Razor Energy Corp. in conjunction with FutEra Power Corp. has announced the successful construction, commission and operation of its co-produced geothermal power project in Swan Hills, Alberta.

Razor Energy Corp. in conjunction with FutEra Power Corp. has announced the successful construction, commission and operation of its co-produced geothermal power project in Swan Hills, Alberta.

The project combines an Organic Rankine Cycle (ORC) Turbine, which captures geothermal heat from the production fluid, and a Natural Gas Turbine (NGT). Both the ORC and NGT have grid interconnections which enable direct sales of electricity to the Alberta grid, and both systems have been running in a steady state while optimisation efforts are being made in order to reach the designed capacity.

Razor produces and injects large volumes of hot production fluid on a daily basis as part of its ongoing conventional oil and gas operations, and FutEra capitalises on that by capturing the geothermal heat energy from the fluid and using it to generate power with zero greenhouse gas emissions. The co-production element of the project means there is no new surface land footprint as the project utilises existing assets such as processing infrastructure, producing wells, produced water reinjection system and an operating gathering and distribution system.

In addition, the co-production approach enables Alberta’s fledgling geothermal industry to develop alongside the powerhouse of Alberta’s world-class oil and gas operations.

Justin Reimer, CEO of Emissions Reduction Alberta, said, “Alberta has long championed the geothermal industry. It is exciting to watch an idea for a pilot project grow into an industry-scale, commercial operation. This made-in-Alberta solution ushers in a new era of clean energy that will spur an entirely new industry in the province that taps into our existing oil and gas resources and expertise.”

FutEra’s next phase of the project will see the addition of solar, and potentially carbon capture, with the objective to create a net negative carbon emitting traditional oil and gas asset.

Halliburton Company has introduced the RockJet family of reservoir-optimised shaped charges for the optimisation of downhole performance.

Halliburton Company has introduced the RockJet family of reservoir-optimised shaped charges for the optimisation of downhole performance.

The RockJet family of charges was developed at the Advanced Perforating Flow Laboratory at the Halliburton Jet Research Centre using real rock under downhole conditions, and are the first charges to be certified using the American Petroleum Institute’s new perforation witnessed test protocol.

The charges allow for operators to enhance well productivity by providing optimum reservoir connectivity through deeper formation penetration and a larger perforation tunnel diameter downhole. They help increase production and improve well productivity by improving reservoir contact through deep and clean tunnels which extend beyond the damage zone.

When tested at downhole conditions, the RockJet charges delivered 22% higher penetration and an 83% increase in area open to flow.

Chris Tevis, Vice President of Wireline and Perforating services, Halliburton, said, “The RockJet family demonstrates our commitment to develop innovative technologies that drive increased production for our customers. In the perforating business, optimising penetration depth and flow area is the key.

“A lot of companies may have charges that are tested on the surface, but how they perform in downhole conditions is difficult to prove. By following the API’s new test protocol, we can provide our customers with confidence that the RockJet charges, custom engineered at JRC’s Advanced Perforating Flow Lab, will perform downhole.”

