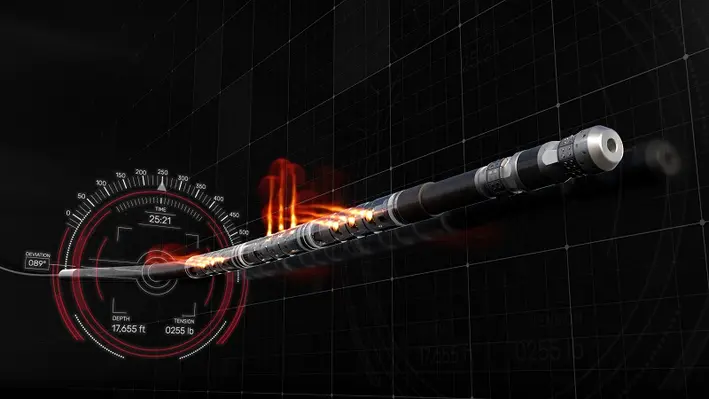

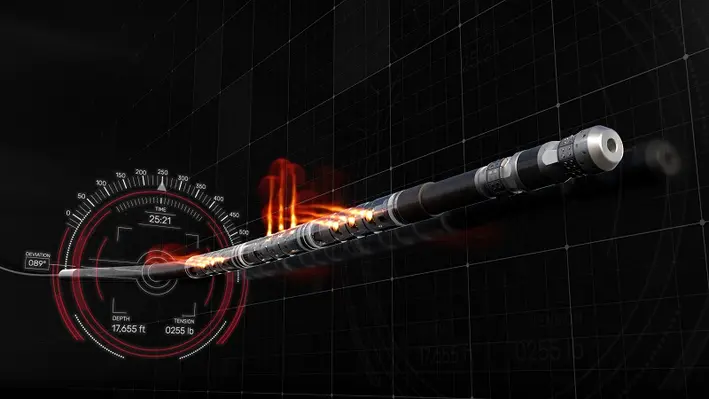

Halliburton, a leading provider of products and services to the energy industry, has announced the implementation of the Auto Pumpdown service within the company's hydraulic fracturing business which enables wireline and pump automation during unconventional completions operations.

The Auto Pumpdown service controls fluid pumps and a wireline unit as a single, fully automated, closed-loop system to maximise Halliburton’s plug and perforating performance and efficiency. The system executes operations to plan and optimises equipment operation for improved consistency.

The service enhances operations by automating tasks previously prone to human inconsistencies and reduces risk by providing prompt feedback to dynamic downhole conditions. These improved consistencies create more efficient operations and reduce required fluids for tool conveyance.

Chris Tevis, Vice President of Wireline and Perforating, Halliburton, commented, “Halliburton’s Auto Pumpdown service ushers in a new era of intelligent plug and perf operations that reduce risk while redefining the level of efficiency and consistency we provide our customers. The service reinforces our leadership in unconventional perforating services by minimising variability in operations, which helps avoid unnecessary and costly well interventions and simultaneously improves efficiencies.”

Multiple perforating crews in North America currently use Auto Pumpdown service. Here, it has demonstrated improved operating efficiencies, reduced fluid requirements, and reduced risk of unnecessary well interventions.

Halliburton will implement Auto Pumpdown service on its North America fleet through 2023 and beyond.

Trendsetter Engineering Inc. has been awarded a contract to support the development of Beacon Offshore Energy LLC’s Shenandoah project in the Gulf of Mexico.

Trendsetter Engineering Inc. has been awarded a contract to support the development of Beacon Offshore Energy LLC’s Shenandoah project in the Gulf of Mexico.

The awarded scope includes a multi-year rental and servicing agreement for the provision of a 20,000 psi Subsea Well Intervention package, with the system delivery expected for Q3 2023.

Trendsetter’s TRIDENT intervention systems provide an innovation solution for subsea well interventions, suitable for offshore mobilisation to a vessel of opportunity and capable of rapid re-configuration to facilitate hydraulic, riser-less light well and risered medium well subsea intervention operations.

