Expro, a provider of energy services, has highlighted the company’s achievements in 2023 along with the progress it has towards its near- and long-term environmental, social and governance (ESG) objectives.

In its 2023 ESG report available here, the company highlighted projects delivered throughout the year, including a custom solution to support the testing of new geothermal technologies in Oklahoma and supporting a pilot project in Japan with carbon capture utilisation.

“In an ever-evolving energy landscape, Expro remains steadfast in our commitment to driving positive change,” remarked Mike Jardon, Chief Executive Officer of Expro. “I am proud to share our achievements from 2023 in this comprehensive report which serves as a testament to our progress in environmental, social, and governance strategies, underscoring the integral role partnerships play in cultivating sustainability for Expro and our clients.

“As we step into 2024, we remain dedicated to fostering a low-carbon future and intend to play a key role in enabling a low-carbon transition.”

Standouts from the 2023 ESG report identified by Expro included:

• Developing lower carbon solutions: Expro has turned commitments into actions to help address customers’ most complex challenges in sustainability. This includes new developments in game-changing projects spanning carbon capture utilisation and storage (CCUS), natural hydrogen and geothermal in Australia, Colombia, Germany and Japan.

• Reducing Scope 1 and Scope 2 greenhouse gas emissions: Expro reduced emissions by 11% from a 2021 baseline, driven by increased use of renewable energy while increasing its ability to track Scope 3 emissions, setting the stage to further integrate ESG reduction initiatives throughout the supply chain.

• Advancing the Expro portfolio with sustainable energy solutions: Expro took large strides forward in its work within the areas of geothermal and CCUS, adapting the company’s solutions across three emerging markets.

• Prioritising safety: The organisation renewed its commitment to safety in the workplace along with the second annual Expro ENGAGE initiative designed to focus on highlighting employees’ safety successes, while teaching and reinforcing best practices, and reducing the company’s Lost Time Incident Frequency (LTIF) to just 0.06.

• Fostering a collaborative and inclusive culture: Believing in the importance of diversity in the organisation, Expro is reaping the benefits of a collaborative and inclusive workplace where ideas are shared through the rollout of Expro Culture of Care and the 2023 Elevate employee pulse survey that ultimately informed company action plans for 2024.

Hannah Rumbles, Expro Director of Sustainability, Marketing and Communications, added, “I am excited to advance our commitment to innovating with purpose, grounded in our values of People, Performance, Partnerships and Planet. Over the past year, we’ve focused on the maturation of our approach to sustainability that we expect will accelerate our journey to a low-carbon future. With this strong momentum, we remain committed to empowering our customers while strengthening our own sustainability practices and performance.”

The Colorado Energy Office (CEO) has opened its first competitive application for the state’s Geothermal Electricity Tax Credit Offering (GETCO), a programme to encourage elevated levels of geothermal production and investment.

The Colorado Energy Office (CEO) has opened its first competitive application for the state’s Geothermal Electricity Tax Credit Offering (GETCO), a programme to encourage elevated levels of geothermal production and investment.

Following the Governor’s ‘Heat Beneath Our Feet Initiative’ to explore more deployment opportunities for geothermal technology within the state, the new tax programme allows for eligible utilities, private businesses, local governments and public-private partnerships to apply for two different types of incentives. The two incentives include an investment tax credit (ITC) for exploring and developing geothermal resources, and a production tax credit (PTC) for producing geothermal electricity.

The ITC can cover up to 30-50% of eligible costs for selected projects not exceeding US$5mn. A total is US$35mn is available in ITCs through to 2032, while the PTCs provide a US$0.003 credit for every kwh of geothermal electricity produced, up to US$1mn per entity per year through to 2032. The first application cycle is open until 30 June, 2024.

Colorado Energy Office’s Executive Director, Will Toor, stated, “This incentive encourages geothermal electricity development across Colorado, advancing innovative technologies that will create jobs in just transition communities and help achieve a 100% clean energy economy here and around the world.”

Colorado utilities are currently on track to reduce emissions from the power sector by more than 80% by 2030 though a mix of clean energy sources. A recent study commissioned by CEO found that the lower cost pathway to achieve 100% clean electricity in Colorado by 2040 will be to rely on geothermal energy, alongside wind, solar, storage and clean hydrogen.

“While wind and solar energy can meet the majority of our electricity needs, geothermal energy is essential for delivering reliable and affordable clean electricity, regardless of the weather,” Toor continued.

Colorado Governor Jared Polis said, “Geothermal energy means lower costs on Coloradans’ energy bills and cleaner air. By breaking down barriers to this clean renewable energy resource, Colorado can move closer to our goal of 100% renewable energy while saving people money on energy, improving reliability, and protecting our air quality.”