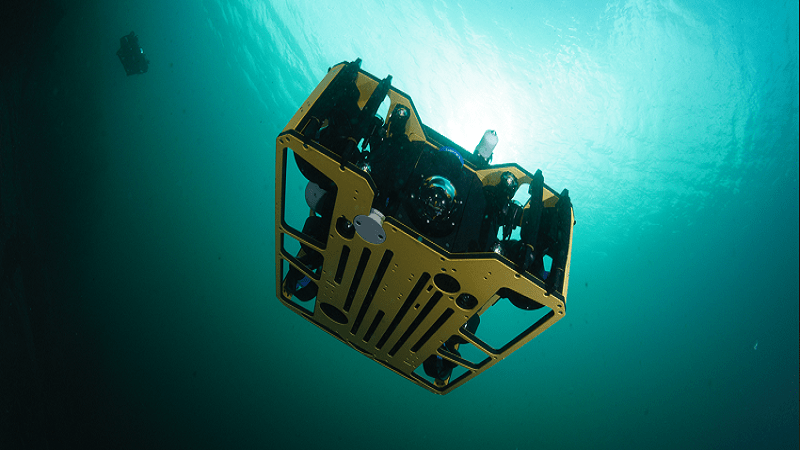

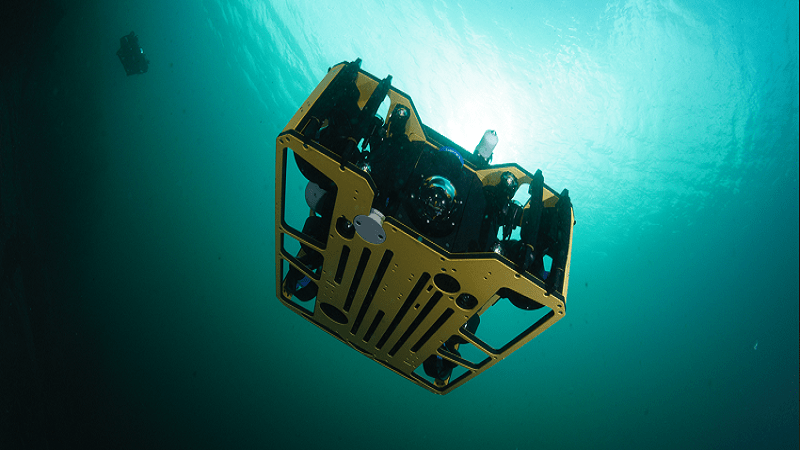

UTEC, a geo-services brand in Acteon’s data and robotics division, has launched ‘iSite Subsea’, a cloud-based platform which gives users an intuitive 360° visualisation of subsea assets and data.

It is developed from UTEC’s iSite collaborative virtual asset and data management platform and is specifically designed to meet the needs of the offshore renewable energy market and oil & gas subsea asset owners. Through iSite Subsea, users can source, view, manage and report on seabed, survey and asset data using a single secure cloud-based interface, enabling interrogation and comparison of data over time, remotely, 24/7 and without specialist software knowledge. Ultimately, this helps to reduce costs, lower risk, enhance health and safety, and deliver better informed decisions.

The new platform facilitates the digital delivery, throughout the lifecycle of a subsea asset, of geophysical, geotechnical, structural integrity monitoring, inspection, and maintenance surveys. It is designed to give developers and contractors access to the data they need to plan, evaluate, execute, and solve safety, environmental and risk scenarios. The end-to-end service delivery ensures that the latest data sets are always available to all users and eliminates the risk of double handling, incomplete data entries, multiple versions, and lost data/information.

“Energy customers have been using iSite to drive safety and efficiency, reducing costs on their above-water assets for more than 10 years,” said Paul Smith, Managing Director, UTEC. “We are now bringing the advantages of our product to the subsea market as a dedicated tool. iSite Subsea development has been driven by our customers’ needs. It is designed to help them reduce the time and costs associated with multiple visits, lower risk and achieve significant health and safety improvements through smart data management and interrogation tools that inform decisions.”

Global leader in well integrity and production optimisation, Coretrax, has successfully delivered its DAV MX circulation sub; a solution which will cool an estimated 400⁰C geothermal well bottom hole temperature by nearly 200⁰C in the US.

Global leader in well integrity and production optimisation, Coretrax, has successfully delivered its DAV MX circulation sub; a solution which will cool an estimated 400⁰C geothermal well bottom hole temperature by nearly 200⁰C in the US.

The solution was deployed during a planned closed-loop geothermal well project by a US operator, where the estimated bottom hole static temperature was 400⁰C. Operating at temperatures this high poses a high threat of equipment failure, so an effective and reliable ‘staging’ method was required in the hole to cool down the temperature-sensitive measurement while drilling (MWD) technology.

Staging is common practice for high temperature wellbores to prevent MED failures which normally involves pumping conventionally through the drill bit to cool the BHA. However, this method can result in the motor rotating the drill bit, causing possible damage in the cased and upper granite section as well as damage to the tech itself, meaning a more reliable method is required.

The application of Coretrax’s DAV MX delivered significant time savings while maintaining well integrity and improving safety. Estimated bottom hole temperatures were reduced from the estimated 400⁰C to 210⁰C. The tool was deployed with the Split Flow Dart, which allowed a limited flow through the motor and drill bit, reducing the rotations per minute while delivering high flow rate to effectively cool the BHA and borehole.