“We are excited to extend our partnership with Beacon and support its Shenandoah development,” said Mike Cargol, Vice President of Intervention Solutions, Trendsetter.

“This award reaffirms Trendsetter’s commitment to the industry for innovative, safe and cost-effective HPHT well control and well intervention systems, building upon our successes with the 15,000 psi TRIDENT system and multiple 20,000 psi well control response packages delivered in recent years.”

Trendsetter’s involvement with the Shenandoah field projects extends beyond the implementation of the intervention system. Earlier this year, the company was also awarded contracts to deliver components of the subsea production and export equipment, including a six-slot production manifold, subsea valves, and Trendsetter’s own TCS connectors.

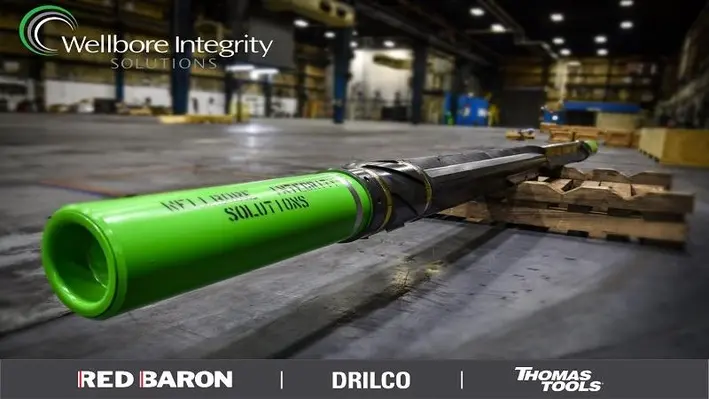

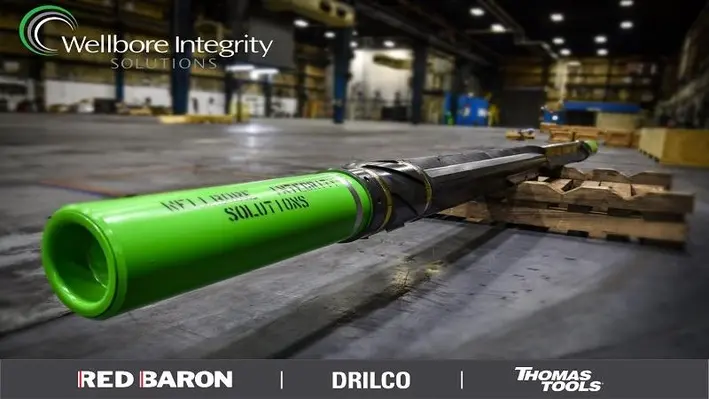

Wellbore Integrity Solutions (WIS) recently presented at the Offshore Well Intervention Gulf of Mexico (OWI GOM) conference, showcasing the service company’s impressive portfolio of well abandonment and debris management solutions with its ProMILL™ technology and Heli-Mag™ , as well as highlighting its success in delivering a project in the Gulf of Mexico.

Wellbore Integrity Solutions (WIS) recently presented at the Offshore Well Intervention Gulf of Mexico (OWI GOM) conference, showcasing the service company’s impressive portfolio of well abandonment and debris management solutions with its ProMILL™ technology and Heli-Mag™ , as well as highlighting its success in delivering a project in the Gulf of Mexico.

With WIS’s extensive knowledge and industry experience of over 75 years, WIS brings together some of the most renowned brand names in wellbore integrity products and services; Red Baron, DRILCO, and Thomas Tools. Each showcases various capabilities from supporting drilling operations and production, to well intervention and well abandonment services. The Red Baron brand focuses primarily on well intervention services, including fishing and remedial for both open and cased hole projects; Wellbore Departure, which consists of sidetracking a wellbore by utilising the TrackMaster Select™ systems; Wellbore Cleanout Tools, which includes equipment such as the Heli-Mag inline magnet, ideal for debris management in multiple applications; Well Abandonment and Slot Recovery services utilising the ProMILL and ProMill Duo™ technologies, and Thru-Tubing Services for various tubular and wellbore projects. DRILCO provides global tubular products and services including field and in-house tubular inspection and repairs, along with manufacturing various drill pipe, whipstocks, fishing and well abandonment equipment. Thomas Tools specialises in rental equipment for special projects or additional assets to rig inventories including blowout preventers (BOPs).

