The Centre of Decommissioning Australia (CODA), the University of Western Australia (UWA) and the UK’s Teesside University’s Net Zero Industry Innovation Centre (NZIIC) have signed a memorandum of understanding (MoU) to collaborate on the establishment of a Western Australia Industry Transformation Hub.

The Centre of Decommissioning Australia (CODA), the University of Western Australia (UWA) and the UK’s Teesside University’s Net Zero Industry Innovation Centre (NZIIC) have signed a memorandum of understanding (MoU) to collaborate on the establishment of a Western Australia Industry Transformation Hub.

The proposed WA Industry Transformation Hub will unite academic expertise, industry leadership and government support to drive innovation in decarbonisation and local manufacturing.

It also marks the latest collaboration between Australia and the UK in the drive towards decarbonisation, which includes the decommissioning of ageing oil and gas infrastructure, among other areas.

The latest MoU brings together expertise from both sides to support Western Australia’s industrial transition to net zero, aligning with a number of Australian government priorities including decarbonisation and the LNG Jobs Taskforce.

“This hub’s focus advances the WA CCUS [carbon capture, utilisation and storage] Action Plan vision of establishing a world-leading CCUS industry to decarbonise heavy industries while supporting economic diversification,” said CODA’s chief executive, Francis Norman.

“It also supports the Made in WA agenda by building local advanced manufacturing capability and skilled jobs, keeping WA at the forefront of global market shifts through strong industry support and innovation infrastructure,” said Norman.

The new ‘hub’ will focus on three core research themes:

Industrial emissions reduction: targeting heavy industries such as oil and gas, mining and cement, developing and deploying CCUS technologies in collaboration with industrial centres like Kwinana and the Pilbara.

Circular economy: supporting the Made in WA agenda, the hub will promote advanced manufacturing, industrial waste recycling and life-cycle design to grow WA’s circular economy.

Knowledge exchange: a joint governance model will embed international collaboration, with NZIIC and WA industry representatives guiding strategic direction to ensure alignment with the state’s Diversify WA priorities.

Each of the MoU partners brings unique strengths to the collaboration: CODA’s extensive Australian and international decommissioning networks, UWA’s track record of supporting Australian industry with applied research, and NZIIC’s strong research base and industrial partnerships in the UK.

Professor Hélène de Burgh-Woodman, Pro Vice Chancellor (Research Training) at UWA said: “The international network established by this MoU will provide a springboard to deliver innovation not just in net zero technologies themselves, but in their process of discovery.”

Earlier in the year, another UK-Australia MoU saw Global Underwater Hub (GUH) and Subsea Innovation Cluster Australia (SICA) team up to pursue subsea opportunities, including decommissioning, across both hemispheres.

Woodside has welcomed the Australian Government’s final decision to grant environmental approval for the North West Shelf Project extension.

The operator’s Executive Vice President and Chief Operating Officer Australia, Liz Westcott, said, “This final approval provides certainty for the ongoing operation of the North West Shelf Project, so it can continue to provide reliable energy supplies as it has for more than 40 years.

The Australian Government approval includes conditions that require additional monitoring and management of air emissions to protect the Dampier Archipelago National Heritage Place.

Thus far, the North West Shelf Project has supplied more than 6,000 petajoules of domestic gas, powering homes and industry in western Australia. If used just for household electricity, this is enough to power homes in a city the size of Perth for 175 years.

Australia’s Department of Industry Science and Resources has released a request for tender (RFT) on the AusTender platform for a lead contractor to deliver Phase 2 of the Northern Endeavour decommissioning programme.

Australia’s Department of Industry Science and Resources has released a request for tender (RFT) on the AusTender platform for a lead contractor to deliver Phase 2 of the Northern Endeavour decommissioning programme.

Phase 2 of the Northern Endeavour programme includes permanently plugging and abandoning nine wells in the Laminaria and Corallina oil fields in a planned two-stage process.

Stage 1 will involve project management, engineering, logistics, regulatory approval, subcontracting and procurement activities to: design and plan to permanently plug and abandon the wells; develop a Stage Gate Review Pack outlining a pricing model with detailed budget, risk profile and Performance Management Framework; and achieve Registered Operator status and monitor and maintain the Laminaria Corallina oil fields.

Stage 2 will include: permanently plugging and abandoning the wells; project management, engineering, procurement and field monitoring; meeting all regulatory requirements, including a National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA) approved Safety Case.

