Interoil Exploration and Production ASA, a Norwegian-based exploration and production company with a focus on Latin America, has announced that its Colombian subsidiary has carried out a downhole intervention to the Vikingo well.

Interoil Colombia Exploration and Production (ICEP) successfully completed the project which included the installation of a jet pump with a modified operational configuration. In doing so, it raised production levels from 105 barrels of oil per day (bopd) up to an impressive 400 (bopd). Production is expected to stabilise at around 200 bopd and the intervention has also improved operational efficiency by reducing lifting costs with the new jet pump configuration.

“This intervention reaffirms Interoil’s confidence in the potential of our assets,” remarked Leandro Carbone, CEO of Interoil. “We are committed to maximising the value of our fields while creating lasting benefits for the local communities, our employees, and shareholders.”

The success of the project has been described by the company as a commitment to optimising production efficiency, extending the economic life of its assets, achieving social and environmental objectives, and exploring opportunities to expand its asset portfolio.

BiSN, a global provider of wel-lok sealing solutions, has achieved a remarkable milestone having reached 500 commercials deployments of its bismuth-based sealing technology.

The technology has now been deployed in more than 20 countries across the world, including in each of the major energy-producing regions having ticked off sites in North America, South America, UK & Europe, Africa, the Middle East, Asia, and Australia.

This new achievement comes off the back of another record setting period for the company, taking less than a year to achieve the last 100 deployments.

“With another year-on-year record of deployments, major operators around the globe are realising how effective wel-lok technology is for applications throughout the life cycle of a well, in addition to new industries,” remarked Paul Carragher, Founder and CEO of BiSN. “This year we have seen the first deployments in gas storage and carbon capture projects signalling new areas of growth and interest in our technology.”

According to the company, its commercial success has been significantly aided by its efforts to expand across the globe. Such an initiative has seen it open new facilities in Australia and Brazil in the last 12 months, which now work in tandem with the existing sites in Norway and Scotland.

Arild Stein, Senior Vice President of Research and Development, explained, “It is critical for BiSN to be where our clients are. The expansion strategy allows for the development of successful and lasting partnerships with operators, and to expand into new industries where our engineered sealing technology can be transformative.”

Despite the success, BiSN has made it clear that it has no intention to rest on its laurels but continues to refine and develop its wel-lok technology. Well suied for well intervention completion and P&A applications, the company is also targeting more use in additional activities such as around gas storage, hydrogen and carbon capture.

“Bismuth as a sealing material is particularly suited for the highly corrosive environment in CCS and gas storage projects,” surmised Stein “Bismuth alloy is impermeable and non-corrosive. We are very excited for this new growth area for BiSN and how it will enable the success of large-scale storage projects.”

