At the Offshore Well Intervention West Africa 2021 conference, Rafael Bastardo, Vice President of Global Sales, Silverwell, outlined his company’s Digital Intelligent Artificial Lift (DIAL) system, designed to eliminate production uncertainty, instabilities, deferment and operational costs.

At the Offshore Well Intervention West Africa 2021 conference, Rafael Bastardo, Vice President of Global Sales, Silverwell, outlined his company’s Digital Intelligent Artificial Lift (DIAL) system, designed to eliminate production uncertainty, instabilities, deferment and operational costs.

As Bastardo explained, gas lift production optimisation is crucial to the future of the offshore oil and gas industry enabling operators to capture real value on their associated assets. ExxonMobil, for example, stated that they evaluated a 22% average oil gain using an optimised gas lift programme.

Traditional legacy Injection Pressure Operated (IPO) gas lift systems (in use for a long time within the industry) have narrow operating windows, injection depth limits, difficulties in assessing lift effectiveness, requires intervention to optimise, and is very sensitive to well dynamics. For this reason, Silverwell developed and released the DIAL system.

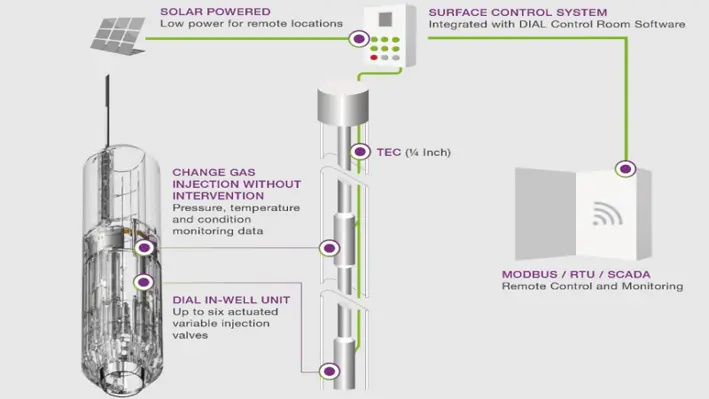

DIAL is a production optimisation system which integrates in-well monitoring and control of gas lift well performance with surface analytics and automation. Each DIAL unit has up to six independent injection orifices (with different port sizes) which can be individually opened and closed from the surface without requiring a drop in casing pressure. The suite of tools is connected to the surface via a tubing encapsulated conductor (TEC) that provides power and communications. This allows for continuous optimisation of gas lifted fields, remotely and without intervention.

To mitigate the challenges experienced by legacy IPO systems, DIAL boasts keys features such as patented binary actuator technology; variable orifice size at any depth; pressure, temperature and flow data; remote monitoring and control; intelligent field-wide management; and no deviation limitation.

These allow operators to capture key benefits such as:

-10% to 40% uplift

-Reduce +20% gas consumption

-Mitigate instabilities

-Deeper injection

-Reduce OPEX by 20% to 30%

-Reduce HSE risk

-No deviation limit

-Multi-million dollar NPV increase

-Eliminate intervention (does not require slickline to operate or adjust).

Unit Specification:

-A collapse pressure rating of up to 6,000 psi, with a 7,500 psi pressure rating coming soon

-10,000 psi burst rate pressure

-125 degrees Celsius max rated temperature, with a 150 under development and testing

-Concentric and slimline profile

-Multiple units per well

-Binary Actuation Technology

-Maximum choked flow rate of 6mmscfd/unit

-Electron Beam welded construction.

Bastardo noted that operators can acquire real time data from each unit, control each valve independently through a sophisticated surface control system and see key information such as the status for injection rate velocity, critical flow indicators and recent events that occurred during logging operation. Operators without SCADA can use radio or satellite communication to send the DIAL system data directly to cloud services which can be accessed remotely.

Silverwell are currently in the process of advancing the technology even further and will soon release units with a fully automated gas lift production optimisation system, drawdown control and water cut management and mitigation of injection pressure instabilities.

A reliable solution

The technology is relatively new (came into the market in 2016) however the trial phase is now complete and there are 15 wells installed with DIAL units globally. They are expected to be installed in 23 wells offshore by Q1 2022.

DIAL units are designed for a lifetime of over 10 years and, Bastardo added, the estimated savings from eliminating intervention was “immense.” He presented several business cases where, in each case, the technology had been very well received by the operator and had achieved substantial returns on investment.

Bastardo added that the best candidate for this technology were those with high frequency or high-cost interventions, assets with dynamic reservoir conditions, deviated wells and ones with constrained surface injection capacity.

In 2022, Silverwell is looking at releasing the system for subsea applications with pressure rating of 10,000 psi.