Nigeria is increasingly looking towards developing its brownfield assets to boost production.

Nigeria is increasingly looking towards developing its brownfield assets to boost production.

This can be achieved with the right technological interventions, giving way to enhanced oil recovery that can substantially meet the region's refining capacity. Compared to greenfield projects that require considerable investments from scratch, brownfield developments cuts down on carbon footprints, thus allowing operators to meet their sustainability requirements. Ideal technological interventions comprise a package offering e-line, slick line, coiled tubing services, well remediation, well control, and idle well management services. Well intervention operations can range from well conversion, casing run operation on a wild cat well, slot recovery, installation of emergency casing head housing slip, well work-over, and drilling and completion, to name a few.

To facilitate more brownfield developments, the Nigerian administration is working to increase collaboration between the local communities, government and the private sector.

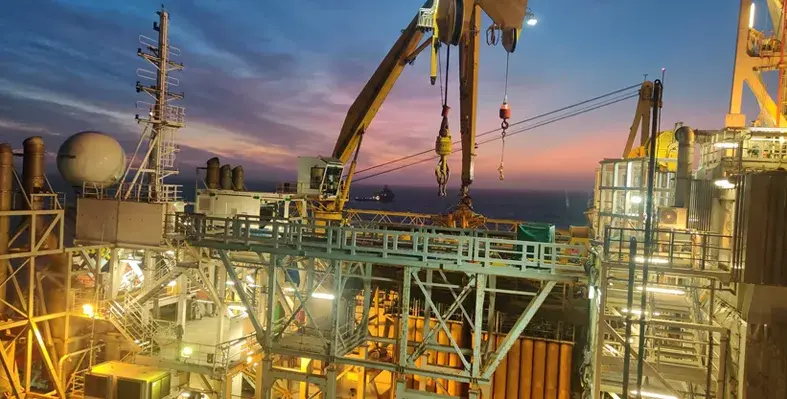

Recently, Nigeria-based offshore construction company called Intrepid Energy Limited joined hands with United Kingdom's Aquaterra Energy to deliver a bespoke subsea well intervention equipment package for a project in Nigeria.

“Working with Aquaterra Energy marks a significant step forward for our intervention operations in Nigeria. Their specialised technology enhances our ability to execute intervention programmes efficiently, maximising performance across our assets. By combining Aquaterra’s technical expertise with our deep understanding of the local operating environment, we’re confident this collaboration will enhance production outcomes and create lasting value for our operations in the region,” said Seun Alonge, CEO at Intrepid Energy Limited.

To know more about the well intervention scene in West Africa, click here.

Aquaterra Energy, a leading provider of offshore engineering solutions, has secured a multi-million-dollar, multi-year contract with Intrepid Energy Limited (IEL) to supply a tailored subsea well intervention equipment package for a project in Nigeria

Aquaterra Energy, a leading provider of offshore engineering solutions, has secured a multi-million-dollar, multi-year contract with Intrepid Energy Limited (IEL) to supply a tailored subsea well intervention equipment package for a project in Nigeria

The turnkey well access system will enable IEL to conduct intervention operations across multiple mature oil wells, enhancing reservoir production.

The contract covers a complete seabed-to-surface intervention package, including Aquaterra Energy’s TRT tieback tooling for production bore and annular access, a lightweight well pressure control system, and an ISO 13628-7 qualified open water intervention riser with an integrated tensioning system. In addition to supplying the equipment, Aquaterra Energy will provide ongoing offshore engineering support throughout the project.

Designed for deployment from jack-ups and lift boats, the 7-3/8” lightweight well access solution offers a cost-effective and operationally efficient alternative to floating vessels, reducing intervention costs while maintaining safety and performance standards.

Andrew McDowell, Delivery Director at Aquaterra Energy, stated, “Our expertise in offshore engineering allows us to develop tailored intervention solutions that address the operational challenges of subsea well access. This system has been engineered for efficiency, ease of deployment, and safety, helping IEL optimise intervention activities across Nigeria while reducing costs. By delivering a complete, integrated package, we are simplifying complex operations and enabling operators to maximise production potential.”

