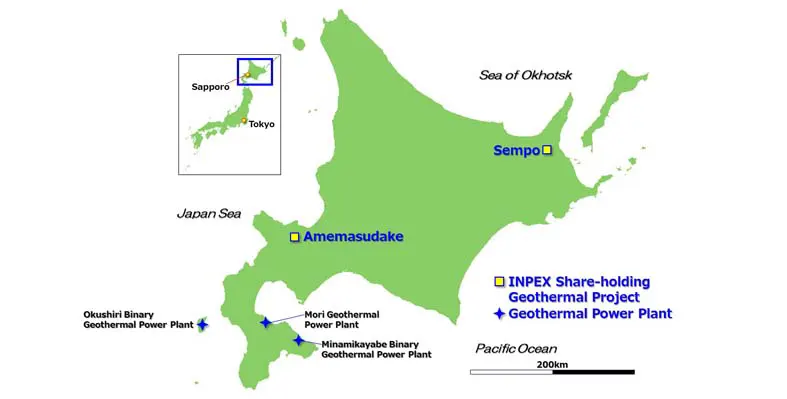

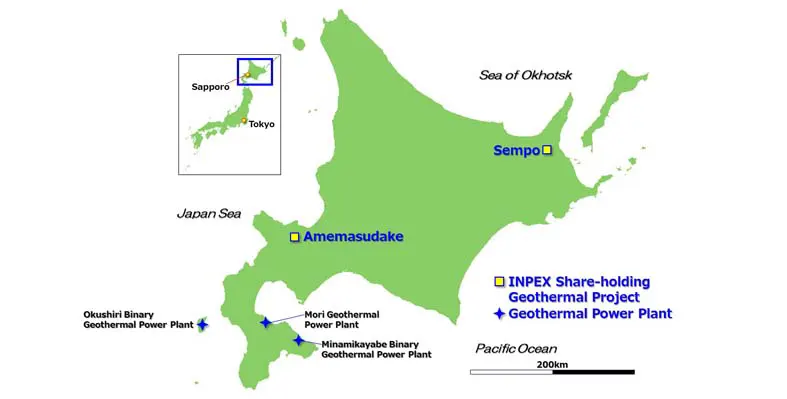

Following encouraging results from extensive surveys, INPEX Corporation has decided to go ahead with exploratory drilling for geothermal energy development in Shibetsu Town, Hokkaido, Japan.

Following encouraging results from extensive surveys, INPEX Corporation has decided to go ahead with exploratory drilling for geothermal energy development in Shibetsu Town, Hokkaido, Japan.

Since its nomination in the process of the 'Selection of Operators for the Musadake Region Geothermal Survey' in Shibetsu Town in 2020, INPEX has been conducting surface and geophysical surveys as well as drilling operations in the Sempo area northwest of Mount Musadake in the western part of Shibetsu Town. It took a positive turn as the company came across geothermal resources from the site, which can potentially actualise its net zero ambitions while expanding its clean energy business in Japan.

INPEX aims to accelerate its geothermal initiatives by tapping into the technologies it cultivated through oil and natural gas development. The company has plans to proactively engage in energy landscape development to help

realise a net zero carbon society while fulfilling its responsibilities for the stable development and supply of energy.

In a drive to leverage Indonesia's vast geothermal poetntial, PT Pertamina Geothermal Energy Tbk and PT PLN Indonesia Power have signed a joint development agreement (JDA) in Jakarta to optimise the capacity of several geothermal power plants (PLTP) in the country.

In a drive to leverage Indonesia's vast geothermal poetntial, PT Pertamina Geothermal Energy Tbk and PT PLN Indonesia Power have signed a joint development agreement (JDA) in Jakarta to optimise the capacity of several geothermal power plants (PLTP) in the country.

This JDA comes after the joint development study agreement (JDSA) that the companies signed in February.

Julfi Hadi, President Director of PT Pertamina Geothermal Energy Tbk, said, "The signing of this JDA demonstrates our strong commitment to increasing the utilisation of Indonesia's abundant geothermal resources to support the acceleration of the national energy transition, achieve the government's commitment to the Enhanced National Determined Contribution (NDC), and the Net Zero Emission programme in Indonesia. We believe this cooperation will accelerate the development of more efficient and sustainable geothermal projects as one of PGE's strategic efforts to achieve 1 GW in the next two years."

The JDA primarily aims to develop co-generation projects in two geothermal working areas. The approach will involve utilisation of brine or hot water from steam separation, to stimulate electricity production.

The initial target for the PLTP Co-Generation (Binary Plant) development is in the Ulubelu Binary Unit and Lahendong Binary Unit PLTP areas, potentially adding 30 MW and 15 MW of installed capacity, respectively.

