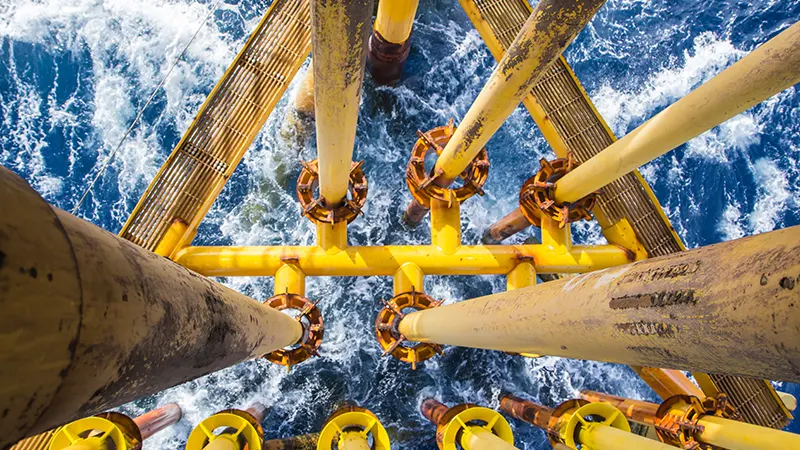

Scientific solutions provider, 3M, has released via Offshore Network a case study illustrating how Indonesian oil and gas corporation Pertamina Hulu Mahakam deployed its ceramic sand screen for its multiple benefits over traditional methods

Scientific solutions provider, 3M, has released via Offshore Network a case study illustrating how Indonesian oil and gas corporation Pertamina Hulu Mahakam deployed its ceramic sand screen for its multiple benefits over traditional methods

While coiled tubing-deployed chemical sand consolidation (SCON) or slickline deployment of through tubing metallic screens are the conventional approaches to sand control, a ceramic screen material reinforcement can be comparatively cost-effective, allow bigger perforation flow area and minimal water contact.

3M's ceramic sand screen solution saves around US$400,000 in terms of rig costs, and 50% when compared to the SCON method. It gives 200% more productivity than possible via the metallic screen.

The ceramic medium’s slick-line deployment can reach a depth accuracy of +/- 0.5m, and can be easily repositioned without the need for a specialist.

Sand control is an especially challenging issue in Indonesia as its hydrocarbons resources are known to be characterised by marginal and multi-layered sand-shale series. Sites such as Tunu and Pecikco, for instance, comprise deltaic sedimentation of poorly sorted sands with an average of 20-30% clay size particles. As the operator of these sites, Pertamina has deployed 3M's offering to initiate active sand control downhole to effectively begin production from the well.

Download the case study to learn about:

*How 3M's ceramic solution is making life easy for operators

*How 3M's ceramic solution gives an edge over other sand control methods

*How Pertamina is designing a pilot application with the help of 3M's ceramic solution

Click here to know more.