In a five-year joint framework agreement with Talos Energy Inc, Helix Energy Solutions Group, Inc gets the first right of refusal regarding specific annual work scopes for Talos’s decommissioning requirements in the US Gulf of Mexico.

In a five-year joint framework agreement with Talos Energy Inc, Helix Energy Solutions Group, Inc gets the first right of refusal regarding specific annual work scopes for Talos’s decommissioning requirements in the US Gulf of Mexico.

Scheduled to start in the second quarter of the year, the agreement outlines a base pricing structure and processes for determining and scheduling specific projects Talos requires.

The projected scopes of work include Talos’s normal course abandonment of offshore wells, pipelines and platforms, primarily on the shelf. Helix’s Louisiana-based shallow water abandonment group, Helix Alliance, plans to utilise derrick barges for structure removals, liftboats for plug and abandonment activities, and dive support vessels (DSVs) for pipeline abandonments, plus multiple offshore supply vessels (OSVs), among other assets in the course of the campaign.

Owen Kratz, Helix’s President and Chief Executive Officer, said, “We are excited to have been awarded this significant framework agreement for well and structure removal and decommissioning. Helix and Talos have worked together on field production, well intervention and decommissioning in the deepwater arena for many years, and this framework expands the relationship onto the shelf, further demonstrating Helix’s position as the preeminent company for full-field decommissioning in the Gulf of Mexico.”

As COP28 shone the spotlight onto the ambitious targets set by the Heads of State and Governments Global Renewables and Energy Efficiency Pledge, wherein 123 countries recognised their commitment to maintaining global warming levels to within 2°C, work is only just beginning throughout the world’s energy network to increase the pace and deployment of renewable sources.

As COP28 shone the spotlight onto the ambitious targets set by the Heads of State and Governments Global Renewables and Energy Efficiency Pledge, wherein 123 countries recognised their commitment to maintaining global warming levels to within 2°C, work is only just beginning throughout the world’s energy network to increase the pace and deployment of renewable sources.

Currently, geothermal energy only accounts for 0.5% of global renewable installed capacity according to the International Renewable Energy Agency, signifying that there is significant room to increase deployment. According to the International Geothermal Association (IGA) there are currently 2,500 active deep geothermal wells globally, boasting an installed capacity of 173GW for heating and cooling purposes. While China is leading the localised heating system charge, the EU, USA and APAC regions are hot on its heels, offering an abundance of potential for geothermal extraction.

From an electrical standpoint, IGA states that there are currently 3,700 active geothermal wells globally boasting an installed capacity of 16.3GW. The US is the global front runner, generating more geothermally-charged electric power than any other region in the world, with that figure only set to increase. In line with the COP28 Renewables Pledge, IGA has promised to triple geothermal output by 2030, bringing overall electric power capacity up to 48GW, and total geothermal generation for heating and cooling systems up to 520GW. North America will prove to be a key player in meeting this target, becoming a driving force in boosting production via pilot projects and new technologies.

Offshore Network’s bespoke 2024 Geothermal Case Study Review shines the spotlight over North America, highlighting a selection of game-changing projects and the companies behind them, including Fervo Energy, GreenFire Energy, Baker Hughes and C Thermal.

Chevron Corporation has announced that for its fourth quarter 2023 it will be impairing a portion of its US upstream assets due to continuing regulatory challenges.

Primarily in California, the challenges in the state have resulted in lower anticipated future investment levels in its business plans according to the statement. It expects to continue operating the impacted assets for many years to come.

In addition, the company indicated it will be recognising a loss related to abandonment and decommissioning obligations from previously sold assets in the Gulf of Mexico as companies that purchased them have filed for bankruptcy and the company deems it probably and estimable that a portion of the obligations will revert to it. As such, the company expects to undertake decommissioning activities on the assets over the coming decade.

Currently, Chevron is now in the process of finalising the financial impacts of these actions and will likely treat them as special items, excluded from adjusted earnings. These actions are currently estimated to result in non-cash, after-tax charges of US$3.5bn to US$4bn in its fourth quarter results.

Leading energy provider Expro has renewed and expanded its agreement with Di Drill Survey Services, a provider of high-end HPHT logging and Gyro survey services for complex abandonment services to both the oil and gas and geothermal sectors.

The strategic partnership agreement strengthens the growing relationship between the two energy service companies who are committed to providing premium well integrity solutions to complex wellbore situations.

