As part of sustainability-driven initiatives to expand domestic energy production in the US Gulf of America, bp has started up the Argos Southwest Extension project.

As part of sustainability-driven initiatives to expand domestic energy production in the US Gulf of America, bp has started up the Argos Southwest Extension project.

This development is the first of a decade-long initiative by the oil major.

The project will generate an additional 20,000 barrels of oil equivalent per day of gross peak annualised average production at the existing Argos platform. Argos, which began production in 2023, is bp’s fifth operated production platform in the Gulf of America with a gross production capacity of up to 140,000 barrels of oil per day.

“The Argos expansion underpins our commitment to investing in America, growing our US offshore energy production safely and efficiently,” said Andy Krieger, bp’s senior vice president for the Gulf of America and Canada. “This project also kicks off a period of significant growth for bp in the Gulf of America, which will continue to play a critical role in delivering secure and reliable energy the world needs today and tomorrow.”

The Argos Southwest Extension project will add three wells and include a new drill center roughly 5 miles southwest of Argos. The subsea tieback, which connects new wells to existing offshore production facilities through pipelines, will extend the footprint of the Mad Dog field discovered in 1998.

The Argos Southwest Extension project was delivered seven months ahead of schedule by implementing concurrent workstreams, optimising project management and engaging in early procurement.

“Argos’ expansion project demonstrates how bp can swiftly bring new barrels to market safely and efficiently,” said Gordon Birrell, bp’s executive vice president of production and operations. “Our ability to move from resource discovery to first oil at record pace underscores our relentless pursuit to grow shareholder value.”

Following Argos Southwest Extension, bp plans to deliver two additional expansion projects in the Gulf of America by 2027.

Oceaneering International has announced its Subsea Robotics segment has upgraded the Ocean Intervention II (OI2), an oceanographic research vessel, in order to perform simultaneous autonomous survey operations.

Oceaneering International has announced its Subsea Robotics segment has upgraded the Ocean Intervention II (OI2), an oceanographic research vessel, in order to perform simultaneous autonomous survey operations.

The purpose-built OI2 was first launched in 2000 to carry out geophysical and geotechnical surveys. Earlier this year the vessel underwent significant upgrades to expand its capabilities and improve performance for modern survey demands.

Peter Buchanan, Senior Director of Survey, Products and Services, Subsea Robotics, Oceaneering, said, “The Ocean Intervention II provides a step change in survey data acquisition productivity with the ability to simultaneously collect AUV, towed geophysical and geotechnical data. We’re excited to offer this enhanced capability to our clients.”

Some of the enhancements included:

With its enhanced configuration, the OI2 transitions between AUV and towed geophysical surveys, and geotechnical sampling, supporting efficient multi-discipline campaigns.

When paired with Oceaneering’s remotely operated USV capabilities and global Onshore Remote Operations Centers, the OI2 becomes a key enabler of fully integrated, low-risk offshore surveys. The next-gen survey approach supports faster data acquisitions, improved decision-making and increased efficiency thro8ugh simultaneous operations.

