Wells and subsurface specialist, Elemental Energies, has announced the acquisition of Norway-based well management and consultancy company, Well Expertise AS.

Wells and subsurface specialist, Elemental Energies, has announced the acquisition of Norway-based well management and consultancy company, Well Expertise AS.

Expected to generate revenues surpassing £50mn in 2024, the acquisition also adds significant growth to Elemental's North Sea expansion ambitions in Norway.

The Well Expertise acquisiton is the latest in a series of strategic acquisitions by Elemental Energies, including Vysus Senergy Wells in December 2022, Norwell Engineering in May 2023 and Sentinel Group in February 2024.

The acquisition established the companies' shared growth ambitions in well management services across oil and gas, decommissioning, geothermal, and carbon capture and storage projects.

Mike Adams, CEO of ElementalEnergies, said, “Norway is a pivotal region for us through its stable energy policy that prioritises both security and transition, aligning with our core ambitions as a business. As a mature market, Norway faces the challenge of managing new production with decommissioning and energy transition which present significant opportunity. This deal marks the start of the next chapter for both companies, as we build a strategic global wells and subsurface partner that will allow operators to outsource larger and more diverse projects with confidence.”

Sigve K. Næsheim, who will continue as CEO of Well Expertise and head up Norway operations, said, “This acquisition marks a significant milestone, underscoring our commitment to providing best-in-class well engineering and project management services. From the outset, our strategic alignment with Elemental Energies has fostered a shared vision to become the go-to global well management partner for projects spanning exploration,production, decommissioning, CCS, and geothermal. As part of Elemental Energies, we are able to expand the development opportunities for our team, bring new perspectives to our projects,and deliver expanded capabilities to our clients.”

Stig Seland, Commercial Manager of Well Expertise and one of its founders, said, "At Well Expertise, we have built long-term relationships with our customers through our collaborative and customer-first approach, which has been the cornerstone of our success. I am very pleased to announce that we can now offer an even broader range of services to our clients. Rest assured, our commitment to putting customers first will remain our primary focus as we continue to support the future of Norwegian energy."

Backed by the Ministry of Economic Affairs and Employment and Salon Kaukolämpö Oy, Lounavoima is developing a geothermal heat well storage at its waste-to-energy (WtE) plant at the Lounapuisto circular economy park in Salo.

Backed by the Ministry of Economic Affairs and Employment and Salon Kaukolämpö Oy, Lounavoima is developing a geothermal heat well storage at its waste-to-energy (WtE) plant at the Lounapuisto circular economy park in Salo.

Following good test run from the first well, three additional wells are now being constructed. The final heat well is expected to be completed by the summer of 2025.

Upon completion, the WtE plant will have six geothermal heat wells with a combined output of 6MW.

Waste heat produced by the WtE plant is stored at a depth of more than 2 kms in the geothermal heat wells to cover the district Salo's heating requirements during the winter.

The first well which was tested last winter runs 1,600-metre-deep, producing 450 MWh of energy from January to March.

A second heat well, which is undergoing tests, was drilled in the autumn of 2023 and a third was drilled in the winter of 2024. Its pipework will be completed in the late summer.

Finnish company Geomachine Oy deployed new drilling equipment which were specially designed for the exploration of the heat wells, achieving a target depth of 2,000 metres. The heat pump process was delivered by Calefa Oy.

Once all the heatwells are brought onstream, the six new geothermal heat wells will have a combined output of as much as 14 GWh a year, which is equivalent to the annual heating need of approximately 700 single-family homes.

“The heat well production will always be used first if the district heat output of the WtE plant isn’t enough. This allows us to primarily replace the need for starting oil heating plants and, in many cases, we can also avoid the need to start a backup power plant,” said Lounavoima and district heating company Salon Kaukolämpö's Managing Director Petri Onikki.

“We have such top expertise here in Finland. Even though the new technology development project has not always gone smoothly, the results have exceeded our expectations. The geothermal heat wells have a multiplying effect on heat production in Salo,” said Onikki. “The project is a successful example of concrete circular economy work at Lounapuisto,” he added.

Shell UK Ltd has signed a contract with Mermaid Subsea Services Ltd to utilise the offshore company's services for a multi-year engineering, preparation, removal and disposal (EPRD) well head severance (WHS) project in the North Sea.

