Plexus Holdings PLC, an AIM quoted oil and gas engineering service business, has announced a rental contract award for Exact Adjustable Wellhead and Centric Mudline Suspension Equipment with Neptune Energy UK.

The contract is for Adjustable Surface Wellhead equipment and Mudline Tooling to allow for the permanent abandonment of a UK North Sea well, with operations planned to commence during Q2 2024.

Plexus’ CEO, Ben Van Bilderbeek, commented, “The number of wells that must be permanently plugged and abandoned is fast growing, particularly in mature offshore locations such as the North Sea. We are therefore delighted that Plexus’ reputation is strengthening within this sector, and that our range of customers is broadening.

“Furthermore this contract continues our progress back into Adjustable Wellhead and Mudline equipment market as an expert in this field and ‘go-to’ company for this type of equipment.”

The contract is valued in excess of £175,000 and is an example of the growing rental wellhead market for jackup rigs engaged in plug and abandonment operations.

Aberdeen-based industrial data and engineering consultancy, Imrandd, has reported its most significant six-month growth period.

Aberdeen-based industrial data and engineering consultancy, Imrandd, has reported its most significant six-month growth period.

The firm has secured a record UK£2mn in topsides asset integrity awards with new and existing clients, amplifying its agile data-driven intelligence services further across the UK.

The firm has won 11 contracts indicating a 27% increase in revenue in Q3 of 2023 compared to the same period last year. As a result, 13 data scientists and multi-discipline engineers have been recruited, ramping up its headcount to 63.

Established in 2015, the company specialises in industrial data solutions helping clients in energy and other sectors to make fast and efficient business decisions in line with commercial and ESG strategies.

The new North Sea campaigns include extracting data from six of Ithaca Energy’s offshore installations, a one-year integrity management contract extension with long-term client Dana Petroleum; a 12-month pipework/ vessel risk-based assessment, and technical integrity scope for Harbour Energy; plus assessing the integrity of the Excalibur Floating Production Storage and Offloading facility for first-time client Ping UK, using Imrandd’s unique data gathering and analysis capability in collaboration with digital asset management specialist, GDi Ltd.

Imrandd founder and CEO Innes Auchterlonie, said, “This record period of growth demonstrates the competitive edge our data solutions and expert engineering guidance is delivering. Particularly where there are facilities operating beyond their original life span, companies are seeking fast, optimal answers to harness their assets’ performance safely and sustainably.

“R&D remains core to our strategy, and we continually reinvest 20% of our efforts into evolving the next generation of our propriety AI and digital software services to help our clients stay ahead of the curve. This has ensured we are well positioned to leverage our expertise to safeguard the effectiveness of our clients offshore and onshore assets as they navigate the energy transition.”

A range of Imrandd’s suite of digital solutions will be utilised across the new campaigns. These include EXTRACT, which digitises legacy asset information and EXACT, which maps and predicts engineering, inspection and maintenance activities to deliver actionable insights which have proven to reduce Opex costs.

Amplus Energy, a provider of economically-viable global field development solutions, has marked its entry into carbon capture with a significant investment into Carbon Circle AS of Norway and support the establishment of Carbon Circle UK in Aberdeen, UK.

Amplus Energy General Manager, Steve Gardyne, will lead Carbon Circle UK, supported by a team of carbon capture specialists from Norway. Further senior Carbon Circle UK personnel are currently being recruited.

The company has made the multi-million-pound investment in light of the emerging carbon capture market in the UK and how this is impacting the UK Government’s net-zero ambitions. Carbon Circle UK is currently working on front end engineering and design (FEED) studies for the decarbonisation of two major industrial sites in the UK. These projects will have a positive impact on the UK Government’s net zero ambitions.

Amplus Managing Director, Ian Herd, remarked, “We are excited by this opportunity to participate within the Energy Transition in the UK through bringing our client focused, innovative approach to project delivery coupled with the ‘best-in-class’ domain knowledge and significant EPC experience already assembled within Carbon Circle. The creation of Carbon Circle UK brings a new, innovative Carbon Capture EPC partner into a UK market with huge potential.”