With all the above available in WIS’ arsenal, the company strives to present the broadest portfolio of services across the well lifecycle, a fact that was highlighted during the company’s presentation at OWI GOM, detailing the importance of effective debris management in all projects concerning well intervention. Delaney Olstad, Well Abandonment Manager at WIS Red Baron, discussed how important the practice is, especially in recent years, in regard to making each project as safe and efficient as possible.

“Debris management is absolutely critical in terms of minimising HSE and operational risks. Studies have shown that debris in the wellbore can lead to premature failure of equipment, which can be both costly to the client in terms of downtime and equipment repairs,” stated Olstad.

“I think it's also more prevalent nowadays than it has been in the past because the seriousness of downtime; some of these offshore operations are into the hundreds of thousands of dollars a day. And if there's downtime because you must deal with swarf, an incredible operation can come, basically, to a standstill because you must address the metal debris and shavings.”

To further improve the practice of effective well abandonment, in 2016 the ProMILL technology was created. ProMILL is a single-trip system which allows operators to handle multiple operations, saving on the overall costs. The milling system combines a bridge plug assembly, section mill, and high-ratio underreamer in a single trip solution, which achieves rock-to-rock zonal isolation, and prepares the formation for an uninterrupted abandonment cement barrier.

“The introduction of ProMILL technology enabled rock-to-rock barriers that ensured the integrity of the abandonment process. The ProMILL system is a single trip BHA designed to reduce the number of trips necessary to meet the project and customer requirements,” commented Olstad.

“In the long term, it is obviously essential that wells, which have been abandoned, are abandoned in a way which will prevent future leaks. The ProMILL has played an important part of that safe and reliable abandonment process.”

Olstad also discussed the importance of creating a system which effectively and efficiently eradicates all potential leak paths during the P&A process, as even the tiniest gap can have disastrous and highly expensive consequences.

“When you abandon a well that means it has reached the end of its lifecycle, so you remove everything from the top side. You might put a marker there to identify the well location and you leave. If after a plurality of time, be it two years, 10 years, 20 years, or more, something changes and a hydrocarbon sneaks out, what do you do?” he said.

“To go back and re-enter the well, and re-abandon the well, is extremely expensive – sometimes 10-to-100 times more expensive – depending on where you are. If you're offshore, where was that well? It might leak and show up a mile and a half away, in any direction. That's why it's unquestionably crucial to do it right the first time and utilise equipment that can do it correctly. Being successful in a single trip is beneficial to everyone involved because it’s less time on the rig and less cost associated with overall operations.

“The WIS Red Baron team focuses on completing our operations in a way which meet both the regulatory and project requirements, so that the well does not leak into our most precious commodities – the water and our environment.”

Not only is WIS creating waves through the industry with its efficiency in eradicating leak paths, it is also making headway with its Wellbore Cleanout Heli-Mag technology; a downhole inline magnet which is used during milling operations to maximise debris recovery. The technology consists of 16 rows of rare earth magnets in a helical configuration which ensure that even the smallest pieces of swarf are removed.

In July 2022, WIS worked with KOSMOS Energy on a project in the Gulf of Mexico which required use of the Heli-Mag inline magnets were used in conjunction with the TrackMaster whipstock system to effectively recover debris as a large volume of cuttings were expected, causing concern about the amount of metal produced during a dual casing exit and having adverse consequences in the wellbore and the BOP stack.

