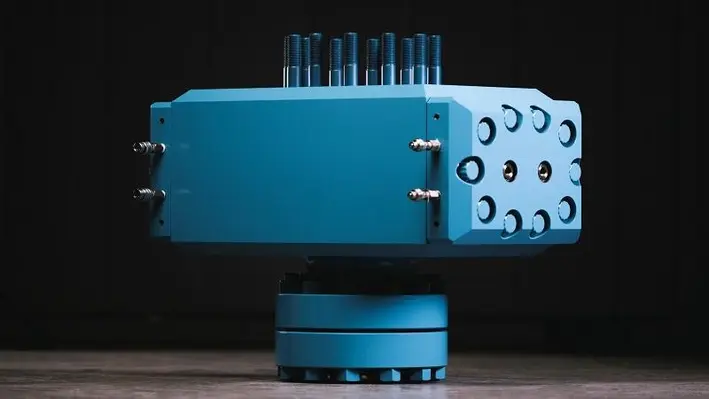

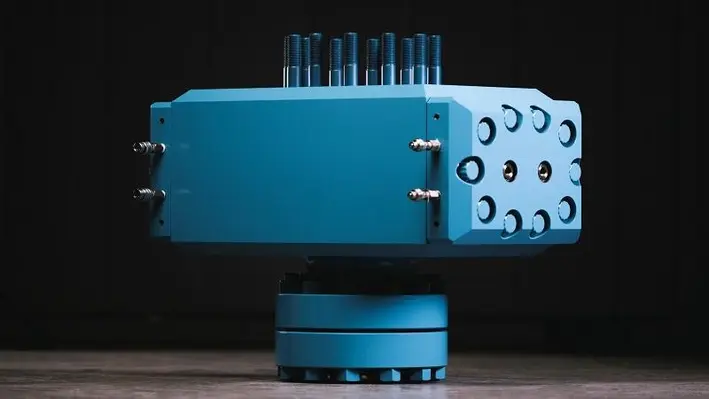

Welltec sees great prospects in the Middle East for its recently launched Welltec Expandable Anchor (WEA).

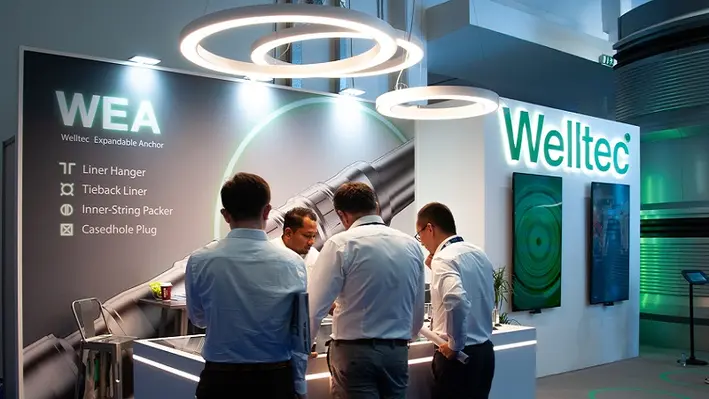

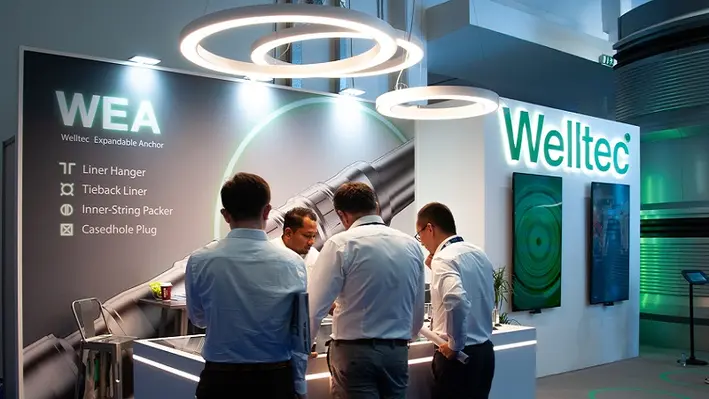

The Welltec Expandable Anchor (WEA) was a key focus at the company’s stand at ADIPEC 2023, where Completion, Intervention, and New Energy & Climate Technology solutions were showcased, all with optimisation and efficiency as core design principles.

