Europe

- Region: All

- Date: June, 2022

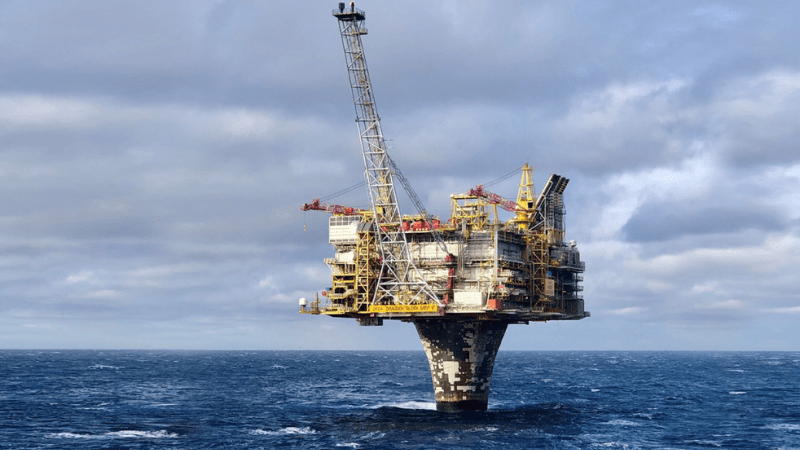

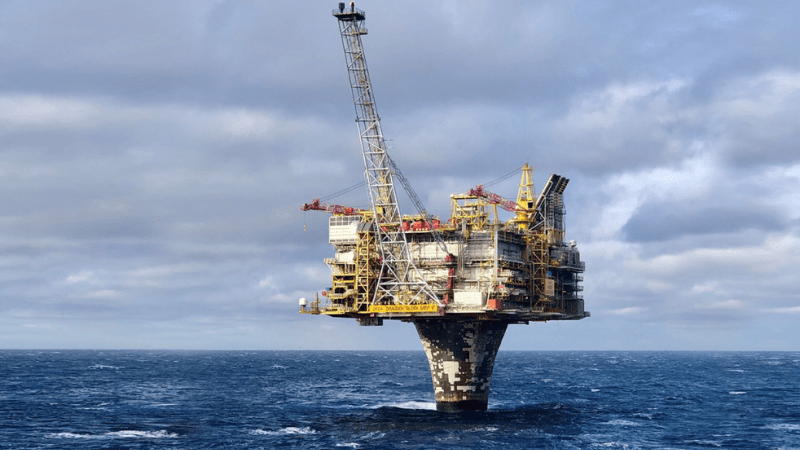

Osbit, an offshore technology company, has delivered a new intervention tower system to FTAI Ocean which comprises 1,300 tonnes of equipment and stands at 40 metres tall.

The tower will enable riser and riserless based well intervention activities in water depths of up to 1,500 metres and integrates a series of innovations derived from the company’s extensive experience in developing well intervention and offshore handling equipment.

The tower’s vertical racking system reduces the need for well centre access, while maximising deck space with its small footprint. An active and passive heave compensated platform supports coil tubing, slickline and e-line operations, while safe personnel access is facilitated via an integrated walk to work system.

For riserless operations, the system has four guide wires and two pod wires integrated with the existing vessel crane which provides up to 250 tonne Safe Working Load (SWL) active heave compensation. The system’s deck skidding system minimises the need for crane lifts, increases the operating window, and enables equipment to be directly loaded into the well centre.

The tower was fabricated and assembled at Wilton Engineering Services in Teesside, UK.

Osbit Director Steve Binney, commented, “Completing this project is a huge achievement for Osbit, and we have worked extremely hard to deliver our largest and most technologically complex engineering system yet. As a team, we have overcome many obstacles to reach this important milestone, which shows not only our capability, but that of North East England, and our fantastic supply chain."