“We ran nine of the Heli-Mag inline magnets close to the milling BHA above the heavyweight drill pipe so that they were in tension to capture all the swarf before it went up hole. But just in case any swarf did by we put one more just below the BOP. And by doing that, we captured 1,600 pounds of swarf on the first day,” said Olstad.

“Overall, the Heli-Mags ended up bringing almost 3,000 pounds of swarf out of the hole. Less than 1% of the total amount of recovered debris, 16 pounds of swarf, made it into the rig’s debris recovery equipment.”

Impressive indeed. Looking to the future, Olstad discussed the importance of having a business emphasis on the significance of integrity within the wellbore, as the industry collectively works harder than ever to protect the environment. As our world becomes more fragile, the big players within the industry, including WIS, are emphasising the importance of making every process as sustainable and as safe as possible.

“This is our world, and we only get one, so it is of paramount importance that we strive to conduct ourselves and our actions as best as possible to preserve it and ensure the longevity of the operations, the environment, and humanity,” Olstad concluded.

At the recently concluded Offshore Well Intervention Gulf of Mexico conference, representatives from Caltex Oil Tools provided a detailed presentation of a recently concluded damaged wellhead repair project where the company utilised new technology and methodologies to successfully bring a well back online.

Since bursting onto the subsea scene in 2018, Caltex has become an established solutions-focused business which provides rentals, services and bespoke engineering capabilities for subsea operations. In the case of the latter, the company and its affiliates offer a range of services including equipment rental to support vessel and rig-based pre-commissioning, controls, completions, intervention and decommissioning activities; consultancy services with experts specialising in business development, sales, remote technologies, subsea controls, diver and diverless interventions, vessel based IMR operations, and emergency response repairs; as well as engineered solutions where it specialises in unplanned emergency response requests to developing transformative technical solutions.

The project that was presented at OWI GOM began when a major operator contacted Caltex over an offline well which had visible damage to the VX profile, FX profile and isolation sealing surface. Knowing Caltex’s extensive capabilities, the operator sought the company’s immediate help to intervene and bring the well back online. In turn, Caltex responded by developing a custom solution for machining the inner wellhead profile to remove the damaged surfaces.

It was in November 2021 when Caltex first began work on the project, with an initial concept to remove protruding materials and polish damages. According to Carter Kacal, Project Manager at Caltex, it was shortly after this, in January, when the project began to grow and the scope developed from what was originally perceived. After analysis of damage, their plans involved to machine the new ID .25’’ beyond the last damage, increase the ID of the wellhead by 0.125’’ and machine a 30° lead-in bevel at top/bottom of the increased ID.

This involved the development of a tool with the goal to machine a new ID of the damaged wellhead to tight specifications which also incorporated an automated system featuring closed loop controls and independent electronic actuator controls. From January onwards, Caltex swiftly developed Software (in just 15 days) and tested the tool to perform the required work before travelling to the manufacturer of the wellhead to perform an SIT at the beginning of March.

The technology utilised in the solution delivered by Caltex, according to Kacal, included a real mix of field-proven to new technology, resulting in a bespoke solution. It included three electronic actuators, an RPM sensor, subsea control units, a localised subsea power bank and an optical communication link connected through the ROV and controlled from the surface.

Kacal commented, “The results of the SIT were extremely positive, better than we could have expected, and well within the specifications we needed to be which is shown in the table.”

“We needed to be within 0.005'' concentricity and we achieved 0.002'' which was great. And then the surface finish that was well below what it needed to be as well. The goal (measured in Ra) was to be 111 Ra or lower. And so you can see there the average of the three numbers [on the table] is around 46. The only thing missing there is the results on the bevel cut. So we needed to cut a bevel as well as machine new diameter. We needed to be 30°, we were at 26°. This was a little steeper than we needed to be, but still successful nonetheless. From that everyone was happy to go offshore and we felt comfortable as well.”

