Welltec has announced its Puncher 218 technology has won at the Hart Energy’s E&P 2023 Special Meritorious Awards for Engineering Innovation (MEA). The MEA programme recognises new products and technologies which demonstrate innovation through their concept, design, and application.

Welltec has announced its Puncher 218 technology has won at the Hart Energy’s E&P 2023 Special Meritorious Awards for Engineering Innovation (MEA). The MEA programme recognises new products and technologies which demonstrate innovation through their concept, design, and application.

“This award is a fantastic acknowledgment of the advances we continue to make within our intervention technologies,” said Alex Nicodimou, Welltec VP for Sales & Marketing.

“We are constantly improving and evolving our portfolio, while also developing new services and new service sizes as in this particular case. The focus is always to help our clients and continue to make operations more efficient, more controllable, and more reliable through technology.”

The Welltec Puncher 218 provides an efficient, e-line conveyed, non-explosive method for equalising pressures between tubular strings. Its innovative design is ideal for extended reach and going beyond narrow internal diameter restrictions, and is currently the slimmest non-explosive puncher capable of creating multiple perforations on a single run in the market.

Jordan Blum, Editorial Director at Hart Energy, said, “Technology has clearly been at the forefront as the industry has challenged the frontiers of exploration, drilling, and production. We applaud Welltec’s commitment to technological progress in the upstream area, and we congratulate them on receipt of this award.”

TotalEnergies EP Nederland has appointed ABL Group, an independent energy and marine consultancy, as marine warranty surveyor for the decommissioning operations of the L7 field in the Dutch sector of the North Sea.

The L7 Restitution Project includes the decommissioning of nine jackets and ten topside modules, including bridge structures from the L7 field. The total weight of the installations is approximately 17,500 tonnes.

ABL will provide marine warranty survey services for the preparations, lifted removals, transportation and relocation to the onshore dismantling yard located in Norway. ABL will also conduct suitability surveys of all the marine units that will be utilised for the project.

Ashley Perrett, ABL’s Country Manager in Scotland, commented, “ABL Group has a long history in the oil and gas sector and vast experience with the challenges and important considerations that can impact decommissioning work. We are delighted to be partnering with TotalEnergies EP Nederland on the L7 project as part of our growing portfolio of work in this area.”

Planning work has already commenced, and offshore operations will occur throughout 2023 and 2024. The installations will be removed using a floating sheerleg crane that will transfer cargo to a barge in sheltered waters near Den Helder, Holland, for onward transit to the dismantling yard located in Vats, Norway. AF Offshore Decom will manage the removal and recycling of the installations.

“Decommissioning of oil and gas fields is a complex task. As a non-productive cost, we fully appreciate the importance of identifying the correct solution to ensure cost-efficiency without compromising safety and quality,” commented Nicholas Kaczynski, ABL Group’s Project Manager for the L7 decommissioning project.

Neptune Energy has announced an agreement to create new ‘digital twins’ of two offshore platforms in the Dutch North Sea, expanding its portfolio of digitised assets to 14 in total.

Neptune Energy has announced an agreement to create new ‘digital twins’ of two offshore platforms in the Dutch North Sea, expanding its portfolio of digitised assets to 14 in total.

The twins will enable engineers to carry out traditional offshore work from an onshore location, accelerating work schedules and reducing costs. UK-based 3D technology specialist, Eserv, will digitise the Neptune-operated D15-A and K12-C platforms, after previously creating digital versions of 12 platforms in the Dutch and UK sectors.

This technology allows Neptune teams to virtually visit assets, leading to thousands of hours of work being completed from office-based locations since the twins were introduced.

Neptune Energy’s Director of Operations for the Netherlands, Stephane Lacote, said, “The use of 3D technologies such as digital twins have provided significant benefits including reducing operational costs by enabling traditional offshore activities to be completed quickly and efficiently, without travelling offshore.