The Department intends to hold four industry briefing sessions for interested parties, each covering a different topic of the programme including commercial, technical, regulatory and financial aspects of the RFT.

The briefings are set to begin during the week of 22–26 September 2025.

Closing date for the submission of bids is 1 December 2025.

The flagship Northern Endeavour decommissioning project is already underway amid initial Phase 1 work at the site, which is located in the Timor Sea, approximately 550 km northwest of Darwin, Australia.

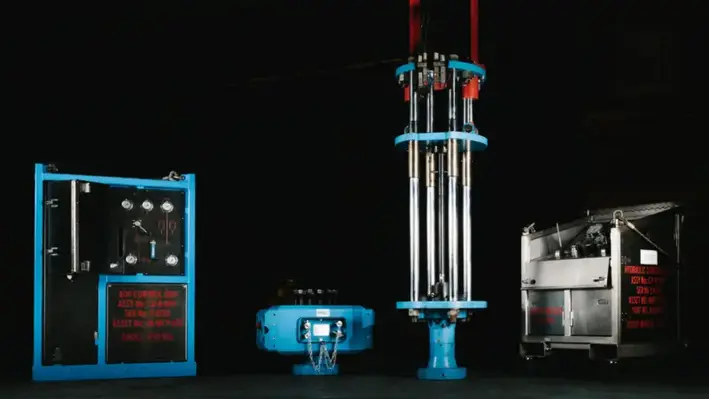

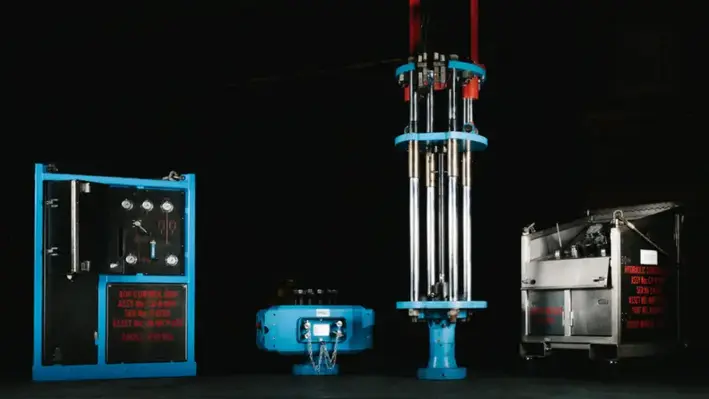

Unity has announced a strategic partnership with Clear Cut Interventions Australia, marking a significant step forward in delivering advanced well intervention and integrity solutions across the region.

Unity has announced a strategic partnership with Clear Cut Interventions Australia, marking a significant step forward in delivering advanced well intervention and integrity solutions across the region.

Stuart Slater, Unity’s Technical Sales Director, said, “Australia is a strategic market for Unity, and we are delighted to have the opportunity to partner with CCI. Together, we are creating something unique for local operators: the assurance of world-class technology delivered with the speed, agility and regulatory confidence of an established Australian partner.”

Combining Unity’s advanced technology with CCI’s knowledge of Australia and regulatory expertise, the partnership will offer accelerated access to engineered well integrity and P&A solutions, joint technology transfer programmes, and comprehensive end-to-end project delivering capability from diagnostics through to remediation.

Managing Director of CCI, Dean McTiffen, commented, “POB limits, tight decks and de-rated cranes can turn simple interventions into major logistics exercises. With Unity’s compact tooling in-country and CCI’s Western Australian team and infrastructure behind it, we’re giving operators a genuinely end-to-end route to safer, faster interventions that fit the real-world constraints offshore.”

Through this partnership, operators will benefit from the local deployment of Unity’s Compact Intervention Suite of Tooling, QV range of Wellhead and Christmas Tree products and Thru Tubing solutions.

A new collaboration is set to advance Western Australia’s decarbonisation and economic diversification ambitions.

A new collaboration is set to advance Western Australia’s decarbonisation and economic diversification ambitions.

The Centre of Decommissioning Australia (CODA), the University of Western Australia (UWA), and Teesside University’s Net Zero Industry Innovation Centre (NZIIC) are coming together to establish a WA Industry Transformation Hub.

The collaboration brings together expertise from Australia and the UK to support Western Australia’s industrial transition to net zero, aligning with government priorities including decarbonisation and the LNG Jobs Taskforce. It builds on the shared industrial heritage of Teesside and Western Australia and will combine CODA’s extensive Australian and international decommissioning networks, UWA’s track record of supporting Australian industry with applied research, and NZIIC’s strong research base and industrial partnerships in the UK.

