Sval, Storegga and Neptune have formed a partnership to apply for a CO2 storage licence in the Norwegian North Sea for the Trudvang project.

The Trudvang licence, located to the East of the Sleipner field, has the potential to store up to 225mn tonnes of CO2 and comes after the Norwegian Ministry of Petroleum and Energy announced a new area in the North Sea for applications related to injection and storage of CO2.

Truls Olsen-Skåre, Senior Vice President Sustainability & HSEQ in Sval Energi, commented, “Carbon capture and storage (CCS) is a solution that can significantly reduce CO2 emissions. The partners have worked jointly since December 2021 to identify, nominate, and apply for this licence. We have undertaken a substantial amount of work already, including subsurface evaluation of the storage complex, and technical and economic assessment of the CCS value chain. This work has shown that Trudvang can be matured into a commercially viable project with safe and efficient carbon storage.

“We will focus on accelerating all phases of the work programme to be able to start injecting CO2 in 2029, and we will continue our work with existing and new parties to mature the full value chain.”

The Trudvang project envisages the capture of CO2 by multiple industrial emitters in Northern Europe and the UK, the shipping of liquid CO2 from export terminals to an onshore receiving terminal in the south-west of Norway and then transport via a purpose-built pipeline to the Trudvang location for injection and permanent storage.

Nick Cooper, CEO of Storegga, remarked, “CCS is essential, as one of the few technological solutions that can prevent CO2 emitted from industrial operations from entering the atmosphere and worsening climate change. Our Trudvang announcement today builds on Norway’s pioneering progress with the world’s first industrial-scale, multi-user CCS project. We look forward to continuing our work with Sval and Neptune to ensure that the Trudvang Project will have a significant impact on carbon emissions and a positive impact on the Norwegian economy.”

Optime Subsea has signed a long-term framework agreement with Wintershall Dea for use of the company’s remote controlled subsea well completion and intervention systems.

Optime Subsea has signed a long-term framework agreement with Wintershall Dea for use of the company’s remote controlled subsea well completion and intervention systems.

Under the agreement, Wintershall Dea will rent three Remoted Operated Controls System (ROCS) including its universal landing string system (panpipe), and two wireless electric subsea control and intervention systems (eSCILS) from Optime Subsea. The latter will also provide technical service personnel to support Wintershall Dea’s operations.

Jan-Fredrik Carlsen, CEO of Optime Subsea, commented, “This contract manifests our position as the leading global supplier of remote-controlled well completion and intervention systems. Our solutions are tailored to simplify subsea, entailing less equipment offshore, lower weight, less logistics, lower HSE risk, lower emissions and lower costs. We look forward to supporting Wintershall Dea in achieving this.”

The ROCS is a fully battery-powered and umbilical-less system for well completion operations, eliminating the need for the costly and heavy umbilical’s which normally run from topside to seabed, as well as the need for a hydraulic unit. In total, this avoids the mobilisation of approximately 50 tonnes of topside equipment. The eSCILS is also a battery-powered and umbilical-less device, used for subsea well interventions and workover operations. eSCILS is lowered to the seabed next to the well and can connected to any type of subsea tree, requiring only a computer for a topside control system, rather than additional rig equipment, and can be mobilised and demobilised in one day. As a result, operations can be done significantly safer, faster and more cost-effective than conventional solutions.

The agreement is valid for a firm period of three years plus two additional two-year options. If both option periods are exercised, Optime Subsea estimated that the contract could generate total revenues of around NOK500mn.

Rovco has successfully completed a contract awarded by Well-Safe Solutions to support its plug and abandonment and decommissioning operations in the southern North Sea.

Rovco provided Well-Safe Solutions with field survey operations, to ensure the safe and efficient decommissioning of a platform which ceased production in 2015. Last year, Well-Safe Solutions signed an agreement with Ithaca Energy to plug and abandon six wells on the platform and work will continue to be carried out by the company this year.

The project utilised the VOS Star, on charter from Vroon, equipped as standard with Seaeye Leopard work-class ROVs, fitted with multi-beam echo sounders, the highest quality 4K stereo cameras, manipulators, recovery basket and photogrammetry technology to carry out specialist hydrographic surveys and underwater asset inspections.

As part of the project, the company supported the client with debris survey and clearance solutions in water depths of 20 to 30 metres, as well as habitat characterisation surveys to mitigate risk and eliminate uncertainty about seabed conditions prior to the client deploying a jack-up vessel at the site.