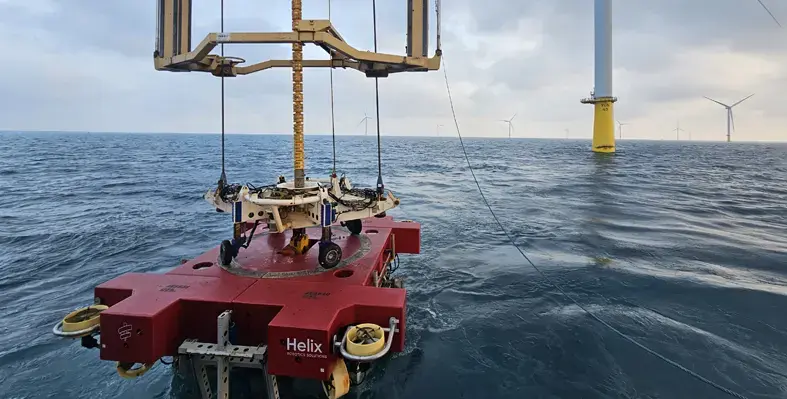

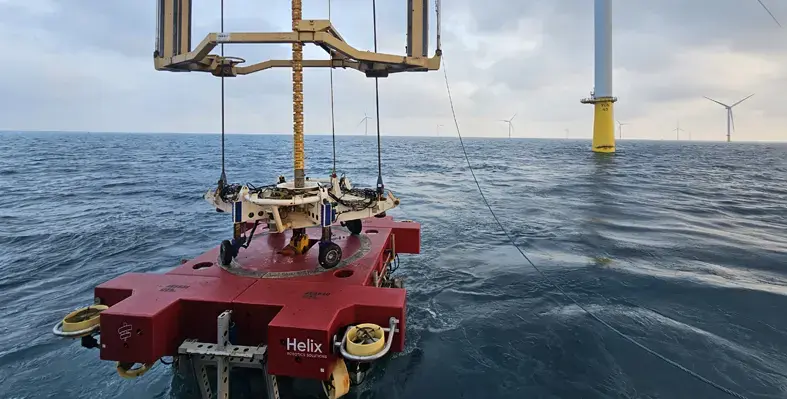

Helix Energy Solutions Group has announced new three-year vessel charter and service contracts with Petrobras for the riser-based well intervention vessels Siem Helix 1 and Siem Helix 2 working offshore Brazil.

Helix Energy Solutions Group has announced new three-year vessel charter and service contracts with Petrobras for the riser-based well intervention vessels Siem Helix 1 and Siem Helix 2 working offshore Brazil.

Finalised following a competitive tender process, the new three-year contracts are valued in aggregate at an estimated US$786mn, in accordance with Petrobras’ estimated value.

The Siem Helix 2, since 2017, has been performing riser-based well intervention activities for Petrobras in the Santos and Campos Basins, and to date has completed more than 100 well interventions.

The Siem Helix 1 previously worked for Petrobras from April 2017 – July 2021 completing 74 well interventions in the Santos and Campos Basins.

Daniel Stuart, Helix’s Vice President-Commercial, said, “We have built a long and productive working relationship with Petrobras for the last seven years. During this time, we have consistently delivered safe and cost-effective well intervention services to the Brazilian market. These new three-year contracts underscore Helix's commitment to innovation, tailored solutions, and leveraging our extensive global well intervention expertise. These contracts reaffirm our Energy Transition business model, empowering clients to optimise production from their existing assets.”

The Siem Helix 1 and Siem Helix 2 are purpose-built, advanced well intervention vessels capable of performing a wide range of subsea services including production enhancement, well decommissioning, subsea installation, offshore crane and Remotely Operated Vehicle operations, offshore construction, and emergency response.

Halliburton has been awarded a contract by Petrobras to provide a range of complete services in integrated well interventions and plug and abandonment for offshore wells in Brazil.

Halliburton has been awarded a contract by Petrobras to provide a range of complete services in integrated well interventions and plug and abandonment for offshore wells in Brazil.

Covering nearly two-thirds of all interventions and plug and abandonment work for Petrobras, the contract holds huge significance for Halliburton as it reinforces the company’s strategic position in the Brazilian market.

Services will include fluids, completion equipment, wireline, slickline, flowback services, and coiled tubing. These will be integrated through Halliburton’s project management service line to ensure efficient and effective execution.

"Our long-standing relationship with Petrobras exemplifies our ability to collaborate and engineer solutions to maximise their asset value. Halliburton’s offshore well intervention capabilities optimise production, extend well life, reduce costs, and access challenging reserves," said Halliburton's Chairman, President and CEO, Jeff Miller, while commenting on the multi-year contract which is set to begin in the second quarter of 2025.

Offshore Network has released the Wells Latin America 2024 Outlook that reviews the region's intervention and decommissioning drives, while considering the wave of new technology revolutioninsing the industry.

Offshore Network has released the Wells Latin America 2024 Outlook that reviews the region's intervention and decommissioning drives, while considering the wave of new technology revolutioninsing the industry.