Aslak Hjelde, CEO of Carbon Circle, added, “We are excited by our partnership with Amplus Energy, a collaboration set to enhance the growth and innovation of the carbon capture sector in the UK. The UK Government’s significant commitment of UK£20bn to Carbon Capture and Storage is a testament to the strategic importance of CCS technologies in achieving national net-zero ambitions. With the support and expertise of Amplus Energy, Carbon Circle is ready to be a major contributor in the UK’s carbon capture sector."

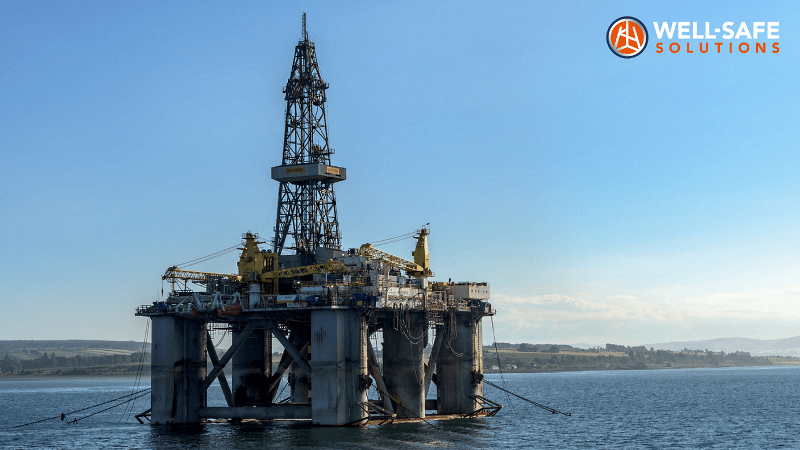

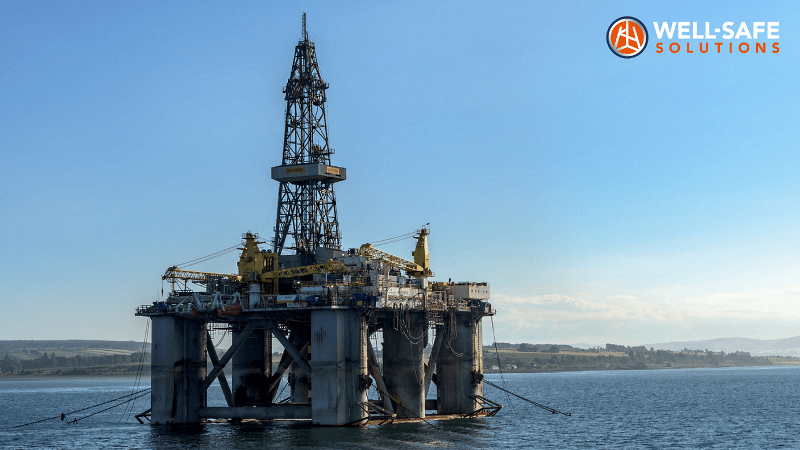

Well decommissioning specialist, Well-Safe Solutions, has signed an agreement with Spirit Energy to add a well from the Appleton field to the existing scope of the Well-Safe Defender rig.

Well decommissioning specialist, Well-Safe Solutions, has signed an agreement with Spirit Energy to add a well from the Appleton field to the existing scope of the Well-Safe Defender rig.

This project will add approximately one month of work to the Well-Safe Defender, which mobilised in March 2023 to plug and abandon 14 wells on the UK continental shelf for Spirit Energy.

Chris Hay, Director of Strategy and Commercial at Well-Safe Solutions, said, “From the earliest days of Well-Safe Solutions over six years ago, we have fostered collaborative working throughout the industry to realise safe, smart and efficient well decommissioning operations.

“Spirit Energy’s decision to grant Well-Safe Solutions this contract extension is an endorsement of the excellent performance of the Well-Safe Defender and its crew. We are proud to continue our relationship with Spirit Energy and look forward to continuing our world-class decommissioning operations later this year.”

Head of Wells for Spirit Energy, Nicky Riley, commented, “Well-Safe’s continued strong performance has allowed us to collaborate further with the team - accelerating the decommissioning of the Appleton well, aligning us further with our strategic pillar of meeting and de-risking our decommissioning operations.”

Unity, Europe’s largest provider of well integrity solutions, has launched a new Wellhead Integrity Verification Programme for operators and integrated service providers who are beginning to plan their well abandonment operations.