Engr Seun Alonge, CEO at Intrepid Energy Limited, added, “Working with Aquaterra Energy marks a significant step forward for our intervention operations in Nigeria. Their specialised technology enhances our ability to execute intervention programmes efficiently, maximising performance across our assets. By combining Aquaterra’s technical expertise with our deep understanding of the local operating environment, we’re confident this collaboration will enhance production outcomes and create lasting value for our operations in the region.”

The project is set to span multiple years, with Aquaterra Energy providing continuous technical support through a dedicated team of engineers.

George Morrison, CEO at Aquaterra Energy, commented, "Delivering reliable and efficient well access solutions for shallow water subsea operations is central to how we support offshore operators. This collaboration with IEL reinforces our commitment to providing cutting-edge engineering solutions that enhance efficiency and reduce operational costs. With West Africa playing an important role in the global energy sector, we’re proud to continue supporting its offshore industry with our expertise and innovative technologies.”

In a major realisation of its production and cost optimisation objectives, the Nigerian National Petroleum Company (NNPC), along with joint venture partner First Exploration & Petroleum Development Company (First E&P), has announced a significant hydrocarbon discovery in the Songhai field, located in OML 85 in the shallow offshore region of Bayelsa.

In a major realisation of its production and cost optimisation objectives, the Nigerian National Petroleum Company (NNPC), along with joint venture partner First Exploration & Petroleum Development Company (First E&P), has announced a significant hydrocarbon discovery in the Songhai field, located in OML 85 in the shallow offshore region of Bayelsa.

Spudded as part of efforts to increase and sustain the joint venture's oil production over the next five years, the well was drilled to a total depth of 8,883 feet measured depth (MD) in 30 metres of water. It encountered hydrocarbons across eight reservoirs, logging over 1,000 feet of hydrocarbon-bearing sands, most of which reveals promising reservoir properties. There has been an indication of substantial oil and gas volumes for commercial exploration. The derived well data will now be integrated for thorough research and analysis to calculate resource estimates and optimise field development plans.

"This discovery marks a major milestone in our efforts to unlock the full potential of our assets. The success at Songhai Field underscores the effectiveness of our exploration strategy and our commitment to delivering sustainable value to all stakeholders," said Segun Owolabi, General Manager, Exploration and Development at FIRST E&P.

"This aligns with NNPC Limited’s mandate to drive production growth and cost optimization. The success at Songhai Field reflects our commitment to strategic partnerships, advanced technology, and efficient operations to maximize Nigeria’s hydrocarbon potential sustainably," said Seyi Omotowa, Chief Upstream Investment Officer of NUIMS. "The discovery also highlights the role of strategic collaboration in expanding Nigeria’s hydrocarbon reserves," he added.

"This discovery reaffirms the potential of Nigeria’s offshore assets and the importance of collaboration in boosting reserves and production. NNPC Limited remains committed to driving efficiency and long-term value creation for the nation," said NNPC’s Group Chief Executive Officer, Mallam Mele Kyari.

Following 2024's extensive eight-well production drilling campaign in the Dussafu Marin permit offshore Gabon, operator BW Energy and partner Panoro Energy have managed to hit their production targets of 40,000 barrels of oil per day (bopd) in November 2024, and has remained consistent since.

Following 2024's extensive eight-well production drilling campaign in the Dussafu Marin permit offshore Gabon, operator BW Energy and partner Panoro Energy have managed to hit their production targets of 40,000 barrels of oil per day (bopd) in November 2024, and has remained consistent since.

This was made possible by a robust workover and electrical submersible pump replacement programme with the help of Borr Drilling's Norve jack-up rig. An effective artificial lifet method, ESPs help pump production fluids from low pressure situations. It is easy to maintain, and is considered a cost effective alternative to vertical turbine, split case and positive displacement pumps.

At approximately 37,153 bopd in the fourth quarter of 2024, the site crossed a milestone as it was the highest quarterly rate achieved since 2018, when the block first started producing.

The current production rate might jump by another 10%, given the scope for the FPSO nameplate capacity to reach beyond 40,000 bopd.