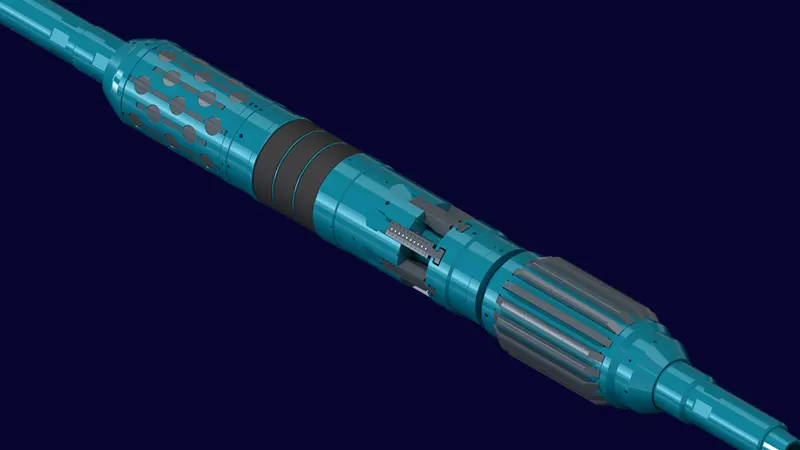

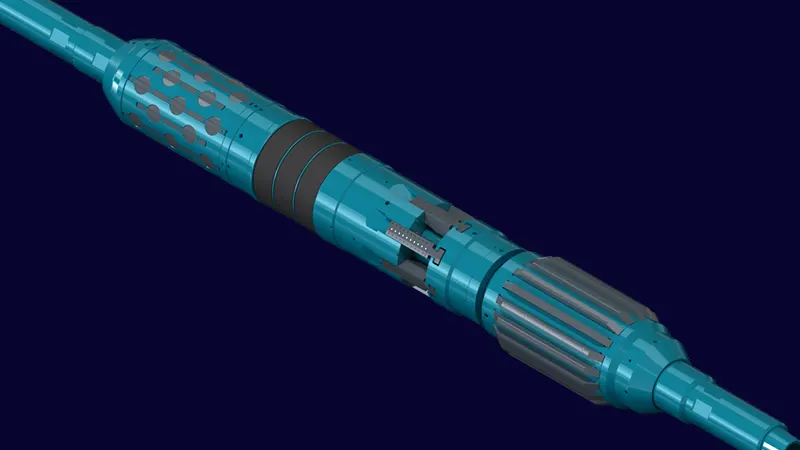

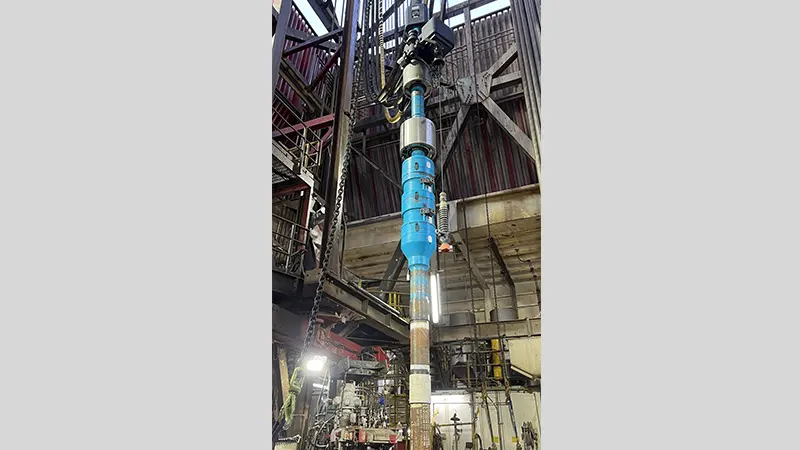

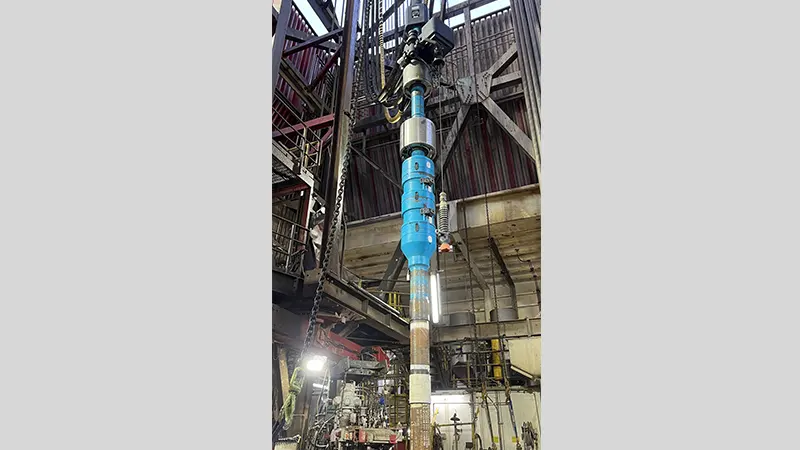

Expro has launched its most advanced BRUTE High-Pressure, High Tensile Packer System to date.

Expro has launched its most advanced BRUTE High-Pressure, High Tensile Packer System to date.

This new system is built to perform in extreme deepwater well conditions, handling the highest differential pressures in the industry. It allows operators to set higher in the wellbore, helping save rig time, reduce operational risks, and meet regulatory requirements more easily.

A key part of this launch is the BRUTE Armor Packer, a major step forward in Expro’s BRUTE range. This system offers unmatched strength and flexibility, with the ability to fully support 20k deepwater projects. When paired with the BRUTE 2 Storm Valve, it forms the most highly rated Storm/Service Packer and Valve combo available in the market, according to the company.

