C-Innovation (C-I) and Grand Isle Shipyard, LLC (GIS), two strategic oil and gas industry partners, have been awarded a plug and abandonment contract by Helix Alliance Decom, LLC, to provide pre-feed services for the decommissioning of three offshore platforms for a major deepwater client.

In Phase I of the project, C-I provided ROV services to deliver marine water inspection and integrated the data within MODS software to provide live operations for the client operating fixed leg platforms in 165-200 ft of water. The GIS Aerobotics Drone Division provided aerial inspection services. The joint technical innovations aim to determine the current condition of the wells and the facility, enabling the timely and cost-effective decommissioning of the wells, platform and jacket for each of the three platforms.

The partnership harnessed its technology to offer increased safety margins. All of the inspections were able to be completed via line wireless transmission from the back of the boat within a connex box without requiring the deployment of personnel on ropes.

Michael MacMillan, Operations Manager, C-I, stated, “The equipment used took very little time to mobilise and provided subsea operations in a safe and efficient manner while using a limited number of personnel. The ability to launch this type of ROV from almost any asset not only allows operations to be efficient but also mitigates safety risks while practically eliminating the traditional risks associated with the launch and recovery of an ROV.”

DaCoda Bartels, GIS Aerobotics Division Manager and Pilot, said, “The GIS drone can safely operate from up to 100 ft away from the asset as we have the camera stabilisation technology to zoom in on an area of interest. Most of these areas are not accessible by human personnel. We are able to live stream the drone's camera view in real time to make informed decisions on the spot. It’s a super fast and super safe alternative, where the only potential risk is to the equipment rather than the personnel.”

MacMillan added, “Our partnership with GIS enables C-I to continue to demonstrate our flexibility to provide resources and equipment in a non-traditional scenario. The availability of equipment and personnel for these types of scopes is more important now than ever, due to the demands of today’s market.”

The Department of the Interior today has proposed a new rule to ensure offshore oil and gas operations on the Outer Continental Shelf are conducted with the utmost safety and oversight standards.

The proposition by the Bureau of Safety and Environmental Enforcement (BSEE) will revise the 2019 Well Control Rule and focus on well integrity and blowout prevention. These innovations will help protect human lives and the environment by incorporating the latest technology and the lessons learned from operator experience and incident data since the current rule was adopted.

“Protecting human lives and the environment has always been BSEE’s highest priority, and this proposed rulemaking will further ensure safe and environmentally responsible offshore energy production,” said BSEE Director Kevin M. Sligh. “These proposed revisions to the Well Control Rule are the result of knowledge and experience gained by stakeholders and BSEE since the 2019 rule was implemented. They will protect workers’ lives and the environment from the potentially devastating effects of blowouts and offshore oil spills.”

In the immediate aftermath of the Deepwater Horizon incident in 2010, BSEE adopted several recommendations from multiple investigation teams to improve the safety of offshore energy operations, leading to the publication of the 2016 Well Control Rule. In May 2019, BSEE published a final rule that weakened certain safety provisions. Today’s proposed rule would revise some of the items that were amended or rescinded in 2019.

To further protect human lives and the environment, the Department is proposing revisions that would:

• Require blowout preventer systems (BOPs) to be able to close and seal the wellbore to the well’s kick tolerance design at all times;

• Remove the option for operators to submit failure data to designated third parties and instead require the direct submittal of failure data to BSEE;

• Require failure analysis and investigations to start within 90 days instead of 120 days;

• Require independent third parties to be accredited by a qualified standards development organisation;

• Specify that surface BOPs on existing floating facilities must follow the dual shear ram requirements when replacing an entire BOP stack;

• Require that remotely operated vehicles be capable of opening and closing each shear ram on a BOP;

• Require the operator to provide test results to BSEE within 72 hours after completion of the tests if BSEE is unable to witness testing.

Publication of the proposed rule also initiates a 60-day public comment period.

Schlumberger, Aker Solutions and Subsea 7 today have announced an agreement to form a joint venture which will help customers unlock reserves, reduce time to first oil and lower development costs while simultaneously delivering on their decarbonisation objectives.