The push behind these industry innovations come from watchdog organisations such as the Brazilian National Agency of Petroleum, Natural Gas and Biofuels (ANP) or Brazilian Institute of Environment and Renewable Natural Resources (IBAMA), which make sure that exploration and production activities are being carried out in a responsible and sustainable manner.

In Brazil, Petrobras have approximately 500 well interventions planned over the next 10 years, and also a significant decommissioning workload, which it has outlined in its 2024-2028 strategic plan. To achieve these feats, the company is actively researching cost-effective means to go about the task. Petrobras has plans to introduce thermite melting delivery in its operations this year. If all goes well, through tubing thermite P&A (TT P&A) delivery is expected by 2026, and the company is eyeing up the prospect of adopting self-abandonment technology by 2030.

The region's growing well intervention industry is taking inspiration from North Sea, where companies such as BiSN and RockSolid are introducing fresh approaches to well services. BiSN’s wel-lok technology, for example, uses bismuth as permanent seal for P&A operations, while RockSolid uses organic well barriers, eliminating the need for rigs or heavy equipments.

Reflecting on these landmark industry transformations that are currently sweeping through the region, Wells LATAM 2024 conference promises fully-rounded discussions and engaging exchanges.

A comprehensive session on plug and abandonment (P&A) regulatory update will be delivered by Rafael Augusto do Couto Albuquerque, Rigs and Wells Coordinator, ANP at the soon to happening Offshore Well Intervention Latin America (OWI LATAM), to be held from 18-19 October 2022, in the city of Rio, Brazil.

A comprehensive session on plug and abandonment (P&A) regulatory update will be delivered by Rafael Augusto do Couto Albuquerque, Rigs and Wells Coordinator, ANP at the soon to happening Offshore Well Intervention Latin America (OWI LATAM), to be held from 18-19 October 2022, in the city of Rio, Brazil.

In this particular session, the region’s premier well intervention conference will provide attendees with in-depth knowledge on analysing the current offshore well decommissioning situation in Brazil to best position businesses and service providers for upcoming P&A work.

Rafael will also shed light on ways to understand the challenges faced by new operators within the Brazilian market to best prepare for future projects. Attendees are also given in-depth knowledge of new intervention technologies and ways to validate the equipment so that the operators and service providers have the opportunity to optimise their toolbox.

OWI LATAM is poised to be the platform for discussion on the region’s offshore well intervention topics. The event features experts from international and regional companies, alongside regulatory bodies and service providers.

OWI LATAM is poised to be the platform for discussion on the region’s offshore well intervention topics. The event features experts from international and regional companies, alongside regulatory bodies and service providers.

To know more about the full programme, click here: https://www.offsnet.com/latam/conference-brochure

Or reach out to the details below:

Rachael Brand

Project Manager

T: +44 (0) 20 3409 3041

Accelerating the company's growth in the Brazilian market, Archer has secured a two-year platform drilling and well intervention contract with Trident Energy do Brasil, amounting to US$20mn.

The contract also leaves scope for an extension by an additional one year upon mutual agreement. This new award supports Archer’s growth in the Brazilian market and underscores our commitment to high-quality, innovative solutions in the energy industry.

Under the contract, Archer will provide comprehensive platform drilling services, including well interventions for regulatory requirements, workover and drilling operations, well maintenance and drilling facilities engineering, to enhance Trident Energy’s offshore assets in Brazil. The platform drilling services are set to commence during second quarter this year, initially on the Pampo PP1 platform, which follows a period of rig reactivation and recertification managed through Archer’s Platform Operations group.

Dag Skindlo, CEO of Archer, said, “We are pleased to be chosen by Trident Energy as their partner for their drilling programme. We look forward to a successful collaboration with Trident Energy and are confident in our ability to contribute to the success of their offshore operations.

