The discussions subjects covered in these postings are covered in my well integrity training courses. Go to www.internationalwellintegrity.com for more details. In this article I would like to comment on the issue of sand production and its measurement. This is a high-level view of the problem, representing the tip of the iceberg.

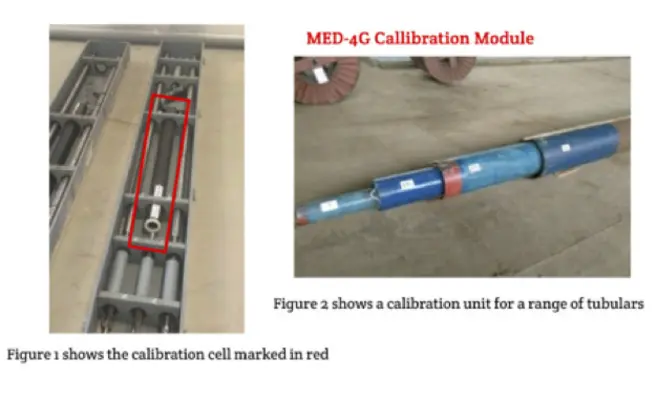

The technology of spectral noise logging is very powerful when in the right hands and can really provide a much direction in problem solving downhole issues. As a tool that listens for sound and does not transmit sound provides a more direct answer of downhole issues, simply relying on a pressure change OR sound of moving particles such as sand. BUT coming back to the issue of calibration, this critical element must be available, repeatable and transparent.

Your service provider should provide comprehensive details of calibrations and especially with dates, times and environmental conditions. Crucially, when calibrating the environment must be insulated from background noise, so having trucks thundering past, that vibrate and shake the work surfaces or having to tip toe past the calibration cell for fear of extraneous interference is not acceptable. But is something I have witnessed recently in one service provider facility, and questions the validity of the calibration and associated logging results.

Reviewing the service provider to ensure and validate their calibration process is key to success. Additionally, auditing of tool servicing and maintenance is crucial, especially as we are coming out of a downturn and cut backs have been severe.

Sand in the flow stream if not fully understood and correctly measured can be catastrophic. Therefore, knowledge of the sand source, the rate it is producing at and where in the well system it reaches when on production, provides a greater understanding of the problem complexity and how it might be mitigated.

A small checklist will help in the diagnostic process -:

1. Sand detection at the surface tells you straight away that you have a problem, but what is the rate of this sand production? How many pounds of sand per million standard cubic feet or thousand barrels?

2. Is the sand production rate dependant? If so, what is maximum rate the well can be produced at without sand at the surface?

3. Is there evidence in the surface equipment of sand? If so, try to sample and analyse and with a geologist determine where in the well is this coming from.

4. Measure wall thickness of elbows and compare to original construction dimensions to help measure the surface rate of metal loss

5. If an intervention is planned choose the logging company carefully, and only accept logging companies who can provide you with a numerical answer to the sand production rate. Just ticking a box to confirm its in the flow stream will not provide you with a full answer. You need to know the sand rate production versus well production rate.

6. Using slickline tools try to determine if the sump depth of the well has changed as this will suggest that the sand is dropping down the well and not all being produced to the surface.

7. Once the sand is better understood, you are then in a position to review, risk assess and determine a course of action that provides a working environment with an action plan if problems occur.