Noting that the initiative can increase PGE's installed capacity by up to 230 MW, Hadi said, "This JDA allows us to focus on increasing electricity capacity and accelerating geothermal energy development as part of the national energy transition strategy. By applying principles of operational excellence, we ensure that every stage from development to project operation is carried out efficiently and with the highest quality, thereby increasing the use of renewable energy."

Following the success of the JDA, the PGE and PLN IP will soon make effective a power purchase agreement (PPA). "We hope this JDA can serve as an example for other renewable energy projects in Indonesia. With strong synergy and collaboration, we can achieve our goal of creating a more sustainable energy future," Hadi said.

Also present at the JDA signing was Norman Ginting, Project and Operations Director of Pertamina New & Renewable Energy (Pertamina NRE), who appreciated and hoped that this collaboration and synergy could continue. "Today, Pertamina through PGE and PLN through PLN IP have successfully signed a JDA as an important milestone for geothermal development. Pertamina NRE highly appreciates this step and hopes that in the future, these two important national energy SOEs can collaborate and synergise to drive more massive decarbonisation," Ginting said.

Vice President of Corporate Communication of PT Pertamina (Persero), Fadjar Djoko Santoso, said, "Geothermal development is an effort to support the Government in achieving the national energy mix target and also Pertamina's effort in developing New Renewable Energy."

James Fisher Decommissioning, part of James Fisher and Sons plc, has completed a significant decommissioning project in the Gulf of Thailand.

After extending the contract with a major offshore engineering, preparations, removal and disposal (EPRD) operator, the project became the largest to date for James Fisher, involving the removal of 25 offshore jackets in support of the client’s wider asset end-of-life campaign.

James Fisher was able to support the client through the expertise of its in-house decommissioning team and equipment, including abrasive waterjet cutting, hydraulic demolition shears and diamond wire saws.

To complete the multi-million-pound project, the decommissioning specialist utilised abrasive cut verification technology which ensured operations are completed successfully on the first attempt and without the need to re-evaluate the initial cut. It is estimated that, by improving efficiency of the operations in this way, cutting time was reduced by 50%.

“We pride ourselves on providing bespoke, environmentally focused solutions to overcome some of the most complex decommissioning structures faced by our customers,” Mark Stephen, Decommissioning Director for James Fisher, remarked. “This type of operation was a first for James Fisher Decommissioning in terms of jacket removal volume and duration, and we are extremely proud to have been part of the project. Utilising our strong in-house decommissioning capabilities and real-time monitoring technology, we saved valuable project time during the cutting process while ensuring the project was completed to the highest standards for our client.”

This represents the latest success for the company since the launch of the decommissioning business line.

Working for a prominent energy company, offshore lifting solutions provider Thunder Cranes offered mobilising its small-footprint, portable modular crane on a small supply vessel to the work site.

Working for a prominent energy company, offshore lifting solutions provider Thunder Cranes offered mobilising its small-footprint, portable modular crane on a small supply vessel to the work site.

After reaching the site, it can be rigged up, load tested, and prepared for lifting operations, all in a day, rather than going with the costly option of a barge or vessel crane, which can also render ineffectual.

While the project involved challenges from limited deck space to heavy lifting requirements, Thunder Cranes was well-equipped to tackle them with its compact, hydraulic powerpack/prime mover, TC20 stiff leg crane with a 60-ft boom length, and a 'self-lifting' package of TC's proprietary.

The choices of equipment and services by Thunder Cranes were reached post a thorough assessment of the client's lifting requirements, platform drawings, general specifications, and project timelines. This was followed by a site visit for verification, which became the basis for practical solutions.

The energy company required solutions with their offshore coiled tubing operations that involved the lifting of their CTU equipment onto their offshore platform which only had a small jib crane of 1.8-ton capacity, while the coiled tubing reel itself weighed 16 tons. Thunder Crane's modern approach with its portable-modular crane technology instead of the traditional large vessel or barge crane helped its client to optimise their logistics and enhance project uptime, while maintaining a high level of safety and cost-effectiveness.

GreenFire Energy Inc. and Stoic Transitional Resources have announced a pioneering collaboration effort for innovative geothermal energy solutions.

GreenFire Energy Inc. and Stoic Transitional Resources have announced a pioneering collaboration effort for innovative geothermal energy solutions.

Through a cross-license agreement that covers GreenFire’s patented GreenLoop technology and Stoic’s patent-pending Flux Crossover, the companies will focus their efforts on repurposing existing oil and gas wells and non-productive geothermal wells to harness the potential of geothermal energy.

GreenFire’s Greenloop technology is a closed loop advanced geothermal system which provides solutions that assure the availability of resilient, sustainable and scalable geothermal energy for a range of applications, including power and direct use heating and cooling. The Stoic technology aims to enhance the GreenLoop performance.

