Europe

- Region: All

- Topics: Decommissioning, Integrity

- Date: Mar, 2024

Well integrity solutions provider Unity has onboarded Ian Retalic as the new Wells Manager, as part of the company's robust 2024 growth plan.

In his new role, Retalic will be tackling senior client relations and international growth, looking into strategies to expand the reach of Unity's well integrity, intervention and plug and abandonment solutions to a global scale.

Untill now, Retalic has been associated with Altus Intervention as the Business Development Manager for eight years, where he served the company’s global provision of well intervention and technology services. His 35 years of experience include strong technical, commercial and leadership skills that are the results of an impressive line-up of positions as Senior Well Services Supervisor for the Brent Field at Shell; Senior Well Operations Engineer and Wells Project Manager for Baker Hughes; Drilling Supervisor and board level Director of Business Development, Marketing and Sales at Leading Edge Advantage and Global Product Line Manager at Lloyd’s Register.

Retalic said, “Unity has positioned itself as a leader in its field with a valuable and unique industry offering. I’m excited to be playing my part in its ambitious growth plans and to be helping operators to benefit from the company’s progressive well integrity, intervention and decommissioning solutions.”

Welcoming the new team member, Stuart Slater, Technical Sales Director at Unity, said, “Ian’s senior level expertise is a great asset and his industry knowledge and practical approach are already proving to be an excellent synergy. I’m sure he will hit the ground running and I’m looking forward to working with Ian as we invest in the strategic growth of our Wells, Decom and Innovation business streams across new geographic and energy sector markets.”

Retalic's appointment to the sales team at Unity follows that of wells and decom specialist Dillan Perras, who joined the board in January.

- Region: North Sea

- Topics: Decommissioning

- Date: Mar, 2024

DOF has been awarded a substantial Subsea Engineering Procurement Removal and Disposal (EPRD) Contract from A/S Norske Shell in the Atlantic region, with more than 100 combined days utilisation of the vessels Skandi Hera and Maersk Installer.

DOF has been awarded a substantial Subsea Engineering Procurement Removal and Disposal (EPRD) Contract from A/S Norske Shell in the Atlantic region, with more than 100 combined days utilisation of the vessels Skandi Hera and Maersk Installer.

Under the contract, the company will deliver an integrated solution of project management, engineering, design, analysis and survey. Services will range from the recovery and recycling of umbilicals, risers, rigid spools and manifolds to other subsea structures and infrastructure, at the Knarr and Gaupe fields. Preparatory work is on before offshore execution begins in Q2 and Q3 2025.

Mons S. Aase, CEO DOF Group ASA, said, "The award continues to demonstrate DOF’s inhouse capability of offering turnkey solutions to our existing and new customers, building on our established capability offering in the decommissioning market."

- Region: North Sea

- Topics: Decommissioning

- Date: Mar, 2024

Marking its latest development as a 'decommissioning milestone', Perenco UK announced that it has successfully completed the plug and abandonment of three subsea wells at the Gawain field in the UK Southern North Sea.

Marking its latest development as a 'decommissioning milestone', Perenco UK announced that it has successfully completed the plug and abandonment of three subsea wells at the Gawain field in the UK Southern North Sea.

Challenging decommissioning campaign

In a campaign that added up to 160 days and included more than 340 air dives, the workforce made sure to remove all associated subsea infrastructure as well. Post decommissioning surveys will continue till the end of the year so that the seabed is left spotless.

Given the challenging winters in the Southern North Sea, the team was able to tackle the project unscathed as they worked considering the health, safety and environment factors. Workers were backed by specialist contractors and a jack-up vessel equipped with an air-based diving, and remotely operated vehicle (ROV) spread to allow for rig-based diving.

Perenco UK SNS Managing Director, Jo White, said, “The completion of this significant project shows the commitment Perenco has to effective and efficient decommissioning of our SNS assets. It highlights the expertise of our specialist teams, with a mindset of developing innovative approaches, while maintaining a strong focus on health, safety and the environment.”