After the 2024 production campaign concluded in October, with the installation of a conventional electrical submersible pump (ESP) system for the DHIBM-7H well as it was brought online, the rest of the seven Hibiscus / Ruche production wells also underwent a workover and ESP replacement programme in January this year.

According to Panoro Energy's Chief Executive Officer, John Hamilton, the Dussafu drilling campaign was expanded to eight wells in order to accomodate first track development of the final two discoveries made in May 2024.

“Our current focus is on fully transitioning all the new wells to conventional ESP systems and restoring production at the three shut-in wells, after which we will drill the exciting Bourdon prospect in line with our infrastructure lead exploration and appraisal strategy aimed at unlocking the substantial organic upside that exists on the block,” said Hamilton, while speaking on the drilling campaign.

As part of its 2025-26 programme in Gabon, Borr Jack-Up XIV Inc will be deployed by Vaalco Energy for the drilling of multiple development wells and appraisal/exploration wells.

"We are excited about the major projects planned for 2025 that are expected to deliver a step-change in organic growth across our portfolio in the coming years. In Gabon, we continue to work with our joint owners at Etame on our shared goal of executing another successful drilling campaign designed to enhance production and add reserves. We have signed a contract with Borr that we believe allows us the flexibility to optimise our drilling and workover plans offshore Gabon.

“We anticipate the programme to begin in mid-2025 with the sequencing and exact number of wells yet to be finalised. We are planning on multiple wells in the Etame field, multiple wells at our SEENT platform and a redrill and several workovers in the Ebouri field to access production and reserves that were previously shut in and removed from proved reserves due to H2S. Over the past three years, we have delivered on our focused strategy and believe we will continue to do so with the organic growth programmes across our diversified portfolio over the coming years,” said George Maxwell, the Chief Executive Officer of Vaalco Energy.

To know more about Africa's well intervention scene, click here.

Baker Hughes has reached an agreement with the Nigerian National Petroleum Corporation (NNPC) and FIRST Exploration & Petroleum Development Company (FIRST E&P) joint venture (JV) to deploy its Leucipa automated field production solution on the JV’s offshore operations in the Niger Delta.

Baker Hughes has reached an agreement with the Nigerian National Petroleum Corporation (NNPC) and FIRST Exploration & Petroleum Development Company (FIRST E&P) joint venture (JV) to deploy its Leucipa automated field production solution on the JV’s offshore operations in the Niger Delta.

The deployment marks the inaugural adoption of the system in Sub-Saharan Africa. The JV will utilise Leucipa’s core workflows to optimise well performance and enhance efficiency by automating functions including performance analysis, opportunity management and scorecards management.

Real-time data will be provided by the technology which will offer more insightful optimisation opportunities across operations, resulting in enhanced decision-making in the field.

Amerino Gatti, Executive Vice President of Oilfield Services & Equipment at Baker Hughes, said, “Leucipa is enhancing the oilfield to be smarter and more efficient, enabling our customers to maximise the value to their assets. Our collaboration with the NNPC/FIRST E&P JV in implementing Leucipa will support the responsible development of energy resources needed in Sub-Saharan Africa for years to come.”

The automated field production solution assists oil and gas operators in proactively managing production and reducing carbon emissions. By focusing on specific outcomes, Leucipa utilises data to drive intelligent operations to minimise inefficiencies, ensure environmentally sound operations, and assist customers in recovering the millions of barrels that would otherwise remain untapped.

TechnipFMC was awarded a substantial contract by Shell Nigeria Exploration and Production Company Limited to supply Subsea 2.0 production systems for the Bonga North development in Nigeria.

TechnipFMC was awarded a substantial contract by Shell Nigeria Exploration and Production Company Limited to supply Subsea 2.0 production systems for the Bonga North development in Nigeria.

The contract covered the design and manufacture of subsea tree systems, manifolds, jumpers, controls, and services, marking a significant step in advancing deepwater technology in the region.