John Fraser, Chief Executive Officer, Coretrax, said, “The geothermal market has experienced significant growth in recent years in response to global environmental objectives and Coretrax already has a tangible track record in supporting these developments globally. Our range of downhole circulation tools are ideally placed to support the high temperatures and complexities of geothermal wells.

“The latest project is a strong example of how technology which has traditionally been applied to oil and gas operations can support this expanding sector to address the most complex well challenges while delivering enhanced reliability and greater efficiencies.”

The downhole circulation tool can be used across a wide range of applications including hole cleaning, displacements, lost circulation material spotting and blowout preventer jetting, among others.

Intelligent Wellhead Systems (IWS), a supplier of digital technologies that improve oil and gas well completion operations, has welcomed Shiblee Hashem to the executive management team as Vice President of Operations.

In his new role, Hashem will lead the growing operations team, including the regional managers and US facilities teams, and work closely with the COO to drive the company’s transformational strategies to meet financial goals.

Hashem brings more than 25 years of oil and gas consulting and operations management experience and throughout his career, he has worked closely with some of the largest independent and national oil companies in Europe, the Middle East, Asia, North and South America, and North, East and West Africa. Drawing upon this extensive experience, he offers a diverse professional background in both executive and technical management. Prior to joining IWS, he held senior management positions with AccessESP (a Baker Hughes Company) and Halliburton.

The new member of the executive management team belongs to the Project Management Institute (PMI) and the US Gulf Coast Section of the SPE. He is currently serving as the Program Chairperson of the SPE’s Bangladesh Section.

Based in Houston, Hashem reports to Steve Sinclair-Smith, Chief Executive Officer of IWS.

Hashem commented, “Safety and efficiency have always been part of the IWS mission. As the company grows in 2023, our focus is on delivering the highest service quality while maintaining safe and efficient operations.”

In other news, Pason Systems has increased its non-controlling investment in IWS through the acquisition of outstanding common shares of IWS for an aggregate purchase price of US$7.9mn and an agreement to invest up to US$25mn in preferred shares of IWS.

There was also cause for celebration when the company’s inVision Digital Valve Control technology received a Special Meritorious Award for Engineering Innovation (MEA) in the Digitalization category from Hart Energy.

As the focus on environmental sustainability has never been more prevalent across all industries than it is right now, the race is on to find long-term renewable solutions to the climate crisis. Operators across the globe are trying to make their innovations in the oil and gas industry as green as possible, but that is not an easy stepping-stone to overcome.

As the focus on environmental sustainability has never been more prevalent across all industries than it is right now, the race is on to find long-term renewable solutions to the climate crisis. Operators across the globe are trying to make their innovations in the oil and gas industry as green as possible, but that is not an easy stepping-stone to overcome.

Geothermal energy could be the answer so many are looking for. It is a method of clean energy which bridges the gap between the oil and gas industry and renewable energy sources in order to reach net zero. The US has already increased federal funding by millions of dollars in 2022 alone to widen the scope of geothermal projects up and down the country, tapping into the underutilized potential beneath our feet.

A key area of interest within the geothermal industry is that of repurposing end-of-life oil and gas wells. Geothermal companies can turn these assets back into active wells, only producing a slightly different end-product, negating the need for decommissioning services and the associated costs. Operators can turn their liabilities into profitable assets at a quarter of the cost while producing green energy.

In spite of the benefits associated with geothermal, there are a number of issues holding the industry back from becoming a mainstream alternative. For one, the extortionate upfront costs associated with starting geothermal projects from scratch prove a wall too vast to climb in most instances, as well as the technological challenges that present themselves when working with temperatures of this calibre.

Nevertheless, advanced methods and technologies are working at mitigating against the challenges posed by geothermal extraction, using expertise from the oil and gas industry to finesse already existing drilling equipment in order to marry the industries together to be able to harness a green energy source born from an oil well.

Trendsetter Engineering Inc. has been awarded a contract to support the development of Beacon Offshore Energy LLC’s Shenandoah project in the Gulf of Mexico.

Trendsetter Engineering Inc. has been awarded a contract to support the development of Beacon Offshore Energy LLC’s Shenandoah project in the Gulf of Mexico.