Using its innovative SubSLAM X2 technology, Rovco also performed jacket inspection operations, providing the client with highly detailed 3D models of the platform footings to precisely identify any scouring across the structure.

Powered by sister company Vaarst, SubSLAM X2 produces 3D reconstructions of underwater assets in real-time, from which users can take measurements with sub-millimetric accuracy. Mounted on an ROV, travelling dynamically at general visual inspection speed, SubSLAM’s ability to zoom in, rotate and fly means that it can provide full coverage of a structure from all angles, as well as the seabed and surrounding environment.

Simon Miller, Chief Revenue Officer at Rovco, commented, “Being awarded a second contract with Well-Safe Solutions underlines their confidence in Rovco’s proven track-record.

“Accurate data sets from subsea surveys and inspections is key to the safety and efficiency of their operations and they know they can rely on our people and our technology to provide the highest quality data in real-time.”

“We’re pleased to be able to play a continuing role in decommissioning and the energy transition in the North Sea, supporting Well-Safe Solutions in its quest to safely and cost-efficiently plug and abandon wells in the Southern North Sea.”

This is the second contract that Rovco has secured with Well-Safe Solutions, having previously performed survey work on an abandoned subsea wellhead in UK waters in 2021.

The OWI EU 2023 conference is just around the corner, coming to Abderdeen from April 25-26, and looks to be back bigger and better than ever in order to capitalise on the breadth of opportunities being presented by companies across the entire well lifecycle.

The OWI EU 2023 conference is just around the corner, coming to Abderdeen from April 25-26, and looks to be back bigger and better than ever in order to capitalise on the breadth of opportunities being presented by companies across the entire well lifecycle.

Building on the success of last year’s first face-to-face format after the pandemic, Offshore Network’s flagship conference has undergone a complete revamp to maximise its offerings to its clients in order to promote the most valuable elements OWI EU has to show.

One of the biggest changes to the conference this year is that of the technology showcase hall, where the largest expo in the event’s history will be held, doubling in size to allow the most diverse technologies and services on the market to be demonstrated. This makes way for exhibitors such as Helix, TechnipFMC and Welltec to have the opportunity to showcase their innovations to regional, major and independent European operators.

Another key highlight at OWI EU 2023 is the new ‘Consult an Operator’ feature, where organisations can hear about a current challenge Shell and BP are facing, and then have the chance to book a closed-door appointment with the operators to pitch a solution. As well as there, there are ample opportunities for networking across the 10 sessions which are incorporated into the agenda, especially as 35% of the registered delegates are major, independent or national operators. These session also include a dedicated drinks reception, courtesy of IWCF and in celebration of Offshore Network’s 10th birthday party.

With this year’s tagline ‘Evolving the industry: Unlock the value of your well stock by utilising revolutionary production enhancement, well integrity and P&A tech in line with regulatory guidance and current market dynamics to exceed goals’ – OWI EU 2023 is set on aiding the necessary steps forward into implementing a more efficient and sustainable roadmap for transformation within the industry.

For more information and session details, the full brochure can be downloaded here. Any questions regarding the conference please reach out to Isobel Singh at

Well-Safe Solutions has signed a multi-year framework agreement with Apache Corporation (now a subsidiary of APA Corporation) to decommission wells in the North Sea, as part of the company’s Plug and Abandonment Club offering.

Well-Safe Solutions has signed a multi-year framework agreement with Apache Corporation (now a subsidiary of APA Corporation) to decommission wells in the North Sea, as part of the company’s Plug and Abandonment Club offering.

The deal will provide Apache with access to the specialist decommissioning assets Well-Safe Defender and Well-Safe Guardia to complete the P&A work on its well stock.

Chris Hay, Director of Strategy and Business Development, Well-Safe Solutions, said, “We are ready to assist Apache with its well decommissioning requirements, affording it the flexibility to book its wells into our campaigns when required.

“Our multi-well, multi-operator P&A Clubs give our clients cost certainty and leverage the cumulative experience gained by our specialist decommissioning teams on both assets across hundreds of wells to date.”

Separate from the frame agreement, Apache has secured a slot for Well-Safe Solutions to plug and abandon subsea wells in the UK Continental Shelf. This work is expected to begin in 2024 as part of a continuous campaign, enabling Well-Safe Solutions to maximise schedule flexibility and improve efficiencies for the member companies within the campaign.

The P&A Club’s focus on operational and cost efficiency aligns with the industry regulator, the North Sea Transition Authority’s, target to reduce the cost of decommissioning upstream oil and gas infrastructure in the UKCS by 35% by the end of 2022.