“Our engineering teams can now virtually visit platforms to support the safe running of operations from anywhere on the planet.”

Digitising operational assets to improve safety and productivity, as well as reduce environmental impacts, supports Neptune’s aims to enhance asset integrity and provide employees with technologies that support collaboration with colleagues globally.

Saipem has been awarded three new offshore contracts along with two competitive FEED contracts totalling approximately US$650mn.

Saipem has been awarded three new offshore contracts along with two competitive FEED contracts totalling approximately US$650mn.

The first of the contracts was assigned by Azule Energy for the Agogo Full Field Development project – a deepwater greenfield development approximately 180 km offshore Angola. The contract encompasses the Engineering, Procurement, Construction and Installation (EPCI) of rigid Pipe-In-Pipe flow lines with associated subsea structures. Saipem will mobilise its state-of-the-art offshore installation vessel FDS2.

The second contract was awarded by EnQuest for the decommissioning of existing infrastructures in the Heather oil field located in the UK sector of the North Sea, around 460 km northeast of Aberdeen. Saipem will carry out the engineering, preparation, removal and disposal of the upper jacket of the Heather platform, utilising the semisubmersible crane vessel Saipem 7000.

The third contract was issued under the Aramco LTA programme in Saudi Arabia, where Saipem will execute the offshore EPCI of one platform topside and the associated subsea flexible, umbilical and cable system.

Additionally, Saipem has been awarded two Front-End Engineering Design (FEED) Competition contracts for gas developments projects. The first one, assigned by Shell Trinidad & Tobago Ltd., is related to the development of the Manatee natural gas fields. The other contract concerns the development of the upstream facilities to feed the natural gas PAPUA LNG project in Papua New Guinea.

All of the above further consolidates Saipem’s position both geographically and in key segments for the offshore business, in particular in decommissioning where the company boasts an impressive track record.

Archer has announced the completion of the Baker Hughes’ UK Coil Tubing and Pumping business acquisition made in February 2023.

Archer has announced the completion of the Baker Hughes’ UK Coil Tubing and Pumping business acquisition made in February 2023.

Dag Skindlo, CEO of Archer, said, “This acquisition is part of our strategy to be one of the leading well services companies in the UK. Together with our well-established platform operations business, Archer is uniquely positioned to serve our customers with a broad range of production enhancements and P&A operations. We are pleased to welcome this highly skilled and experienced team to Archer and look forward to adding value to existing and new customers.”

The team of AIS Survivex, an offshore training provider in the UK, has received an insight into life on board a decommissioning rig courtesy of Well-Safe Solutions.

Members of AIS Survivex were invited on board the Well-Safe Defender to let them experience life on a bespoke well plug and abandonment semi-submersible rig which accommodates 110 energy workers. It was described as an enlightening experience which allowed the team to understand more about the working conditions and challenges for the people they help train. AIS Survivex has been delivering and managing all training for Well-Safe since 2019 and is currently carrying out a range of training to prepare the Well-Safe Defender’s crew for its forthcoming campaigns.

The rig itself used to be used for drilling operations in the North Sea but, since being taken into Well-Safe’s ownership in 2022, has been converted to play a part in the energy transition as a bespoke well decommissioning asset. Currently, the rig is undergoing a host of efficiency enhancements ahead of its mobilisation this month for a well P&A campaign with Spirit Energy on the Trees and Chestnut fields.

laire Adams, Training and Competency Advisor at Well-Safe Solutions, commented, “With over 360 staff working for Well-Safe Solutions, we are focused on safe, smart and efficient delivery of well plug and abandonment – and all of this begins with effective training. AIS Survivex have supported Well-Safe Solutions on multiple occasions by providing multi-skilled trainers to provide rig-based training on all our assets as part of our rig readiness plans.