The awarded scope includes a multi-year rental and servicing agreement for the provision of a 20,000 psi Subsea Well Intervention package, with the system delivery expected for Q3 2023.

Trendsetter’s TRIDENT intervention systems provide an innovation solution for subsea well interventions, suitable for offshore mobilisation to a vessel of opportunity and capable of rapid re-configuration to facilitate hydraulic, riser-less light well and risered medium well subsea intervention operations.

“We are excited to extend our partnership with Beacon and support its Shenandoah development,” said Mike Cargol, Vice President of Intervention Solutions, Trendsetter.

“This award reaffirms Trendsetter’s commitment to the industry for innovative, safe and cost-effective HPHT well control and well intervention systems, building upon our successes with the 15,000 psi TRIDENT system and multiple 20,000 psi well control response packages delivered in recent years.”

Trendsetter’s involvement with the Shenandoah field projects extends beyond the implementation of the intervention system. Earlier this year, the company was also awarded contracts to deliver components of the subsea production and export equipment, including a six-slot production manifold, subsea valves, and Trendsetter’s own TCS connectors.

Chevron Corporation has announced a joint venture with Baseload Capital to develop geothermal projects in the US.

Chevron Corporation has announced a joint venture with Baseload Capital to develop geothermal projects in the US.

Through its Chevron New Energies business, the two companies will collaborate on driving geothermal opportunities, including identifying locations with the best prospect for development and streamlining the next generation of geothermal technologies from conception to commercialisation. The agreement will allow the two companies to highlight the importance of geothermal energy and raise awareness on the criticality of it as a supply option.

Chevron and Baseload Capital believe the answer to reaching a low-carbon future is through the utilisation of all energy forms working together, and geothermal will provide a reliable source of baseload power which will be a critical element in developing future energy systems. The joint venture will leverage the two companies’ operational experience, combined with core competencies from the oil and gas sector, particularly surrounding subsurface, wells, drilling and completions to advance geothermal technologies.

The first project site has already been identified as Weepah Hills, Nevada. Previous geothermal research and exploration projects already exist in Esmerelda County, and the two companies will pursue development of these going forward.

Barbara Harrison, Vice President, Offsets and Emerging, Chevron New Energies, said, “We believe that to make the geothermal ecosystem a reality, we must take these important steps through collaboration and partnership, and this example with Baseload Capital is a great start towards pursuing our lower carbon goals for the future.”

CEO of Baseload Capital, Alexander Helling, commented, “It is time for the geothermal industry to take its place as an obvious part of the energy mix. Right now, everything is in the industry’s favour to move from niche to mainstream.

“We have no time to waste and no excuse for not picking up the pace here and now. Together with Chevron, we believe that the transition to a greener planet, with the help of geothermal, is going to be much faster.”

Technology firm BeyonC has been selected to join Chevron Technology Ventures’ (CTV) Catalyst Programme, an initiative to help start-up companies enhance their technologies in order to benefit the energy sector.

Technology firm BeyonC has been selected to join Chevron Technology Ventures’ (CTV) Catalyst Programme, an initiative to help start-up companies enhance their technologies in order to benefit the energy sector.

The programme acts as an incentive for BeyonC to further develop its proprietary technology designed to improve the safety of subsea inspections all the while reducing carbon emissions, improving asset reliability and reducing costs.

The BeyonC technology platform has been shown to dramatically reduce CO2 footprints with its mini-ROVs (Remotely Operated Vehicles) when it comes to providing asset integrity data, as opposed to surveys carried out by large offshore vessels. The technology supplies CP status and visual surveys for offshore installations, mapping the integrity status for offshore facilities and providing operators with decision-data.

With its patent-pending technology, BeyonC will target oil and gas pipelines and plans to deliver the first offshore wind integrity survey in 2023.

From its launch in 2017, the CTV Catalyst Programme aims to accerlate the maturation of early-stage companies which show promise in creating technologies that will prove beneficla to the energy industry. By joining the programme and meeting the milestones head on, BeyonC will be presented the opportunity to have its technology commercialised and complete trials with global operators.

Thomas Sperle, Chief Executive Officer, BeyonC, said, “We are proud and excited to join the CTV Catalyst programme. This is a major recognition from the industry that we expect will enable BeyonC to accelerate development and commercialisation of our propriety and unique technology. We are delighted that out technology-focused approach has been recognised by Chevron Technology Ventures and we look forward to counting collaborations in the next phase of our growth and development.”