Europe’s largest provider of well integrity solutions, Unity, is developing a new additive manufactured lightweight gate which can be retrofitted to Christmas Tree gate valves to remediate seal integrity issues in low-pressure wells.

Europe’s largest provider of well integrity solutions, Unity, is developing a new additive manufactured lightweight gate which can be retrofitted to Christmas Tree gate valves to remediate seal integrity issues in low-pressure wells.

The gate has been designed as a solution for late life, depleted and shut-in offshore wells, where the tubing head pressure is too low to effectively seat the gate and seal the well. The patented design reduces the weight of the gate by around 60%, while retaining its intrinsic strength and would save operators around UK£250,000 per well by replacing a single surface component rather than the complete well control package.

The new technology is a result of a collaborative research and development project with Net Zero Technology Centre and Spirit Energy.

Technical Sales Director at Unity, Stuart Slater, explained, “The use of metal additive manufacturing means that we can offer attractive cost-savings and efficiencies to the industry, reducing raw materials, waste and operator investment in stock holding. The delivery of single items is fast and more energy efficient than traditional forgings, with an impressive 90% average reduction in lead times.

“But the real saving in this case is achieved by approaching the problem from a different angle, so rather than replacing the whole surface well control package we can quickly replace just a single small component, which offers huge cost and efficiency benefits.”

According to the most recent ‘Wells Insight Report’ from the UK’s North Sea Transition Authority, the current active UKCS well stock comprises of 2,629 wellbores, 1,661 of which are producing, while the number of shut-in wells rose by 65 to 781 in 2021. Shut-in well stock is now at a historical high, with 30% of all wells being shut in as significant intervention on infrastructure is cited as one of the top three limiting factors.

Unity’s technology is entering the latter stages of development as prototype testing has already been completed on a 2-1/16” gate, with a 5-1/8” gate now in manufacture to qualify the product for commercialisation.

Data and subsea service provider, Reach Subsea ASA, has secured a decommissioning contract for work in the North Sea.

The contract represents about 40 project days for execution in Q1 2023, and will see the utilisation of the Olympic Delta vessel. Reach Subsea have an existing cooperation with Olympic Subsea for the vessel, and both parties have agreed to extend their collaboration for the entirety of 2023.

“The market activity is high, and we are pleased to see that we are able to secure contracts across a range of segments. Continuing the good cooperation with Olympic both on ROV services and joint marketing of vessels, shows that our common service offering has been well perceived by clients,” said Jostein Alendal, CEO of Reach Subsea.

The extended collaboration comprises an additional 150 days of frim work for the two ROVs currently mobilised on the vessel. Reach Subsea is contracted to provide this service to Olympic for the charter duration to a tier 1 oil and gas contractor.

DOF Subsea has been awarded an Engineering, Preparatory works, Removal, Transportation, Recycling and Disposal (EPRD) contract by Norwegian energy giant Equinor Energy AS.

The contract is in relation to the Heimdal subsea decommissioning works and includes the recovery and disposal of approximately 2,000 tons of subsea equipment. The offshore work is scheduled in two main campaigns across three DOF vessels between 2024 and 2028, with project management and engineering work to start immediately. The preliminary work will be delivered by DOF’s expert cessation team based in Bergen, Norway.

Mons S. Aase, Group CEO, DOF, said, “I’m pleased that we are once again trusted to deliver a complex subsea project for Equinor. I look forward to completing the project successfully and safely.”

Heimdal is the Equinor-operated field in the North Sea, which has been operational since 1985. The contract states DOF Subsea are responsible for the removal, dismantling and recycling of the main platform topsides and jacket.