Indeed, little time was wasted in doing so as, by the middle of March, the tool was offshore and ready to perform. Kacal continued, “We had a timely mobilisation with no downtime for the tool. We performed the operation in five days (from mobilisation to demobilisation) which included less than 24 hours operation of the tool itself. Then, once we pulled it off and actually tested the wellhead, everything was successful and eventually the well was able to be brought back online.”

For a job that began in November and had to contend with workscope changes along the way, it was a remarkably quick turnaround for the company which was ultimately successful. Kacal remarked that, alongside the timeliness of the operation, what worked very well was the automated system with closed loop controls alongside the performance of the tungsten carbide tool tip. He added that given slightly more time they could have spent more time developing and optimising the tool, however this did not overtly affect the performance and it has given the company confidence that they could deliver another project of similar scope and time effectively again.

“If there's ever an opportunity, we'd love to be able to try our hand at it again because we've proved it, we've developed it. At the moment I would say many people just don’t really know that is out there and no one really discusses if they have a damaged wellhead or not. So we want to show, with this example, that this technology is available and we have the ability to remediate the wellhead with a less invasive strategy than what is currently out there. At OWI GOM we had some interested discussions around this and people seemed definitely interested so we shall see what the future holds.”

Baker Hughes has announced that it is acquiring AccessESP, a leading provider of advanced technology for artificial lift solutions, to further transform core oil and gas operations by reducing costs and downtime for operators.

AccessESP’s ‘GoRigless ESP System’ provides proprietary solutions that enable an electrical submersible pump (ESP) to be deployed and retrieved with conventional, light-duty intervention equipment without the need for a rig or requiring the well production tubing to be pulled.

These technologies significantly reduce the cost of, and downtime between, workovers used in the replacement of ESPs, which is of increasing importance in offshore and remote areas.

Maria Claudia Borras, Executive Vice President of Oilfield Services at Baker Hughes, commented, “Combining AccessESP’s alternative deployment technology with Baker Hughes’ world-class ESP capabilities creates a truly differentiated solution for our customers. This transaction reinforces Baker Hughes’ commitment to transforming our core business by focusing on leading, future-proof technologies that support growth opportunities and enhance our portfolio.”

AccessESP’s innovative deployment system provides more efficient solutions compared with traditional methods. By reducing heavy intervention, operators can increase oil recovery, efficiency and profitability while reducing costs and managing resources more efficiently. Lightweight intervention systems also reduce HSE risks, while light workover techniques enable ESP maintenance to be completed more quickly and at a lower cost than existing methods.

AccessESP has approximately 55 employees with facilities in North America and the Middle East. The transaction is expected to close in the second half of 2022 and will be integrated into Baker Hughes’ Oilfield Services segment.

With integrity issues continuing to plague wells across the globe (affecting an estimated 30% of wells around the world), Expro has engineered the Octopoda annulus intervention system to enhance production and assure well integrity without disrupting operations.

According to Expro, the Octopoda is a unique, proven and advanced technological solution which allows direct access to the well annuli which can help bolster production rates, firm up well integrity and allows customers to regain shut in wells and make them economically profitable again.

With advanced corrosion protection for up to 20 years, Octopoda can help create a sustainable impact on asset production and revenue.

In a recent demonstration of its capabilities, Octopoda was used on a Chevron offshore platform well to intervene the A annulus and replace base oil with water ahead of resin placement on top of the packer.

Chevron had previously seen a 50% reduction in the impact of the resin when it was added to an earlier well containing base oil.

Deploying Octopoda meant Chevron avoiding the use of production tubing for circulation via a stimulation vessel or coil. This eliminated the need for communication between the production tubing and the A annulus meaning the barrier remained intact between the reservoir and the A annulus.

Expro displaced the base oil and established circulation by pumping fresh water through the annulus intervention system. Despite experiencing space limitations caused by control lines, clamps, and centralisers.

This was the first time the A annulus had ever been intervened using a conveying hose. Furthermore, it proved the efficiency benefits of Octopoda’s annular intervention over conventional practices by reducing time, costs and personnel. The operation lasted three days compared to an estimated 10-13 days, avoiding the conventional lube and bleed method or the need to punch and circulate the well.

