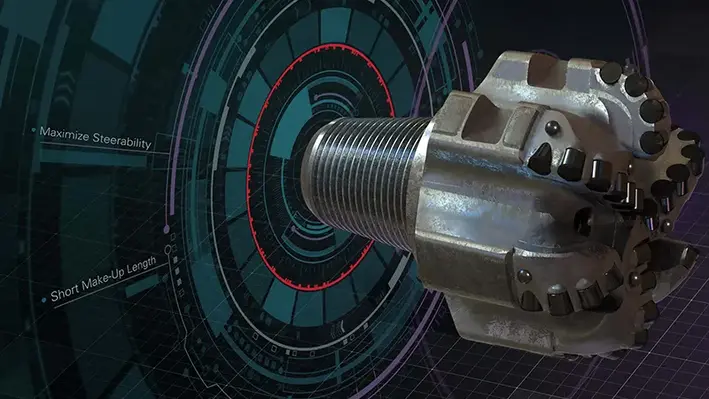

Halliburton has launched its first shankless matrix-body bit called the HyperSteer MX directional drill bit.

Halliburton has launched its first shankless matrix-body bit called the HyperSteer MX directional drill bit.

Improving durability and maximising directional control, the bit promises longer runs and fewer trips, resisting erosion and abrasion, and performing reliably in high-flow, abrasive environments.

"HyperSteer MX directional drill bits mark a major step forward in drilling. The technology combines the precise steerability of HyperSteer directional drill bits with a durable matrix body. It allows operators to drill longer in harsh environments and supports efforts to minimize well time and maximize directional performance for customers," said Amr Hassan, Vice President, Drill Bits and Services, Halliburton.

The tool utilises advanced matrix materials to resist erosion and abrasion, extend bit life in abrasive, high-flow environments, and improve efficiency and reliability during operations. It deliver precise steerability that boosts performance in vertical, curve, and lateral sections, and reduces well time as well as well construction costs. The bit reduces trips, lowers exposure to unplanned events, and maintains directional precision in the most abrasive environments.

HyperSteer MX directional drill bits adds to the HyperSteer portfolio, reflecting the oilfield services provider's engagement in innovative engineered solutions for asset value maximisation.