Project Director, Steve Bedford, added, “The delivery of this project is Osbit’s biggest milestone yet and is testament to the unbelievable efforts of the whole Osbit team, most of whom have made a direct contribution towards making this happen. This tower system is a prime example of how we work from first principles, combining our proven technology modules with fresh thinking to produce exciting engineering systems for the offshore world.

"It has also been rewarding to watch our team grow and develop as they supported this project’s development, and we are already applying this learning on to our latest projects and concepts for the offshore wind market. With the build complete, we are looking forward to providing further support to FTAI Ocean now that preparations are underway for transportation to Singapore.”

- Region: All

- Topics: Integrity

- Date: June, 2022

In the oil and gas industry, tubing retrievable subsurface safety valves (TRSSSV) are routinely tested to ensure they provide fail-safe well protection. However, it is not uncommon for these safety valves to reveal seal integrity issues when closed.

As the hydraulic control line bypasses all conventional wellhead valve closure systems, this increases the risk of well integrity being compromised and the likelihood of uncontrolled hydrocarbon gas migrating to the surface.

When control line gas ingress is a known issue, it is feasible to manually isolate at the control line inlet, however under an emergency shutdown (ESD) situation, when the safety of personnel is the highest priority, manual intervention may not be possible, potentially leaving an exposed route for hydrocarbon gas to migrate through the main hydraulic power unit (HPU).

In 2016, during a routine test, a North Sea operator discovered gas seeping through the TRSSSV through a failed seal, travelling up the control line, accumulating at the HPU. Whilst this was a scheduled test and manual intervention was possible, it was categorised as a severe risk should an ESD situation arise. Oilenco identified the necessity for a fully autonomous solution and designed the Gas Ingress Isolation Valve (GiiV).

The primary purpose of the GiiV is to perform the same function as manually isolating the control line, but without human intervention. Situated in close proximity to the control line inlet, the system is fully autonomous and does not require additional infrastructure to operate. By using elements of the existing well control system, the GiiV can detect a reduction in pressure of the safety valve control line system. When the system is depressurised sufficiently to fully close the downhole safety valve, the GiiV automatically isolates the control line.

To reopen the GiiV, pressure from the HPU is applied, and with the GiiV open, further system pressure re-opens the downhole safety valve allowing operations and production to resume.

The GiiV has been designed so the isolation process can be repeated time and time again as often as required without human intervention.

Whilst the GiiV does not fix the root cause of the gas ingress, it acts as a safety barrier allowing the operator time to plan a solution, protecting people, the asset, and the environment.

Warren Ackroyd, Managing Director, Oilenco, said, “Presenting this solution to market was a game changer in offshore safety and hydrocarbon gas ingress management. Each GiiV complies with UKCA certification, and we are constantly reviewing the technology to ensure it continues to play a vital role in the life safety and asset integrity of offshore assets.

There are currently 18 GiiV’s in the field installed by various operators across the North Sea, Vietnam, and Indonesia with a further 14 units currently in production in 2022. As Oilenco celebrate six years since the conception of the GiiV, this tried and trusted product has become a safety critical solution for gas ingress challenges and an established part of well integrity assurance.”

- Region: North Sea

- Topics: Decommissioning

- Date: June, 2022

Specialist well-decommissioning services provider Well-Safe Solutions has announced the completion of its third investment round, raising £50 million for the company.

Specialist well-decommissioning services provider Well-Safe Solutions has announced the completion of its third investment round, raising £50 million for the company.

Well-Safe Solutions said it will use the funds for the purchase of its third rig and to broaden the capabilities it offers to clients around the world. The funding round was led by MW&L Capital Partners, a London-based principal investment and financial advisory firm, with participation from a consortium of new and existing investors.

The latest investment brings the total capital raised by the company to over UK£150mn.

Phil Milton, Chief Executive Officer of Well-Safe Solutions, said, “This further investment demonstrates our strong investor support, enabling ongoing growth here in the UK as well as delivering the next stage of Well-Safe’s international growth.”