Octopoda’s small footprint compared to a pumping vessel or unit reduced lifting risks and required only a two-man crew from Expro. The base oil was collected in a closed loop in the system, avoiding its exposure to the environment.

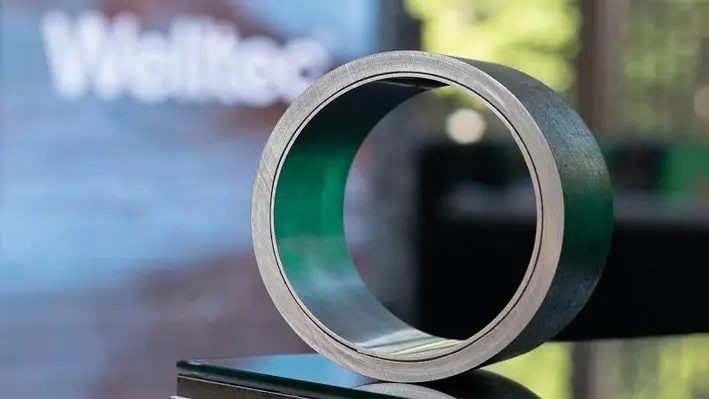

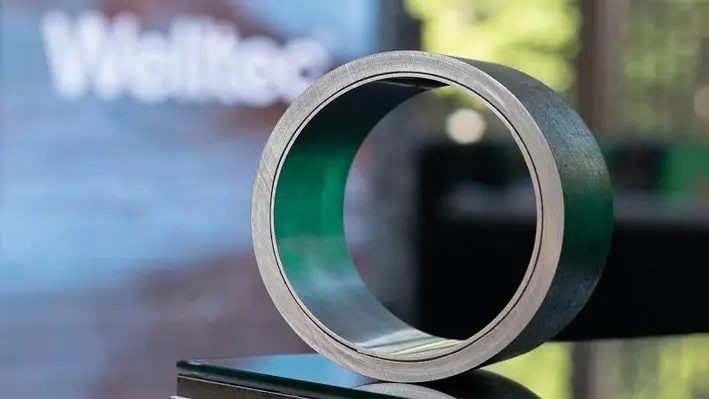

Welltec has formed an exclusive partnership with Isealate AS to become the largest shareholder in the innovative company which provides a patented patch-thru-patch technology.

Chief Commercial Officer at Welltec, Tommy Eikeland, commented, “Well leaks and damages are among the primary concerns raised by our customers during the intervention and workover phase. This acquisition perfectly complements our existing technology portfolio and adds a new dimension in terms of metal expandable capabilities. Once fully integrated, we will be able to set patches and Welltec Annular Barrier technology on either wireline or drill pipe, providing our customers with the ultimate re-lining and repair solutions for well integrity.”

Isealate’s downhole patches can currently be run on wireline and provide multiple benefits typically associated with straddles and larger steel patches without any compromise or trade-offs. The ultra-slim patches have a variety of applications from water-shut off and leak repair, to damaged casing or completion repair, whilst managing to maintain a near full bore ID with minimal restrictions allowing patch-thru-patch operations.

Isealate AS Founder and Board Member, Bengt Gunnarsson, commented, “The integration with Welltec will allow us to bring our unique technology to more operators and deliver it through a global partner with a proven track record. In the meantime, this enables our team to fully focus on further development of the unique patch technology

“Welltec has a truly international field service organisation and management support structure, along with unique engineering, mechanical and electronic capabilities, combined with inhouse manufacturing capacities, which made them the obvious partner choice,” Bengt added.

Helix Energy Solutions Group, Inc. has announced that it has entered into a definitive agreement to acquire 100% of the equity interests of the Alliance group of companies for US$120mn million cash at closing, plus the potential for post-closing earnout consideration.