Patrick Hanson, Expro’s Senior Geothermal Development Manager, said, “Our ability to partner with such a respected and entrenched company such as Di Drill aligns with our geothermal growth strategy to better serve the industry in regions where we don’t have physical locations or an established well intervention footprint. Di Drill shares the same core principals of safety, quality and integrity as Expro, this partnership was an easy decision.”

Daniel McCall, President of Di Drill Survey Services, commented, “We are honoured to have the ability to continue to grow our relationship with such an esteemed service provider in the energy sector. The ability to extend and offer existing services and additional new technologies to our business partners will allow for seamless operations between multiple services from a single provider. Thank you to the Expro team for trusting us to represent your incredible technology.”

A previous agreement enabled Expro to provide its high temperature Kinley Caliper and downhole camera product lines to Di Drill to service predominantly geothermal operations in western US. The new agreement will also include Expro’s annulus intervention solution, Octopoda, with Di Drill making its gyros available for Expro’s specific call-in work. The agreement also extends joint operations into newer regions such as Oregon, Washington, New Mexico, and across the border into Mexico.

The University of Texas at has received a US$4.9mn grant from the US Department of Energy (DOE) to conduct research on two potential climate change solutions around the Earth’s subsurface: the storage of carbon dioxide and the generation of energy.

A team of UTEP researchers will lead a multi-institutional team in accelerating climate change solutions. Other contributors will come from Florida State University, the University of Utah, Sandia National Laboratories and Alma Energy LLC. Together, they will target solutions for two DOE objectives, reducing carbon dioxide in the atmosphere and enhancing the effectiveness of geothermal energy capture.

Son-Young Yi, Ph.D., an Associate Professor in the Department of Mathematical Sciences, is the grant’s Principal Investigator and forms the UTEP contingency of the team alongside Co-PIs James Kubicki, Ph.D., a Professor in the Department of Earth, Environmental and Resource Sciences and Zhengtao Gan, Ph.D., an Assistant Professor in the Department of Aerospace and Mechanical Engineering.

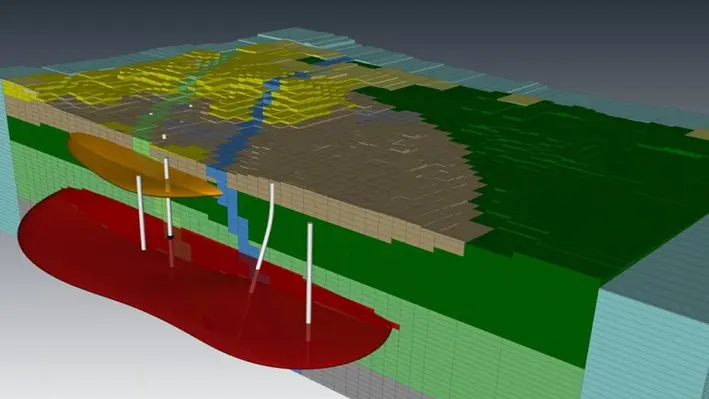

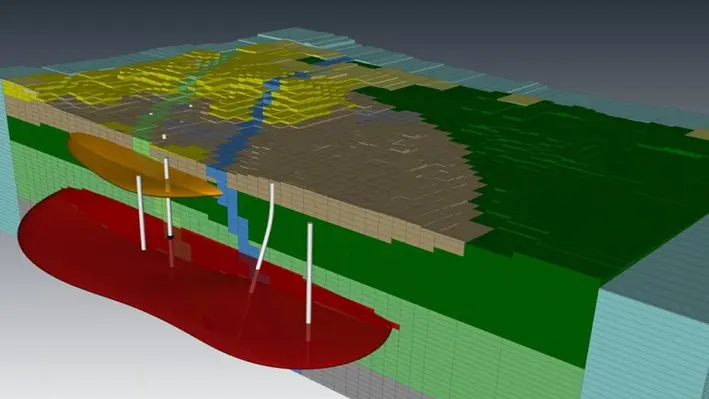

The researchers will create computational models, using machine learning algorithms, that can help the clean energy industry reduce carbon dioxide in the Earth’s atmosphere and create a reliable means of accessing geothermal energy.

“There is a bevy of interactions taking place underground which influence the amount of energy that can be extracted from a particular location and the rate of production that a particular location will offer over time,” Gan said. “Our team will work with an industry partner to create computational models that can mitigate the exploration risks and help players in this industry identify the best areas for geothermal energy extraction.”

According to the team, the increased efficiency may result in greater quantities of energy extracted and sustained rates of production, which will hopefully translate to a more accessible and affordable way for Americans to power their homes.