“Two AIS Survivex multi-skilled trainers were delivering a suite of courses to our crew onboard the rig to enhance personnel and team compliance against our matrix. The input of the AIS Survivex trainers is paramount in ensuring the relevant Well-Safe Solutions personnel held the correct training certification to ensure operational compliance prior to the rig mobilising for its upcoming P&A campaign with Spirit Energy. Collaborative working is key to our success and a safety-first mentality is critical for offshore workers.”

BiSN, a supplier of downhole sealing solutions and technology, has caught up with representatives from Aker BP regarding the successful plug and abandonment campaign conducted in the Valhall oilfield in 2020.

Aker BP needed to safely P&A 30 wells in the Valhall field in the North Sea and partnered with BiSN to deploy Wel-lok technology to create safe and cost-efficient Wel-lok plugs. After extensive testing conducted over the past two years, it has been shown that not only did this provide a permanent plug and abandonment solution, it allowed for new wells to be drilled and operated safely for the next 30 years.

“As part of the success story, we are monitoring the same wells today and we’re proud to say that out of the 30 wells today there is no leakage,” said Kjetil Vadset, Senior Drilling Engineer, Aker BP.

For two years prior to commencing the campaign in 2020, Aker BP and BiSN carried out a joint testing programme at BiSN’s Houston location to ensure Wel-lok technology was the safest, most cost-effective option. As a result of completing this rigorous testing programme, BiSN Wel-lok technology received acknowledgement of consent for use, including DNV-GL verification and PSA (NORSOK) evaluation of bismuth.

“Qualifying Wel-lok technology for use in the North Sea and securing a long term partnership with Aker BP were two major priorities for BiSN at the time,” said Paul Carragher, Founder and CEO of BiSN. “We are looking forward to continuing to develop a one team relationship with Aker BP on their forthcoming P&A campaigns.”

By implementing Wel-lok technology over traditional cement, it is estimated that the campaign saved approximately three months of rig time, or approximately US$2mn per well.

As part of the campaign, BiSN delivered the largest bismuth plug ever deployed to date. Produced at BiSN’s UK facility, the tool weighed in at 33,191 lbs and sealed up to 30 inches in the wellbore.

“We're very proud. The operation has gone beyond expectations. We planned and hoped for 72 hours per installation. We're down to 33 hours per installation just now,” said Vadset.

For the consideration of the secretary of state for energy security and net zero, Dana Petroleum (E&P) Limited has submitted a draft decommissioning programme for the Western Isles floating production storage and offloading (FPSO) vessel and its associated mooring systems, risers and dynamic umbilicals.

The associated infrastructure of the FPSO are located within UK block 210/24a in the northern North Sea which lies approximately 90 km to the northeast of Shetland and 58 km from the UK/Norward median line.

The draft decommissioning programme covers one vessel and associated subsea infrastructure including 12 mooring lines (three groups of four lines), nine flexible risers and two dynamic umbilicals.

Well-Safe Solutions, an international well decommissioning specialist, is supporting the decommissioning of two suspended wells in bp’s Kate field in the North Sea, 220 km from Aberdeen.

The programme of work, expected to be executed from the Noble Innovator jack up vessel during Q2 2023, will see Well-Safe Solutions carry out well engineering support services using its bespoke well decommissioning delivery process (WDDP).

Ruth Thomas, Subsurface Team Lead at Well-Safe Solutions, commented “We are very much looking forward to supporting bp with this work scope, which involves detailed subsurface and well engineering basis of design studies ideally suited to our specialist capabilities.

“Well-Safe Solutions will be instrumental in establishing and evaluating key subsurface isolation criteria including identifying and quantifying zones of flow potential and risks associated with redevelopment. In addition, we will also examine existing barriers and optimise the barrier strategy, taking into account the attributes of the region to safely and efficiently deliver this project.”

James Richards, Well Abandonment Director at Well-Safe Solutions, added, “The well decommissioning delivery process guides operators through the well plug and abandonment process efficiently and effectively, without the extended commitments and high costs historically associated with engineering resources over long periods.”