Unity, Europe’s largest provider of well integrity solutions, has launched a new Wellhead Integrity Verification Programme for operators and integrated service providers who are beginning to plan their well abandonment operations.

The programme contains a package of technical support, products and innovative technologies to deliver an inspection, maintenance, repair and assurance service to verify that the wellhead and Xmas Tree equipment is in good condition and fully prepared for operations.

The integrity verification provides a complete check of the Xmas Tree, wellhead and near-surface well equipment and delivers value by reducing risk, cost, downtime and man hours while improving safety and efficiency. It aligns with the industry’s preparatory ‘Phase 0’ stage of plug and abandonment and is a critical stage intended to prevent the significant costs associated with unplanned downtime due to equipment failure after rig-based operations have commenced.

Unity’s Technical Sales Director, Stuart Slater, commented, “Working closely with operators over the life of their wells and through the decommissioning process, we have seen an escalating need for good integrity planning before embarking on P&A operations. Already attracting a high cost burden, operators are looking to mitigate additional risk, expense and downtime caused by unexpected surface equipment failures.

“Awareness among our clients of the need to include a full wellhead integrity review in their pre-abandonment planning is increasing and we are ideally placed to work in partnership with the wider industry to deliver this specialist service.”

Plexus, an oil and gas engineering services business which is focused on establishing its patented leak-proof POS-GRIP wellhead and associated equipment, has been awarded a contract for Exact and Centric equipment for a North Sea plug and abandonment (P&A) project.

The company is securing a reputation for its safety, time and cost saving capabilities and is an exclusive licensee to SLB for its range of EXACT Adjustable Wellhead and CENTRIC Mudline systems. The new contact for a leading North Sea operation has been secured through SLB, with the work taking place in Q4 2023.

It will utilise EXACT and CENTRIC equipment and will generate equipment rental revenues in the region of UK£100,000 for Plexus. The collaborative project has been described as a ‘milestone’ by the company, building on the ongoing relationship between the two company. The company also hopes it will firm its reputation in the field of adjustable wellhead and mudline technology.

“Our continued growth into the expanding P&A market is highly encouraging particularly as this project utilises the EXACT and CENTRIC technology specifically designed to provide the safest and quickest tieback and drilling solutions for not only these types of P&A wells, but also exploration and appraisal wells,” commented Plexus' CEO Ben Van Bilderbeek.

"The contract is also an excellent example of the continued collaboration between SLB and Plexus where we believe that SLB recognises Plexus capabilities in Adjustable Wellhead and Mudline projects. We are confident that further opportunities for similar work will arise in the future."

Petroac, a leading energy services company, has celebrated the awarding of a significant deal with Saipem to support the decommissioning of a platform offshore the United Kingdom.

Under the terms of the multi-million-pound contract, the companies will work as an integrated team to remove the 20,000 tonne topside using the Saipem 7000, a large semi-submersible heavy lifting vessel.

Nick Shorten, COO of Petrofac’s Asset Solutions business, remarked, “As our sector pursues cleaner sources of energy, decommissioning is a key enabler for the transition. Supporting Saipem and their customer, we look forward to leveraging our knowledge of North Sea operations and service provision, and 20 years of decommissioning experience to deliver a safe and predictable programme that can serve as a case study for the North Sea’s transition.”

Petrofac will execute the three-year project over two phases. The first will include preparations onboard the platform, the second will be on the Sapiem 7000 for the removal campaign. The scope of Petrofac’s contract includes the module separation, lift point inspection, lift point installation, riser and caisson severing.

Well-Safe Solutions has appointed Alexa Duncan as the company’s first Energy Transition Manager as it looks to add carbon capture and storage (CCUS) and geothermal project capabilities to its offering.

Well-Safe Solutions has appointed Alexa Duncan as the company’s first Energy Transition Manager as it looks to add carbon capture and storage (CCUS) and geothermal project capabilities to its offering.

Duncan has more than a decade and a half of experience under her belt in project management and well engineering for international operators, and will play a pivotal role in the delivery of these energy transition business streams.

Duncan said, “Well-Safe Solutions is at the forefront of the well plug and abandonment industry and working closely with clients to reduce their carbon footprint. With the North Sea Transition Authority (NSTA) estimating CO2 storage capacity of 78 billion tonnes on the UK continental shelf alone, there is a clear opportunity for Well-Safe Solutions to apply its considerable expertise when assisting our clients on the journey to net zero carbon emission.