The proposed joint venture will comprise the subsea businesses of Schlumberger and Aker Solutions, with Subsea 7 purchasing 10% of the joint venture for US$306.5mn. This combination brings together deep reservoir domain and engineering design expertise, an extensive field-proven subsea production and processing technology portfolio, world-class manufacturing scale and capabilities, and a comprehensive suite of life-of-field solutions to customers all over the world.

The transaction is subject to regulatory approvals as well as other customary closing conditions, and is expected to close during the second half of 2023.

The board of directors of the joint venture will consist of three representatives from Schlumberger, two from Aker Solutions and one from Subsea 7. As part of the transaction, the new joint venture will form part of Subsea Integration Alliance, currently an unincorporated alliance between Schlumberger and Subsea 7.

Olivier Le Peuch, Chief Executive Officer of Schlumberger, said, “This joint venture will bring together world-class businesses that are uniquely positioned to provide subsea technologies to help our customers improve recovery and reduce overall subsea development costs. Customers will benefit from enhanced services that leverage digital and technology innovation to drive improved performance while increasing energy efficiency and reducing CO2 emissions.”

Kjetel Digre, Chief Executive Officer of Aker Solution, commented, “By combining our strong and complimentary competence and technologies, this compelling combination will deliver an industry step change that will benefit our customers, employees and significantly increase shareholder value. The offshore market activity is increasing, and this joint venture will drive enhanced offerings both in terms of subsea production economics and low-carbon solutions.”

John Evans, Chief Executive Officer of Subsea 7, added, “We are excited to build on our highly successful alliance with Schlumberger and partnership with Aker Solutions. This new joint venture is a critical step as we collaborate on the integrated subsea projects that drive maximum value for our customers.”

Baker Hughes is set to acquire Quest Integrity, a subsidiary of Team, Inc. and a global leader in the development and delivery of technology-enabled asset inspection and reliability management solutions across the pipeline, refining, petrochemical and power generation sectors.

Baker Hughes’ asset integrity solutions include pipeline inspection services that detect, characterise, locate and size anomalies in the wall of a pipeline that might potentially compromise its integrity. Quest Integrity’s technology will expand this capability to support ‘difficult-to-inspect’ pipelines where the construction or operation of the line does not allow for conventional inline inspection methods to yield reliable results.

The acquisition includes Quest Integrity’s Invista and Furnace Tube Inspection (FTIS) technology. Invista enables new inspection capability that extends across pipelines, marine loading lines, petrochemical, chemical, refining, power, utility and other industrial segments and facilities, such as airports. FTIS technology applies the same principles to enable the inspection of heater coils, a critical component in furnaces, detecting issues with corrosion and deformation for customers in the petrochemical and refining industries.

Quest Integrity also brings significant engineering expertise, with a focus on conducting critical assessments to deliver actionable insights and verify asset integrity across a diverse range of industrial assets such as pipelines, pressure vessels, tanks, and turbine blades.

Rami Qasem, Executive Vice President of Digital Solutions at Baker Hughes, commented, “The acquisition of Quest Integrity marks another step in Baker Hughes’ commitment to help customers ensure their asset infrastructure is safe and reliable and demonstrates how we continue to invest for growth in this area. Today’s announcement strengthens Baker Hughes’ unique capability to bring holistic industrial asset management services to our customers.”

The acquisition is expected to close in Q4 of 2022 and will be integrated into the Process & Pipeline Services product line within Baker Hughes’ Digital Solutions segment.

Nauticus Robotics, Inc., a developer of subsea and surface robotic services using autonomy software, has entered into an agreement with Shell to advance to the qualification phase for a more efficient means of acquiring subsea integrity data utilising Nauticus’ Aquanaut and Hydronaut robotic platforms.

The collaboration will enable Shell to add an advanced tool to its subsea asset integrity management lineup with the potential to improve subsea operations. Shell and Nauticus will collaborate with the industry’s leading inspection tooling service providers, to fully integrate into Nauticus’ robotic service solution.

