To tackle field development work in the US Gulf of Mexico, bp has onboarded C-Innovation (C-I) to deliver a significant contract that also covers inspection, maintenance, and repair (IMR) services.

To tackle field development work in the US Gulf of Mexico, bp has onboarded C-Innovation (C-I) to deliver a significant contract that also covers inspection, maintenance, and repair (IMR) services.

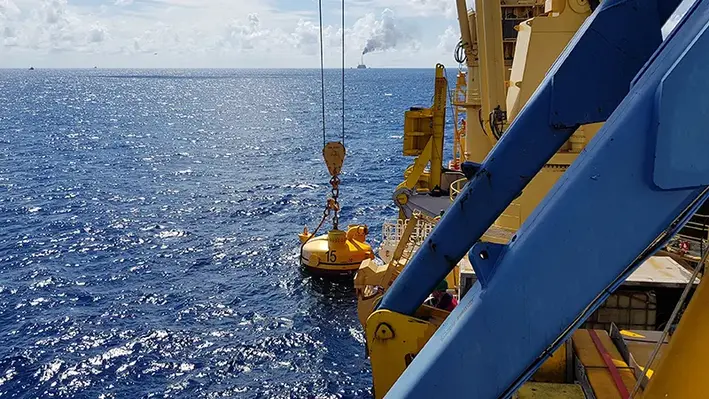

The contract gives bp access to C-I's vast fleet of specialised subsea and supply vessels, besides the provision of its special light construction vessels, C-Constructor and MV Holiday. Each of these vessels come equipped with 150 MT subsea cranes and two Schilling UHD work class remotely operated vehicles (ROVs).

These two dedicated IMR construction vessels will be deployed for project management, engineering, equipment, logistics, and port services, alongside aiding construction, inspection, survey and decommissioning projects. “C-I will act as the contracting lead from front end engineering to offshore execution," said Ryan Combs, C-I’s bp Programme Manager.

The company is proud of its offshore service packages that are customised to suit individual client needs. Delighted on acquiring this three-year contract that has an additional two one-year extensions scopes as well, Combs said, "This multi-year contract in the Gulf of Mexico secures the C-Constructor and Holiday to support a diverse array of subsea activities ... A crucial factor in winning this award is C-I’s access and integration of the unmatched resources available within the Edison Chouest Offshore (ECO) family of companies. This new award is the continuation of a well-established relationship with bp and demonstrates our ability to deliver on our commitments and continuously improve our services year after year.”

Turnkey RLWI services

C-I has been present in the US Gulf of Mexico since 2017, where its vessels have completed more than 60 riserless light well intervention (RLWI) projects in the Gulf of Mexico, especially in the deepwaters.

"One thing that sets us aside I believe is our ability to control our own destiny and to take on the contract as a whole," said the company's Vice President, David Sheetz.

C-I's turnkey RLWI services are diverse enough for the most part of the well intervention system, including provision of the vessel, ROVs, subsea intervention system, pumping system, coiled tubing, nitrogen and stimulation fluids. The company is also known to have remediated multiple hydrates in the Gulf of Mexico.

The bp-operated Mad Dog field, which is known for its exceptional production count, had also seen the deployment of C-I's IMR ROV vessel, MV Dove, which helped mitigate several risks involved in the project. Some of these included armoring with Lexan polycarbonate, designing of new manipulator mounting subframes so that the reach of the manipulators can be extended by 12 inches, and the installation of enhanced manipulator control systems.

"C-I was engaged by bp early in the project lifecycle to provide input into the design of the subsea hardware and installation capabilities of the ROV, which would face limited access to the installation location beneath the facility. The C-I project team engaged with the ROV operations groups, offshore managers and tooling group in order to evaluate the risks involved with the execution of the project and ultimately secured a successful outcome,” said Combs.

To know more about the global well intervention scene, click here.