Safety Executive, and in Norway by NORSOK standards, similar legislation is available. But what is more interesting is that the UK offshore oil and gas organization (https://oilandgasuk.co.uk) offers a series of three comprehensive documents on well abandonment practices:

-

- “Guidelines for the Suspension and Abandonment of Wells.”

- “Guideline on qualification of materials for the abandonment of wells.”

- “Guideline on Cost Estimation of well abandonment operations.”

We will refer again next week to these documents as they will help us answer questions like “Can only cement be used as a barrier?”, but for now, let’s focus more on how to do it instead of on what to use.

The guideline defines that “abandonment of wells is concerned with the isolation of rock formations that have flow potential” and defines flow potential as coming from “formations with permeability and pressure differential with other formations or surface.” The assessment of flow potential is expected to consider the likelihood of flow under future conditions, i.e., “re-development for hydrocarbon extraction (possibly with enhanced recovery techniques),” underground gas storage projects, etc.

So, all penetrated zones with the potential to flow require isolation from each other and surface by a minimum of one permanent barrier or two when appropriate. Two barriers from the surface are required if the zone is hydrocarbon bearing or contains over-pressurized water.

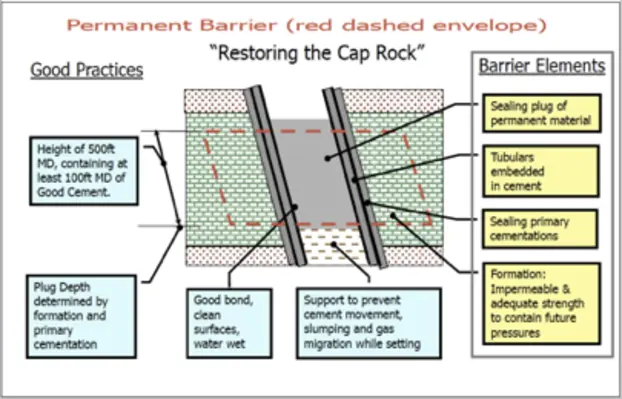

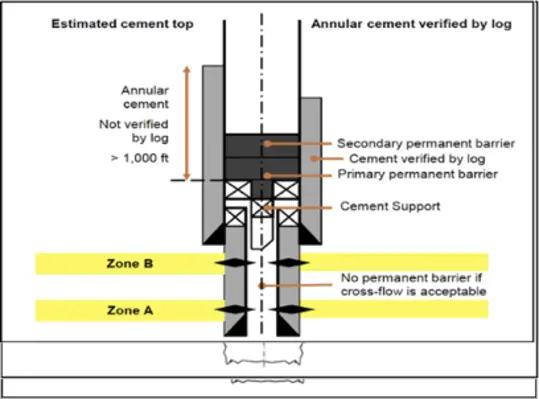

Figure 1. Source: Guidelines for the Abandonment of Wells, p12 (OGUK, 2015)

The barriers should be set in front of a suitable caprock (impermeable, laterally continuous and with adequate strength and thickness ). It should overlap annular cement and meet a specific list of best practices. See figure 1 for more details.

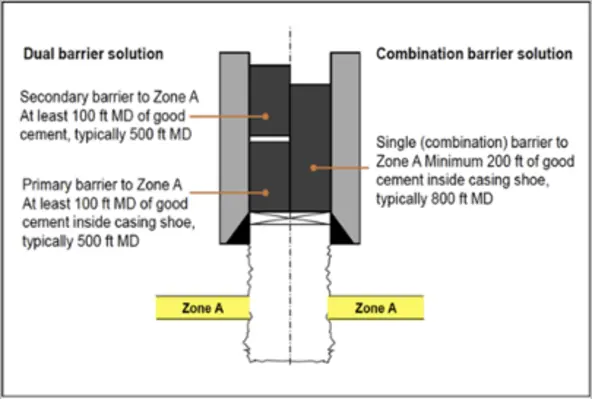

Figure 2. Example of permanent barriers for an open hole if potential internal pressure does not exceed the casing shoe fracture pressure. Source: Guidelines for the Abandonment of Wells, p16 (OGUK, 2015).