An initial feasibility study for the phase-gated project was recently completed, and the team will now move onto the operational qualification phase, which focuses on remote operations of the robotic duo using supervised autonomy and tool control using Nauticus’ acoustic communication networking technology. The collaboration is targeting the preliminary work required for an offshore pilot project.

Todd Newell, SVP of Business Development at Nauticus, commented, “Working with a leading company such as Shell marks an exciting milestone for Nauticus, and this collaboration further validates the superior capabilities and extensive use cases of our robots across the energy sector. Implementing our supervised autonomous method – one that has proven more robust and dynamic than most of its kind – is expected to provide our partner and future customers more than 50% cost savings compared to today’s methods of operation.”

This collaboration will utilise the Nauticus’ flagship and fully electric subsea robot, Aquanaut, which is deployed from the company’s small surface vessel, Hydronaut –used for the transport, recharge, and communication for Aquanaut, among other tasks. Together, this robotic pair will function as a unified solution to bring a new means of conducting subsea work to the offshore services industry. Their inherent autonomous architectures will allow a transition to far more autonomous operations over conventional solutions.

“An exciting aspect of this project is the opportunity to combine the strengths of advanced inspection tooling with the advanced marine robotic capabilities developed by Nauticus Robotics,” said Ross Doak, Deepwater Robotics Engineer of Shell’s robotics team. “This project aims to fundamentally improve how we collect subsea facility data, through the combination of ‘AUV native’ tooling design, supervised autonomy, and recent improvements in remote communications.”

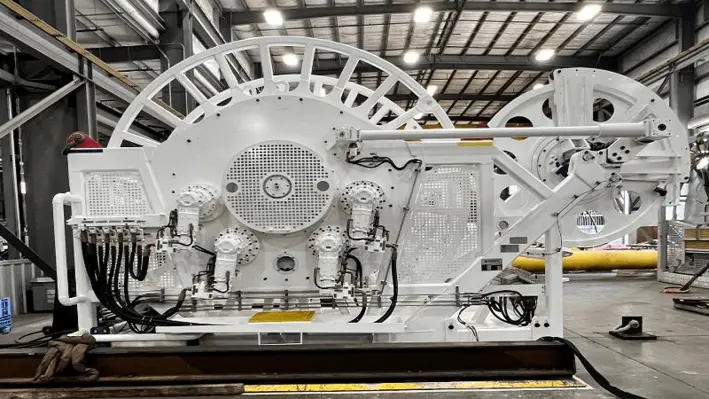

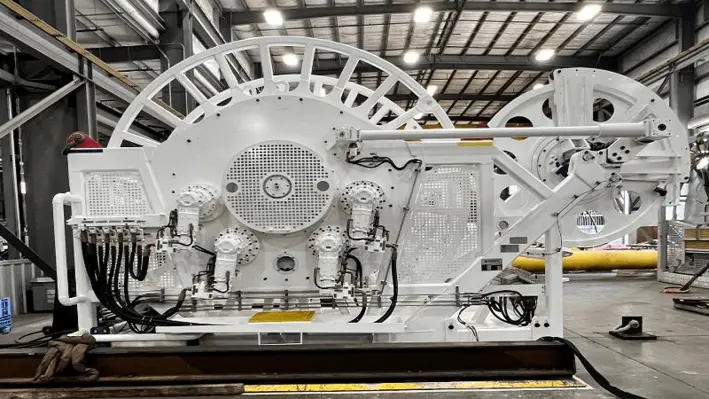

Logan Industries International Corporation, a machine designer, manufacturer, field service and repair company, has successfully delivered a unique, space saving coiled tubing (CT) reeler suite for OneSubsea.

Logan’s CT reelers are coiled tubing winches, where the reelers provide full torque control for the tubing without the need for a standard injector head. This reduces space required compared to standard tubing reeler / injection head combination, and allows for a larger fluid storage footprint on deck. When the equipment required to handle CT has a small footprint, more deck space can be dedicated to hauling fluid, which increases profitability for the operator.