This latest technology was first used in a high-spec 20k deepwater project in the Gulf of America for a major energy company. In April 2025, Expro successfully deployed the 12.25” BRUTE Armor Packer System rated to 12,850 psid. The test confirmed the system's ability to handle extreme downhole pressures, proving its reliability in demanding offshore settings.

Following this success, Expro also introduced a new 20”/22” BRUTE Packer System. This tool was designed to overcome previous challenges faced by retrievable mechanical packers in large casing sizes. Traditional systems often struggle with tight internal diameters in subsea wellhead housings and casing adapters. Expro’s new packer offers double the expansion of standard systems, improving casing isolation for testing, suspension, and squeeze operations—without limiting performance.

In June 2025, the new 20”/22” packer was successfully used in a major offshore campaign in the Gulf of America. It passed through tight wellhead areas and expanded fully in a larger ID section below. The system achieved pressure integrity on the first try, confirming its ability to reduce rig time and risk while improving efficiency.

Jeremy Angelle, Vice President of Well Construction at Expro, said,“This launch sets a new standard for deepwater packers. The BRUTE system offers top-level pressure and tensile performance with unmatched adaptability. It proves Expro is leading the way in supporting the future of 20k offshore developments. We're not just meeting the industry's toughest standards – we're defining them.”

The Department of the Interior has updated its guidelines for states applying to federal programmes specialising in the cleanup of orphaned oil and gas wells.

The Department of the Interior has updated its guidelines for states applying to federal programmes specialising in the cleanup of orphaned oil and gas wells.

The revised guidelines mean two federal grant programmes have been updated: the US£780mn Orphaned Wells State Matching Grant Program and the US$1.93 billion Orphaned Wells State Formula Grant Program.

The revisions eliminate non-statutory requirements and reduces the burdens placed on state grant recipients, including removing the requirement that states conduct pre- and post-plugging methane measurements; recognizing the discretion states have in identifying and plugging orphaned wells; and eliminating the Department’s post-award environmental review and approval process.

Acting Assistant Secretary of Policy, Management and Budget, Tyler Hassen, said, “States know their land and their needs best. By cutting unnecessary barriers, we’re helping them clean up old wells faster, protect communities and support energy development.”

Eva Vrana, Deputy Assistant Secretary for Policy and Environmental Management, commented, “These changes make it easier for states to get to work. States can move more quickly to plug wells and reduce environmental risks.”

The updated guidance supports the Trump’s administration initiatives to prioritise the USA’s energy independence and cut regulations. By giving the states more flexibility and speeding up plugging efforts, DOI is helping to achieve this goal.

The coiled tubing market is experiencing significant momentum, particularly in North America, due to increased offshore well intervention activities.

A recent report by Allied Market Research titled "Coiled Tubing Market" reveals that the global market was valued at US$3.0 billion in 2020 and is expected to grow to US$4.7 billion by 2030, registering a CAGR of 4.5% during the forecast period from 2021 to 2030.

Coiled tubing—long, continuous steel or composite tubing used in oil and gas operations—has become a key tool for offshore interventions. It offers flexibility, rapid deployment, and minimal surface footprint, making it ideal for offshore applications such as cleanouts, acidizing, fracturing, and stimulation. As operators seek to optimize well performance and prolong the life of maturing offshore assets, coiled tubing has emerged as a cost-effective solution for maintaining and enhancing productivity.

In North America, the presence of substantial offshore resources and a mature oil and gas industry has positioned the region as a dominant player in the coiled tubing market. The U.S. leads in offshore well intervention, supported by continued investment in deepwater and ultra-deepwater drilling. The integration of advanced coiled tubing technologies—such as real-time data monitoring, improved corrosion resistance, and enhanced injectors—has further strengthened its application in complex offshore environments.

Well intervention remains the largest service segment in the market, accounting for a significant share due to its widespread use in maintaining offshore production. Despite the advantages, offshore coiled tubing operations are challenged by high operational costs and equipment wear, especially in high-pressure, high-temperature wells.

However, these challenges are being addressed through technological innovation and automation. Leading oilfield service providers such as Halliburton, Schlumberger, Baker Hughes, and Weatherford are investing in research and development to improve equipment durability and operational efficiency.