The omens for the offshore decommissioning market are looking positive as the industry prepares for 2023 and all that it has in store.

While a turbulent geopolitical environment has caused market fluctuations over the last few years (with Covid restrictions giving way to war in eastern Europe), a healthy oil price has been enjoyed through most of 2022, which is expected to settle in short- to medium-term. In addition, the pandemic revealed more than ever the pressing concerns around the fragile nature of our environment and has spurred the energy industry to promote sustainable practices wherever possible. In the case of the latter in the offshore world, there has been a renewed focus on decommissioning responsibilities, to ensure operators leave their stomping grounds as tidy and climate-friendly as possible.

Such concerns have been expounded by developments in Australia where the ongoing decommissioning of the Northern Endeavour FPSO (and the controversy around the trailing liabilities attached to it) has pushed this issue even more to the fore. The understanding of the forthcoming decommissioning wave has never been so developed, and the perception that we must get ahead of this, lest we get swept away by it, is sharp. By example, a recent report by Offshore Energies UK indicated that around the UK more than 2,000 North Sea wells are to be decommissioned at a cost of around UK£20bn. OEUK Decommissioning Manager, Ricky Thomson, said, “The UK’s decommissioning sector is snowballing and will continue growing for years to come.”

Fortunately, a healthy oil price and an ever-growing demand for oil and gas is filling the coffers of operators across the globe, making the burden of end-of-life activities easier to bare. Owing to these developments, industry reports are indicating that the global offshore decommissioning market will experience a strong growth in the immediate and long-term future. One report published by Visiongain, for instance, has forecasted that the market (which it valued at US$10.275bn) will grow at a CAGR of 6.5% between 2023 and 2033.

The opportunity to capitalise here is a tantalising one, with Thomson adding that with right government support the decommissioning challenge can be turned into gain, with the potential to create thousands of jobs. Indeed, many in the industry are not ignorant of this opportunity but are making moves to capitalise on this potentially lucrative market. At the end of 2022, for example, Harbour Energy, ConocoPhillips, Spirit Energy and Repsol Sinopec formed a well decommissioning collaborative initiative in conjunction with the Net Zero Technology Centre (NTZC). The initiative will enable new technologies to be trialled and tested in collaborative field trials enabling faster, lower-cost trials and wider industry adoption.

So, while no one knows for certain what 2023 will hold for the decommissioning sector, the strong position it has started the year in is a positive sign for its future growth and development in years to come.

HydraWell has revealed the latest development in its perforation, wash & cement (PWC) technology in the HydraCT which could reportedly signal a major industry shift for the future of P&A activities.

The HydraCT is an advanced PWC system which is specifically designed for coil tubing applications with the potential to cut Co2 emissions by 80% and costs by up to 60%. Last month, it was successfully debuted in Alaska, USA, which was the first project of its kind to use coil tubing, eliminating the need to mobilise a rig to site. By running coil tubing as the deployment method, the rigless HydraCT campaign spanned less than 24 hours.

HydraWell’s Chief Executive Officer, Mark Sørheim, commented, “Our first successful campaign demonstrates there is no doubt the HydraCT technology is an ideal solution for coil tubing applications.

“Our research has shown there is industry demand for more sustainable and cost-effective alternatives in plug and abandonment operations and we will continue to respond to this demand by creating superior solutions which are carefully aligned with the needs of clients and the market.”

“Working without rigs is the next chapter for P&A activities and we will remain at the forefront of guiding how the sector can move away from the need for a rig to pull pipe towards rigless, coiled tubing using HydraCT,” continued Mark. “HydraWell regards sustainability as one of its top priorities as we strive for efficiency gains while minimising our environmental footprint.

“HydraCT is a key component in the path towards rigless P&A and this breakthrough technology has allowed us to make huge strides in supporting our clients’ environmental savings as well as working for the greater good of the industry as a whole.”