“This is an exciting opportunity because crossing scales and putting together a picture of geochemical processes is a grand challenge in subsurface applications,” Kubicki said. “The potential to bring geothermal energy to the El Paso region and to help address carbon dioxide removal from the atmosphere is a dream come true.”

One method being researched for storing excess carbon dioxide is geologic carbon sequestration, which is the injection of the gas in underground geologic formations, such as saline aquifers – reservoirs of salt water that are located deep beneath layers of rock. A drawback to this approach is the possibility for the gas to seep, or leak, back to the surface and re-enter the atmosphere, Yi said.

“Our computational models will analyze the behavior of carbon dioxide across different scales, from the microscale to the macro scale, so that we can simulate and predict how long carbon dioxide will stay in the underground rock formations,” Yi said. “The work is ambitious as no model exists yet that has been able to link data about carbon dioxide’s behavior across scales, but if we’re successful, our models will help the clean energy industry understand the long-term evolution of the injected carbon dioxide and better identify optimal locations for carbon dioxide injection with respect to minimizing leakage.”

Energy services provider Expro has completed a well cement placement project for a prominent operator from the US, Gulf of Mexico, delivering an inner-string cementing on a subsea well's 22" surface casing in a water depth of approximately 2,000 m in the Mississippi Canyon area

Energy services provider Expro has completed a well cement placement project for a prominent operator from the US, Gulf of Mexico, delivering an inner-string cementing on a subsea well's 22" surface casing in a water depth of approximately 2,000 m in the Mississippi Canyon area

When integrated with Expro’s other well construction technologies, the company’s innovative Cure technology range, including SeaCure, QuikCure, and CoreCure, offers a comprehensive package for ultimate cement placement and provides a complete 'head-to-shoe' solution.

Expro's Cure technologies allowed the operator to overcome ongoing offset well challenges. These included prolonged wait on cement (WOC) periods when transitioning directly from the jet string to the 22" surface casing, and tasks associated with drilling out a 22" shoetrack.

Jeremy Angelle, Expro’s Vice President of Well Construction, commented, “Our integrated cementing solution helped save approximately 18 hours of cement related drill-out, clean-out, and WOC time when compared to offset wells. By using our Cure technologies, we removed the requirement for a shoetrack to be left in the casing string, helping to avoid previously experienced cement sheath-related challenges. In addition, the QuickCure solution reduced WOC time. This latest project highlights Expro’s commitment to provide solutions that empower our clients to overcome operational challenges and achieve excellent results.”

The Cure technology range was added to Expro’s portfolio of cost-effective, innovative solutions within the company’s well construction product line as part of the Company’s acquisition of DeltaTek in February. The DeltaTek range of low-risk open water cementing solutions help increases clients’ operational efficiency, delivers rig time and cost savings, and improves the quality of cementing operations.

Subterra Renewables, one of the leading geothermal utility providers in North America, has announced its expansion into Western Canada and the US following its affiliate companies’ recent acquisition of Earth Drilling Co. Ltd.

Subterra Renewables, one of the leading geothermal utility providers in North America, has announced its expansion into Western Canada and the US following its affiliate companies’ recent acquisition of Earth Drilling Co. Ltd.

One of the west coast’s leading drilling suppliers, the transaction includes the acquisition of Nevada-based Harris Exploration, a high-profile source of drilling and installation services in Nevada, California and Arizona. Earth Drilling and Harris are now part of Subterra’s group of companies that provide coast-to-coast access to geothermal drilling for geo-exchange system installations.

Matthew Tokarik, President of Subterra Renewables, said, “We are thrilled to officially welcome our valued collegaues from Earth Drilling and Harris Explorations to our growing network of experienced talent as we scale up our operations and ramp-up assets to meet the rapidly growing demand for community developments powered by renewable energy.

“Aligning ourselves with seasoned leaders that bring a combined 115 years of geo-drilling and exploration experience across North America provides is with immediate access to best-in-class services as we build out our coast-to-coast business. An opportune time as electrification and renewables take their place in a net-zero world.”

John Paul Wegleitner, CEO of Earth Drilling, commented, “We are excited and proud to be combining our visionary teams and resources as we diversify our geo-drilling operational opportunities to support a rapidly growing renewables industry under the Subterra group of companies.”

Subterra Renewables’ Chief Revenue Officer, Kareem Mirza, concluded, “This is a strategic move to ensure our renewable energy sector’s supply chain is adequately equipped with nation-wide access to expeditious and precision-tested talent and services. We are establishing ourselves as a vertically integrated geothermal utility provider whose reach spans across North America – best suited to meet the fast-growing renewable energy movement as district communities transition to electrification, powered by geothermal exchange systems.”