“The capital raised in previous investment rounds has been instrumental in enabling the company to put in place a world-class portfolio of bespoke well plug and abandonment (P&A) assets, backed by expert onshore and offshore teams. These investments are now bearing fruit thanks to recent contract wins and workscopes throughout the North Sea for our rigs and well engineering teams.”

“As we continue to build upon Well-Safe’s operational record, we are looking forward to exporting this model to new markets, which have expressed an interest in our collaborative, multi-well, multi-operator approach to well decommissioning,” Phil added.

Well-Safe was recently awarded its first contract with Ithaca Energy for the Well-Safe Protector jack up rig, which will be used to decommission several wells located in the Southern North Sea. The business also announced the acquisition of the ex-Awilco Drilling WilPhoenix semi-submersible rig, which is to be renamed the Well-Safe Defender.

The Aberdeen-based company said that it is building on this positive momentum, with over 100 new employees joining the company in the past 12 months.

Alasdair Locke, Chairman and majority Shareholder of Well-Safe Solutions, said, “This financing allows a step-change in the capabilities of Well-Safe Solutions, enabling us to be competitive on a global basis. I’m grateful for the support from existing and new investors.”

Julian Metherell, a founding partner of MW&L Capital Partners, added: “We are delighted to continue to partner with Well-Safe to build a world-class decommissioning business.”

- Region: North Sea

- Topics: Decommissioning

- Date: June, 2022

EXCEED has announced the award of a milestone, vessel-based well plugging and abandonment campaign to be carried out in partnership with Mermaid Subsea Services UK (Mermaid) on behalf of four operators.

EXCEED has announced the award of a milestone, vessel-based well plugging and abandonment campaign to be carried out in partnership with Mermaid Subsea Services UK (Mermaid) on behalf of four operators.

The result of a tranche of initial bids from the strategic partnership builds upon EXCEED’s 130+ well abandonment track record and is the company’s largest vessel-based well P&A campaign to date, whilst representing Mermaid’s entry into the North Sea marketplace.

Due to commence Q3, the multi-operator vessel-based campaign is thought to be one of the largest campaigns of its type to be undertaken on the UKCS for at least a decade, and currently comprises the decommissioning of ten E&A wells across Northern, Central and Southern areas.

Based on the campaign approach, which has been highlighted as an important lever in the cost reduction of well P&A, the potential for this to become a multi-operator programme was the objective upon which the partnership was founded.

Mermaid Operations Director, Scott Cormack, explained, “New contracting models are critical to achieving the decommissioning cost reduction target set by the North Sea Transition Authority (NSTA). However, the NSTA reported in 2021 that these models were yet to become the norm and that a lack of collaboration was, in part, responsible.

“Our aim is to help address that situation, not only through our own collaboration with well management leaders EXCEED, but also by encouraging operators to consider the benefits of a lump sum, campaign approach to decommissioning. That this has been the precise outcome of our first campaign is testament to the clear appetite for this approach amongst the operator community,” Scott added.

John Anderson, Commercial Director for EXCEED commented, “Our well decommissioning experts have worked on some of the sector’s highest-profile abandonment campaigns, and it’s clear to us that this partnership brings something unique to the sector; a turnkey well P&A service, which provides not only the technical downhole capabilities but also complete control over vessel schedules.

“In this way, we can optimise timings to allow for multi-operator campaigns. With mobilisation/demobilisation accounting for a third of the total well P&A cost, this approach makes good economic sense, as well as minimising the environmental impact of multiple, separate campaigns.”

NSTA Head of Decommissioning Pauline Innes said, “The NSTA is actively promoting multi-operator, well-decommissioning campaigns – which can deliver substantial cost efficiencies, reduce emissions and give suppliers confidence to invest – and is encouraged this approach has gained traction in the North Sea market.”

- Region: North Sea

- Date: June, 2022

Plexus Holdings PLC, an oil and gas engineering services business and owner of the proprietary POS-GRIP friction-grip method of wellhead engineering, has been awarded a purchase order for plug and abandonment equipment and services from Oceaneering International Services Limited, a division of Oceaneering International Inc.