Engineered and rigorously tested over the past couple of years, the WEA is a 4-in-1 life-of-well completion system for anchoring in cased hole. Firmly rooted in proven metal expandable packer technology, it provides industry-leading reliability, efficiency, and flexibility, as explained by Kevin Wood, Sales Director for Completions in the Middle East.

“The WEA has three key benefits. It is reliable, with essentially no moving parts; it’s basically a metal expandable sleeve that is secured onto a casing. It is efficient, as it is slimline and full bore, so operators can circulate fluids or cement at high rates compared to other products. It can also be rotated when run in hole making for efficient installation in deviated and challenging wells. And it is flexible; one particular size of WEA can cover multiple casing grades and we can also add or take away modular parts, depending on the environment in the well.”

The product is available in a full range of sizes, with key completion applications as a liner hanger, tieback liner, inner-string packer, and casedhole plug. All versions of the product are qualified to the API 19LH V1 standard and are fully compatible with Welltec’s Metal Expandable Packer (MEP) portfolio.

The WEA clearly addresses a market need, as illustrated by several installations taking place immediately after qualification, with a requirement from one Middle East operator for product delivery within eight weeks. Facilitated by its in-house design and manufacturing capabilities, Welltec was able to deliver the solution in seven weeks.

Prospects in the region are very encouraging, Wood said, “ADIPEC has been big for us; we signed a two-year call-off contract with ADNOC Onshore for the WEA technology which can address several of the challenges they face on some wells.

“The products covered under the call-off agreement are for the prevention of sustained casing pressure – this is annular casing pressure that can makes its way back to surface, a challenge which has cost the industry around US$75bn since 2009,” he continued. “Around 35% of wells globally exhibit gas pressure in the annulus, and the only way to deal with that is to flare it off, or vent it off, both of which are harmful to the environment. That’s where this anchor and our technology come in. It’s a life-of-well solution, providing a barrier in the well. It’s important that when a well comes to the end of its life, it is decommissioned correctly. The problem with cement is that over the life of the well it expands and contracts, which creates leaks through the cement. Using the Welltec Annular Barrier, which the anchor is incorporated with, gives you a fully qualified barrier that you can abandon above, thereby future-proofing the well for abandonment.”

This in effect helps reduce emissions. The emissions reduction angle certainly chimes with ADIPEC’s central theme of decarbonisation. Wood stressed the company’s commitment to the energy transition, which is “in our DNA – it’s not just a buzzword for us”. He explained that Welltec is playing a key role in Project Greensand, which involves the long-term storage of CO2 by injecting it into depleted reservoirs in Denmark. To support this, and similar projects, Welltec’s New Energy & Climate Technology segment has already constructed an advanced testing facility in Denmark that enables full-scale downhole components to be tested against real-world CO2 well-type environments including high pressures, temperatures, and flow rates.

“The test loop and background to Project Greensand have opened up a lot of conversations here, especially with COP28 coming up,” he said.

Elsewhere in the Middle East, Welltec is active in Qatar and Saudi Arabia, the latter of which provides a manufacturing hub supporting regional activity, and keeping lead times to a minimum. Wood commented that this has been a “huge success”, and expansion of the hub is on the cards. “We can not only deliver quickly compared to our peers, we can also manufacture in the region.”

As far as future product development goes, Welltec has a couple of technologies in the field-trial phase. One is the Isealate Springblade Patch, a unique relining and repair solution for downhole applications. The first in-field deployment successfully took place in Europe in October.

“We also provide a service that can radially expand an existing casing string: the Saturn Expander. This can be utilised in wells where there is casing pressure,” said Wood.

“It expands the casing, compresses the cement on the outside, and cures any microannuli or leaks you might have.

“These solutions are coming to fruition now, and there is a lot of interest in the region, particularly given that many wells here suffer from casing pressure.”

Fugro, a leading geo-data specialist and surveying services company, has completed the Middle East’s first remotely operated subsea inspection using a low-carbon emission unscrewed surface vessel (USV).