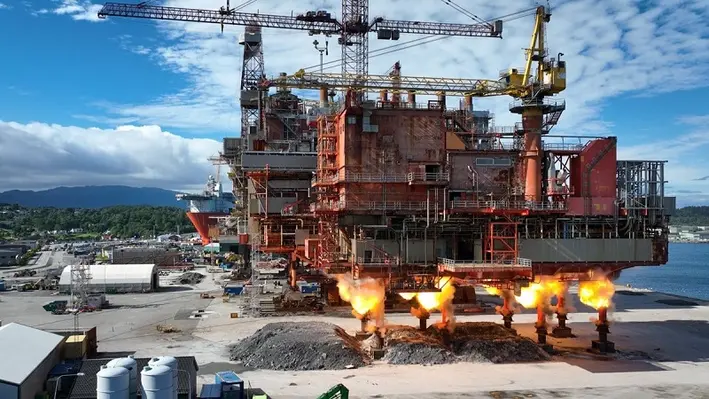

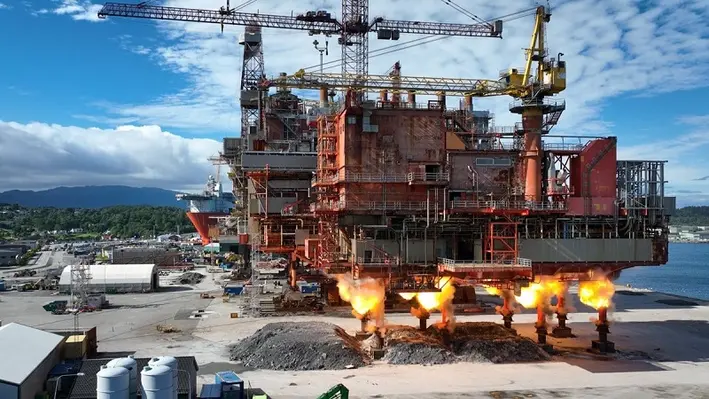

Aker Solutions can now offer operators a Second Life Report on the raw materials a platform contributes to the circular economy as part of its decommissioning offering in light of the fact that 99% of a drilling platform can be recycled.

Aker Solutions can now offer operators a Second Life Report on the raw materials a platform contributes to the circular economy as part of its decommissioning offering in light of the fact that 99% of a drilling platform can be recycled.

The report spotlights the quantity of materials yielded in decommissioning work, and for topsides with heavy lift records, that leads to a lot of valuable raw materials. Maintaining more sustainable economic activity relies heavily on reusing as many materials as possible, as far less energy is used in the recovery of recycled materials than in the production of newer ones. Steel recovered offshore has many unique qualities and uses that can be capitalised on.

However, the process of rendering these huge structures into salvageable materials can be a brutal endeavour. For example, on its final journey, the drilling platform used in the Norwegian Valhall oil and gas field was carried on the Pioneering Spirit heavy lift vessel only to be left at the Aker Solution’s Stord yard in May 2022 as large machines waited to demolish it. The 6,700 ton platform was first stripped of all hazardous materials and electrical waste before it was levelled by explosives. This process, however, speeds up the demo and makes it safer by bringing down heavy structures to ground level, avoiding the need to work from height.

The original Valhall installations have produced over one billion barrels of oil equivalent since the field entered production in 1982, with two platforms having been recycled at the Stord yard, and a third will be decommissioned later this year. While the original structures will continue on as raw materials, Aker Solutions has aided Aker BP in extending the life of the remaining Valhall centre for an extra 40 years.

Aker Solutions has already accumulated a pipeline of orders for structural teardowns in the North Sea, and already have some 40,000 tons of recovered hulks awaiting dismantling and recycling at the Stord’s yard.

Oilenco Norge AS, sister company to well intervention and abandonment company Oilenco Ltd, has appointed Dean Reynolds as Business Development Manager for their Norway operation.

Reynolds will transfer from Oilenco to Oilenco Norge AS after four years with the market-leading company and will be responsible for the growth of the Oilenco brand in Norway.

Reynolds, who has more than 20 years’ experience in the oil and gas industry, commented, “Oilenco is an innovative company bringing together bespoke design engineering expertise and custom manufacturing services to support clients with the most demanding of challenges. In my new role as Business Development Manager for Oilenco Norge, I will be responsible for developing client relationships, raising awareness of Oilenco products and capabilities, whilst demonstrating our compliance with the latest industry standards and high-quality service the company provides.

“Over my career I have gained valuable knowledge and experience from the front end, working offshore, understanding the needs of engineers, as well as supporting oil companies to provide a superior service to their customers. I am sincerely grateful to work for a fast paced, forward thinking company like Oilenco and to be given this opportunity to showcase our evolving product range to the Norwegian market.”

Blair McCombie, Operations Director, Oilenco Ltd remarked, “Oilenco have been working alongside oil and gas companies in the Norwegian sector since 2008, and following the establishment of Oilenco Norge in 2021, it is critical we have a dedicated operation and technical support in region. This appointment strengthens our position and shows commitment to provide a more collaborative service to our clients. As a significant producer of oil and gas, we look forward to supporting the Norwegian sector, bringing efficiencies to their well intervention operations through our design, manufacturing and engineering capabilities. Dean is a great asset to the company and addition to the Oilenco Norge team, and with his technical knowledge and years of experience, is a talented resource to work alongside our client to supply the service they require.”