"This contract builds on our continued growth as we continue to strengthen our position in the growing energy market in Brazil. Our legacy in Brazil stretches back to 2010, when we commenced our work for Equinor on the Peregrino fields, followed by the successful establishment and growth of our well services division over the last few years. We are excited about the Brazilian market and how our core services offering can support the broad spectrum of client well programmes in Brazil.”

Energy technology company Baker Hughes has announced a significant order from Petrobras for workover and plug and abandonment (P&A) services in pre- and post-salt fields offshore Brazil.

Energy technology company Baker Hughes has announced a significant order from Petrobras for workover and plug and abandonment (P&A) services in pre- and post-salt fields offshore Brazil.

The multi-year project is set to begin in H1 2025. Baker Hughes’ integrated solutions portfolio will aid with the deployment of wireline, coiled tubing, cementing, tubular running, wellbore intervention, fishing, and geosciences services across all of Petrobras’ offshore fields. The agreement also includes Baker Hughes’ remedial tool, completion fluids and production chemicals.

Maria Claudia Borras, Executive Vice President, Oilfield Services & Equipment at Baker Hughes, said, “Baker Hughes brings to this important project a comprehensive technology portfolio, a deep understanding of localisation, and a rich history of working in Brazil.

“Flawlessly integrating these capabilities will be essential to the success of the project. Our expertise in integrated solutions is the foundation for efficiently taking energy forward in Brazil.”

To support the project and help advance Latin America’s energy landscape, Baker Hughes will expand its Rio de Janeiro facilities to include coiled tubing and tubular running services to contribute to the growth of the Brazilian industry.

Export credit agency UK Export Finance (UKEF) will be supporting Brazilian contractor Ocyan's decommissioning drive with a US$7.5mn guarantee.

Export credit agency UK Export Finance (UKEF) will be supporting Brazilian contractor Ocyan's decommissioning drive with a US$7.5mn guarantee.

After initial discussions with UKEF, Ocyan onboarded Scottish business Maritime Developments Ltd in 2022 who would take care of the equipment needs for the decommissioning project in Brazil. This was made possible using the UKEF grant which helped Ocyan procure financing from ABC International Bank to successfully set off the MDL deal. The grant will be applicable on a reimbursement basis, boosting its access to working capital.

Charlotte Wiltshire, European Head of Wholesale Banking, ABC International Bank plc said, "We are delighted to continue our support of UK businesses in conjunction with UKEF, leveraging off Bank ABC Group’s MENA and international footprint. This is an important milestone transaction, promoting the UK’s expertise in the oil and gas decommissioning and renewable energy arena. Bank ABC is looking forward to enabling similar energy transition projects in future."

A subsea pipelaying specialist from Aberdeen, MDL's wheeled horizontal lay system technology will be deployed by Ocyan to remove hundreds of kilometres of subsea cables and pipes from defunct FPSO oil and gas rigs in Brazilian waters.

Andrew Blaquiere, MDL Managing Director, said, "MDL is known worldwide for our forward-thinking technology that enables challenging scopes to progress on time and on budget, and this delivery to a Brazilian indigenous company is proof of that. Our engineering studies identified limitations with existing technology on the market when it came to recovery capability from deep waters like those in Brazil. The alternative for these operations would be to use a specialist construction vessel, resulting in high cost and scheduling challenges.

"In a true MDL ‘We Build Innovation’ style, we put our heads together, brainstormed alternative approaches – and delivered the Wheeled HLS. As a result, the client – and the Brazilian market – gained a cost-effective way to kit-out a vessel of opportunity to handle high loads and tackle recovery projects – this way enabling more sustainable end-of-life operations."

The first-ever overseas grant from UKEF also stands to benefit more than 70 Scottish businesses which are responsible for the entirely local MDL model.

Private equity investors Buckthorn Partners and One Equity Partners (OEP) have acquired Acteon Group, an international offshore energy infrastructure services businesses, in a move to develop the organisation’s capabilities in key markets.

