Petronas' natural gas development project offshore Brunei Darussalam will see engineering, procurement, construction, installation and commissioning (EPCIC) work by McDermott.

Petronas' natural gas development project offshore Brunei Darussalam will see engineering, procurement, construction, installation and commissioning (EPCIC) work by McDermott.

A subsea contract between Petronas and McDermott, this follows front-end engineering design, engineering optimisation and readiness planning delivery for the project, also by McDermott.

A significant conventional gas project from Brunei, the latest contract will require McDermott to support the development of a subsea production system and associated infrastructure. The company will be delivering umbilicals, risers and flowlines, which will connect six wells to a floating production unit for natural gas recovery. It will also cover EPCIC services for a gas export pipeline that will supply feedstock to Brunei's liquefied natural gas (LNG) sector.

"Transitioning from FEED to a full EPCIC award underscores McDermott's engineering excellence and proven ability to deliver complex subsea projects across the region," said Mahesh Swaminathan, McDermott's Senior Vice President, Subsea and Floating Facilities. "It also reinforces McDermott's collaborative approach in working with customers to drive engineering value. We look forward to continuing our collaboration with PETRONAS Carigali Brunei and its partners to advance this project safely and efficiently."

Project management will be led from McDermott's engineering center of excellence in Kuala Lumpur, Malaysia, supported by teams across other McDermott offices and project sites.

The Brunei gas development project aims to deliver a long-term solution for natural gas supply, covering the region's domestic energy needs and LNG export commitments.

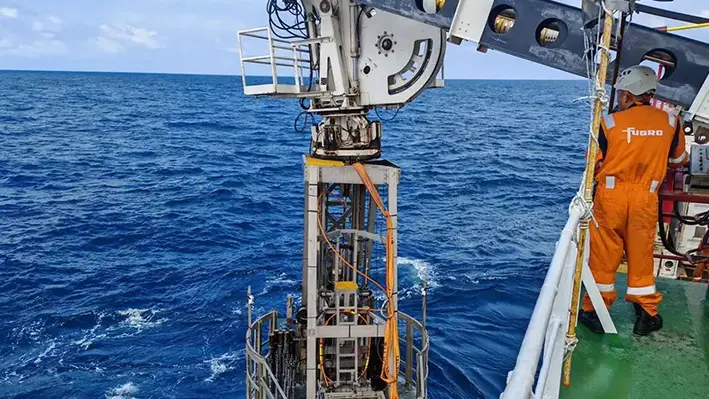

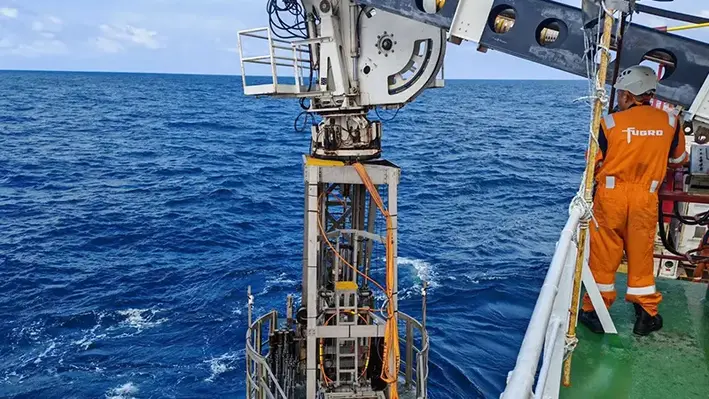

Fugro has secured a significant contract with Mubadala Energy (South Andaman) RSC Limited to deliver cutting-edge soil investigation services for the South Andaman Deepwater Development offshore Indonesia.

Fugro has secured a significant contract with Mubadala Energy (South Andaman) RSC Limited to deliver cutting-edge soil investigation services for the South Andaman Deepwater Development offshore Indonesia.

ADES Holding has secured a new contract for its Compact Driller standard jack-up through its Shelf Drilling subsidiary for work offshore Brunei.

ADES Holding has secured a new contract for its Compact Driller standard jack-up through its Shelf Drilling subsidiary for work offshore Brunei.

The contract, awarded with Brunei Shell Petroleum, covers plug and abandonment operations offshore, and is expected to commence in Q4 2026. The contract has a two-year term and is worth approximately US$63mn.

Mohamed Farouk, CEO of ADES Holding, said, “We are delighted to announce our first contract award following the successful acquisition of Shelf Drilling, a milestone that reinforces our strategic vision and solidifies our presence in Southeast Asia, a region of immense opportunity and growth. This award reflects Shelf Drilling’s proven track record of safety and operational excellence, particularly its unique experience delivering P&A services in the region.