This is the first unit Logan has delivered with a removable drum, which means the unit footprint can remain static on the vessel while the drums can be taken to a shore base for unspooling and respooling. They are transported in a purpose-built DNV lift rated drum basket, fully secured and protected. The swap out drum also makes the machine faster to build, reducing typical assembly time for the drum and drive train from two weeks to two days.

At 15,000 psi working pressure, 10,000 feet of 2 in. CT was provided on the drum, with live swivel and isolation valves on the unit. The suite of equipment provided for this work includes a spare drum, adapter to allow it to fit into most tubing service spoolers at the tubing manufacturer’s facilities, transport basket and lifting set along with the reeler, HPU, control stand and interconnect lines. Logan also provided a purpose-built overboarding platform with a translating / clamshell to accommodate OneSubsea’s unique end connection philosophy.

Dean Carey, Technical Director, Logan, commented, “We placed a work deck, dimple connector, test tool, controls and safeguards on this overboarding platform to give the crew plenty of access to the volume of space under the overboarding point. The overboarding platform also provided a reeler deck loading spreader effect on the vessel’s deck. We believe this is truly the next evolution in coiled tubing deployment offshore, and provides significantly more convenience for our customers. This is one of the most comprehensive reeler equipment suites Logan has had the pleasure to provide, and we expect it to remain in service for quite some time.”

Baker Hughes has announced that it is acquiring AccessESP, a leading provider of advanced technology for artificial lift solutions, to further transform core oil and gas operations by reducing costs and downtime for operators.

AccessESP’s ‘GoRigless ESP System’ provides proprietary solutions that enable an electrical submersible pump (ESP) to be deployed and retrieved with conventional, light-duty intervention equipment without the need for a rig or requiring the well production tubing to be pulled.

These technologies significantly reduce the cost of, and downtime between, workovers used in the replacement of ESPs, which is of increasing importance in offshore and remote areas.

Maria Claudia Borras, Executive Vice President of Oilfield Services at Baker Hughes, commented, “Combining AccessESP’s alternative deployment technology with Baker Hughes’ world-class ESP capabilities creates a truly differentiated solution for our customers. This transaction reinforces Baker Hughes’ commitment to transforming our core business by focusing on leading, future-proof technologies that support growth opportunities and enhance our portfolio.”

AccessESP’s innovative deployment system provides more efficient solutions compared with traditional methods. By reducing heavy intervention, operators can increase oil recovery, efficiency and profitability while reducing costs and managing resources more efficiently. Lightweight intervention systems also reduce HSE risks, while light workover techniques enable ESP maintenance to be completed more quickly and at a lower cost than existing methods.

AccessESP has approximately 55 employees with facilities in North America and the Middle East. The transaction is expected to close in the second half of 2022 and will be integrated into Baker Hughes’ Oilfield Services segment.

With integrity issues continuing to plague wells across the globe (affecting an estimated 30% of wells around the world), Expro has engineered the Octopoda annulus intervention system to enhance production and assure well integrity without disrupting operations.

According to Expro, the Octopoda is a unique, proven and advanced technological solution which allows direct access to the well annuli which can help bolster production rates, firm up well integrity and allows customers to regain shut in wells and make them economically profitable again.

With advanced corrosion protection for up to 20 years, Octopoda can help create a sustainable impact on asset production and revenue.

In a recent demonstration of its capabilities, Octopoda was used on a Chevron offshore platform well to intervene the A annulus and replace base oil with water ahead of resin placement on top of the packer.

Chevron had previously seen a 50% reduction in the impact of the resin when it was added to an earlier well containing base oil.

Deploying Octopoda meant Chevron avoiding the use of production tubing for circulation via a stimulation vessel or coil. This eliminated the need for communication between the production tubing and the A annulus meaning the barrier remained intact between the reservoir and the A annulus.

Expro displaced the base oil and established circulation by pumping fresh water through the annulus intervention system. Despite experiencing space limitations caused by control lines, clamps, and centralisers.

This was the first time the A annulus had ever been intervened using a conveying hose. Furthermore, it proved the efficiency benefits of Octopoda’s annular intervention over conventional practices by reducing time, costs and personnel. The operation lasted three days compared to an estimated 10-13 days, avoiding the conventional lube and bleed method or the need to punch and circulate the well.