Helix Energy Solutions Group, Inc. has announced that it has entered into a definitive agreement to acquire 100% of the equity interests of the Alliance group of companies for US$120mn million cash at closing, plus the potential for post-closing earnout consideration.

Alliance is a Louisiana-based privately held company that provides services in support of the upstream and midstream industries in the Gulf of Mexico shelf, including offshore oil field decommissioning and reclamation, project management, engineered solutions, intervention, maintenance, repair, heavy lift and commercial diving services.

Helix said that the transaction aligns with its ‘Energy Transition’ business model, by expanding its decommissioning presence in the Gulf of Mexico shelf and advancing Helix’s ESG initiatives by responsibly supporting end-of-life requirements of oil and gas projects.

The transaction also augments Helix’s decommissioning and life-of-field maintenance service capabilities through the addition of Alliance’s comprehensive shallow water assets, including a fleet of Jones Act-compliant lift boats, offshore supply vessels, a heavy lift derrick barge and diving vessels, as well as plug and abandonment systems, coiled tubing systems and snubbing units.

The deal further positions Helix to further penetrate the North American decommissioning market, with published reports forecasting nearly US$3bn of decommissioning expenditures between 2022 and 2025, and the potential to expand into the global market. Based on the assets being acquired, the parties’ assumptions and market conditions, and anticipating Alliance's potential annual EBITDA in excess of US$30-40mn, the transaction is expected to add accretive free cash flow and diversify Helix’s asset base and revenue stream, at an attractive valuation.

According to Helix, the deal will help in preserving a strong financial position and liquidity, as Helix’s pro forma cash, liquidity and net debt would approximate US$145mn, US$186mn and US$119mn, respectively. The transaction is also expected to enhance the financial performance outlook, with expected continued improvements in free cash flow resulting in expected strong liquidity and leverage position.

Owen Kratz, Helix’s President and Chief Executive Officer said, “Based on a number of markets and regulatory drivers and our current expectations, we fully believe that the offshore oil and gas decommissioning market will grow significantly in the near term. This acquisition complements Helix’s present deepwater abandonment offerings by adding shelf and facility abandonment capabilities and significantly enhances our position as a full-field abandonment services provider, both in the Gulf of Mexico and globally. We also see possibilities to expand our opportunities within our existing late-life production business.”

Steve Williams, owner of Alliance said, “Our recent successes in acquiring and developing businesses and assets to establish Alliance as an offshore shallow water energy services company has led us to Helix, who we see as the industry standard in deepwater energy services.”

The acquisition is expected to close in mid-2022 and is subject to regulatory approvals and other customary conditions.

Baker Hughes has launched the MS-2 Annulus Seal, designed to save substantial operational rig costs by reducing rig trips.

The new integrated sealing solution, the latest technological development to the MS-SN, has already been adopted by multiple customers in North and South America.

The MS-2 Annulus Seal integrates with Baker Hughes’ existing MS-800 wellhead system and helps to lower the cost of well construction and intervention, expands intervention options and ensures security and confidence of well integrity in challenging conditions.

“We constantly strive for technological optimisation and delivering the most advanced solutions to our subsea customers,” said Neil Saunders, Executive Vice President of Oilfield Equipment at Baker Hughes. “Through our new MS-2 Annulus Seal, we are helping to transform the subsea market and are developing quality technology that delivers long-term value, reliability and efficiencies for subsea customers.”

The MS-2 can be installed in a single trip, with an integrated lock ring that results in improved rig efficiency by providing immediate lockdown of up to 2mn pounds force without the need for a second trip, saving rig time. The MS-2 also provides easier access to wells, with no need for supplemental lockdown devices. It is tested to 20,000 psi, and to 200 load cycles ensuring life-of-field reliability and further demonstrating the seal integrity.

C-Innovation, LLC (C-I), an affiliate of Edison Chouest Offshore (ECO) and its family of companies, have signed a two-year contract for continued Riserless Light Well Intervention (RLWI) services onboard the Island Venture offshore support vessel.