Key focus areas include industrial emissions reduction (including CCUS technologies), circular economy and advanced manufacturing; and knowledge exchange and work-integrated learning.

“This hub’s focus advances the WA CCUS Action Plan vision of establishing a world-leading CCUS industry to decarbonise heavy industries while supporting economic diversification. It also supports the Made in WA agenda by building local advanced manufacturing capability and skilled jobs, keeping WA at the forefront of global market shifts through strong industry support and innovation infrastructure,” said Francis Norman, CODA's CEO.

Not long after Decom Engineering secured work in Australia’s nascent decommissioning sector, the UK-based company has appointed Nick McNally as its new Managing Director to steer its global growth ambitions.

Not long after Decom Engineering secured work in Australia’s nascent decommissioning sector, the UK-based company has appointed Nick McNally as its new Managing Director to steer its global growth ambitions.

The appointment was announced on the website of the Centre of Decommissioning Australia, or CODA, reflecting its significance to the nation’s decommissioning efforts.

“This is an exciting new stage for Decom as the business evolves from a highly respected niche engineering firm into a globally recognised technology partner,” said McNally in a statement.

“With new markets opening up, and recent contract wins in Australia, Brazil and the Gulf of Mexico, the opportunities ahead are considerable and my focus will be on building the infrastructure, capability and culture to meet that growth head-on.”

McNally, who has served as Decom’s Commercial Director since 2019, takes up his new role at a key time for the company as it steps up international expansion and technological innovation in the decommissioning sector.

His appointment reflects the Aberdeen-based company’s strategic focus on scaling operations, expanding into new markets, and strengthening its position as a leading provider of patented cutting technologies to the global energy industry.

Under his leadership, Decom succeeded in rolling out a new ultra-light chopsaw with improved cutting performance, which has seen the C1-16UL deployed across complex subsea projects in various challenging offshore environments.

The company has been buoyed by recent project wins in Australia.

Last year, it executed three market-entry Australian contracts to strengthen its position within the Asia Pacific region, including the deployment of its chopsaw cutting technologies on behalf of a major operator in the Bass Strait alongside two other clients in Australian waters.

Together, the contracts amounted to more than UK£500,000.

Decom is now actively progressing ISO certification alongside additional IP coverage and is looking to expand its workforce from 16 to over 25 staff within the next 18 months, with new roles across engineering, operations and business development.

“With international demand growing and increasing interest in our cutting technology, we’re focused on scaling responsibly, strengthening our systems, investing in our people and remaining agile, which enables us to move into new markets such as offshore wind and onshore decommissioning,” said McNally.

As well as the Australian market, the company is also chasing emerging business opportunities in North America, with demonstration events planned for the United States later this year as it evaluates potential partnerships and future growth.

A well operations management plan and multidisciplinary collaboration have been critical success factors in ensuring Exxon Mobil's Bass Strait decommissioning project is carried out safely , efficiently and in compliance with regulatory requirements,

A well operations management plan and multidisciplinary collaboration have been critical success factors in ensuring Exxon Mobil's Bass Strait decommissioning project is carried out safely , efficiently and in compliance with regulatory requirements,

In an article on the Exxon Mobil website, Project Manager Richard Perry talks about how Exxon Mobil is executing the largest offshore decommissioning project in its global history in Bass Strait.

ExxonMobil’s wells team is permanently and safely plugging and abandoning hundreds of wells in Bass Strait, as it retires infrastructure that has reached the end of its productive life. To date, the company has safely plugged and abandoned over 200 offshore wells, using specialised equipment to install cement plugs at depths equivalent to a 20-storey building. These plugs undergo rigorous pressure testing to ensure long-term integrity and environmental protection.

“To guide this work, our team developed a first-of-its-kind Well Operations Management Plan, ensuring all plug and abandonment activities meet strict regulatory requirements and adhere to the highest safety standards,” Parry explains. “This plan draws on ExxonMobil’s global experience managing successful decommissioning campaigns in Canada, the United States, and the North Sea, while also incorporating innovative practices that improve both efficiency and environmental outcomes.

“Our Bass Strait well plug and abandonment program is among the largest of its kind globally,” he adds, noting that it relies on close collaboration across a multidisciplinary team—including geoscientists, well integrity engineers, reservoir specialists, regulatory experts, and safety, health and environment professionals—to ensure each well is retired safely, responsibly, and in full compliance with environmental expectations.