- Region: UK

- Topics: Geothermal

- Date: Mar, 2024

In line with its decarbonisation plans, the British Geological Survey has initiated a £1.7mn renewable energy system, including the installation of a geothermal heat pump that also serves as a 'living laboratory' at its headquarters in Keyworth, Nottinghamshire.

In line with its decarbonisation plans, the British Geological Survey has initiated a £1.7mn renewable energy system, including the installation of a geothermal heat pump that also serves as a 'living laboratory' at its headquarters in Keyworth, Nottinghamshire.

Primarily funded by the Natural Environmental Research Council (NERC) with a further contribution from the Government’s Public Sector Decarbonisation Scheme, the installed system comprises of 28 boreholes drilled to a depth of 225 m.

Living laboratory

With advanced monitoring enabled to assess running costs and efficiency, the site will also serve as a laboratory for organisations considering to replace fossil fuel boilers with clean heat pumps. In fact, the institute will conduct further studies through rock samples to help get a better understanding of the flow of heat and water underground, which can be resourceful for those taking up similar projects in the future.

The geothermal setup at the BGS campus that substitutes greenhouse gas-emitting gas boilers will save approximately 30 tonnes of carbon dioxide per year, and reduce the organisation’s heating bill.

"Geothermal energy is heat that naturally occurs under the ground and is available 24/7 across the UK. This project will demonstrate the deployment of ground-source heat pump technology to decarbonise existing buildings across the public sector estate," said David Boon, Senior Engineering and Geothermal Geologist at BGS.

- Region: Europe

- Topics: Geothermal

- Date: Mar, 2024

The city of Kalisz, Poland, is set to receive PLN14mn (approx. US$3.5mn) from the National Fund for Environmental Protection and Water Management to subsidise the drilling of a geothermal well in the city.

The city of Kalisz, Poland, is set to receive PLN14mn (approx. US$3.5mn) from the National Fund for Environmental Protection and Water Management to subsidise the drilling of a geothermal well in the city.

The Ministry of Climate and Environment granted the funding to carry out work checking the availability of geothermal reserves by drilling a vertical borehole to depths of 1,700 m next to the Aquapark swimming pool complex within 2024-2025.

Exploring reserve potential

Kalisz has been rumoured to be the home of rich geothermal reserves, and this exploration project aims to discover if there is indeed truth to that statement.

Kalisz’ Mayor, Krystian Kinastowski, stated, “We have been waiting for this information for a long time, but it was worth developing projects, documents and analyses for many years.

“We will drill a geothermal well in Kalisz to check the availability of geothermal waters under out city […] We hope that we will be able to discover hot springs and the water found in them will be used to heat homes and for recreational purposes.”