Decommissioning and P&A specialist, Mermaid Subsea Services UK, has been awarded a multi-well contract on behalf of North Sea operator following the completion of its inaugural vessel-based P&A campaign.

Decommissioning and P&A specialist, Mermaid Subsea Services UK, has been awarded a multi-well contract on behalf of North Sea operator following the completion of its inaugural vessel-based P&A campaign.

The two-year contract includes the decommissioning of 22 wells, representing the integrated subsea provider’s largest contract to date, and the creation of 12 new roles at Mermaid’s Aberdeen headquarters.

Scott Cormack, Mermaid Regional Director, commented, “We are delighted to announce the award of this contract, which follow hot on the heels of our well P&A activity during Q4 2022 with collaborative partner, Exceed.

“This project serves to underline the reputation we have so quickly gained for safe, efficient and cost-effective vessel-based well P^&A, which draws upon or core team’s combined track record across the decommissioning sector.”

According to the company, activity relating to the newly acquired contract is already underway.

Vår Energi ASA is set to plug and abandon a well in production licence PL229, northwest of Hammerfest, following the discovery of oil in the operated 7122/8-1S Countach well.

The well was drilled in one of the segments that form the Countach prospect and preliminary estimates place the size of the discovery in the tested segment between 3-13mn bbls of total recoverable oil equivalents. The potential of the Countach prospect, in the undrilled segments, is estimated at up to 23mn bbls of total recoverable oil equivalents.

Following the discovery, the well will now be permanently plugged and abandoned, and the licensees will evaluate drilling an appraisal well in the future.

Rune Oldervoll, EVP Exploration and Production in Vår Energi, said, “Countach reinforces the company’s position as the leading exploration company on the Norwegian shelf. This discovery is yet another in a series of successful exploration wells in the Barents Sea in recent years, including Lupa – the largest discovery on the Norwegian shelf in 2022.

“At the same time, the discovery confirms our exploration strategy and our position in the area. We will consider potential commercial development options and tie-in of the discovery to Goliat FPSO. Due to late arrival of the drilling rig on the field this winter, we have not been able to carry out the planned sidetrack before the environmental drilling restrictions commence on 1 March. We look forward to continuing to explore the area around Goliat at a later point in time.”

The well was drilled to a measured depth of 2,989 metres and oil was encountered in the Realgrunnen and Kobbe formations. With extensive data now collected for further assessment, the well will be permanently plugged and abandoned.