Once all wells have been safely plugged and abandoned, each platform is placed in a safe state until it is ready to be removed and safely transported to Barry Beach Marine Terminal for dismantling.

“We remain committed to transparent engagement with our community—keeping stakeholders informed and ensuring our work aligns with local expectations,” Perry concludes.

Reach Subsea’s pioneering Uncrewed Surface Vehicle (USV) in on-route to Australia to deliver subsea services for Woodside Energy.

Reach Subsea’s pioneering Uncrewed Surface Vehicle (USV) in on-route to Australia to deliver subsea services for Woodside Energy.

Reach Remote 2 will perform reservoir monitoring on the Scarborough gas field by utilising the company’s gWatch technology. gWatch, used widely across Norwegian gas fields, measures time-lapse gravity and seafloor deformation to detect small changes in mass and pressure. The precision measurements significantly reduce uncertainty in gas reservoirs and aquifer influx to enhance workflows and support accurate production forecasts.

Reach Remote 2’s operation in Australia will demonstrate the USV’s ability to reduce offshore personnel operational risks, cut costs and reduce environmental impact compared to traditional crewed vessels.

Reach Subsea’s CEO Jostein Alendal said, “Seeing the Reach Remote 2 vessel sail ‘down under’ to deliver world-class services to a company like Woodside Energy is a proud moment for all of us at Reach Subsea. This project clearly demonstrates that the transition to a robotic future is not a vision – it is happening now. We are reducing HSE risks by removing personnel from hazardous environments, reducing operational costs and cutting the carbon footprint of offshore activities by up to 90%.

“It is a major leap forward for the industry and a testament to what innovative technology can achieve.”

The deployment marks the beginning of Reach Subsea’s Inspection, Maintenance and Repair (IMR) operations in Australia, and highlights the company’s expanding global presence.

Recent events in Australia’s decommissioning space demonstrate the complexity of offshore decommissioning campaigns from the environmental and work, health and safety perspectives.

Recent events in Australia’s decommissioning space demonstrate the complexity of offshore decommissioning campaigns from the environmental and work, health and safety perspectives.

Lessons learned from these experiences will assist the industry to prepare itself to meet the large influx of decommissioning work ahead, according to a new insight paper from law experts at Pinsent Masons, co-authored by Cormac Mercer and Laura Slocombe, which continues below:

Last week, the Wilderness Society commenced proceedings against the National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA) in the Federal Court seeking judicial review over its approval of an environmental plan (EP) from Santos WA Northwest Pty Ltd (Santos) for its Reindeer wellhead platform to be “left in a preserved state for future phases”. This is despite Santos’ Reindeer field having ceased production this year.

Offshore activities, including decommissioning, must be approved by NOPSEMA. The approval process involves lodging certain documents, including an EP, along with an operation management plan and a safety case. The EP is generally the most significant, and potentially problematic, of these.

The Wilderness Society has publicly claimed that, by approving Santos’ EP, NOPSEMA did not enforce Santos’ duty under the Offshore Petroleum and Greenhouse Gas Storage Act 2006 (Cth) (OPGGS Act) as titleholder of the Reindeer facilities to maintain financial assurance, in particular in relation to decommissioning the infrastructure and remediating damage to the surrounding environment.

Section 571(2) of the OPGGS Act requires a titleholder to maintain financial assurance sufficient to give the titleholder the capacity to meet costs, expenses and liabilities arising in connection with, or as a result of:

the carrying out of the petroleum activity;

the doing of any other thing for the purposes of the petroleum activity; or

complying, or failing to comply, with a requirement under the OPGGS Act in relation to the petroleum activity.

The duty imposed by section 571(2) of the OPGGS Act extends to covering any costs, expenses or liabilities arising in connection with, or because of, compliance with a titleholder’s duty under section 572C of the OPGGS Act, which relates to the escape of petroleum.

If NOPSEMA’s decision to approve Santos’ EP is ultimately quashed by the Federal Court, it could result in NOPSEMA assessing EPs in the future on the basis of demonstrated financial capacity to undertake decommissioning. The Wilderness Society matter is now before the Federal Court.

This litigation contributes to the recent rise in legal challenges to NOPSEMA’s EP approvals. Whether this leads to a more conservative approach to decommissioning activities by titleholders and NOPSEMA, potentially disincentivising developers from exploring innovative decommissioning solutions with positive environmental outcomes, remains to be seen.