“In addition, extensive growth is also predicted within the geothermal market. I’m passionate about the energy transition and very much looking forward to collaborating with our highly experienced well engineering and subsurface teams on upcoming projects internationally.”

James Richards, Well Abandonment Director at Well-Safe Solutions, added, “Recruiting a professional of Alexa’s calibre to our team is a clear endorsement of our ambition n in this sector. Our own market research and client feedback indicates an opportunity for us to apply the lessons and collaborative working practices we deliver in well plug and abandonment to these fields.”

The long-serving Northern Producer FPSO, which has spent the last fifteen years at EnQuest’s Dons field in the North Sea, has arrived at Kishorn Port in Scotland for decommissioning.

As per an announcement made on social media, the FPSO has been welcomed at Kishorn Port where preparations are beginning for the decommissioning, recycling and possible re-use of the 12,500 Gt vessel.

Kishorn Port Ltd. thanked the teams of KPL, Ferguson Transport & Shipping, the shore-based marine services team, Green Marine, Jifmar Scotland, Shearwater Marine Services, Ross-shire Diving Services, Chisholm's Recovery Specialists, Interocean Marine Services and its client Northern Offshore Ltd.

The company expressed its delight at landing the contract and finally receiving the vessel for end-of-life operations. It stated that it believes it will be the first time work of this nature has been carried out in a dry dock, with a semi-submersible FPV, as well as being a first for KPL and Kishorn Port under the EU recycling license.

The future decommissioning, demolition and recycling of the Northern Producer will be carried out by lead contractor Liberty Industrial working with KPL and its partners.

Following its arrival, the dock gates would be going back in and sealed before the dock is pumped dry. Survey work will follow once high and dry and necessary steps in its EU Licensing process will follow, working closely with SEPA, HSE the asset owner.

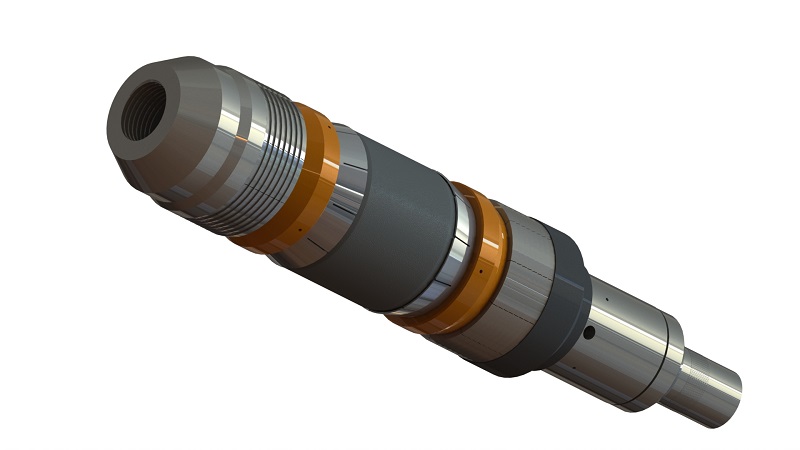

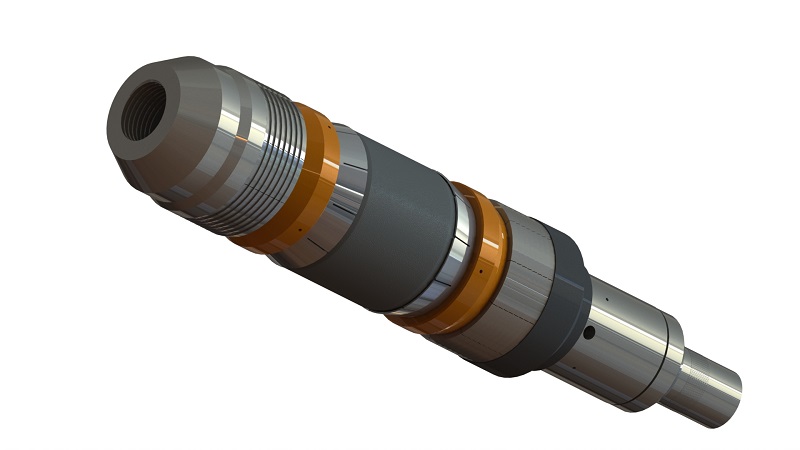

The CX-2 bridge plug, a solid and tested base for cement plugs designers to deliver enhanced efficiency and reliability, has been successfully deployed for the 1,000th time by Coretrax, a global leader in oil and gas well integrity and production optimisation.