“This track record underscores the rationale behind our acquisition. We are pleased to begin our partnership with BSP and remain committed to delivering safe and efficient operations in support of their activities in Brunei. It is a testament to the dedication of the combined teams and the strength of our integrated platform. We look forward to building on this momentum and continuing to deliver exceptional results for our clients and partners.”

Malaysian well interventions specialist, United Asiapac Energy Bhd, has launched an initial public offering (IPO) on the ACE Market of the local stock exchange.

Malaysian well interventions specialist, United Asiapac Energy Bhd, has launched an initial public offering (IPO) on the ACE Market of the local stock exchange.

According to filings lodged with Bursa Malaysia, the company aims to use the IPO to bolster its services and operational capabilities to take advantage of emerging opportunities in Malaysia’s upstream sector.

Specifically, that includes plans to strengthen its technical capabilities by acquiring new well intervention tools and equipment.

“To support future business growth, it is essential that our group has available well intervention tools, equipment and DNV-certified cargo baskets that we can mobilise

simultaneously in order to meet our project deadlines,” its stock market prospectus notes.

In line with this goal, the company plans to acquire a break-out unit for installation at its Kemaman base, to be used for the assembly and testing of well intervention tools.

Presently, the group’s tools and equipment are transported to a third-party facility within the Kemaman base for assembly, testing and inspection, which requires careful planning to ensure project timelines are met and incurs additional logistical costs.

“We also intend to purchase DNV-certified cargo baskets, which are used to transport tools during every mobilisation,” the company added.

The group boasts strategic locations in Kemaman and Labuan, which it claims give it a competitive edge over other industry players, which are predominantly international firms.

United Asiapac Energy added that it also intends to introduce new well intervention solutions to broaden its service offering.

“We plan to introduce e-line, slickline and wireline recovery services, particularly for small hole fishing,” its prospectus notes.

“In addition, we plan to offer hydrocarbon well cleanout services to remove obstructions and debris through the procurement of specialised tools. This expansion is a direct response to increasing market demand and enquiries from existing and prospective clients seeking for well intervention solutions under a single service provider.”

The company also said that it intends to expand its services in Sabah, as well as acquire a new corporate office in the Kuala Lumpur area.

Sarawak expansion is also in its sights.

“We aim to expand our market presence in well intervention solutions within Sarawak,” it notes in the Bursa Malaysia filings.

“The state presents significant opportunities for growth, driven by the anticipated increase in greenfield exploration activities and the maturing of existing hydrocarbon fields. With new fields being explored and developed, and mature fields nearing the end of their productive life, the resulting demand for well intervention, particularly P&A services, appears promising.”

HEA Energy, a fast-growing offshore services provider based in the UAE, has officially expanded its fleet with the addition of HEA Survey, a highly versatile subsea support and survey vessel designed to meet the evolving demands of modern offshore operations.

HEA Energy, a fast-growing offshore services provider based in the UAE, has officially expanded its fleet with the addition of HEA Survey, a highly versatile subsea support and survey vessel designed to meet the evolving demands of modern offshore operations.

The ABS-classed, Panamanian-flagged vessel represents a major step forward for the company as it continues to strengthen its capabilities across the Middle East’s offshore oil, gas, and renewable energy markets.

Built by Jiangsu Islands Shipbuilding in China, HEA Survey was conceived as a multi-role offshore workhorse capable of undertaking a wide spectrum of subsea activities. These include high-precision survey work, ROV support, subsea inspection campaigns, light well intervention, dive support, heavy lifting, firefighting duties, and anchor-handling operations. Although the vessel’s construction began in 2013 and was significantly delayed, with completion only achieved in late 2024, she emerges with a thoroughly modern design tailored to today’s offshore requirements.

Measuring 59.25 metres in length with a beam of 15 metres, the vessel features a robust diesel-electric propulsion system engineered for operational flexibility. Two 2,100hp engines, paired with multiple generators and controllable-pitch propellers, deliver up to 12 knots while enabling dynamic load management. This configuration allows the vessel to operate efficiently during low-speed survey work or station-keeping a critical capability for precision subsea tasks. An electrically driven bow thruster further enhances lateral manoeuvrability, making the vessel suitable for operations in both shallow and deepwater environments.