The new contract follows a previous agreement in which the Island Venture performed interventions on multiple deepwater wells in the Gulf of Mexico.

David Sheetz, C-Innovation’s Vice President, said, “This new award is a continuation of nearly three years of setting new standards in the RLWI space. We are constantly working to change the way the industry looks at RLWI work to increase production in this ever-changing market. We look forward to the next few years on this project, and we are already making plans to expand the offering, including numerous dock upgrades to facilitate even more efficient fluid handling and waste removals to minimise required between-wells maintenance time.”

With no safe vertical access to several subsea wells under a platform, the C-I Subsea Projects Group was able to find a solution by utilising a well service jumper to perform well interventions. This collaborative effort between C-I and the operator allowed C-I to perform the intervention without disrupting the platform’s operations.

George Wilson, C-I’s RLWI project manager, commented, “C-I is committed to ensuring the continual improvement of the quality, health, safety and environmental aspects of its operations and services. The two-year RLWI work is no exception: with over one million man-hours, C-I had zero recordable incidents. So far this year, C-I has clocked over 135,000 hours with no recordables.”

Sheetz added, “The contract award for additional RLWI work is a credit to the entire RLWI team. Our team continues to provide creative solutions and methodologies to perform interventions that have not been achievable from a conventional RLWI approach. The collaboration of various subsea disciplines within our group has contributed to the successes, and our offshore teams continue to deliver on every execution that comes their way. C-I’s subcontractors, Halliburton, Baker Hughes and Caltex Oil Tools, were also key to the new award. I am extremely proud to work with some of the brightest people in our industry.”

C-Innovation, an affiliate of Edison Chouest Offshore (ECO) and its family companies, is celebrating its 15-year anniversary.

This milestone was reached by continuing to provide its customers with the most advanced remotely operated vehicles (ROV) systems and industry-leading ROV services. Such offerings have seen the company operate across the globe alongside major operators such as bp.

Since its foundation in 2007, the company has grown into the largest owner and operator of Schilling Robotics ROV systems in the world, with a fleet of 57 work class ROV systems. In addition to ROV services, it has now expanded into providing AUV, offshore survey, pipeline and well intervention services – recently demonstrated with the award of a light well intervention contract with a major operator in the Gulf of Mexico.

The addition of these services has steadily expanded C-Innovation’s footprint on the oil and gas industry.

Richard Bourque, Chief Operating Officer of C-Innovation, commented, “The past 15 years has seen multiple ROV companies come and go, while C-I has continued to grow and expand our offerings with additional vessels and advanced solutions.

“The key to remaining successful during a time when new competitors emerged and existing competitors faded away has always been the loyalty and hard work of our employees and the support of our clients. Reaching this 15-year milestone is proof to our clients and competitors that we are, and will continue to be, a leading ROV services provider in the oil and gas industry.”

Helix Energy Solutions Group, a leading provider of offshore energy services, has entered into a new multi-year contract with Shell Offshore to provide well intervention services in the Gulf of Mexico.

The three-year contract, commencing in March 2022, includes an anticipated 75 days utilisation per year with the option to add additional utilisation days.

Helix will provide either the Q4000 or Q5000 riser-based semi-submersible well intervention vessel, a 10k or a 15k Intervention Riser System (IRS), remotely operated vehicles, project management and engineering services to cover operations from fully integrated well intervention to fully integrated plug and abandonment well services.

The Q4000 and Q5000 well intervention vessels provide an optimal platform for a wide variety of tasks, including subsea well intervention, field and well decommissioning, installation and recovery of subsea equipment, well testing and emergency well containment.

Scotty Sparks, Helix’s Executive Vice President and Chief Operating Officer, commented, “Shell continues to be a valued customer of Helix. We appreciate their continued confidence in our fully integrated well intervention services, our commitment to safety and cost-effective and efficient solutions. We are confident in the efficiencies and value we bring to our customers, and this contract further signals the increasing demand for our services.”

Page 2 of 5