- Region: North Sea

- Topics: Decommissioning

- Date: Mar, 2024

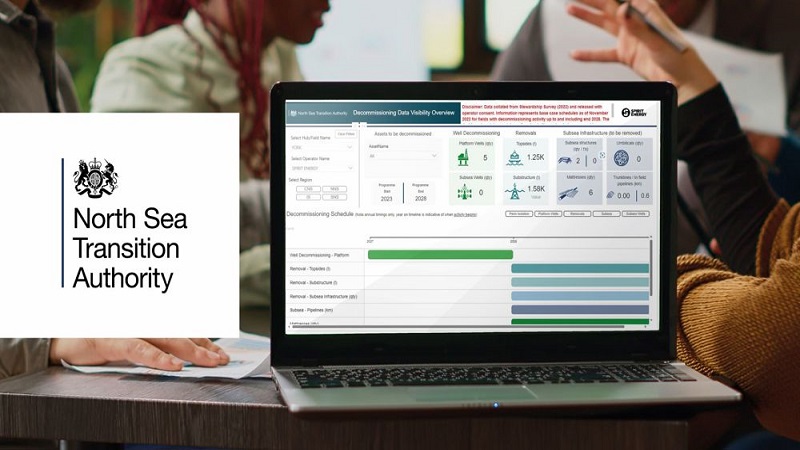

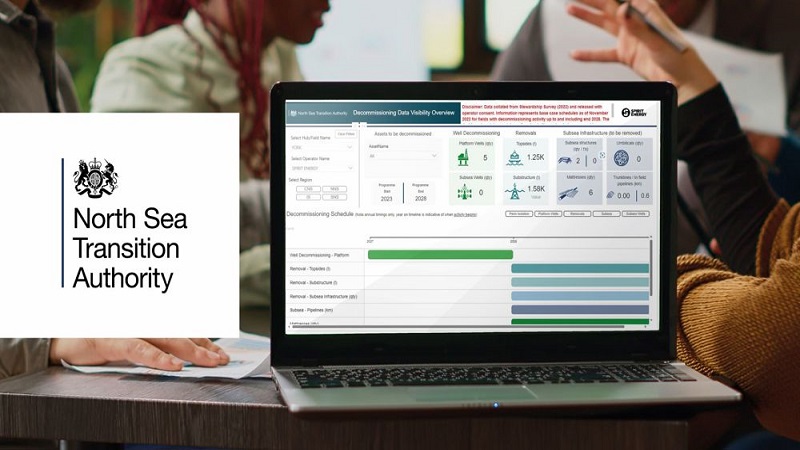

The North Sea Transition Authority (NSTA) has released the latest version of the Decommissioning Data Visibility Dashboard in a bid to make decommissioning operations more cost-efficient.

When first piloted by the organisation in 2021, the platform included field-specific information of just three operators. Now, that number is up to 15, unlocking even more vital information about upcoming work to potential suppliers. This will allow for enhanced collaboration and careful planning to achieve more cost-effective decommissioning operations, ultimately making them more attractive.

According to NSTA, the interactive dashboard provides suppliers with the confidence to invest in technologies and training by reducing the uncertainty and lack of transparency around the timing of decommissioning activities. Armed with data from the annual UKCS Stewardship Survey, it shows how many wells, subsea structures and pipelines the companies plan to decommission – as well as the weight of platforms to be removed – over the next five years.

Alastair Bisset, NSTA Head of Decommissioning and DaRT Co-Chair, remarked, “Suppliers need to know when decommissioning work is going to happen so that they can invest with confidence and plan effectively. The dashboard was created to help plug this knowledge gap, so it is very satisfying to see this group of leading operators put their weight behind it.”

Increasing decommissioning capacity

Operators will be able to use this data to identify potential collaboration opportunities to decommission wells together (thereby saving costs) while service providers have the chance to discover what skills and resources will be in demand at an earlier date.

Scott Barr, Executive Vice President, North Sea, at Harbour Energy and DaRT Co-Chair, commented, “This dashboard will help provide the supply chain with the visibility and confidence they need to deliver UK decommissioning works in a timely and cost-competitive way. It will also enable organisations to better understand future demand for skills and resources and to further increase their capacity to invest in technology and training programmes accordingly.”

- Region: Europe

- Topics: Geothermal

- Date: Mar, 2024

Austrian fruit and vegetable producer and marketer, Frutura, has commissioned an energy module from Orcan Energy allowing the company to transfer excess heat from geothermal drilling into clean power.

Austrian fruit and vegetable producer and marketer, Frutura, has commissioned an energy module from Orcan Energy allowing the company to transfer excess heat from geothermal drilling into clean power.

The Orcan Energy module produces around 625MWh of electrical energy per year, enabling Frutura to save approx. 100 tons of CO2 annually.

In 2016, the company opened Frutura Thermal Vegetable World in Styria, Austria, marking a significant step for a new era of sustainable agriculture. Thermal water is used to heat greenhouses, and until recently the excess heat generated by geothermal drilling remained unused. Now, Futurua is converting the heat into clean energy with the help of Orcan Energy’s module and utilizing the geothermal borehole all year round, enhancing energy efficiency.