BiSN, a leading supplier of downhole sealing solutions and technology to the global oil and gas industry, has been awarded a key contract by a major oil and gas operator in the North Sea.

The three-year contract (which features two one-year extensions) requires BiSN to use its proprietary Wel-lok alloy barrier technology to safely and efficiently plug and abandon oil and gas wells in the North Sea. The technology is a cost-effective and environmentally-driven solution that provides a permanent well-barrier and gas-tight seal in single and multiple annuli.

The scope of work includes providing BiSN Wel-lok alloy plug barrier technology, which ensures a permanent plugging and abandonment of oil and gas wells so that they are securely and reliably sealed, vastly reducing corporate liability and potential environmental impact. BiSN's alloy plugs are a superior solution compared with conventional technology that uses cement, elastomers, resin, or others as sealing elements that deteriorate over time, particularly in harsh environments.

Paul Carragher, Founder and CEO of BiSN, commented, “We are pleased and very excited that BiSN has been awarded this major contract. This is another step forward in the execution of our company mission to provide unique barrier solutions that protect the earth’s natural resources. Our strategic objectives, which include providing our novel technology and best-in-class services, focus on working collaboratively with our customers to support and exceed their well abandonment objectives.”

Mark Nicol, BiSN Regional Business Development Manager – UK, Europe & Africa, added, “This award recognises BiSN’s differentiating technology and capabilities to deliver a permanent well barrier in challenging offshore oil and gas wells. We look forward to collaborating with this operator and all associated stakeholders to successfully complete this project.”

Claxton, the University of Aberdeen, the National Decommissioning Centre and the Net Zero Technology Centre (which is providing funding and oversight), have continued to move ahead in the delivery of the Underwater Laser Cutting (UWLC) system, an alternative and clean underwater cutting technology ready to take the decommissioning market by storm.

Claxton, the University of Aberdeen, the National Decommissioning Centre and the Net Zero Technology Centre (which is providing funding and oversight), have continued to move ahead in the delivery of the Underwater Laser Cutting (UWLC) system, an alternative and clean underwater cutting technology ready to take the decommissioning market by storm.

UWLC improves efficiency when used for downsizing activity or applicable subsea decommissioning scopes and offers the flexibility of deployment methods in storage ponds, tanks and offshore. It was noted by the partners that the technology has the potential to ‘revolutionise’ subsea cutting.

The initial phase of the partnership, delivered between 2019 and 2021, saw the development of the UWLC system targeted at delivering offshore cutting trials in 70 metres seawater depth. The Net Zero Technology Centre funding supported partners in the development of underwater capable optics; the design and manufacturing of an underwater laser cutting head; procurement and packaging of a 15KW laser generator for offshore operations; and design and manufacture of control system software and hardware suitable for 50 bar hyperbaric conditions.

Successful delivery of this phase was demonstrated through subsea cutting performed at 70 metres seawater depth. This included 250 underwater cuts performed on structural steel up to 120 mm thick; Human Machine Interface (HMI) and 500 metre depth capable electronic control system; the design and manufacture of 500 metre depth rated subsea laser cutting head; and the system verified at technology readiness level 6 and suitable for further development.

The next phase of the partnership is planned for 2023-24 and involved the development of the UWLC system targeted at delivering a cutting tool suitable for real offshore cutting scope. The Net Zero Technology Centre will provide funding once again for this stage and a Tier 1 oil and gas producer and vessel operator will also contribute.

This phase will include a selection of suitable cutting opportunities; the development of the laser cutting head through the incorporation of lessons learned from phase 1; the development of a cutting tool to manipulate the laser cutting head to suit the cutting scope; and the integration of the HMI and electronic control from phase 1 into the intelligent cutting tool to optimise cutting head manipulation and performance.

The success of the second phase will be measured by performance on an actual offshore cutting scope against typical mechanical or abrasive cutting solutions. The objective is to demonstrate the system as a proven cutting technology for suitable applications, with the system being verified at technology readiness level 7 and suitable for further commercialisation.

“It is fantastic to be involved in such a great partnership and work with an inspiring team on this development project,” commented Craig Baxter – Decommissioning Technical Manager, Claxton. “The technology is showing great promise in delivering cross sector decommissioning work scopes. I am looking forward to delivering an offshore decommissioning work scope through 2023 with a view to commercialising the technology and opening it up as a cutting solution available to the oil and gas, nuclear and offshore wind decommissioning market.”

Page 20 of 36

Copyright © 2026 Offshore Network