With the increase in unconventional and offshore drilling projects, the North American coiled tubing market is poised for continued growth. The demand for safe, reliable, and sustainable well intervention services is expected to rise, reinforcing coiled tubing’s role in the future of offshore oil and gas operations.

The coiled tubing market is experiencing significant momentum, particularly in North America, due to increased offshore well intervention activities.

A recent report by Allied Market Research titled "Coiled Tubing Market" reveals that the global market was valued at $3.0 billion in 2020 and is expected to grow to $4.7 billion by 2030, registering a CAGR of 4.5% during the forecast period from 2021 to 2030.

Coiled tubing—long, continuous steel or composite tubing used in oil and gas operations—has become a key tool for offshore interventions. It offers flexibility, rapid deployment, and minimal surface footprint, making it ideal for offshore applications such as cleanouts, acidizing, fracturing, and stimulation. As operators seek to optimize well performance and prolong the life of maturing offshore assets, coiled tubing has emerged as a cost-effective solution for maintaining and enhancing productivity.

In North America, the presence of substantial offshore resources and a mature oil and gas industry has positioned the region as a dominant player in the coiled tubing market. The U.S. leads in offshore well intervention, supported by continued investment in deepwater and ultra-deepwater drilling. The integration of advanced coiled tubing technologies—such as real-time data monitoring, improved corrosion resistance, and enhanced injectors—has further strengthened its application in complex offshore environments.

Well intervention remains the largest service segment in the market, accounting for a significant share due to its widespread use in maintaining offshore production. Despite the advantages, offshore coiled tubing operations are challenged by high operational costs and equipment wear, especially in high-pressure, high-temperature wells.

However, these challenges are being addressed through technological innovation and automation. Leading oilfield service providers such as Halliburton, Schlumberger, Baker Hughes, and Weatherford are investing in research and development to improve equipment durability and operational efficiency.

With the increase in unconventional and offshore drilling projects, the North American coiled tubing market is poised for continued growth. The demand for safe, reliable, and sustainable well intervention services is expected to rise, reinforcing coiled tubing’s role in the future of offshore oil and gas operations.

To read more about the report or explore insights from other regions, visit: www.world.einnews.com

Helix Energy Solutions has announced a new plug and abandonment agreement with ExxonMobil in the Gulf of America.

Helix Energy Solutions has announced a new plug and abandonment agreement with ExxonMobil in the Gulf of America.

The operator’s Louisiana-based shallow water abandonment group, Helix Alliance, has secured a three-year framework agreement for P&A services within the region.

Owen Kratz, President and Chief Executive Officer of Helix, said, “This agreement underscores our commitment to delivering high-value, fit-for-purpose decommissioning services. This agreement also demonstrates Helix Alliance’s position as a trusted partner for comprehensive offshore solutions, providing well intervention, diving, heavy lift, and marine support services on the US Gulf of America shelf.”

The Woodside Energy-operated Trion deepwater oil and gas development offshore Mexico will receive tubular running services (TRS) and cementing services from Expro to build the greenfield project

The Woodside Energy-operated Trion deepwater oil and gas development offshore Mexico will receive tubular running services (TRS) and cementing services from Expro to build the greenfield project

Before the project is ready for its first targeted oil in 2026, the three-year contract involves the deployment of Expro's well construction technologies, which are designed to deliver effective problem-solving from top drive to target depth. The comprehensive suite of services will involve TRS casing, drilling and completions, casing accessories, cement heads, and Expro's Skyhook system.

Set to be Mexico's first deepwater oil production facility, the Trion greenfield project will be supported by Expro to achieve maximum well performance optimisation alongside technical execution. Its approach will be backed by practices driving cost-effectiveness and operational reliability throughout the project lifestyle.

Woodside and Expro go back a long way, with the latest partnership seeing the establishment of a new Expro hub in the region as Woodside manage operations from its Tampico shore base and office. This will also generate local employment and economic upliftment.

Jeremy Angelle, Vice President of Well Construction said, “With our extensive track record and a reputation as a trusted provider of TRS solutions, we are proud to play a key role in this world-class development. This contract win reflects not only the strength of our technical capabilities and commercial offering but also our legacy of supporting Trion exploration wells through Frank’s TRS and VERSAFLO TM systems.