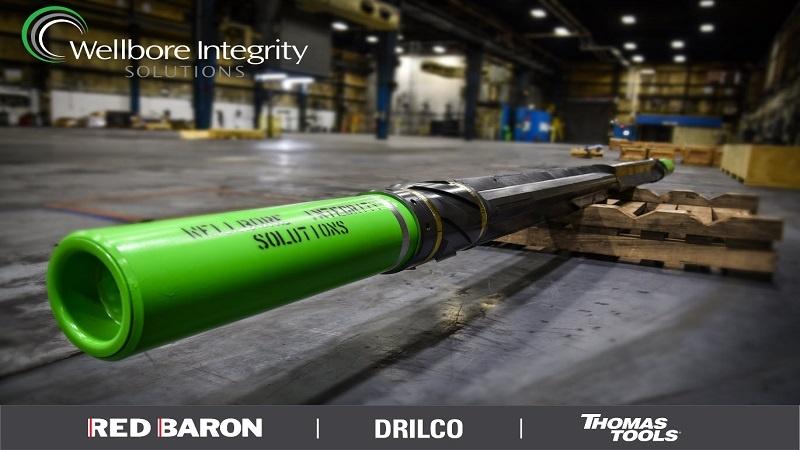

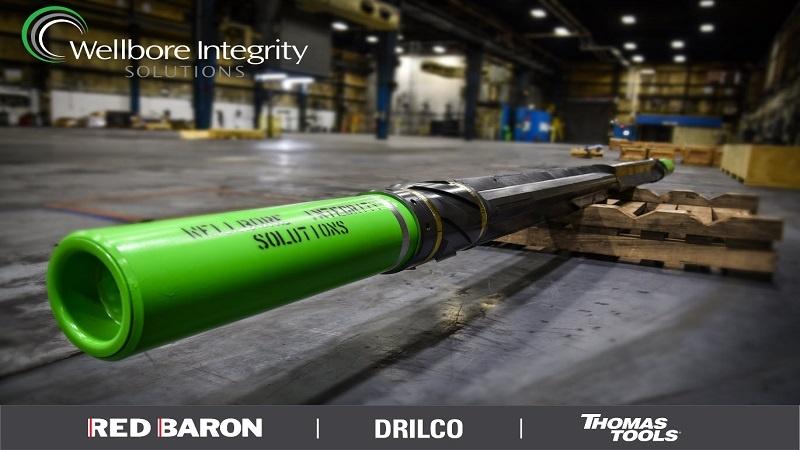

Wellbore Integrity Solutions (WIS) recently presented at the Offshore Well Intervention Gulf of Mexico (OWI GOM) conference, showcasing the service company’s impressive portfolio of well abandonment and debris management solutions with its ProMILL™ technology and Heli-Mag™ , as well as highlighting its success in delivering a project in the Gulf of Mexico.

Wellbore Integrity Solutions (WIS) recently presented at the Offshore Well Intervention Gulf of Mexico (OWI GOM) conference, showcasing the service company’s impressive portfolio of well abandonment and debris management solutions with its ProMILL™ technology and Heli-Mag™ , as well as highlighting its success in delivering a project in the Gulf of Mexico.

With WIS’s extensive knowledge and industry experience of over 75 years, WIS brings together some of the most renowned brand names in wellbore integrity products and services; Red Baron, DRILCO, and Thomas Tools. Each showcases various capabilities from supporting drilling operations and production, to well intervention and well abandonment services. The Red Baron brand focuses primarily on well intervention services, including fishing and remedial for both open and cased hole projects; Wellbore Departure, which consists of sidetracking a wellbore by utilising the TrackMaster Select™ systems; Wellbore Cleanout Tools, which includes equipment such as the Heli-Mag inline magnet, ideal for debris management in multiple applications; Well Abandonment and Slot Recovery services utilising the ProMILL and ProMill Duo™ technologies, and Thru-Tubing Services for various tubular and wellbore projects. DRILCO provides global tubular products and services including field and in-house tubular inspection and repairs, along with manufacturing various drill pipe, whipstocks, fishing and well abandonment equipment. Thomas Tools specialises in rental equipment for special projects or additional assets to rig inventories including blowout preventers (BOPs).

With all the above available in WIS’ arsenal, the company strives to present the broadest portfolio of services across the well lifecycle, a fact that was highlighted during the company’s presentation at OWI GOM, detailing the importance of effective debris management in all projects concerning well intervention. Delaney Olstad, Well Abandonment Manager at WIS Red Baron, discussed how important the practice is, especially in recent years, in regard to making each project as safe and efficient as possible.