The order includes tieback and subsea well control equipment together with hydraulic controls and services. The rental equipment will be used to support Oceaneering's vessel-based P&A services for a six-operator joint campaign in the Dutch Sector of the North Sea.

Ben Van Bilderbeek, CEO of Plexus, commented, "We are delighted to be working with Oceaneering on this North Sea project and anticipate this opportunity leading to further potential for P&A work for Plexus, especially given the sector's growth forecasts. This new order for our unique services on a multi-well campaign is a major step forward for Plexus and represents a diversification of our business into support-vessel based P&A work."

"After many lean years and following the collapse and near collapse of many companies in the oil and gas services sector in 2015/16, it is reassuring to see a widely reported recovery in drilling activity and capital expenditure around the world. Encouragingly this has led to an increased level of interest in our Exact-EX exploration wellhead rental services, Centric-15 mudline hangers and our POS-GRIP ‘HG’ production wellhead technology, for which we are positioning the company to benefit, by way of planned investment in additional inventory and increased customer engagement."

This order is estimated to generate revenues of circa UK£500,000 for Plexus in calendar year 2023, and has the potential to lead to other similar work in the North Sea and internationally both with Oceaneering and other customers.

- Region: North Sea

- Topics: Decommissioning

- Date: June, 2022

Fairfield Energy recently announced the removal of the topsides from Dunlin Alpha platform which is the latest milestone in the decommissioning of the four fields which make up the Greater Dunlin Area.

Following the hook down and removal activities undertaken by the HAF Consortium (Heerema Marine Contractors and AF Offshore Decom) last month, Heerema’s SSCV Sleipnir transferred the remaining modules to its deck before removing the main 11,750-tonne Module Support Frame (MSF) in a single lift. The Sleipnir then returned to AF Offshore Decom’s Environmental Base at Vats where more than 95% of the Dunlin topsides will be recycled.

The Dunlin Alpha installation, located approximately 137 km northeast of Shetland and in a water depth of 151 m, produced its first oil in 1978. In the 37 years that followed, more than 522 million barrels of oil were recovered from the Greater Dunlin Area, comprising the Dunlin, Dunlin S/W, Osprey and Merlin fields. Fairfield Energy acquired the assets in 2008 and took over full operatorship in 2014, maximising production during its late-life stage and then progressing its subsequent decommissioning programmes.

Alan Scott, General Manager for the Greater Dunlin Area Decommissioning Project said, “This is a poignant milestone for an installation which has been a central part of UK North Sea production since the industry’s earlier days. Notably, in 1978 it was the first field to produce into the Sullom Voe Terminal on Shetland, paving the way for the many which came after.

“The Greater Dunlin Area itself has made its mark but it’s important not to forget the thousands of people who have visited or called the platform their working home. Dunlin has always been blessed with a strong team spirit and this is another core part of its legacy, having influenced the careers of many across the industry. I’d like to thank everyone who has been involved with Dunlin over the years, helping the asset overcome any challenges and achieve its many successes,” Alan Scott added.

An agreement was reached with the UK authorities in 2015 that the fields had reached Maximum Economic Recovery (MER), enabling Fairfield to begin the multi-asset, multi-year decommissioning of the Greater Dunlin Area. Since then, Fairfield has developed, consulted upon and gained the approval for its decommissioning proposals and executed a series of scopes which, at their peak, employed 600 personnel from over 26 drilling, subsea and topside operations companies.

Gary Farquhar, Platform and Infrastructure Decommissioning Manager said, “Project execution has involved the P&A of 12 Osprey and four Merlin subsea wells; the decommissioning of the extensive subsea infrastructure associated with those satellite fields; the decommissioning of subsea power import, gas import and oil export infrastructure; the P&A of 45 platform wells; and the engineering down of the Dunlin Alpha topsides. We are pleased to have added Topsides Removal to the list of activities that have been safely and efficiently executed.”