Shell UK Ltd has signed a contract with Mermaid Subsea Services Ltd to utilise the offshore company's services for a multi-year engineering, preparation, removal and disposal (EPRD) well head severance (WHS) project in the North Sea.

Planned in three annual batches, the first phase of the decommissioning project is scheduled to begin later this year. The WHS solution will be delivered by a bespoke vessel for which Mermaid will be accumulating key stakeholders accross the supply chain.

The initial campaign will involve the removal of well head protection covers from the sea floor, before lifting them to the surface for transportation onshore.

The well head flow base structures will then be retrieved using specialist tooling.

The final activity will cover well head severance and recovery operations, for which bespoke underwater cutting tooling and techniques will be deployed by Mermaid.

Each stage of the project will be followed by clearance of debris, as well as seabed and over trawl surveys where necessary. All the recovered materials from the project will be put to reuse and recycling.

Scott Cormack, Regional Director for Mermaid Subsea Services (UK), said, “This a milestone contract for Mermaid and we are very grateful to Shell for putting their faith in our team. We look forward to kicking off work this year.

“The North Sea is on the cusp of a multi-decade decommissioning boom and Mermaid plans to be front and centre of that with our bespoke solutions and leading expertise.”

SLB and Ormat Technologies have entered into a strategic collaboration to develop integrated geothermal projects which reduce the associated risks while improving overall economics and ensuring long-term reliability.

SLB and Ormat Technologies have entered into a strategic collaboration to develop integrated geothermal projects which reduce the associated risks while improving overall economics and ensuring long-term reliability.

The integrated offering will provide developers with a comprehensive suite of solutions, including exploration and resource assessments to power plant commissioning and operation.

Both SLB and Ormat will provide operators with traditional and next-gen geothermal solutions, such as enhanced geothermal systems (EGS) and advanced geothermal solutions (AGS), with SLB obtaining a license of Ormat’s ESG patent.

The collaboration combines Ormat’s expertise in geothermal fields and project development, power plant design, manufacturing, operations, and engineering, procurement and construction capabilities with SLB’s expertise in reservoir characterization, well construction, completions and production technologies.

Irlan Amir, Vice President of Renewables and Energy Efficiency for SLB, said, “Geothermal energy represents a significant opportunity for the energy transition, providing clean, baseload renewable power. By combining our expertise with Ormat’s, we can help customers unlock the full potential of geothermal resources and accelerate the deployment of this sustainable energy source.”

Paul Thomsen, Vice President of Business Development at Ormat Technologies, commented, “Ormat’s world class geothermal development and technology expertise perfectly complements SLB’s significant reservoir knowledge and well construction technologies and expertise. Together, we can deliver more projects, offering exceptional value to our developers and contributing to a cleaner energy future.”

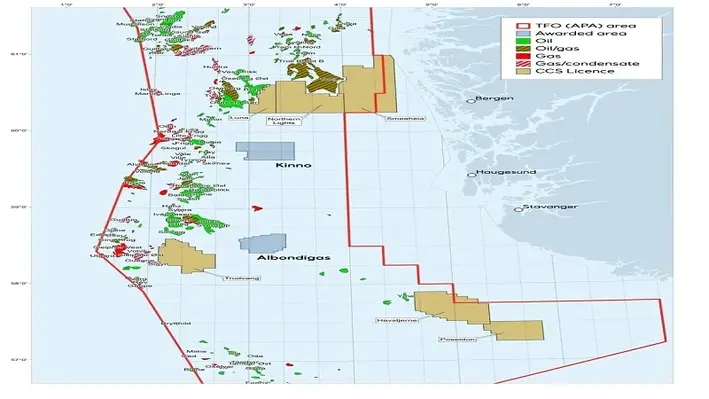

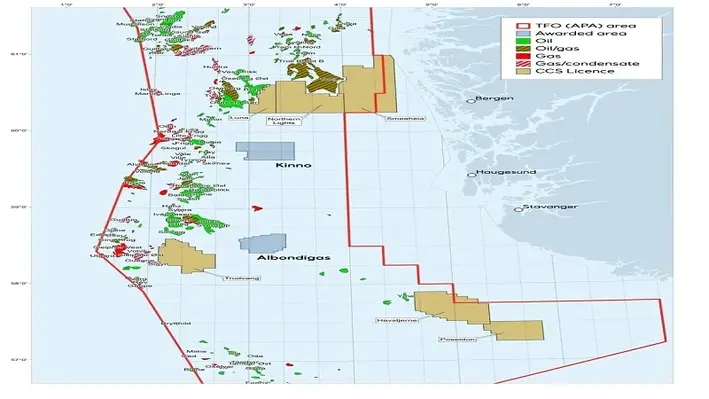

The Ministry of Energy has awarded Equinor the Albondigas and Kinno licenses in the North Sea for CO2 storage development.