Jonathan Landes, President, Subsea at TechnipFMC, commented, “Shell was the first to adopt our Subsea 2.0® configure-to-order solution, and continues to deploy it across multiple basins—underscoring its commitment to the technology globally. This award further positions us for future deepwater opportunities in the region.”

For TechnipFMC, a “substantial” contract is between US$250 million and US$500 million. This award was included in inbound orders in the fourth quarter of 2024. The contract highlights TechnipFMC's growing footprint in the subsea market and its strategic partnership with Shell.

On January 15, 2025, Chevron has announced that it did not find commercial hydrocarbon reserves in its exploration well, Kapana 1X, located in Namibia’s Orange Basin within the PEL90 block.

On January 15, 2025, Chevron has announced that it did not find commercial hydrocarbon reserves in its exploration well, Kapana 1X, located in Namibia’s Orange Basin within the PEL90 block.

Despite the absence of viable reserves, the company emphasised that the well provided valuable geological data, enhancing its understanding of the basin. Chevron indicated that it plans to continue exploring Namibia in the future, as the country remains a key area of interest for oil producers.

Namibia has recently become a hotbed for offshore oil discoveries, with several large-scale finds making headlines as some of the biggest of the century. However, not all exploration efforts have been successful. Last week, Shell revealed a US$400 million write-down on an offshore discovery in Namibia, deeming it commercially unviable.

In a separate development, Namibia’s national oil company announced in April that it had entered into a deal with Chevron, granting the US company an 80% operating working interest in an offshore block in the Walvis Basin, marking a new phase in Chevron’s involvement in the country’s energy sector.

Shell Nigeria Exploration and Production Company Limited (SNEPCo), a subsidiary of Shell plc, has reached a final investment decision (FID) for the Bonga North deep-water project off Nigeria’s coast.

This subsea tie-back will connect to the Shell-operated Bonga Floating Production Storage and Offloading (FPSO) facility, where Shell holds a 55% interest.

The Bonga North project encompasses drilling and starting up 16 wells—split equally between production and water injection wells—alongside upgrades to the Bonga Main FPSO and new subsea hardware installations. The initiative aims to sustain production at the Bonga facility, with recoverable resources estimated at over 300 million barrels of oil equivalent (boe). Peak production is expected to reach 110,000 barrels of oil per day, with first oil anticipated by the decade's end.

Zoë Yujnovich, Shell’s Integrated Gas and Upstream Director, described the project as a significant investment contributing to stable liquids production and reinforcing Shell’s Upstream portfolio. Bonga North’s development aligns with Shell’s strategy to drive cash generation through its Integrated Gas and Upstream business into the next decade.

SNEPCo operates Bonga North in partnership with Esso Exploration and Production Nigeria Ltd. (20%), Nigerian Agip Exploration Ltd. (12.5%), and TotalEnergies Exploration and Production Nigeria Ltd. (12.5%), on behalf of the Nigerian National Petroleum Company Limited (NNPC). Situated in OML 118, Bonga is a deep-water field with production beginning in 2005. It achieved its one-billionth barrel milestone in 2023, and the FPSO has a production capacity of 225,000 barrels of oil daily.

Bonga North’s recoverable volumes exceed 300 million boe, classified as proven and probable (2P) under the Society of Petroleum Engineers’ standards. The project is also expected to surpass Shell’s hurdle rate for its Upstream business, leveraging near-field opportunities, technical expertise, and simplified, replicable operational models.

Halliburton, a leading provider of products and services to the energy industry, has announced that it will open new facilities in Namibia to support the country’s in-country operations.

The facilities are located across the country, representing a combined footprint of approximately 20,000 sq m. The Windhoek office will handle support services; a Walvis Bay site will focus on cementing and drilling fluids services and warehousing; Swakopmund will house sperry drilling, well completions, testing & subsea, and wirelines & perforating services; while Lüderitz will support cementing and wirelines operations.

Up to 200 Namibians are expected to be employed at the facilities, helping to foster local expertise in relevant technologies and contribute to the country’s economy.

“These new facilities allow us to operate close to our customers, collaborate in real time, and deliver the advanced technologies and services that maximise asset value,” remarked Antoine Berel, Vice President, Halliburton Sub-Saharan Africa (South). “We are proud to support Namibia’s oil and gas industry, contribute to the economic success of the country, and create opportunities for local people.”