- Region: North Sea

- Topics: Decommissioning

- Date: June, 2022

Ithaca Energy, an oil and gas operator has contracted Well-Safe Solutions to plug and abandon (P&A) six wells on the Anglia Platform in the Southern North Sea.

The contract – for an undisclosed sum – will see the Aberdeen-based well decommissioning specialists provide project management, well engineering and all managed delivery services for the project.

The Well-Safe Protector, a heavy-duty harsh environment jack-up rig, is nearing the end of extensive technical preparations and will mobilise to the field in late summer 2022.

Matt Jenkins, Chief Operating Officer at Well-Safe Solutions, said, “This full-service contract is further vindication of our operating model and allows Ithaca to realise the benefits of Well-Safe’s extensive experience in the Southern North Sea. Well-Safe delivers environmentally-friendly and cost-effective well decommissioning operations, unlocking key learnings over multi-well, multi-operator campaigns."

An option to P&A an additional three subsea wells is also available during 2023.

Jane Eddie, Bid Manager, added, “We have worked closely with Ithaca Energy to design a contract which meets their needs and – crucially – those of Offshore Energies UK, the North Sea Transition Authority and other industry stakeholders.”

“Our team is uniquely positioned to support Ithaca Energy with their decommissioning obligations, as we are the first UK-based company with owner-operated rigs to exclusively perform well P&A operations.”

Ricky Thomson, OEUK Decommissioning Manager, said, “Decommissioning has a crucial role to play in helping the UK deliver its net zero ambitions, as outlined in the North Sea Transition Deal. The UK’s decommissioning industry has an incredibly exciting future ahead, and projects like this will be vitally important to realising those ambitions.

This contract announcement follows recent news of Well-Safe Solutions’ purchase of the WilPhoenix semi-submersible rig from Awilco Drilling. The rig will now undergo conversion for well P&A activity and has been renamed the Well-Safe Defender.

- Region: North Sea

- Date: June, 2022

The Petroleum Safety Authority Norway (PSA) has given OKEA consent to use COSL Promoter for permanent plug and abandonment of wells on the Draugen field.

COSLPromoter is a semi-submersible drilling rig designed to operate in water depths up to 750 metres. This compact unit is designed for North Sea / Norwegian Sea and worldwide use in harsh environments. Station keeping is maintained by an 8-line mooring system or by dynamic position mode maintained by 6 fixed pitch, variable speed thrusters (DP3).

Draugen is a field in the southern part of the Norwegian Sea. The field has been developed with a concrete fixed facility and integrated topside, and has both platform and subsea wells. Stabilised oil is stored in tanks at the base of the facility. Two pipelines connect the facility to a floating loading-buoy. Production started in 1993.

The water depth in the area is 250 metres. Draugen was discovered in 1984, and the plan for development and production (PDO) was approved in 1988. It produces oil from two formations. The main reservoir is in sandstone of Late Jurassic age in the Rogn Formation. The western part of the field also produces from sandstone of Middle Jurassic age in the Garn Formation. The reservoirs lie at a depth of 1,600 metres and are known to be relatively homogeneous, with good reservoir quality.