The Ministry of Energy has awarded Equinor the Albondigas and Kinno licenses in the North Sea for CO2 storage development.

Considered important building blocks for developing the Norwegian Continental Shelf into a leading area for CO2 storage in Europe, each of the licenses are expected to have a storage capacity of 5 million tons of CO2 annually.

"We are very pleased to see the Norwegian authorities have made new CCS storage acreage available for exploration and that we have been awarded these two licenses. We see that demand for CO2 storage is increasing in several countries, and it is crucial to bring forward new CO2 storages quickly, so that we can offer industrial solutions that can support large scale decarbonisation of hard-to-abate industries in Europe," said Grete Tveit, Senior Vice President for Low Carbon Solutions in Equinor.

Equinor expect 4-8% real base project returns for its early phase CO2 storage business, and further value uplift potential when commercial markets are developed.

Equinor is maturing a ship-based solution and a massive pipeline to connect industrial emissions in Europe with storage opportunities at the Norwegian Continental Shelf. The planned pipeline named CO2 Highway Europe will have capacity to transport 25-35 million tons of CO2 per year from Belgium and France.

The Albondigas and Kinno licenses will serve as additional storage opportunities to the Smeaheia storage license which was awarded to Equinor in 2022. Smeaheia will be used as the anchor storage for this pipeline development.

Equinor is also about to complete the first phase of the Northern Lights CO2 transport and storage facility together with Shell and Total Energies. It will be ready to receive CO2 by the second half of this year.

"Scale-up of CO2 transport and storage is essential to meet the interest and demand for this type of services. Gaining access to more CO2 storage capacity aligns well with our ambition of having 30 to 50 million tons of CO2 transport and storage capacity per year by 2035," said Tveit.

The UK National Geothermal Centre (NGC) has been launched to accelerate the UK geothermal sector and enhance the role it can play in decarbonising the UK’s future energy mix.

With funding from the Net Zero Technology Centre (NZTC), Durham University, SHIFT Geothermal, and The Reece Foundation, the NGC aims to support research and innovation, develop expertise and drive the creation of a policy, regulation and investment framework which enables geothermal advancement. It will drive collaboration between government, industry, and academia, promoting the integration of geothermal energy into the future renewable energy mix as a low carbon option for heating homes and industries, and power generation.

The geothermal sector has the potential to meet 10GW of the UK’s projected heating demand and 1.5GW of the anticipated electricity demand by 2050. Geothermal expansion could create 50,000 jobs for the future and result in an annual reduction of 10 million tonnes of CO₂ emissions.

Nigel Lees, chair of the NGC, said, “The launch of the National Geothermal Centre today represents a significant step in realising the opportunities that geothermal energy provides the UK. For several decades there has been a growing and meaningful contribution to our understanding of geothermal potential in the UK, yet we remain in the nascent stages of development with pockets of knowledge and expertise.

“The Centre will embrace and build on this, working collaboratively with all stakeholders to ensure a common understanding of the opportunities and challenges whilst giving a consistent voice and advocacy to fully unlock the geothermal potential in the UK and play a crucial part in the delivery of our net zero ambitions.”

Norwegian energy producer Equinor will deploy Emerson's suite of Roxar downhole monitoring tools to achieve optimal results from the Rosebank oil and gas field offshore the United Kingdom.

Norwegian energy producer Equinor will deploy Emerson's suite of Roxar downhole monitoring tools to achieve optimal results from the Rosebank oil and gas field offshore the United Kingdom.

With an estimated capacity of more than 300 million barrels of recoverable oil resources, the Rosebank field is considered a significant asset in meeting the UK’s energy security requirements. The first phase of the Rosebank field development will involve a refurbished, electrification-ready floating production storage and offloading vessel connected to a subsea production system. Startup of the Rosebank field’s first phase is planned for 2026-2027.