The milestone was achieved for a project in the North Sea, with Coretrax revealing the CX-2 has now been deployed for more than 40 customers across 12 regions since its initial launch in 2012.

The CX-2 permanent cast iron bridge plug is constructed of drillable materials and features a built-in setting mechanism. It is set with both hydraulic pressure and mechanical pull and has an innovative release system, with a slim outer diameter (OD), a large inner diameter (ID). This allows cementing operations to be completed as part of the one trip system whilst minimising cement disturbance, ultimately eliminating the need for a dedicated cementing trip and further reducing rig time.

According to Coretrax, the solution has saved an average of three hours per run and so far delivered 3,000 hours of rig time savings for operators.

John Fraser, Coretrax CEO, remarked, “Coretrax has a long history and proven track record in the UKCS, so it is fitting that we achieved this milestone deployment in the North Sea. Our CX-2 bridge plug is a staple in our portfolio and has built an unrivalled reputation for delivering cost and time efficiencies in P&A operations.

“As the decommissioning sector continues to ramp up, our innovative technology combined with our experienced personnel allows us to remain at the forefront of well abandonment and able to tackle to most complex well challenges, while delivering greater efficiencies.”

Well-Safe Solutions, a well plug and abandonment specialist, has strengthened its commercial team by hiring Paul Simpson as Business Development Manager in a bid to continue its international growth strategy.

Simpson has more than 25 years’ experience in global well intervention management and business development, including time spent as part of a multi-skilled well abandonment team tasked with delivering the safe abandonment of bp’s North West Hutton project in the North Sea.

Simpson remarked, “I’ve watched with interest the continuing growth of Well-Safe Solutions over the past few years, with the creation of Well-Safe Solutions and the Well-Safe Resources service line underlining the company’s continued expansion this year.

“Throughout my career, I’ve prided myself on successfully integrating service lines to boost efficiency and answer specific challenges facing clients, building mutually-beneficial relationships in the process.

clients, building mutually-beneficial relationships in the process.

“I’m looking forward to contributing to the company’s continued growth as we target clients across the land and offshore well decommissioning markets in a number of geographies worldwide.”

Chris Hay, Director of Strategy and Commercial, commented, “I’m delighted to welcome someone of Paul’s calibre to Well-Safe. Paul’s arrival comes at an exciting time for the business, as we continue the implementation of our international growth strategy as well as strengthening our position in the North Sea market.

“Building on his considerable experience and skills in client management, Paul will work closely with our customer base to identify new opportunities and develop solutions for safe and efficient well decommissioning.”

Getech, a world-leading locator of subsurface resources, has completed a geothermal study for Angus Energy, outlining significant potential in a UK development.

Getech, a world-leading locator of subsurface resources, has completed a geothermal study for Angus Energy, outlining significant potential in a UK development.

Angus Energy is committed to utilising its oil and gas drilling and engineering expertise to develop geothermal energy projects. To achieve this, the company enlisted Getech’s subsurface proficiency to locate and access promising areas for geothermal energy production in southwest England.

Getech delivered an in-depth geoscientific interpretation that included structural mapping, depth estimation and heat flow analysis. The assessment enables Angus Energy to make informed decisions regarding future development projects.

Richard Bennet, Acting Ceo AT Getech, said, “Given the drive for new was to decarbonise operations and provide consistent heat and power, investment in alternative energy sources such as geothermal is ramping up. Getech’s subsurface and geoscience expertise is helping Angus Energy take an important step toward developing sustainable energy solutions that bolster the UK’s energy security and advance decarbonisation efforts.”

Richard Herbert, CEO of Angus Energy, commented, “We are pleased to have made good progress in bringing some of our traditional skills and focus on subsurface assessment out of the world of hydrocarbons into that of alternative energies. We are grateful to Getech for their professionalism which will assist in de-risking future geothermal drilling programmes by all players in this developing sector.”

Page 10 of 31

Copyright © 2025 Offshore Network