Octopoda’s small footprint compared to a pumping vessel or unit reduced lifting risks and required only a two-man crew from Expro. The base oil was collected in a closed loop in the system, avoiding its exposure to the environment.

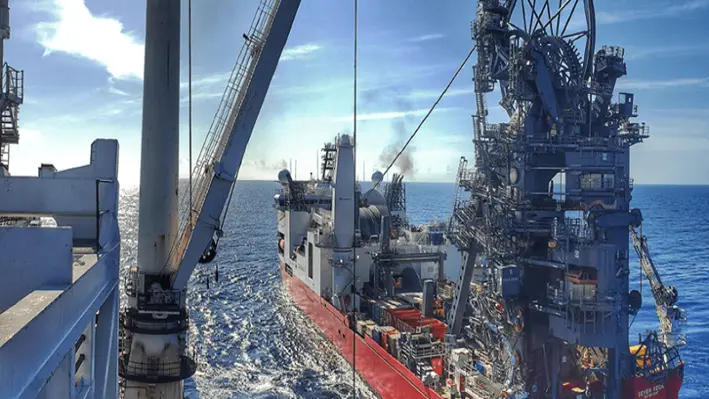

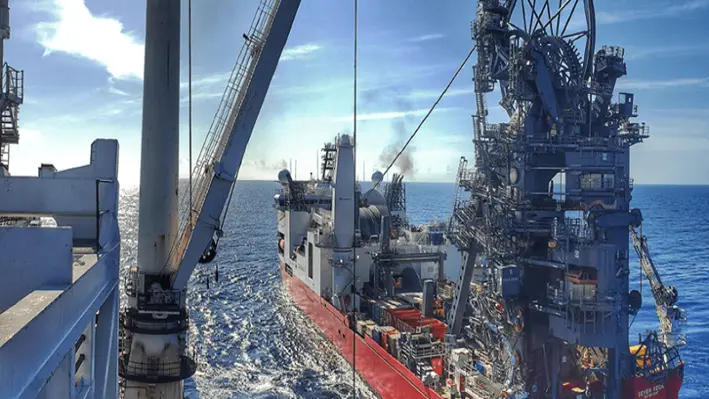

Helix Energy Solutions Group has completed the acquisition of all the equity interests of the Alliance group of companies which will expand its decommissioning presence in the Gulf of Mexico.

The acquisition will also advance the company’s Helix’s environmental, social and governance (ESG) initiatives by responsibly supporting the end-of-life requirements of oil and gas projects.

Owen Kratz, President and Chief Executive Officer of Helix, commented, “We are pleased to have completed our acquisition and added Alliance to the Helix family, which complements Helix’s existing deepwater abandonment offerings by adding shelf and facility abandonment capabilities and significantly enhances our position as a full-field abandonment services provider.

“The acquisition marks a meaningful step in our participation in the Energy Transition, and we are excited to welcome our new colleagues to the Helix family.”

Helix also announced that it has amended its existing asset-based revolving credit facility (ABL Facility). The amendment aligns with Helix’s Alliance acquisition, expanding the eligible credit line and establishing a link in its pricing to sustainability targets. The key features of the amendment include increasing the size of the ABL Facility to US$100mn and including ESG/sustainability-linked performance targets that may result in adjustments to commitment and borrowing rates.

Kratz continued, “We have increased the size of our ABL Facility to accommodate the increase in our expected borrowing base with the Alliance acquisition. We are also pleased to have included a sustainability-linked performance target that may reduce our fees under the facility and we are appreciative of the support from our bank group in this amendment.”

Global well integrity and production optimisation expert Coretrax has successfully deployed the ReLineMNS system across three wells and expanded a total of more than 27,000 ft of tubulars, a world record-breaking project in the Utica Basin, for a major gas operator with its ReLine Expandable Technology.

With one of the expandable liners reaching 9,000 ft in its expansion, all installations smashed the previously held record of 7,243 ft by at least 1,000 ft.