The company deployed the Fugro Pegasus USV (which is part of the Blue Essence fleet, built by SEA-KIT International) to perform site survey and inspection services on an offshore gas platform offshore UAE for operator Atlantis, ahead of its forthcoming decommissioning programme.

Fugro conducted the operation from its onshore remote operations centre (ROC) in Dubai, using a specialist team of mariners and surveyors to perform the subsea work on the UAQ3 platform within the Umm Al Quwain gas field. The Fugro Pegasus USV was equipped with a Blue Volta electric remotely operated vehicle which was used to inspect the integrity of the platform’s structure. It also generated a detailed map of the surrounding seabed.

All of this was streamlined to the ROC where it was reviewed in real-time during the operation. This data enabled the team to identify and investigate areas of further interest in the delivery of a comprehensive risk assessment for the client.

The economical design and optimised fuel systems of the company’s USVs eliminate 95% of carbon emissions against conventional vessels. This also allows them to remain at sea for up to two weeks without refuelling.

Patrick Boyce, Drilling Manager at Atlantis (UAQ), commented, “Fugro’s remote survey technology aligned seamlessly with our projects HSEQ, technical goals and was the most attractive commercial choice. The Fugro Pegasus was able to mobilise on time and despite difficult sea conditions, it completed the full scope of work in 40% of the allotted time frame. The USV operation was managed by the technical team at the very impressive Fugro ROC. Communications with the USV were strong throughout and provided excellent imaging results. Of particular note was the evident expertise and professionalism of the Fugro team, who have obviously dedicated many months to honing their execution procedures.”

Hannes Swiegers, Fugro’s Director of IRM Services & Remote Operations for the Middle East and India, surmised, “This is a significant milestone for our Middle East business and demonstrates how novel technologies can play a key part in delivering our clients’ long-term safety, sustainability and in-country value ambitions. Together with our clients, we are setting a new standard in geo-data acquisition and analysis through continuous innovation, reducing time, risk and carbon emissions. This new era of remote and autonomous technology will define the future of offshore operations in the energy sector and contribute towards a safer and more sustainable world.”

Aquaterra Energy, a leader in global offshore engineering solutions, has announced a multi-million-pound contract with a major Abu Dhabi based operator, working in partnership with TPMC, to provide offshore riser equipment and services for a decommissioning campaign offshore Abu Dhabi.

Aquaterra Energy will provide a completion and workover riser system complete with AQC-CW connectors, as well as an additional subsea riser system, tieback engineering and rig modifications. It will do this to decommission eight wells, in 80 m water depths by 2029. Throughout the contract Aquaterra will deliver a complete end-to-end managed service, providing engineering services, expertise and personnel.

The completion and workover riser system, complete with AQC-CW connectors, is certified to BS EN ISO 13628-7 2006 and can operate in water depths of up to 1,500 m. The system has been designed to withstand repeat make and breaks, whilst offering a gas tight metal-to-metal seal.

Aquaterra Energy will work closely alongside in-country partners to manufacture and transport the project equipment. Local in-country inspectors will be deployed to ensure the high quality of work throughout the project.

James Larnder, Managing Director, Aquaterra Energy, remarked, “We are delighted to have secured this work in the Middle East and to expand on our decommissioning and riser expertise. This is an important region for us as a business and we’ve seen significant growth here over the last few years. We plan to continue this momentum and are on course to increase both our presence and revenue in the region by the end of the year. This project represents a step forward in this journey as we spearhead our global expansion.”

Andrew McDowell, Operations Director at Aquaterra Energy, added, “Winning this tender further demonstrates our team’s global riser system expertise, understanding of operational requirements in the Middle East, and the significant advantages of our independent connector OEM status. We’re looking forward to utilising our experience and working closely alongside engineers in the UAE, sharing our knowledge, and building on existing local capabilities to deliver a top-class end-to-end service.”

After identifying the Middle East as a key geography to support its global growth plan, the contract marks another significant step forward in the region for Aquaterra Energy. It has now delivered intelligent engineering solutions to more than 35 projects in the Middle East to date.

Saipem has been awarded two new offshore contracts, one for an Engineering, Procurement, Construction and Installation (EPCI) project in the Black Sea and one for decommissioning activities in the North Sea, with the total value amounting to approximately US$850mn.