Emerson's advanced well completion monitoring systems enable advanced oil recovery techniques, optimise reservoir performance and verify well integrity in real time. A challenging task amid harsh environment conditions, the Roxar integrated downhole network technology provides an uninterrupted coverage of pressure and temperature data from active wells, which leads to safe operation, production optimisation and well integrity maintenance.

While Europe has often spearheaded geothermal progress and innovation, the past few years have played witness to a stagnated playing field as financial blockades and unclear legislation has somewhat slowed the project pipeline. However, after funding through both private and public channels continues to gain momentum, the region has the resources and drive to become a major market player within the geothermal market once again.

While Europe has often spearheaded geothermal progress and innovation, the past few years have played witness to a stagnated playing field as financial blockades and unclear legislation has somewhat slowed the project pipeline. However, after funding through both private and public channels continues to gain momentum, the region has the resources and drive to become a major market player within the geothermal market once again.

In January 2024, the European Union Parliament overwhelmingly endorsed a resolution that called for a new geothermal energy strategy to be implemented across the region. The resolution calls for an industrial alliance on geothermal energy, as well as the installation of an insurance programme to mitigate against financial risk. This endorsement is a huge step for the region and will hopefully provide reassurance and confidence in the market to warrant further investment.

However, while the parliamentary push is a step in the right direction, concerns are still being drawn around the commerciality of the commodity for geothermal, and the debate about whether the long-term payoff and associated risks are worth the investment.

With the above issues and more industry insights set to be discussed at the upcoming GTS EU 2024 later this year, including topics around expediting growth, new technology and scalability, enhancing the transition, attracting external stakeholders and commercial considerations, the bespoke outlook offers an alternative look into the pioneering industry.

An interdisciplinary joint project on geothermal development in Germany, AGENS has received a €44.4mn grant from the Federal Ministry for Economic Affairs and Climate Protection (BMWK), based on a resolution of the German Bundestag.

An interdisciplinary joint project on geothermal development in Germany, AGENS has received a €44.4mn grant from the Federal Ministry for Economic Affairs and Climate Protection (BMWK), based on a resolution of the German Bundestag.

Defined as the 'Demonstration of an adaptive, multilateral reservoir development for geothermal energy for seismicity and cost mitigation in the Upper Rhine Graben' that will be delivered over a span of five years, the AGENS initiative involves geopfalz, Institute for Geothermal Resource Management at ITB gGmbH, Johann Wolfgang Goethe University of Frankfurt am Main, Rhineland-Palatinate Technical University of Kaiserslautern-Landau, Ruhr University Bochum, geomecon GmbH, and the Technical University Bergakademie Freiberg.

In a sub-project of the AGENS that will be spearheaded by Stadtwerke Speyer GmbH-subsidiary Geopfalz GmbH & Co. KG in Schifferstadt city, Geopfalz will create 'Rhein-Pfalz' – the first deep geothermal duplicate, a basic building block for geothermal heat supply. This will ensure decarbonisation of the heat supply in Speyer and Schifferstadt, creating public awareness on sustainable living.

Reasearchers will also take into account the larger economic impact of the project.

With an allocation of €24.3mn, the project will look into a pioneering exploration technique, in which several side boreholes are drilled from a main borehole. The reservoir can be developed in a geomechanically and hydraulically optimised manner that reduces the risks of induced seismicity while increasing productivity.

A remaining funding of around €20.1mn will go to the other project partners.

Geo-Energie Suisse AG is an associate partner in the AGENS project. The project also involes the Federal Ministry of Education and Research (BMBF), which is supporting as part of the supplementary project LISAGENS with an additional funding volume of approximately €1.8mn to address questions of basic research.

DeepOcean, an ocean services provider that is dedicated to enabling the energy transition and sustainable use of ocean resources, has been awarded a significant recycling project on the UK continental shelf.

Provided by an unnamed international operation, the contract will see DeepOcean oversee project management and engineering operations for a comprehensive campaign that will span more than 120 days. With offshore decommissioning activities scheduled this year, the project is segmented into five sub-campaigns including the recovery of concrete mattresses, spools, flexibles, flowlines, jumpers, suction anchor, multiple structures and final debris clearance with the addition of a subsea rock installation campaign to conduct final seabed remediation.

Gary Scott, UK Commercial Manager & Legal Counsel at DeepOcean, commented, “We are delighted to have been selected to perform this decommissioning project and this contract award reflects our team's proficiency in executing complex subsea projects with a focus on safety, environmental responsibility, and efficiency.”