The two entities have announced a significant injection of investment that will be used to improve Acteon’s standing with suppliers and customers. The company has been active since 1989 and now provides specialist engineering, services and technologies across all phases of the offshore lifecycle in 14 countries worldwide.

A key focus of this new occurrence will be placed on developing the organisation’s capabilities across survey, foundations, moorings, decommissioning, and consulting engineering services in support of the offshore renewable offshore oil and gas sectors.

“Acteon’s products and services are key to the energy transition in constructing, maintaining and supporting offshore energy infrastructure,” remarked Rob Willings, Partner at Buckthorn. “We are very pleased to acquire Acteon and its market-leading capability in managing offshore renewable, and offshore oil and gas infrastructure. Our ownership will bring stability to the business, and investment and expertise to grow and develop the company.”

Alongside the investment, the senior ranks of Acteon have been bolstered by the appointment of Brice Bouffard Chief Executive Officer. Brice brings a wealth of business experience highly relevant to Acteon and its key segments.

Helix Energy Solutions has announced the extension of its decommissioning contract with Trident Energy do Brasil Ltda.

The contract extension is for an additional 12 months and in direct continuation of the current contract. The extension is expected to begin in the fourth quarter of 2024 at rates in line with the improved well intervention market. The original contract commenced late 2022 offshore Brazil in the Campos Basin and utilises the Siem Helix 1 riser-based well intervention vessel and a 10K Intervention Riser System. Helix is providing fully integrated plug and abandonment well services through its Subsea Services Alliance partner SLB as well as project management and engineering services.

Helix and Siem Offshore have signed six-year charter extensions for both the Siem Helix vessels, with the Siem Helix 1 term extending through December 2030 and the Siem Helix 2 term extending through December 2031. The Siem Helix vessels are purpose-built advanced well intervention vessels capable of performing a wide range of subsea services including production enhancement, well decommissioning, subsea installation, offshore crane and Remotely Operated Vehicle (ROV) operations, offshore construction and emergency response.

The Helix Producer I (HPI) contract has also been extended by one year, to 1 June 2025. Since 2016, the HPI, a ship-shaped dynamically positioned (DP2) floating production unit, has been located at Green Canyon Block 237 producing oil and gas through the existing Phoenix Field subsea infrastructure. The vessel is designed to produce hydrocarbons and export to shore via pipeline or tanker.

Scotty Sparks, Helix’s Executive Vice President and Chief Operating Officer, stated, “We are pleased to announce that Helix has successfully executed these contract extensions, reflective of improving market conditions and increased demand for Helix’s assets and services.”

In a recent update on the SPS-88 well from the Bauna Project site in Brazil, Karoon Energy said that it will install a lightweight intervention vessel (LWIV) to start an intervention process so that the impacted well can be brought back to production.

Production from the SPS-88 well was first affected in November 2023 due to the formation of hydrates owing to an equipment failure in the gaslift dehydration unit of the floating, production, storage and offloading (FPSO) platform. Of the 12 subsea wells from the area that are joined to the Altera&Ocyan-operated FPSO via flowlines, two Patola wells were bought online last year. While the company closely worked with the FPSO operator, and had the faulty equipment successfully replaced and topsides issues resolved to remove the hydrates by circulating fluids, a mechanical blockage in the gas lift valve still obstructs the well's production capacity.

The obstruction has led the company to decide upon undertaking a 20-day intervention process by LWIV that will cost it approximately US$5-10mn. Subjected to engaging a LWIV and ancillary services and equipment, the company noted on its latest statement that this work will be initiated on the fourth quarter of 2024.

As highlighted on its statement, the intervention work will reflect on Karoon's production costs as it will swing between the range of US$10.5-15.0 per boe for the year from the previous US$9.0-14.0 per boe. While the Bauna FPSO comes with a storage capacity of 631,000 boe, the intervention plans has also led it to lower its last year production goals to stand around 9.0mn boe.

Page 5 of 10

Copyright © 2026 Offshore Network