- Region: North Sea

- Date: June, 2022

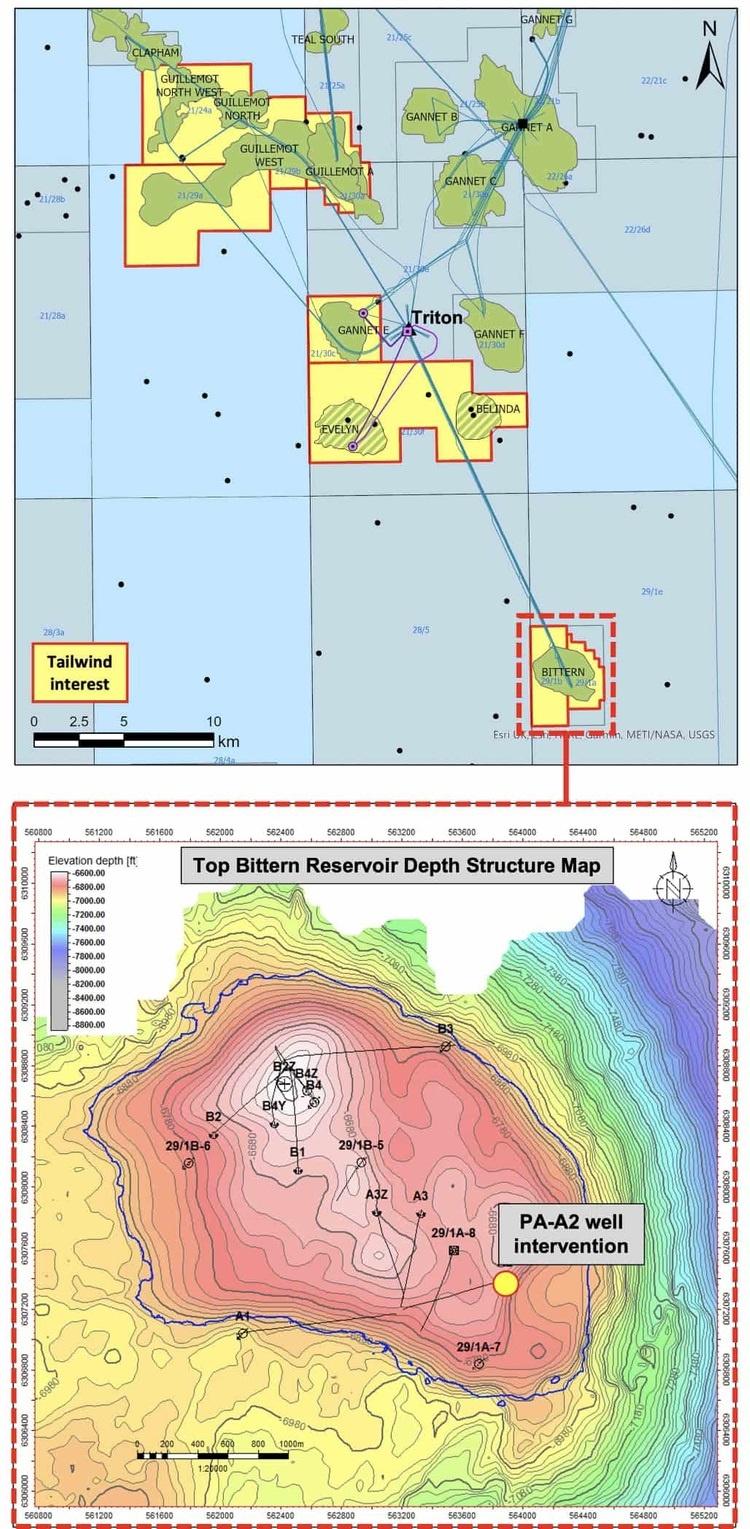

Tailwind Energy has successfully completed a well intervention in the Dana-operated Bittern Field, located in the North Sea.

On well PA-A2, new perforations were added to the upper reservoir and a water shut-off plug in the lower reservoir section.

This intervention has increased the oil rate from c. 1,000 boe/d to c.3,000 boe/d, marking a significant boast to production.

The news comes soon after the company reported a strong financial performance across 2021 with robust figures. In the 2021 CEO review, it was reported that actual production averaged 14,000 boe/d and all assets performed at, or over plan except for Columbus. As a result, the company recorded an increase in revenue to US$382mn relative to US$263mn in 2020. Such a strong performance has allowed the company to recycle cash back into the business and last year it invested the highest capital spend programme to date which included two wells being successfuly drilled and completed.

More Articles …

Page 22 of 37

Copyright © 2024 Offshore Network