To execute the workscope, DeepOcean has stated that it will employ its advanced fleet including the Edda Freya, a state-of-the-art vessel suited for operations worldwide. The ship will utilise its 2,300 sq m of deck space and 400Te AHC crane, with two moonpool launched 220 HP Kysdesign WROVs. The Normand Jarstein will also be deployed.

As outlined by DeepOcean, upon successful recovery, all items will be transported and offloaded onshore for appropriate reuse, recycling, or disposal, adhering to stringent environmental regulations. Through close collaboration with DeepOcean’s selected waste management contractor, reuse options for all concrete mattresses will be sought, demonstrating our commitment to the environment and needs of our client with a continued focus to maximise re-use for all recovered materials.

Aberdeen-based Odfjell Technology Ltd has solidified is plug and abandonment (P&A) and slot recovery range with a £3mn-acquisition of McGarian TDC Ltd.

Aberdeen-based Odfjell Technology Ltd has solidified is plug and abandonment (P&A) and slot recovery range with a £3mn-acquisition of McGarian TDC Ltd.

This acquisition will advance Odfjell’s Well Services division, and add to the company's 20 years of experience in designing whipstocks, casing and packer milling, fishing and remedial products.

Representing as much as 45% of an asset’s decommissioning costs, the P&A market is at a dynamic stage right now.

Odfjell Technology boasts of a completely integrated service for P&A campaigns using innovative operational models for the challenges of different well constructions, varying downhole geologies and adjacent infrastructure.

Odfjell Technology AS CEO Simen Lieungh said, “We are delighted to welcome McGarian TDC Ltd to the Odfjell Technology family. Their engineering and product design capability perfectly complements our existing competencies.

“P&A represents a significant investment for our customers involved in of end-of-life operations. Our aim has always been to provide an efficient service with a focus on safety and environmental security – this strategic acquisition enables us to further strengthen that commitment to our customers.”

Bruce McGarian, Owner of McGarian TDC Ltd, added, “Joining forces with Odfjell Technology presents an exciting opportunity for us to leverage our expertise on a larger scale.”

Equinor has awarded DeepOcean a four-year frame agreement for marine services that includes subsea intervention and repair contingency for subsea pipelines, structures and high voltage cables for not only oil and gas fields but also offshore renewables.

Equinor has awarded DeepOcean a four-year frame agreement for marine services that includes subsea intervention and repair contingency for subsea pipelines, structures and high voltage cables for not only oil and gas fields but also offshore renewables.

The agreement comes with a scope for extension up to another four years.

Geographically the agreement is valid for work on the Norwegian continental shelf and internationally for planned Equinor work and for contingency work for the PRSI pool members, which comprises 23 energy companies that cover their offshore pipeline and power cable repair contingency via the pool.

The contract delivery will be managed by DeepOcean from its Haugesund-based office in Norway.

“Such a long-term agreement allows us to constantly evolve working methods, collaboration models and technologies, with the objective of making offshore operations and subsea cable repair work as cost-effective as possible. We look forward to supporting Equinor and the PRSI Pool members over the coming years,” said Olaf A Hansen, Managing Director of DeepOcean’s European operation.

For work in the offshore oil and gas industry, the frame agreement covers planned or unplanned marine services using remote operated intervention methods with or without the use of PRS equipment.

Under the agreement, DeepOcean is also expected to be equipped to produce multiple engineering or preparedness studies as requested by Equinor or PRSI pool members.

“DeepOcean has a 400 people-strong engineering team that are specialists on solving subsea challenges across industries. We are industry agnostic and share learnings and experiences from subsea operations across different types of operations and industries in order to develop the best possible solutions for our clients. Our experience from oil and gas is highly valuable for offshore renewables – and vice versa," said Normann Vikse, Offshore Renewables Director at DeepOcean.

DeepOcean has already received the first call-offs for work under the new frame agreement.

On behalf of Gassco and Equinor, DeepOcean will perform seabed preparations and complex remote hot tap tie-in operations at three different locations on the Norwegian continental shelf. Hot tapping is a method of connecting to a pressurised system, such as a pipeline, without removing the pipe from service.

On behalf of Gassco with Equinor acting as technical service provider, DeepOcean has already performed marine services to support baseline inline inspection of a large sized pipeline.

Page 12 of 36

Copyright © 2026 Offshore Network