A considerable 350-square-metre aft working deck, reinforced to handle seven tonnes per square metre, gives HEA Survey the capacity to support modular mission packages such as ROV hangars, geotechnical equipment, and ISO container-based systems. With a maximum payload of up to 500 tonnes and a 25-tonne SWL crane, the vessel is well-equipped for heavy offshore logistics and deployment work.

Despite not being DP-classed, the combination of controllable-pitch propellers, bow thrusters, and a diesel-electric system ensures reliable station-keeping for a broad range of survey and subsea activities. The vessel also features a complete suite of modern navigation and communication electronics, including S- and X-band radars, AIS, echosounder, GPS, Doppler log, and MF/HF radio equipment.

Accommodation onboard is fully air-conditioned and compliant with ILO standards, providing comfortable living quarters for up to 48 crew members across a mix of single, double, and quad cabins. Safety provisions are SOLAS-compliant, with liferafts, immersion suits, fire monitors, and a dedicated MOB boat with davit launch capability.

Entering service in the UAE, HEA Survey positions HEA Energy to meet growing regional demand for multi-role offshore support vessels particularly within subsea construction, well intervention, offshore survey campaigns, and the expanding clean-energy marine sector.

MISC has secured a major contract from Petronas Carigali for the provision of a Floating Production Storage and Offloading (FPSO) unit in support of a key natural gas development project in Brunei.

MISC has secured a major contract from Petronas Carigali for the provision of a Floating Production Storage and Offloading (FPSO) unit in support of a key natural gas development project in Brunei.

This significant award follows an international competitive bidding process, with MISC emerging as the chosen partner for the project.

The contract stipulates a 12-year charter for the FPSO, with an option for Petronas Carigali to extend the agreement for up to three additional one-year terms. MISC will also take responsibility for the operation and maintenance of the floater throughout the charter period. The FPSO is expected to begin operations in the first half of 2029, playing a pivotal role in the Kelidang offshore gas development.

While MISC has not disclosed the specific name of the project, it is confirmed that the floater will be deployed in the Kelidang field, located approximately 125 kilometres off Brunei’s coast. The gas development encompasses three key discoveries: Kelidang North East, Keratau, and Keratau South West.

The project is a collaboration led by Petronas Carigali, in partnership with Shell and Brunei National Petroleum Company. Central to the project’s development is the installation of the FPSO vessel, designed to handle up to 450 million standard cubic feet per day (mmscf/d) of gas. The FPSO will be stationed at a depth of around 150 metres, supported by an advanced network of subsea flowlines connecting up to six subsea wells, each located at depths reaching up to 2,000 metres.

The pre-bid process began in January 2024, with leading contenders such as Yinson, Bumi Armada, and others competing for the deal. The project's total capital expenditure is estimated at around US$750mn, positioning it as a high-profile energy investment in the region.

Increased drilling know-how and technology adoption is helping to build momentum at CNOOC Limited, including advanced tools for oil well intervention.

Increased drilling know-how and technology adoption is helping to build momentum at CNOOC Limited, including advanced tools for oil well intervention.

Most recently, the company announced the start of production from its Weizhou 11-4 Oilfield Adjustment and Satellite Fields Development Project in the Beibu Gulf Basin of the South China Sea, its latest completion.

Presenting its 2025 interim results, back in August, CNOOC flagged how it remained committed to innovation-driven growth, utilising digital and intelligent tools in its upstream work.

Net production increased by 6.1% year-on-year, while natural gas was up 12% in the same period, a reflection of its prowess in the field.

Key technologies for reserves and production growth were developed and applied, the company noted in a statement, while reserve utilisation and oil recovery rates continued to improve, and natural decline rates of oilfields offshore China remained at a low level.

“Intelligent injection-production technologies were deployed on a large scale to help control the natural decline rate,” the company added.

Advanced geophysical technologies were also applied to improve the quality of seismic data from deep plays.

CNOOC added that it promoted intelligent drilling and completion, with the construction speed of demonstration projects accelerating by 26%.

It also integrated satellite remote sensing, unmanned equipment, and AI algorithms, to enhance its emergency response capability against typhoon-related risks, laying solid foundation for safe production.

Its latest Weizhou 11-4 development, located in water depths of 43 metres, leverages various adjacent existing facilities.

The main production facilities include a newly-built unmanned wellhead platform and a central processing platform, connected to an existing platform through a trestle bridge.

Under the development plan, 35 development wells are set to be commissioned, including 28 production wells and seven water injection wells.

The project is expected to achieve a plateau production of approximately 16,900 barrels of oil equivalent per day in 2026.