Environmental approvals for major offshore decommissioning projects will continue to be under increased scrutiny, adding to the complexity of offshore decommissioning campaigns. Businesses operating in the offshore space should ensure that EPs and assessments, including consultation, are undertaken in a comprehensive manner with a close eye on recent legal and scientific developments.

Work, health and safety

In general, offshore decommissioning is an inherently hazardous process that exposes workers to a variety of physical and psychosocial risks.

Infrastructure requiring decommissioning is often located in harsh and unpredictable marine environments which are geographically isolated. Remote work has become a well-known psychosocial hazard in many industries but is particularly acute in the renewable energy industry, due to minimal access to resources and support, often for prolonged periods of time.

In addition, other obvious physical hazards include the handling of hazardous chemicals and contaminants; manual handling challenges in bringing infrastructure to shore; fires and explosions; and interactions with people and mobile plant, including sea vessels.

NOPSEMA is paying close attention to offshore decommissioning works in Australian waters and is cracking down on operators who are failing to mitigate risks.

Recently, NOPSEMA issued three general directions to Woodside for its Stybarrow and Griffin fields off the Western Australian coast and Minerva field offshore of Victoria.

Each direction requires Woodside to undertake and document a risk assessment to identify and evaluate all risks to health, safety and the environment associated with Woodside’s removal activities. This includes a requirement that “control measures” are in place to reduce risks to as low as reasonably practicable. NOPSEMA’s intervention comes off the back of an oil spill incident at Woodside’s Griffin field. In addition to potential environmental damage, there were concerns that workers were exposed to hydrogen sulphide, an extremely toxic gas, due to the spill.NOPSEMA has powers to enforce WHS compliance on offshore projects that reflect the powers of state, territory and Commonwealth regulators under the model harmonised work health and safety laws. For example, inspectors can:

enter offshore facilities to conduct inspections and interviews;

issue provisional improvement notices, prohibition notices and infringement notices; and

take possession of plant and samples.

NOPSEMA can also commence criminal and civil prosecutions, seek injunctions - stopping someone doing a certain action or activity - and apply for adverse publicity orders against corporate entities, with reputational impacts.

Operators of decommissioning projects in Australian offshore environments are reminded that they must take all reasonably practicable steps to protect the health and safety of workers at the facility and of any other persons who may be affected by their activities. This is a legislative obligation prescribed by the OPGGS Act, largely mirroring the primary duty under the harmonised work health and safety framework that requires a person conducting a business or undertaking to ensure, so far as is reasonably practicable, the health and safety of workers and others.

If risks cannot be fully eliminated, which is usually the case in high-risk workplaces such as offshore decommissioning facilities, operators should not wave the white flag and sit still. They have a duty to ensure that all risks are minimised, so far as is reasonably practicable, particularly those which are known, obvious and foreseeable.

Following the release of a new study exploring the infrastructure and capabilities required to support offshore oil and gas decommissioning in the Northern Territory, a timetable of potential projects and opportunities is coming into focus.

Following the release of a new study exploring the infrastructure and capabilities required to support offshore oil and gas decommissioning in the Northern Territory, a timetable of potential projects and opportunities is coming into focus.

It begins with subsea infrastructure and mooring systems associated with the Northern Endeavour project, coming ashore from 2025, and continues through the decades culminating with potential involvement on Ichthys, coming ashore from 2058 onwards.

However, the intermittent nature of the work means the establishment of a permanent, local decommissioning and abandonment (D&A) workforce is unlikely to be economic, compared with resources and labour at rival locations, notably Western Australia (WA).

Australia's Centre of Decommissioning (CODA) released its Northern Territory report in July highlighting some of the limitations of the region, as well as areas in which it can play a meaningful role in the nation’s decommissioning efforts.

“It is not deemed credible for large fixed facilities (i.e., non-wellhead platforms) or floating facilities to be decommissioned in the Northern Territory,” the report notes.

However, the state does appear to hold a great deal of promise in aiding work to process related subsea infrastructure and mooring systems.

From a planning perspective, CODA states, the following are the most credible oil and gas decommissioning opportunities in the Northern Territory:

2025: Subsea infrastructure and mooring systems associated with the Northern Endeavour, coming ashore from 2025.

2032-2036: Subsea infrastructure, mooring systems and a wellhead platform associated with Montara, coming ashore between 2032 and 2036.

2038: Subsea infrastructure, mooring systems (CALM buoy) and a wellhead platform associated with Blacktip, coming ashore from 2038.