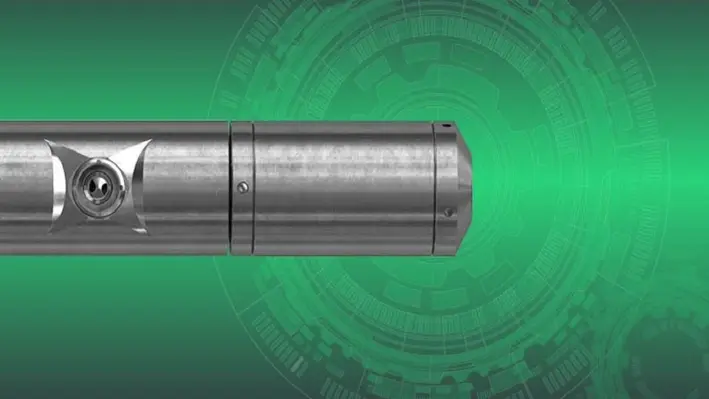

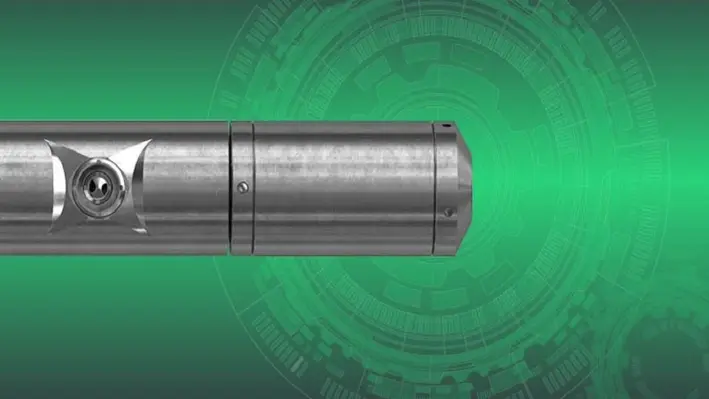

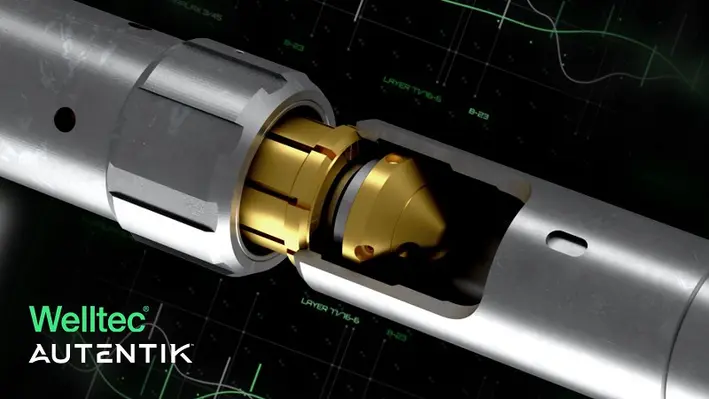

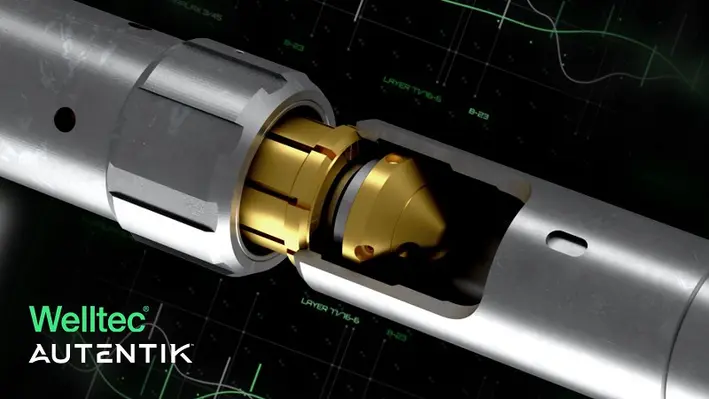

Completion and intervention leader, Welltec A/S, has announced the acquisition of Autentik AS, a niche technology provider which specialises in electric wireline fishing and intervention solutions.

Completion and intervention leader, Welltec A/S, has announced the acquisition of Autentik AS, a niche technology provider which specialises in electric wireline fishing and intervention solutions.

Autentik has a proven track record of delivering innovative solutions to its clients across the North America, Europe, Africa and the Middle East, and its expertise in downhole fishing will complement Welltec’s existing portfolio. With the acquisition, Welltec will be better positioned to serve its clients with the latest surface-controlled technology advancements and solutions. Together with Welltec’s manufacturing capabilities, the acquisition will bring an accelerated technology shift in how to conduct well access operations safely and efficiently.

Tommy Eikeland, CCO Welltec, said, “We are excited to welcome Autentik into the Welltec family. There is a mutual admiration for innovation and understanding of risk-taking which, to a certain level, is required when developing new technology. Together with their interventions expertise, this will add tremendous value and momentum to our organisation and enhance our ability to provide our clients with cutting-edge solutions.”

CEO of Autentik, Roy Kristiansen, commented, “This partnership will bring Autentik’s true passion for innovation and new solutions to transform wireline interventions together with Welltec’s global reach and market leadership in completion and intervention. This is a historic step in the life of Autentik, and a move that will benefit the clients and partners we work with.”

Page 19 of 36

Copyright © 2026 Offshore Network