The offshore decommissioning market is entering a phase of significant change, particularly across the Asia–Pacific region, where ageing infrastructure, evolving regulations, and rising environmental expectations are reshaping industry priorities.

Governments throughout APAC are tightening their regulatory frameworks, introducing more comprehensive guidelines to ensure that the dismantling of offshore assets is carried out responsibly and with minimal environmental impact. These regulatory pressures are pushing operators to embrace innovative, sustainable technologies as they update their decommissioning strategies.

A major influence on this shift is the accelerating move towards renewable energy. As countries in the region prioritise cleaner energy sources, many oil and gas platforms are being retired to make room for offshore wind developments and other low-carbon alternatives. This transition is generating sustained demand for specialist decommissioning services, creating opportunities for companies able to support safe and efficient asset removal.

Collaboration is also becoming a defining feature of the offshore decommissioning market. Operators, contractors, and regulators are increasingly pooling expertise to streamline projects, share resources, and establish consistent industry standards. This cooperative approach supports smoother project delivery while encouraging the development of best-practice frameworks across the sector. Governments are also placing greater emphasis on local content, encouraging the involvement of domestic firms and promoting workforce development around decommissioning activities.

Several key drivers are shaping the market’s expansion. Ageing offshore infrastructure remains one of the most pressing, with more than 200 platforms in APAC expected to require full decommissioning by 2030. Analysts anticipate an annual market growth rate of around 10% as companies tackle end-of-life assets and associated safety and environmental risks.

At the same time, investment in renewable energy across APAC is forecast to exceed US$50bn by 2027, accelerating the removal of outdated platforms to support offshore wind and related developments. Evolving regulatory structures, particularly in markets such as Australia and Japan, are expected to increase compliance costs by as much as 15% over the next five years, compelling firms to enhance their decommissioning frameworks.

Technological advances especially in robotics, automated systems, and remotely operated vehicles—are helping to reduce project costs by as much as 20% while improving safety and precision. These innovations are strengthening the competitiveness of companies adopting them.

Market segmentation highlights several trends: Well Plugging and Abandonment remains the dominant service type due to strict environmental requirements, while Pipeline and Power Cable Decommissioning is emerging rapidly in response to renewable energy expansion. Shallow-water decommissioning still holds the largest market share, though deepwater activity is growing quickly as operators venture into more challenging environments. In terms of structure, Topside remains the largest segment, with Substructure decommissioning expanding at the fastest pace due to improved removal techniques.

TechnipFMC has secured a major integrated EPCI contract from Italian energy company Eni for the deepwater Maha development offshore Indonesia, marking another significant step in their long-standing collaboration.

TechnipFMC has secured a major integrated EPCI contract from Italian energy company Eni for the deepwater Maha development offshore Indonesia, marking another significant step in their long-standing collaboration.

This project is particularly notable as it will be the first time Eni deploys TechnipFMC’s Subsea 2.0 configure-to-order technology in Indonesia, signalling a shift towards more standardised and efficient subsea solutions in the region.

Building on the companies’ previous successes at Jangkrik and Merakes, the new Maha facilities will be connected to the existing Jangkrik floating production unit (FPU). Under the scope of work, TechnipFMC will handle the design and manufacture of subsea tree systems, flexible flowlines, a manifold and associated control systems, and will also oversee the installation of the full subsea production package.

Although the precise contract value has not been disclosed, it is classified as a substantial award, indicating a worth in the region of US$250mn to US$500mn.

Jonathan Landes, president of subsea at TechnipFMC, said, “The Maha development provides a significant opportunity to strengthen our relationship with Eni and deliver greater timeline certainty through the application of Subsea 2.0 technologies and integrated delivery.

The forward look for well services and interventions across the Asia Pacific market, and for other industry providers, bodes well as spending levels accelerate across the region.

The forward look for well services and interventions across the Asia Pacific market, and for other industry providers, bodes well as spending levels accelerate across the region.

In the latest insight paper by Westwood, offshore investment is expected to remain resilient despite a turbulent year for global oil markets.

Between 2025 and 2029, offshore engineering, procurement, construction and installation investment is projected to reach US$310bn globally, with APAC accounting for 27% of this spend, it notes.

Southeast Asia alone is set to award US$37bn in new offshore contracts, led by deepwater gas projects in Indonesia, and emerging carbon capture and storage (CCS) initiatives in Malaysia.

Thailand is also embarking on its maiden CCS scheme.