Saipem has been awarded two new offshore contracts, one for an Engineering, Procurement, Construction and Installation (EPCI) project in the Black Sea and one for decommissioning activities in the North Sea, with the total value amounting to approximately US$850mn.

The first contract was assigned by Turkish Petroleum OTC for the second phase of the Sakarya FEED and EPCI Project, and entails the engineering, procurement, construction and installation of a 16” pipeline, 175 km long at 2,200 m water depth in the Turkish Black Sea Waters. The offshore operation will begin in summer 2024 and will be conducted by Saipem’s flagship vessel, Castorone.

The other contract has been assigned by EnQuest Heather Ltd. for the decommissioning of the existing Thistle A Platform located in the UK sector of the North Sea. Saipem’s activities will include the engineering, preparation, removal and disposal of the jacket and topsides, with possible extension to further subsea facilities. The services will be carried out by the Saipem 7000, one of the largest semi-submersible heavy-lifting vessels currently in the world.

Fabrizio Botta, Saipem Chief Commercial Officer, said, “These important awards demonstrate Saipem’s excellent competitive positioning in the Offshore Engineering & Construction market a sector that is experiencing a full expansion momentum of which Saipem is ready to seize the opportunities.

“The contract awarded in the Black Sea is a confirmation of Siapem’s prominent positioning and of its long-standing relationship with the clients. The North Sea contract, finally, is a further example of Saipem’s capabilities in a segment where the combination of innovative engineering, unique assets and safe operations is crucial.”

Thunder Cranes, a leading provider of portable, modular, offshore rental cranes with a dynamic lift capacity ranging from 2 to 60 tons, has re-opened its operations in the Middle East with a base in the United Arab Emirates.

The company’s temporary installation cranes are designed to be versatile and adaptable, with a number of tie-down scenarios, on-deck placement configurations, and boom-length options to choose from.

The cranes allow clients to efficiently and cost-effectively support P&A, well intervention, facility engineering and decommissioning jobs, without compromising safety, time, and performance.

Previously Thunder Cranes had operated in the region with a base in Dubai from 2009 to 2019. The newly re-opened office and yard facility will enable Thunder Cranes to more effectively serve the UAE and Middle East moving forwards.

Dinesh Arumugam, CEO of Thunder Cranes, said, “As a market-leading provider of portable-modular offshore rental cranes, Thunder Cranes is committed to helping customers in the UAE and across the region with cost-effective and efficient lifting solutions to support offshore projects.”

James Fisher and Sons plc and Abu Dhabi’s NMDC Group have signed a memorandum of understanding to collaborate on key projects and opportunities in the oil and gas sector as well as decommissioning, offshore wind and marine civil construction industries worldwide.

The two entities will develop a series of collaborative joint ventures and consortia to deliver major projects across multiple sectors, markets, and geographies. This will enable them to expand their capabilities jointly in areas such as offshore wind, turnkey oil and gas decommissioning, and accelerating the energy transition, a top priority for most nations today. They will bring their combined client base significant cost and operational efficiencies as well as additional choice in the market.

The initial focus for the partnership will be on diving opportunities within the Middle East region through James Fisher’s subsidiary James Fisher Subtech and the NMDC Group’s wholly owned subsidiary, National Petroleum Construction Company (NPCC).

Eoghan O'Lionaird, Chief Executive Officer of James Fisher and Sons plc, commented, “By leveraging NMDC’s extensive engineering capabilities, offshore asset base and financial strength, coupled with James Fisher’s geographic breadth, established market position, and specialist knowhow in decommissioning, diving, offshore wind and the energy transition, our alliance will allow us to co-develop more efficient and cost-effective solutions and capabilities to create value for customers at a scale and breadth that we could not do alone.”

Yasser Zaghloul, Chief Executive Officer, NMDC Group, added, “NMDC is focused on strengthening global partnerships as part of our strategic vision and to build on our credentials as a global energy and marine dredging EPC major. Over the past months, we have built our geographic footprint considerably. The partnership with James Fisher will drive collaboration in the oil and gas sector, including decommissioning, as well as the offshore wind and nearshore civils markets.