"This project represents an exciting opportunity to showcase our innovative technologies on a historic deepwater development, and we look forward to building a strong, long-term partnership with Woodside in Mexico.”

The Trion field is situated in the Perdido Fold Belt, approximately 180 km off Mexico’s coastline in the Gulf of Mexico, in water depths of around 2,500 meters.

Click here to register for Offshore Network's international well intervention and decommissioning conferences.

![]() Beacon Offshore Energy's Shenandoah floating production system in the Gulf of America is being served by Danos Operations Services via a contract signed by the partners.

Beacon Offshore Energy's Shenandoah floating production system in the Gulf of America is being served by Danos Operations Services via a contract signed by the partners.

The production services contract will be delivered by a team of production operators, instrumentation and electrical technicians, mechanics, and offshore installation managers. Several employees began work on the platform in 2024.

“We are honoured to support Beacon Offshore Energy with production services,” said CEO Paul Danos. “Danos is a people-focused company, and we’re proud to introduce our new partner to the high-performing employees and strong customer service that define our team.”

In the final stages of hook-up with production expected later this summer, the Shenandoah facility boasts of a nameplate capacity of 120,000 barrels of oil per day. Located approximately 230 miles from New Orleans, the project represents a major investment in the future of US offshore production.

Founded in 1947, Danos started out as a small tugboat company, gradually expanding its services with the evolving offshore industry, now employing about 1,300 production services personnel in the Gulf of America. Its comprehensive suite of services include production, supply chain and energy systems. It delivers fabrication, construction, coatings and other project services as well.

Click here, to register for Offshore Network's international well intervention and decommissioning conferences.

CAM Integrated Solutions has announced its official entry into the offshore decommissioning market, marking a significant milestone for the company as it continues to broaden its service offerings.

CAM Integrated Solutions has announced its official entry into the offshore decommissioning market, marking a significant milestone for the company as it continues to broaden its service offerings.

CAM’s new Decommissioning Division will provide clients with turnkey solutions that ensure the efficient and environmentally responsible retirement of end-of-life assets. By integrating decommissioning with its existing services, CAM is positioned to deliver great value to operators navigating end-of-life asset strategies offshore in the Gulf of Mexico.

To spearhead the new initiative, CAM has appointed Brady Barras as the Vice President of Decommissioning. With more than 31 years of experience in the offshore oil and gas industry, Barras will bring his wealth of expertise to decommissioning project through the Gulf and beyond.

Craig Pierrotti, CEO of CAM Integrated Solutions, said, “We are thrilled to be entering the decommissioning market, a natural next step in the evolution of CAM’s integrated service offering. Brady’s depth of knowledge, hands-n experience, and commitment to operational excellent make him the ideal person to lead this new endeavour. I am confident that with Brady at the helm, CAM will quickly establish itself as a trusted and forward-thinking partner in the decommissioning space.”

An upgrade to autonomous hydraulic fracturing technology, Chevron USA and Halliburton have jointly developed a new process that allows closed-loop, feedback-driven completions in Colorado

An upgrade to autonomous hydraulic fracturing technology, Chevron USA and Halliburton have jointly developed a new process that allows closed-loop, feedback-driven completions in Colorado

This intelligent fracturing process combines automated stage execution with subsurface feedback to optimise delivery of energy into the wellbore without relying on human intervention.

The new process ensures efficiency and consistency during fracture execution. To top that, these new technologies come with added control functionality. Backed by digital automation and real-time feedback from the subsurface, autonomous workflows adjust completion behaviour with the goal of improving asset performance.

A combination of technologies from the wellsite to the cloud is required to enable this new approach to intelligent completions. Halliburton’s ZEUS IQ intelligent fracturing platform, comprised of OCTIV auto frac and Sensori monitoring, provides the necessary closed feedback loop and control capability. Chevron’s hydraulic fracturing and subsurface knowledge is built into an algorithm to enable the advanced decision making.

“We drive innovation in the digital space,” said Shawn Stasiuk, Halliburton’s Vice President of Production Enhancement. “We built the digital environment down to the field level and enable our customers to test their best ideas.”

Chevron’s work in closed-loop automation changes the approach to hydraulic fracturing in shale and tight rock formations. Operations can now react to a localized environment through real-time adaptation rather than performance forecasting.