Halliburton has indicated that the announcement is a demonstration of the importance of the country’s growing oil and gas sector, with the new facilities dedicated to supporting this growth while strengthening the company’s regional presence.

Island Drilling Company has announced the successful completion of its recent contract with Tullow Oil.

Island Drilling Company has announced the successful completion of its recent contract with Tullow Oil.

The operations, conducted in Mauritania over a period of three months, were carried out in water depths ranging from 208 meters to 1200 meters using dynamic positioning (DP) alone.

Throughout the project, all health, safety, and environmental (HSE) standards, and key performance indicators (KPIs) were achieved. The plug and abandonment (P&A) operations were completed within the planned timeframe and under budget, reflecting the efficiency and effectiveness of the collaboration.

The feat was achieved through the company's 'one team' approach by excellent cooperation between its offshore and onshore segments.

Oilenco Ltd, a leading provider of specialised well intervention solutions and services, has announced a series of promotions and new roles to its top team as it seeks to expand its global reach and begin the next phase of its journey.

One of the primary changes to the company’s structure will be the appointment of Blair McCombie to the position of Managing Director. Having joined the company as an operations director in 2017, McCombie has been instrumental to the growth of the organisation, its increase in revenue year-on-year, and the almost doubling of its workforce in the last two years. Now, McCombie is tasked with leading the company onto new horizons, and will oversee its overall performance and future direction.

In undertaking this sizeable task, Oilenco has ensured McCombie is well supported with a number of further key appointments. This includes the promotion of Davie Nicoll to the role of Buiness Director for Africa; the introduction of Graham Masson as Business Director for UK and Europe earlier this year; and the transition of Warren Ackroyd, Owner and previous Managing Director of the company, to the new job of Technical Director. Kim Ackroyd will continue her role as Finance Director, completing a formidable, experienced lineup that will focus on implementing strategies for regional growth and create a strategic focus on driving innovation.

“As well as expanding our global reach, one major component of growth is investment in developing our product portfolio through enhancing our existing products as well as new product development,” remarked Blair. “With Warren’s invaluable expertise and a dedicated team under his direction, we are able to listen to our clients, creating solutions that meet their needs, as well as the needs of the global well intervention and P&A industry.

"The knowledge, experience, and creativity of the Oilenco team is what sets us apart and allows us to provide reliable, high-quality solutions and services. Since starting with the company, I have seen a shift to a more service-led environment, where clients rely on a variety of services including design, manufacture, redress, refurbishment, product rental and training, all within Oilenco’s capabilities and areas we will continue to develop. As we celebrate 15 years this year and we kick-start our next chapter, I am delighted to become managing director, leading the company in the next phase of its journey.”

SLB, a global technology company, has announced the award of a contract by TotalEnergies to SLB OneSubsea, a joint venture between SLB, Aker Solutions and Subsea7. The project includes a 13-well subsea production system scope, including associated equipment and services, in the development of the Kaminho project, offshore Angola.

TotalEnergies will work with SLB OneSubsea to deliver a sustainable project that will improve production in Angola. During the Kaminho project’s first phase of development for the Cameia field, SLB OneSubsea will collaborate with TotalEnergies to deploy a highly configurable subsea production platform with standardised vertical monobore subsea tree, wellhead, and controls system.

“We are excited for this opportunity to unlock the large potential of the Kaminho project together with TotalEnergies,” commented Mads Hjelmeland, CEO of SLB OneSubsea. “Our collaborative contract model enables us to leverage both standardisation and highly configurable subsea production platforms, creating greater efficiencies and long-term value for this and future projects in Angola and around the world.”

The Kaminho project overall will involve more than 10 million man-hours in Angola, mainly with offshore operations and construction at local yards. SLB OneSubsea will play a significant role in supporting the Kaminho project locally in Angola for offshore operations including assembly, manufacturing of modules, installation, commissioning, and life-of-field services.

Page 3 of 9

Copyright © 2026 Offshore Network