"We will share, in particular, our collective strengths and expertise to support the energy transition agenda. In addition to drawing on our substantial engineering and fabrication expertise, we can bolster James Fisher’s service capability through our extensive asset portfolio that includes a fleet of 22 offshore vessels.”

Norwell Engineering, a global well engineering and project management firm, has secured a multi-million dollar contract to deliver an integrated offshore decommissioning project in the UAE on behalf of operator Sinochem Corporation (Sinochem).

Norwell Engineering will develop the abandonment strategy for Sinochem’s UAQ Gas Field as well as detailed well and facilities decommissioning planning, tendering and procurement services, logistics, marine support and operational execution.

Mike Adams, General Manager of Norwell Engineering, said the company partners with client decommissioning teams to address technical, safety, environmental and legislative considerations.

He commented, “While the decommissioning sector is heating up with several well engineering firms active in the space, our experience and technical focus across the entire field provides operators with a different perspective – reducing risks and identifying efficiency savings during every phase.

“The wells are the most complex and costly element of an integrated decommissioning scope and this is what Norwell has specialised in for more than 30 years. Together, with our subsurface partners, and growing topsides decommissioning team, we are in an excellent position to support clients such as Sinochem with end-to-end project management of their integrated decommissioning scopes.”

Sinochem, is a leading, state-owned, player in the global oil exploration and production sector. The UAQ Gas Field was the first offshore gas field independently developed and built overseas by Sinochem. As part of the integrated project, Norwell will be responsible for developing the abandonment strategy, as well as detailed well and facilities decommissioning planning, tendering and procurement services, logistics, marine support and operational execution.

Norwell will then deliver dismantling of the platform equipment before moving the platform onshore, where it will be handed over to the UAE government.

Marine and lifting equipment specialists Motive Offshore Group (Motive) and subsea and decommissioning equipment rental specialists Hiretech Limited (Hiretech) have joined forces to bring superior technology and service solutions to the Middle East.

Motive, with its UAE hub and existing catalogue of subsea marine and lifting equipment services, is bolstering its current suite with Hiretech’s extensive rental fleet of decommissioning and subsea technology, bringing much-needed consolidation and in-market offshore services support for the region.

Graeme Chalmers, Regional Manager Middle East at Motive Offshore Group, commented, “Having worked with Hiretech for many years, we’re thrilled to formalise our partnership. Harnessing our skills and insights, developed in-step with Scotland’s trailblazing strides in the oil & gas and offshore wind markets, we understand the importance of market consolidation when it comes to keeping costs low and are looking forward to offering greater levels of support from our Middle East base.

“2022 is a big year for Motive. This partnership marks the next stage of our journey, and we are looking forward to continuing to expand our global footprint through increasing sales by 15% in this key region.”

Along with the technology and equipment, Hiretech will also deliver a comprehensive training programme to Motive’s engineers and technicians, enabling seamless delivery of products and technical support.

Andy Buchan, CEO, Hiretech Limited, remarked, “Hiretech has historically served the Middle East region from the UK. This new Middle East partnership puts our equipment in country, significantly reducing mobilisation times and costs for our Middle Eastern clients, with the additional advantages of utilising the extensive commercial, logistical, technical and equipment support available from the Motive FZE team.”

Claxton, the lead brand of Acteon’s drilling and decommissioning segment, is set to acquire decommissioning personnel and assets from Oceaneering.

The agreement was signed recently with the anticipated closure date of 30 March, 2022. Certain staff in Norway will transfer to Claxton, along with decommissioning assets, including well and pile abrasive cutting and recovery systems and associated tooling. Also included in the deal are conductor drilling, pinning and cutting systems, diamond wires saws, dredges and various ancillary equipment items. This equipment will initially be deployed from Acteon’s bases in Norway, Dubai and Aberdeen.

In addition, Oceaneering is establishing a master services agreement where Claxton will provide services to support the company’s wider scopes. This could potentially include its multi-client Rig Chase decommissioning campaigns.

Sam Hanton, Acteon Drilling and Decommissioning Segment Managing Director, commented, “The deal will increase our capacity, the range of technologies at our disposal and our decommissioning expertise, and reinforce Claxton’s position as one of the leading global suppliers of offshore cutting services.”