Stoic’s Flux Crossover combined with the GreenLoop technology will enhance performance by optimising flow patterns, minimising parasitic heat loss and double heat transfer efficiency. The two companies announced a partnership last year for the development of geothermal projects through utilising abandoned wells in New Zealand and Canada.

Steven Brown, President of GreenFire Energy Inc., said, “We are pleased to be collaborating with Stoic Transitional resources. GreenFire Energy’s technology has the capability to economically repurpose idle geothermal wells and expand implementations in geothermal fields. Collaborating with Stoic’s technology will enhance performance and broaden GreenFire Energy’s solutions.”

Joe Tarrant, Co-Founder and Chief Commercial Officer at Stoic, commented, “Our commitment extends beyond innovation to fostering sustainable partnerships and empowering communities. Stoic’s pioneering approach to clean energy aligns perfectly with our mission, emphasising the value proposition for data centre customers.”

With the race to a net zero future continues to heat up across the globe, more eyes are turning towards geothermal methods as a suitable alternative for energy. While the US continues to dominate the word stage when it comes to geothermal production, there is a giant lying under the surface across the Asia Pacific.

With the race to a net zero future continues to heat up across the globe, more eyes are turning towards geothermal methods as a suitable alternative for energy. While the US continues to dominate the word stage when it comes to geothermal production, there is a giant lying under the surface across the Asia Pacific.

With Indonesia boasting a predicted capacity of 27GW, and both the Philippines and New Zealand ramping up their installed capacity year-on-year, APAC has become one of the key global players in the geothermal game, already producing 35% of geothermal generation worldwide.

However, the burning question that faces the region is do the myriad of issues presented by factors such as limited resources, a lack of governmental funding and a challenging topography to contend with mean that the colossal potential lying underground will have to remain as such, rather than be utilised as a fruitful source of energy?

As the majority of geothermal resources are associated with volcanic activity in high terrain, exploration projects become more challenging and require additional resources and infrastructure, such that the region may not have access to. Financial stability is also a crucial factor waging a war against the utilisation of geothermal energy throughout APAC as the resource is not necessarily a commercial viable option for many operators.

Nevertheless, measures are being put into place to mitigate against these challenges, with government policies changing to accommodate green energy funds and private sectors and investing higher sums into the industry, there is a hope of prosperous future.

The Asia Pacific Geothermal Transition Outlook attempts to analyse the key players within the region and outlines where the pitfalls and mitigations lay ahead of the inaugural GTS APAC 2024 conference in Jakarta from 9-10 July.

In a breakthrough exploration of 250mn-year-old granite in South China, China Petroleum & Chemical Corporation (Sinopec) has completed the drilling of Fushen-1 Well in Hainan.

In a breakthrough exploration of 250mn-year-old granite in South China, China Petroleum & Chemical Corporation (Sinopec) has completed the drilling of Fushen-1 Well in Hainan.

At 5,200 m, it is the deepest geothermal exploration well in China.

Started in last August, the company notes this as a milestone reached in less than a year.

This has been made possible by Sinopec's deployment of several independently developed innovative technologies, including the combination of dual-drive drilling and high-pression injection, to reach the temperature limit of hot dry rock stipulated by the national energy industry standards, while forming the key technologies of detection and evaluation of deep geothermal resources.

Sinopec's next steps will include extensive research and field tests at Fushen-1 Well, building the first platform that brings together research, education, and experimentation of deep geothermal in South China. This will help formulate theoretical methods and technical systems applicable to the region, paving the path towards the country's 'Dual-Carbon' goal.

China's geological surveys have revealed that the hot dry rock geothermal resources within the range of 3 kms to 10,000 m underground in China's land area are equivalent to 856 trillion tons of standard coal. Every 2% of them equals 2,993 times the annual energy consumption of China in 2023. The country has an accumulated geothermal heating capacity of nearly 100 mn sq m with several multi-million-square-meter regional geothermal heating projects already built and in operation.

Contact has released a statement stating that its Tauhara project is likely to be online by winter this year, with an initial capacity of at least 152MW.

Contact has released a statement stating that its Tauhara project is likely to be online by winter this year, with an initial capacity of at least 152MW.

This comes as the company notes steady progress of the commissioning works at the Tauhara geothermal plant, post successful completion of remedial work to the steam separation plant.

Power station commissioning activities are all in place to start before it is synched to the system by early May. This will be followed by 30-day reliability run required to support commercial operations.

The company has acknowledged the project team's tireless contribution to deliver the Tauhara commissioning timeline and do justice to the project's worldclass standards. It considers the Tauhara geothermal project a part of Contact26, the company’s strategy to lead the decarbonisation of New Zealand.

Referencing the many mature offshore fields that are drawing ever-closer to retirement, Baker Hughes has published a 'Perspectives' article exploring why improving the cost for plug and abandonment is not only an industry opportunity but an industry imperative.