“Oil and gas companies – including regional NOCs – continue to prioritise decarbonisation, though the approach is evolving toward more disciplined oil and gas investment and cost efficiency,” Westwood notes in the paper.

“This shift is expected to drive down industry costs, even as supply chain margins remain under pressure.”

These macro trends are influencing not just oil and gas, but also the region’s growing offshore wind sector, it adds.

This could mean a weakening in rates for the offshore marine fleet that services the region’s oil and gas industry.

There are currently 84 active platform supply vessels and 449 anchor handling tug/supply vessels in the Asia Pacific region, operated by key incumbents such as Wintermar, HADUCO and Nam Cheong.

Dayrates for offshore support vessels have softened from recent record highs yet continue to exceed historical averages, according to Westwood, sustained by firm utilisation levels amid tightening supply as units are redeployed out of the region.

In its concluding remarks, Westwood notes that the Asia Pacific offshore market is navigating both challenges and opportunities as 2025 draws to a close.

From ageing fleets and cost pressures to the promise of offshore wind and deepwater gas, the region is poised to play a key role in the global energy transition, it adds.

As Asia Pacific continues to evolve, Westwood notes that staying informed and engaged will be key for all stakeholders across the energy value chain.

“As frameworks evolve and investment flows shift, collaboration between operators, service providers and governments will be essential to unlocking sustainable growth,” it states.

“Innovation in technology, financing and project execution will define the next chapter of offshore energy.”

With an aim to advance optimal and sustainable energy supply, PETRONAS, through Malaysia Petroleum Management (MPM), has signed several Memoranda of Understanding (MoUs) at ADIPEC 2025.

With an aim to advance optimal and sustainable energy supply, PETRONAS, through Malaysia Petroleum Management (MPM), has signed several Memoranda of Understanding (MoUs) at ADIPEC 2025.

In the spirit of global collaboration and technology driven innovation, the MoUs include partners such as SLB, Beicip-Franlab, ConocoPhillips, Eliis, PTTEP, Microsoft, Shell, and TotalEnergies. The partnerships will drive seismic imaging and artificial intelligence (AI) and machine learning (ML) development enabled by high-performance computing (HPC).

Senior Vice President of MPM, Datuk Ir. Bacho Pilong, said, “Partnerships like these are essential in advancing Malaysia’s upstream landscape. By combining the strengths of energy operators and technology innovators we are not only strengthening our exploration and development capabilities but also setting the foundation for a more efficient and resilient Malaysia upstream sector."

The partners will work together to leverage dynamic modelling and agentic artificial intelligence (AI) for real-time data integration, uninterrupted predictive analysis, and proactive decision-making. With the deployment of Normally Unattended Facilities and Remote Autonomous Operations (NUF-RAO), partners can reap benefits right from subsurface evaluation to offshore facility optimisation.

These advancements will also support more efficient technical evaluations and investment decisions. These collaborations fit perfectly with MPM's managerial role in ensuring the best petroleum arrangements and drawing high-value upstream investments.

Tredwell, a leading Malaysian energy solutions provider, has announced the signing of a new distribution agreement with Matrix Composites & Engineering.

Tredwell, a leading Malaysian energy solutions provider, has announced the signing of a new distribution agreement with Matrix Composites & Engineering.

Under the agreement, Tredwell will distribute Matrix’s MAX-R low friction centraliser range across Malaysia, helping operators enhance well construction efficiency, safety, and sustainability.

Tredwell is a Malaysian-based energy solutions provider delivering innovative engineering and technology services to the oil and gas industry.

With a strong presence across East and West Malaysia, it specialises in well completion, well intervention, and drilling solutions, supported by in-house research and development and strategic global partnerships.

The company is committed to advancing operational efficiency and sustainability through high-quality, reliable, and cost-effective technologies.

The signing ceremony for the new distributorship took place at the Adipec industry showcase in Abu Dhabi, with Aaron Begley, CEO of Matrix Composites & Engineering, and Tengku Mohd Adam, CEO of Tredwell, formalising the agreement.

The new partnership strengthens Matrix’s presence across south-east Asia and expands its global network, according to Begley.

“Malaysia is a key market for Matrix, and this partnership reflects our commitment to delivering innovative composite solutions to operators in the region,” he said.

It also marks another milestone in Matrix’s strategy to expand its global reach through strong regional partnerships, enabling localised support and faster delivery of advanced composite technologies.

“We are excited to work with Tredwell to support customers in achieving operational excellence.”

Page 2 of 15

Copyright © 2026 Offshore Network