Federal economic development agency, Pacific Economic Development Canada (PacifiCan), announced last week that it would provide CAD$3.6mn in funding to Kitselas Geothermal harness geothermal energy in British Columbia for commercial use.

Federal economic development agency, Pacific Economic Development Canada (PacifiCan), announced last week that it would provide CAD$3.6mn in funding to Kitselas Geothermal harness geothermal energy in British Columbia for commercial use.

Kitselas Geothermal aims to decarbonise local industry to provide social, environmental and economic benefits to the traditional territory of Kitselas First Nation. In the first phase of its geothermal project, the ‘Fuel of Recognition’ at the M’Deek Reservoir, it is designed to replace 270,000 gigajoules per year of natural gas, reducing greenhouse gas emissions by more than 13,000 tonnes per year.

With the funding from PacifiCan’s Jobs and Growth Fund, Kitselas Geothermal will drill production wells to harness geothermal energy, with the project expecting to generate 170 jobs for Indigenous workers and furthering the economic benefits for the region. This funding will help Indigenous communities across British Columbia seize new opportunities that power a net-zero future.

The Honourable Harjit S. Sajjan, Minister of Emergency Preparedness and Minister responsible for PacifiCan, said, “This announcement on World Geothermal Energy Day reflects the Government of Canada’s commitment to building a net-zero future. By harnessing the power of geothermal energy in Northern B.C., Kitselas Geothermal brings us one step closer to that future. PacifiCan will continue working with Indigenous communities in B.C. to create lasting economic development that advances reconciliation.”

Alison Thompson, Director of Kitselas Geothermal, added, “Development of the ‘Fuel for Reconciliation’ geothermal energy project is a significant step towards Kitselas First Nation’s economic independence. The project also contributes to B.C.’s and Canada’s transition towards clean energy by demonstrating technology, training highly qualified professionals, and providing a proving ground for regulatory reform that will benefit both future project phases and other geothermal projects elsewhere in the country.”

Ormat Technologies has broken new ground as it has partnered with DEEP Earth Energy to launch Canada’s first 5MW conventional geothermal power plant.

Ormat Technologies has broken new ground as it has partnered with DEEP Earth Energy to launch Canada’s first 5MW conventional geothermal power plant.

The two companies have signed a Notice to Proceed Agreement, marking the first step in redefining the region’s energy landscape by bringing the green energy source online. The project marks a significant milestone in Canada’s commitment to sustainable energy as the region has long since been established as having vast geothermal potential.

DEEP Earth Energy’s President and CEO, Kirsten Marcia, said, “We are grateful to have such a strong and committed partner as DEEP prepared to become Canada’s first commercial conventional geothermal power producer. Together, we will revolutionise the geothermal power industry, incorporating DEEP’s first-in-the-world horizontal well design and Ormat’s ORC power generation equipment.”

Ran Reshef, Vice President of International Sales for Ormat Technologies, commented, “It is with great honour that we find ourselves at the forefront of this pivotal transformation in the Canadian energy landscape. As we move forward, let it be known that this is just the beginning.”

Seequent, a Bentley Subsurface company, has agreed to acquire Flow State Solutions, a leader in geothermal simulation software, in a bid to cement its position as a comprehensive subsurface provider for the geothermal sector.

Graham Grant, CEO, Seequent, remarked, “Geothermal has the potential to help solve the world’s biggest energy challenges. With this acquisition, Seequent’s best-in-class subsurface analysis software enables a full understanding of geothermal asset performance.”

The geothermal reservoir, wellbore and surface network simulation software of Flow State Solutions helps customers better understand geothermal resources for development and optimisation. As per the agreement, the company’s Volsung portfolio will be combined with Seequent’s capabilities to create a robust end-to-end solution for reservoir analysis. Detailed models of the subsurface built in Leapfrog Energy can be utilised in Flow State Solutions’ simulation environment to build a full picture of a geothermal asset.

Flow State Solutions co-founder, Jonathon Clearwater, who will join Seequent as Technical Domain Expert, Reservoir Engineering, commented, “We are excited to join Seequent’s energy team. By combining Seequent’s expertise and our technical capability in geothermal modeling, we are looking forward to making a significant contribution to the renewable energy transition through improved management of natural resources.”

Simon Webbison, Vice President, Exploration and Resource Management, Ormat Technologies, said, “Ormat Technologies is one of the largest and most active geothermal companies globally, and we are delighted to see the combination of Seequent and Flow State Solutions software capabilities through this acquisition. We already use both companies’ software to better understand our geothermal assets and predict performance, and we are looking forward to working with the joint team to continue driving our success.”

Page 14 of 24

Copyright © 2026 Offshore Network