The total setting time from beginning expansion to exiting the top of the liner took only nine hours per well over a total of seven days on location. Covering the well integrity issue with one full-length liner, the overall setting time was significantly less than that of competing products on the market, setting at approximately 1,000ft per hour.

Coretrax’s technology was deployed into each of the wells with a 4.25” outer diameter liner. On expansion of the liner, the post-expansion of the inner diameter was 4.1” with an internal pressure capability of well over 10,000 psi, covering the wellbore issues identified.

Scott Benzie, Chief Technical Officer at Coretrax said, "Our advanced no shoe expandable technology allows operators to effectively isolate well integrity issues and immediately proceed with their next operations without the requirement to drill out a shoe, enabling our clients access to huge time and cost savings on their projects."

“The engineered materials used in the expandable technology ensure reliability is maintained through the operation, resulting in a consistent expansion reflecting our attention to detail.

“Our highly skilled team members from the operations and applications departments were key to the success of this world record, and delivering our valuable services for each well. This project pays testament to the strong and trusting relationship we have built with our client.”

Energy services provider Danos has been awarded the opportunity to support the Promethean Decommissioning Company (PDC) and Petrofac alliance, to decommission multiple facilities in shallow water fields in the Gulf of Mexico.

CEO Paul Danos said, “Danos is honoured to join the efforts with PDC and Petrofac to provide safe and efficient operational and construction support for the alliance. We look forward to planning and executing this project with our partners and applying our 75 years of experience, safety and operational excellence in the Gulf of Mexico.”

The project, which began at the end of May, includes ten platforms, 196 wells and 32 pipeline segments in the South Pass and East Break fields of the Gulf.

This multi-year programme will allow Danos to support the PDC and Petrofac alliance and its decommissioning program with several of its service lines, including production workforce, construction, fabrication, and instrumentation and electrical.

Danos has many years of experience supporting decommissioning work through various service lines in the Gulf of Mexico as well as internationally.

“Having been appointed decommissioning operator for this project, we are delighted to have Danos join us and support the alliance we have formed with Petrofac. Together, our mission is to deliver safe, lean, integrated, best practices and technology-driven decommissioning operations which will reflect the highest ESG standards and include the minimising of GHG emissions/intensity and the environmental footprint of operations. Danos’ experience and knowledge will prove invaluable to the successful delivery of this program,” said Aditya Singh, President of Promethean Energy.

“Danos’ longstanding relationships in the Gulf of Mexico and comprehensive range of services positions them to provide the expertise needed for the programme,” a Petrofac representative said.

Schlumberger and Subsea 7 have signed an agreement to renew Subsea Integration Alliance for a further seven years.

Subsea Integration Alliance is a worldwide non-incorporated alliance between Subsea 7 and Schlumberger’s OneSubsea subsea technologies, production and processing systems business, to jointly design, develop and deliver integrated subsea development solutions.

Over the past seven years, the alliance has successfully combined the complementary capabilities and market-leading technologies of OneSubsea and Subsea 7, and worked collaboratively with clients to design, develop and deliver integrated SPS and SURF solutions proven to optimise the cost and efficiency of deepwater developments.

John Evans, CEO of Subsea 7 commented, “The success of Subsea Integration Alliance is a result of the drive and commitment of both Subsea 7 and OneSubsea to deliver an enhanced experience and outcome for our clients. Driven by the demonstrable benefits to clients of this mode of collaborating, integrated projects are expected to remain a significant component of the subsea market. We look forward to extending our relationship with OneSubsea as we address the opportunities of the offshore energy market.”

The alliance continues to build momentum and, in recent years, has been awarded major greenfield projects in Australia, Brazil, Africa and Turkey, as well as significant tie-back work in the Gulf of Mexico and Norway.

“Subsea Integration Alliance has proven to be a tremendous success,” said Abdellah Merad, EVP, Core Services and Equipment, Schlumberger. “Having been awarded 12 integrated projects and more than 130 early engineering studies around the world, it has helped– and will continue to help – customers achieve maximum value from their subsea developments through industry-leading innovation and expertise.”

Page 18 of 24

Copyright © 2026 Offshore Network