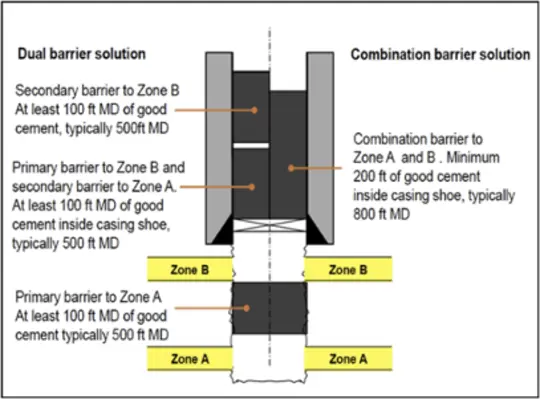

Figure 3. Example of open hole permanent barriers if zone A requires isolation from zone B, but the potential pressure from zone A does not exceed the casing shoe fracture pressure (one permanent barrier is adequate). Source: Guidelines for the Abandonment of Wells, p17 (OGUK, 2015).

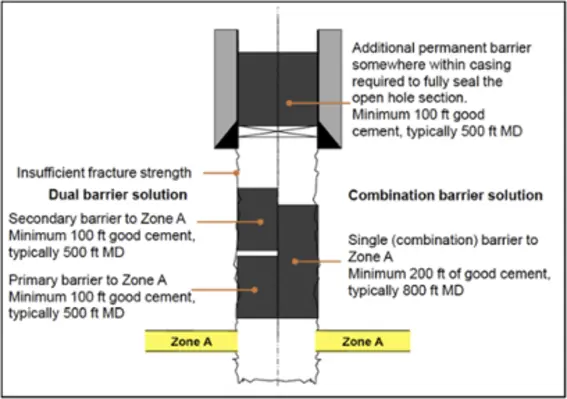

Figure 4. Example of open hole permanent barriers if potential internal pressure exceeds the casing shoe fracture pressure (two permanent barriers are required). Source: Guidelines for the Abandonment of Wells, p16 (OGUK, 2015).

The need for one or two barriers to isolate an open hole section is dictated by the conditions defined above regarding flow potential, and examples of its placement in open hole situations are shown in the guideline, see figure 2,3 and 4 for details.

For case hole sections, casing alone is not considered a barrier to the lateral flow, due to the potential for casing leaks, but cemented casing could be “as long as there is sufficient confidence in the quantity and quality of the cement in the annulus.” What this means is: If a log is available, 100 ft of good cement will do. If no logs are available then 1,000 ft of cement, using the theoretical top of cement as calculated by “differential pressures or monitored volumes during the original cement job,” would be required to allow for uncertainty. See figure 5.

Figure 5. Example of a cased hole abandonment schematic. The right side shows annulus cement verified by a log and the left side an estimated cement top. Source: Guidelines for the Abandonment of Wells, p19 (OGUK, 2015).

WHAT ABOUT THE REST OF THE WORLD?

A great place to get more information or examples of other countries legislation is the website of the Global Carbon Capture and Storage Institute which “presents an overview of official regulations concerning well abandonment for a selected number of countries and states… (based on) …countries and regions considered (…) significantly engaged in oil and gas production (and/or with good) accessibility of regulatory data”.

The main European producers, the US/Canada, China, Japan, Australia and the International conventions are discussed there.

For those of you sitting in a country that falls in the goal-setting approach group, you’ll have greater flexibility to design a fit-for-purpose well abandonment plan (which more likely will be significantly cheaper, too).

Having less clear guidelines in place puts increased emphasis on the regulatory bodies to carefully review, and subsequently approve, any plans for well decommissioning to ensure they will achieve long-term well integrity. In countries like Venezuela, with no clear governmental guidelines documented, well abandonment plans drafted by the operators go to the ministry of energy and mines and (sometimes) to the ministry of environment and waters. There, they are evaluated and approved case by case.

In these countries that have adopted a goal-setting approach, it is common to see the operators refer to guidelines like the one from OGUK to demonstrate that they have followed “industry best practice.” To experience their governments adopting international regulations, with slight modifications suitable for their geographic areas and demands, and to abide their needs and laws, wouldn’t be a surprise.

WHAT’S NEXT?

The guidelines, as mentioned earlier, also state what materials and tools can be used when and how. In the next article, I will cover how cement is not the only alternative to abandon wells, and what “melting the cap rock” means for well abandonment.

Since the regulations varies so much from country to country and operators take different approachs to P&A based as much on local legislation as on their own standards, please share with us your experiences from where you have worked. What did the law say, and what can you recall from the standards for P&A from those operators you worked with?

Miguel Diaz

Miguel has 20 years’ experience from operations, technical advisor, quality assurance, business development and management positions in the oil & gas industry from all areas of the high-pressure pumping services. He has worked in South America, the Caribbean Sea, central and eastern Europe, Sub-Sahara Africa and the middle east. Miguel serves as one of our cementing experts and is our Business Development Manager for the Middle East and North Africa region.