The article highlighted that, for the first time in history, a large proportion of offshore oil and gas infrastructure is now careening towards costly decommissioning as productivity wanes. According to Wood Mackenzie Lens data, by 2030 global decommissioning expenditure will hit an average of US$15bn a year, rising to US$25bn in 2035. Between 2021 and 2050, a staggering US$400bn will be spent.

Lorna Yuill, leader at Oil Field Services and Equipment (OFSE) Baker Hughes Growth Hub leader, said, “If we can properly support the well decommissioning phase, we can save our customers money while at the same time securing good outcomes for the environment.”

The team of OFSE Growth Hub has therefore sought to address this challenge and devise solutions to reduce the looming expense of decommissioning. One such envisioned answer is a Swiss Army-knife-life universal tool that can interface with virtually all vendor systems, offering advantages in terms of operators only having to deal with one supplier for one set of tools across a field of ageing wells.

“A customer might spend US$15mn on the single set of tools,” remarked Yuill, “but if they needed to go to four OEMs to decommission aging equipment across a field, they’d have to spend more than US$40mn on tools alone.”

She added that using just one set of tools to decommission the various components of any number of wells in a field, is more efficient, than having to use a variety of tools, and can therefore also reduce time spent on the decommissioning by between 30% and 50%.

View the full opinion piece from Baker Hughes, including real life examples of agnostic tooling being supplied, an exploration of how passive well monitoring systems can further help reduce costs and how the company is working to secure the safety of offshore decommissioning projects at: https://www.bakerhughes.com/company/energy-forward/aging-subsea-wells-brim-opportunity

Sapura Energy and Norway-based AF Offshore Decom launched their joint decommissioning venture called Kitar Solutions at OTC Asia 2024.

Sapura Energy and Norway-based AF Offshore Decom launched their joint decommissioning venture called Kitar Solutions at OTC Asia 2024.

Sapura's strategic assets and AF Offshore Decom's extensive North Sea decommissioning expertise have resulted in Kitar Solutions, which will undertake decommissioning projects with a customised approach, while prioritising risk mitigation and sustainability.

Sapura Energy defines Kitar as a comprehensive suite of engineering, preparations, removal and disposal (EPRD) services that streamlines the decommissioning process, and reflects the company's dedication to advancing decommissioning techniques and promoting effective waste management and recycling.

Kitar Solutions boasts of unique capabilities from facility isolation and cleaning, removal and disposal of topsides, jackets and subsea structures, to engineering and verification surveys. It has dedicated zones for both ship disposal and offshore structure disposal, where installations can be dismantled, recycled and repurposed.

Offshore Network has released a free-to-download report outlining the developing prospects for the Asia Pacific’s offshore well intervention industry.

The wider energy sector is facing daunting challenges in the shape of increasing electricity consumption and the ever-increasing demand to limit environmental impact. While the rise of cleaner energy sources such as renewables appear unstoppable, there does, however, remain a place at the table for oil and gas, with fossil fuels set to continue to be an important component of the energy mix for the decades ahead. This trend is particularly pronounced in Asia, which is set to dominate global oil demand growth in 2024 and beyond.

While drilling has traditionally provided the answer to meeting growing demand, rising costs, uncertainty of success and environmental concerns are turning heads away from this activity and towards the potential of well intervention. The emergence of this is also being encouraged by the need for plugging and abandonment, a concern ever-growing in urgency as the region’s well stock continues to age. With market conditions opportune for well intervention to take centre stage, there remain some key challenges that must be overcome before it can fully step into the spotlight and fulfil its potential.

Offshore Network’s latest outlook assesses these key challenges such as collaboration and operator-service provider disharmony while examining the vast opportunities the region is offering.

Pertamina Geothermal Energy (PGE), an Indonesia-based company, has signed a Memorandum of Confidentiality Agreement with Turkish energy company Kipaş Holding to start a cooperation for the utilisation of geothermal energy.

Pertamina Geothermal Energy (PGE), an Indonesia-based company, has signed a Memorandum of Confidentiality Agreement with Turkish energy company Kipaş Holding to start a cooperation for the utilisation of geothermal energy.

The Indonesian Embassy in Ankara facilitated PGE’s efforts to seek cooperation in geothermal exploration with various companies throughout Türkiye. PGE and Kipaş Holding are both interested in carrying our exploration projects cooperatively in both Türkiye and Indonesia, and are open to the possibility of a joint investments elsewhere.

The signing of the agreement was carried out by Julfi Hadi, President Director of PGE, and Mehmet Şişman, General manager of Kipaş Holding, witnessed by the Indonesian Ambassador to Türkiye, Achmad Rizal Purnama.

“We are happy to have met with Pertamina Geothermal Energy and hope that the cooperation will be fruitful with an exchange of information and experience for geothermal energy sector improvement in both Türkiye and Indonesia,” commented Şişman.

Page 7 of 14

Copyright © 2025 Offshore Network