2047-2052: Subsea infrastructure and mooring systems associated with the Prelude and Crux developments, coming ashore between 2047 and 2052.

2050-2055: Subsea infrastructure, mooring systems and a wellhead platform associated with the Barossa and possibly the Bayu Undan developments, coming ashore between 2050 and 2055.

2058-2063: Subsea infrastructure and mooring systems associated with Ichthys, coming ashore from 2058 and 2063.

Crucially, the report suggests that based on the estimated decommissioning dates, there does not appear to be significant overlaps in the decommissioning windows of the various developments.

Lack of overlap means that each decommissioning campaign will need to be established separately – including leases on land, and mobilisation of a workforce and equipment.

“Between the defence and offshore oil and gas industries, there is unlikely to be the demand to sustain a continuous decommissioning workforce especially compared with other jurisdictions such as WA,” it notes.

“Given decommissioning requires specialist capability, this will result in a short-term or ‘project’ based workforce,” it adds.

A new report by an alliance of unions and leading environmental organisations has recommended the establishment of a nation-first decommissioning hub in Western Australia to manage the state's growing number of retired offshore oil and gas assets.

A new report by an alliance of unions and leading environmental organisations has recommended the establishment of a nation-first decommissioning hub in Western Australia to manage the state's growing number of retired offshore oil and gas assets.

The WA Can’t Wait report, a collaboration between Greenpeace Australia Pacific, Unions WA, Conservation Council WA, Maritime Union of Australia - WA Branch, The Wilderness Society, Australian Manufacturing Workers Union - WA Branch, Electrical Trades Union - WA Branch, argues that a WA decommissioning hub would deliver thousands of secure, skilled jobs, protect marine ecosystems and coastal communities, and bring scrap steel and other materials into local domestic circular supply chains.

Recommendations include:

• A decommissioning hub be built in Western Australia, near current fossil fuel infrastructure and where green recycling facilities can be established

• Oil and gas operators are held financially responsible and a fully industry-funded clean-up be mandated

• Existing laws are strengthened and enforced to ensure a full and timely decommissioning

• The safety of workers and the environment is prioritised

• Investment in ports, recycling facilities and local workforces is increased to support decommissioning and emerging offshore wind and other renewable energy industries.

Geoff Bice, Greenpeace Australia Pacific WA Campaign Lead, pointed out that 89% of Australia’s 5.7 million tonnes of offshore oil and gas infrastructure is in West Australian waters.

“A decommissioning hub is WA-positive, and the industry should foot the bill for their own mess. This isn’t just a clean-up plan, it’s a once-in-a-lifetime opportunity to build a world-leading industry.”

Matt Roberts, Conservation Council of Western Australia Executive Director, said,“50% of Australia’s offshore oil and gas infrastructure is due to be decommissioned by 2030 and most of it is in WA. It is critical that companies are held to account to deliver on their environmental responsibilities. There are also huge opportunities for new jobs in decommissioning and metals recycling. These are the jobs of the future that will help us transition to renewable energy."

Will Tracey, Maritime Union of Australia WA Secretary, said, “We welcome this practical, worker and community-focused contribution to solving a national decommissioning bottleneck. This is how we keep high value jobs in WA and secure economic strength for decades to come, building a bridge between the energy past and a just, sustainable future. It’s time for the government to act on what workers and communities are calling for: full removal, local recycling, and a Future Made in Australia that starts in WA.”

Integrated energy services giant, Kent, has been awarded a technical advisory services contract by the Australian Government to support the permanent plugging and abandonment of the Laminaria-Corallina fields in the Timor Sea.

Integrated energy services giant, Kent, has been awarded a technical advisory services contract by the Australian Government to support the permanent plugging and abandonment of the Laminaria-Corallina fields in the Timor Sea.

The contract also includes advisory services for the removal of associated subsea infrastructure within the fields.

The award underscores Kent’s position as a trusted decommissioning partner following its existing work conducted on the Northern Endeavour FPSO facility, as well as its expanding footprint within the APAC region. Under the initial two-year contract, Kent will deploy a team of technical and regulatory experts to provide strategic and operational support throughout the decommissioning phase.

Michael Costello, Executive Vice President – Development, APAC & Americas, said, “This contract is a testament to the trust the Australian Government has placed in Kent’s decommissioning expertise. We are proud to continue supporting the safe and responsible transition of offshore assets, prioritising environmental outcomes and technical integrity at every stage.”

Page 3 of 13

Copyright © 2026 Offshore Network