Luke Pirie, Director of Offshore Projects Group, Oceaneering, added that the deal allows the company to strategically focus on its integrated solutions offering while ensuring access to decommissioning services through a partnership and the new master services agreement with Claxton.

Unity, one of Europe’s largest providers of well integrity solutions, has launched a new range of compact technologies to solve common industry challenges and support Unity’s surface well integrity, shallow intervention and well decommissioning services.

For offshore operations, the new products reduce well bay space requirements, simplify and accelerate offline mobilisation and reduce person on board, cost and risk. Due to these efficiencies, the products all offer between 50-75% savings in OPEX.

The new technology range includes a compact dual-bore xmas tree isolation system, a compact valve removal tool and a compact shear-seal valve. The products complement Unity’s existing Surface Intervention System (SIS), the first product in this compact technology range. It is already delivering multi-functional operations such as inspection, plug setting, milling and xmas tree removal, at reduced cost and improved efficiency compared to wireline or coiled tubing intervention. The SIS is the most compact of its type on the market with a footprint of around 2 sq ft, requiring only two technicians to operate.

The new dual-bore xmas tree isolation system has a footprint of just 1.5 sq ft with an operating height of only 6 ft above the well cap. It can be mobilised and deployed rapidly for shallow plug setting, particularly suited to support and reduce the cost of P&A operations. It can be deployed offline without the need for traditional intervention equipment, saving around 60-75% or more per well. Time savings from rig-up to rig-down are in the order of two to three hours compared to two to three days for wireline or coiled tubing interventions and the system is quickly and easily moved between wells.

The valve removal tool is also designed for use in cramped well bays and delivers an impressive, industry leading, 1,200 ft/lbs torque with optional hydraulic operation without the associated space normally required for such operations. Its rental price is around 60% lesser than similar products.

The new compact shear-seal valve is designed to reduce the weight and geometry of intervention pressure control equipment. It utilises a hydraulically actuated ram but is 50% lighter and 30% smaller than the next closest comparable product. It is rated to cut slickline, wireline, SIS rods and coiled tubing and is modular in design, allowing dual redundant stack-up configurations. Its compact size and reduced weight improve handling and help to reduce concerns over structural integrity on late-life assets.

Gary Smart, CEO at Unity said, “Unity is engaged in long term contract work on over 1,000 wells around Europe, the Middle East and Africa. Our investment in this new compact technology range has followed on the back of significant contract wins over the last 18 months, which have highlighted several common technical challenges faced by the industry, particularly in the late-life, P&A and well decommissioning market. We are very excited to be offering such an impressive step-change in savings and technical advancement to the market.”

D&A GOM 2022

Innovative technology for decommissioning and related operations will soon be on display at D&A GOM 2022, arriving in Houston, Texas, on 18 May. At this event, the offshore community is set to reunite face-to-face to discuss the challenges and opportunities marking decommissioning and abandonment in the region, listen to sessions delving into current complex situations and network to help each other optimise their strategies. To find out more, download the brochure: www.offsnet.com/da-gom/conference-brochure

Or contact:

Joseph Watson

Project Manager

Offshore Network Ltd.

t: +44 (0) 20 3409 5720

e:

3D at Depth Inc., an expert in commercial Subsea LiDAR (SL) laser technology has announced that the U.S. Patent and Trademark Office has issued patent No.11,125,875 (“Underwater Optical Metrology System”).

The claims of the newly issued patent are directed towards systems for determining the location of underwater objects, making measurements between objects, and facilitating the positioning of objects underwater using optical and acoustical metrology techniques.

Through the combination of optical and acoustic technologies, 3D at Depth’s LiDAR can be used across the life cycle of the field from installation to decommissioning. The granting of this new patent benefits 3D at Depth in ensuring that its Subsea LiDAR (SL) technology and solutions continue to lead the field in providing precise measurement in underwater metrology while expanding and future proofing applications in the subsea LiDAR market. The patent award is part of a larger portfolio that demonstrates 3D at Depth’s achievements and contributions in developing subsea and surface measurement solutions to drive innovation and support customer requirements.

