At the OWI LATAM 2021 conference, Artur Barbosa, Business Development Manager at Archer, gave a presentation on secure and efficient P&A of wells, which focused on the company’s Stronghold Barrier setting and Barrier Verification systems, part of its suite of recovery and P&A solutions. The presentation demonstrated how the Stronghold systems provide an economical and effective alternative to traditional plug and abandonment (P&A).

Barbosa started by giving an overview of Archer, a global oil services company with a 45-year history and strong focus on safety. Its solutions support drilling services, well integrity, intervention, P&A and decommissioning. The company operates in 40 locations in 19 countries across the globe, with more than 5,000 employees.

“In our current portfolio we have 33 platforms, three subs, and two modular rigs, where we are responsible for operations, maintenance and certification of drilling equipment on these assets; rental division providing specialised equipment for offshore operations; engineering solutions for enhancing customers’ assets performance; cased hole wireline services; and oiltools, which provide solutions for well cleaning and cementing, slot recovery and P&A,” he explained.

“Archer can provide all these services in an integrated services contract model, reducing the interfaces with subcontractors and making Archer the focal point of drilling and well services activities,” he stressed.

Barbosa gave an outline of Archer’s wide-ranging capabilities and solutions across the well lifecycle from exploration and development through workover intervention, to abandonment and slot recovery. He emphasised that Archer can provide the customer full life cycle in P&A and slot recovery solutions for cut and pull, casing exit and barrier setting and verification.

“The advantage of the Stronghold barrier system is it eliminates the need for milling during P&A operations,” he explained.

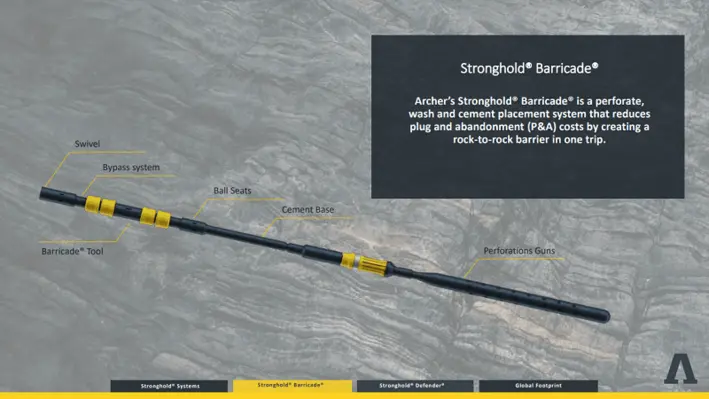

“For barrier setting, the Stronghold Barricade system is designed to perforate a selected casing section, wash and clean and set a permanent barrier,” he said. It reduces P&A costs by creating a rock-to-rock barrier in one trip.

“The Barricade Plus is an improvement on the system; it deals with higher circulation and pressure and bypass capabilities, and is designed to deal with larger casing sizes,” he continued.

“For barrier verification we have the Defender, which is designed to verify the integrity of the barrier, and it’s the most efficient way for us to P&A a well.” It enables operators to perforate and test an annular barrier in a single trip.

“The Fortify is an improvement on this system, with a unique pressure verification system,” he went on.

Barbosa added that the company has conducted more than 200 successful jobs all over the globe, resulting in US$250mn in savings for customers.

Barbosa explained in detail the schematics and operation sequence of the systems, and shared some technical paper references where these technologies and their benefits are explored in depth. These include SPE-191528-MS (TotalEnergies), SPE-193945-MS (Aker BP), SPE-193989-MS (Shell) and SPE-197149-MS.

He also referred to a case study illustrating the successful deployment of the Stonghold Barricade in the Gulf of Mexico. In this case, a major deepwater operator needed to set a 330ft cross sectional cement barrier in 13 3/8” x20 casing. This well, in over 6,000 ft MD water depth required a cement barrier to be placed just above the 20” casing shoe in order to meet the qualifications to plug and abandon the well.

The Archer 13 3/8” Stonghold Barricade was successfully deployed for washing and cementing of the 330ft long interval with even rates at 1200 lpm. The tests run after performing the operation firmly tagged top of cement 6ft above the planned height, and a successful positive/negative test allowed the operator to move on with the completion of the plug and abandonment.

Barbosa gave another example of the application of the Barricade washing tool , where it was used with the Thor casing cleaning and recovery system, which is designed to perforate, clean and recover the casing in a single trip, the method being to move the friction in the casing, and recover the casing.

“The challenge is where we have significant barite, where it would be very time consuming to recover the casing, with multiple cutting required. With this solution we could make two cuts in the casing, perforate, wash out the barite, activate our plug and recover the casing. That was the business case for one of the jobs with our Thor system. In this case the customer was finding it difficult to pull the casings out, so we used our Samurai cutting tool to cut the casing with two cuts, then ran in hole with the Thor, washed the section and recovered the casing.”

The presentation stimulated a number of questions, which were addressed in a lively q&a session to conclude the session.