Manfred Hohensinner, Managing Partner for Frutura, said, “Now that we have become independent of fossil fuels for heat generation, it was a logical step to convert the excess heat from geothermal drilling into electricity. Orcan Energy was the ideal partner for us, providing all the flexibility we need to respond to any changes in the future thanks to their modular approach.”

Andreas Sichert, CEO of Orcan Energy, commented, “Together, we combine the direct use of geothermal heat with the production of electricity. With Orcan Energy, heat-to-power is also possible on a smaller scale thanks to our modular approach.

“In particular, the simple combination with our standardised modules has great potential: We can meet both the heat and electricity requirements of the building sector, commercial and industrial businesses with geothermal energy in a decentralised, CO2-free and attractively priced way.”

- Region: North Sea

- Topics: Decommissioning

- Date: Feb, 2024

Plexus Holdings PLC, an AIM-quoted oil and gas engineering services business, and owner of the proprietary POS-GRIP friction-grip method of wellhead engineering, has won a contract valued in excess of £1mn to provide specialised equipment and services for multiple plug and abandonment (P&A) activities in the North Sea.

Plexus Holdings PLC, an AIM-quoted oil and gas engineering services business, and owner of the proprietary POS-GRIP friction-grip method of wellhead engineering, has won a contract valued in excess of £1mn to provide specialised equipment and services for multiple plug and abandonment (P&A) activities in the North Sea.

Under the terms of the contract, Plexus will provide Exact adjustable surface wellhead equipment, and specialised centric mudline system tooling and services for P&A operations on wells in the Dutch sector of the North Sea. Operations are planned to commence in Q2 2024 for a period of nine months. Exact adjustable wellheads and centric mudline systems are part of the Plexus licence/collaboration agreement with SLB.

Commenting on the contract, Plexus' CEO Ben Van Bilderbeek said, "The number of wells that must be permanently plugged and abandoned is fast growing, particularly in mature offshore locations such as the North Sea, where the OEUK indicated that decommissioning would account for 25% of oil and gas expenditure in 2023, up from 12% in 2022, and encouragingly I believe this trend will continue. We are therefore delighted that Plexus' reputation is strengthening within this sector, and that our range of customers is broadening. Furthermore, this contract demonstrates the progress we are making in getting back into the adjustable wellhead and mudline equipment market as an established expert in this field and 'go-to' company for this type of equipment and service."

- Region: Europe

- Topics: Geothermal

- Date: Feb, 2024

The Federal Government of Austria, through the Climate and Energy Fund (Klima und Energiefonds), has announced a new funding programme worth EUR10mn to support deep geothermal projects.

The Federal Government of Austria, through the Climate and Energy Fund (Klima und Energiefonds), has announced a new funding programme worth EUR10mn to support deep geothermal projects.

The ‘Deep Geothermal Energy’ programme will support feasibility and preliminary studies, exploration and investigation measures, pilot drillings and the preparation of projects for the economic use of deep geothermal energy.

The aim of the funding programme is to create the basis for the implementation of efficient and environmentally-friendly deep geothermal projects. The Climate and Energy Fund will support companies and public institutions in five modules:

• Module One – Basic preliminary studies

• Module Two – Feasibility studies

• Module Three – Exploration

• Module Four – Pilot drilling

• Module Five – Citizen participation and information events

Climate and Energy Fund Managing Director, Bernd Vogl, said, “Our new programme helps to develop and implement projects for deep geothermal energy in heating networks and in industrial processes.

“The entire spectrum extends from planning to exploration to pilot drilling. This is intended, among other things, to reduce the risks associated with geothermal drilling. We are excited about the projects that will emerge from this initiative.”

More Articles …

Page 7 of 37

Copyright © 2024 Offshore Network