“Debris management is absolutely critical in terms of minimising HSE and operational risks. Studies have shown that debris in the wellbore can lead to premature failure of equipment, which can be both costly to the client in terms of downtime and equipment repairs,” stated Olstad.

“I think it's also more prevalent nowadays than it has been in the past because the seriousness of downtime; some of these offshore operations are into the hundreds of thousands of dollars a day. And if there's downtime because you must deal with swarf, an incredible operation can come, basically, to a standstill because you must address the metal debris and shavings.”

To further improve the practice of effective well abandonment, in 2016 the ProMILL technology was created. ProMILL is a single-trip system which allows operators to handle multiple operations, saving on the overall costs. The milling system combines a bridge plug assembly, section mill, and high-ratio underreamer in a single trip solution, which achieves rock-to-rock zonal isolation, and prepares the formation for an uninterrupted abandonment cement barrier.

“The introduction of ProMILL technology enabled rock-to-rock barriers that ensured the integrity of the abandonment process. The ProMILL system is a single trip BHA designed to reduce the number of trips necessary to meet the project and customer requirements,” commented Olstad.

“In the long term, it is obviously essential that wells, which have been abandoned, are abandoned in a way which will prevent future leaks. The ProMILL has played an important part of that safe and reliable abandonment process.”

Olstad also discussed the importance of creating a system which effectively and efficiently eradicates all potential leak paths during the P&A process, as even the tiniest gap can have disastrous and highly expensive consequences.

“When you abandon a well that means it has reached the end of its lifecycle, so you remove everything from the top side. You might put a marker there to identify the well location and you leave. If after a plurality of time, be it two years, 10 years, 20 years, or more, something changes and a hydrocarbon sneaks out, what do you do?” he said.

“To go back and re-enter the well, and re-abandon the well, is extremely expensive – sometimes 10-to-100 times more expensive – depending on where you are. If you're offshore, where was that well? It might leak and show up a mile and a half away, in any direction. That's why it's unquestionably crucial to do it right the first time and utilise equipment that can do it correctly. Being successful in a single trip is beneficial to everyone involved because it’s less time on the rig and less cost associated with overall operations.

“The WIS Red Baron team focuses on completing our operations in a way which meet both the regulatory and project requirements, so that the well does not leak into our most precious commodities – the water and our environment.”

Not only is WIS creating waves through the industry with its efficiency in eradicating leak paths, it is also making headway with its Wellbore Cleanout Heli-Mag technology; a downhole inline magnet which is used during milling operations to maximise debris recovery. The technology consists of 16 rows of rare earth magnets in a helical configuration which ensure that even the smallest pieces of swarf are removed.

In July 2022, WIS worked with KOSMOS Energy on a project in the Gulf of Mexico which required use of the Heli-Mag inline magnets were used in conjunction with the TrackMaster whipstock system to effectively recover debris as a large volume of cuttings were expected, causing concern about the amount of metal produced during a dual casing exit and having adverse consequences in the wellbore and the BOP stack.

“We ran nine of the Heli-Mag inline magnets close to the milling BHA above the heavyweight drill pipe so that they were in tension to capture all the swarf before it went up hole. But just in case any swarf did by we put one more just below the BOP. And by doing that, we captured 1,600 pounds of swarf on the first day,” said Olstad.

“Overall, the Heli-Mags ended up bringing almost 3,000 pounds of swarf out of the hole. Less than 1% of the total amount of recovered debris, 16 pounds of swarf, made it into the rig’s debris recovery equipment.”

Impressive indeed. Looking to the future, Olstad discussed the importance of having a business emphasis on the significance of integrity within the wellbore, as the industry collectively works harder than ever to protect the environment. As our world becomes more fragile, the big players within the industry, including WIS, are emphasising the importance of making every process as sustainable and as safe as possible.

“This is our world, and we only get one, so it is of paramount importance that we strive to conduct ourselves and our actions as best as possible to preserve it and ensure the longevity of the operations, the environment, and humanity,” Olstad concluded.

Page 12 of 19

Copyright © 2025 Offshore Network