Carl Embry, Chief Executive Officer, 3D at Depth, stated “The award of this patent reinforces the strength of our technical service offering. In order for our clients to provide safe and reliable operations, they require accurate measurements and monitoring of their underwater assets. By using our survey services along with our advanced subsea LiDAR (SL) laser systems, we can reliably provide them with precise, repeatable and millimetric 3D point clouds, thus ensuring fast, accurate measurements”.

“Since we first commercialised subsea LiDAR in 2014, minimising time and increasing efficiencies for our customers’ offshore operations was a key driver in our innovations,” stated Neil Manning, Chief Operating Officer, 3D at Depth. “Our Subsea LiDAR’s field-proven benefits are now used across the energy and maritime sectors from offshore oil and gas to nuclear and renewables. These patents remain a cornerstone of a new generation of optical survey subsea measurement technology.”

Global engineering company Aker Solutions has signed a letter of intent (LOI) with AF Gruppen, a leading contracting and industrial group, to merge the two companies’ existing offshore decommissioning operations into a 50/50 owned company.

Global engineering company Aker Solutions has signed a letter of intent (LOI) with AF Gruppen, a leading contracting and industrial group, to merge the two companies’ existing offshore decommissioning operations into a 50/50 owned company.

With the signing of the letter, the companies plan to create a leading global player for environmentally friendly recycling of offshore assets. By joining and focusing their assets, the companies hope to unleash the decommissioning potential across the globe and make a significant contribution towards a sustainable and green transition of the offshore sector.

Kjetel Digre, CEO of Aker Solutions commented, "By combining Aker Solutions’ offshore, engineering and project execution capabilities with AF Gruppen’s decommissioning and construction capabilities, we aim to increase customer efficiency throughout the decommissioning process and maximise the total recycling potential.”

“The company will be uniquely positioned to offer integrated end-to-end services from well plug and abandonment to planning, removal, dismantling and recycling at its own environmental base. Sustainability and circular economy ambitions will be key focus areas for the new entity, and we see increased activity in the market for decommissioning and recycling moving forward.”

Amund Tøftum, CEO of AF Gruppen, added, "Our ambition is to establish a unique recycling player, positioned to offer a total decommissioning solution for the global offshore recycling market. The two parties have complementary strengths and capabilities, with potential to build a global offshore recycling powerhouse. Furthermore, the new entity will deliver on the green, circular ambitions outlined in the UN’s sustainable development goals.”

The two companies represent unmatched and complementary engineering and construction capabilities, offshore and onshore. Jointly, the two units brings extensive capabilities in running large-scale offshore projects, lifecycle and value chain competence and a broad global portfolio of customers and projects. The joint company will have an order backlog of approximately NOK2.5bn.

The transaction is expected to be completed during the second half of 2021 and is subject to due diligence and regulatory approvals by the Norwegian Competition Authorities (NCA).

Achieving a circular economy

Goal 12 in the UN’s sustainable development goals (SDG) is to ensure sustainable consumption and production patterns, in an urgent need to end our reliance on raw materials and achieve a circular economy. These goals will be met by viewing old structures as material banks of dynamic and valuable resources, rather than fixed and final objects. The recycling of steel from decommissioned oil platforms represents a significant contribution to reducing greenhouse gas emissions compared with ordinary steel production in this way and will help to achieve this goal of the UN.

The unit aims to recycle as much of the materials from the decommissioned offshore platforms as possible. Reusing steel results in 70% less CO2 emissions than ore-based production, which corresponds to an emission reduction of 1kg CO2 per kilo of recycled steel. In 2020, AF Offshore Decom, a specialised contractor within AF Gruppen, demolished and facilitated the recycling of approximately 22,000 metric tons of steel, corresponding to a reduction of alternative CO2 emissions of 22,000 metric tons.

The decommissioning market

The offshore decommissioning market has a vast untapped global potential, with approximately 10,000 operational platforms. In the North Sea alone there is more than 900,000 metric tons of top deck expected to be removed during the period from 2020 to 2029. Based on today’s current annual decommissioning spend, it implies that it will take operators approximately 100 years to deplete liabilities for current assets. Thus, a further ramp up of pace is necessary, leading to a positive contribution to the demand for this type of services.

Page 1 of 2