“At Chevron, we focus on continuously advancing asset performance safely through the innovation of our subject matter experts, new technology, and strategic collaborations. This real-time adaptive feedback loop is expected to further drive efficiencies and improve overall asset performance,” said Chevron’s Kim McHugh, Vice President of the Rockies Business Unit.

Click here, to register for Offshore Network's international well intervention and decommissioning conferences.

ExxonMobil has awarded EnerMech a contract to deliver a complete flowline decommissioning package for the Hoover Diana development in the Gulf of Mexico.

ExxonMobil has awarded EnerMech a contract to deliver a complete flowline decommissioning package for the Hoover Diana development in the Gulf of Mexico.

The scope includes decommissioning subsea flowlines, marking EnerMech’s first major decommissioning campaign in the region. An expert team integrating multiple service lines will be deployed from EnerMech’s Energy Solutions division to complete the full scope of work, including coiled tubing, pressure pumping, chemical services, filtration, separation and pipeline gauging.

In more detail, the scope includes flushing, pigging and filling subsea pipelines to safely remove hydrocarbons and prepare for decommissioning. This involves flushing the umbilical, pipeline flushing and seawater fill operations for the subsea flowline loop, as well as nitrogen flushing via subsea vessel, coiled tubing services and sweater filling for the Northern Diana flowline.

EnerMech CEO, Charles Davison Jr., said, “The Hoover-Diana project marks our first large-scale decommissioning engagement in the Gulf of Mexico, building on the strong relationship we’ve developed with ExxonMobil in Guyana since 2018.

“Securing this new contract following a competitive tender is a testament to our deep expertise, integrated capabilities, and the trust ExxonMobil continues to place in our team. Our early engagement has allowed us to develop a tailored methodology that maximizes efficiencies, minimizes risks, and ensures a safe, cost-effective execution.”

The Hoover and Diana fields have been a landmark offshore development for 25 years. This project will utilise the once pioneering floating production deep draft caisson vessel which gained prestige for being the deepest draft drilling and production system in the world.

Integrated decommissioning solutions, late-life asset management, and engineering services tailored for deepwater wells are among the key investment opportunities in the Gulf of America decommissioning market.

Integrated decommissioning solutions, late-life asset management, and engineering services tailored for deepwater wells are among the key investment opportunities in the Gulf of America decommissioning market.

That’s according to a new report from Verified Market Research, which highlights that joint ventures and strategic partnerships are on the increase, in response to high CapEx requirements given the average cost per well decommissioning of around US$1-5mn. The rise in offshore renewable energy projects also presents opportunities to repurpose infrastructure or convert platforms to artificial reefs.

However, risks include fluctuating oil prices affecting operator cash flows, particularly now with the Iran/Israel conflict sending oil prices spiralling, and an ever-changing US tariff regime impacting the oil market. Complex regulatory requirements and regulatory uncertainty, with the rolling back of some Biden-era legislation, can also pose a challenge, along with environmental liabilities. Legal challenges from improper decommissioning and long project timelines (often 12-36 months) pose further capital exposure. Due diligence on operator history, liability transfers, and local regulatory adherence is critical for financial stability and ROI predictability, the report advises.

Key trends include a shift toward sustainable decommissioning, cost optimisation strategies, and integration of robotics and ROVs (remotely operated vehicles) to enhance efficiency and safety. There is a growing focus on sustainability, spurred by both consumer pressure and regulatory requirements, with increased use of eco-friendly materials, implementation of energy-efficient processes, and introduction of waste reduction initiatives. Reflecting developments in the industry generally, the decommissioning market is embracing digital transformation, incorporating cutting-edge technologies such as AI, IoT, and blockchain, which is significantly enhancing operational efficiency and boosting innovation.

Stringent U.S. federal mandates on well abandonment and subsea asset removal are pushing operators to adopt ESG-aligned practices, the report finds. ESG frameworks now play a decisive role in decommissioning project bids and funding eligibility, with green decommissioning, carbon footprint reporting, and stakeholder transparency becoming market entry norms. Companies integrating ESG metrics into decommissioning lifecycle planning are positioned to attract sustainable capital flows and maintain a competitive edge in this evolving offshore energy transition market, the report suggests.

Page 4 of 23

Copyright © 2025 Offshore Network