Tekmar Group, based in the UK, has secured another significant contract in the Middle East, continuing its strong momentum in the region

Tekmar Group, based in the UK, has secured another significant contract in the Middle East, continuing its strong momentum in the region

This new deal, valued at over $10 million, involves the provision of Tekmar's advanced cable protection system, TekDuct, and engineered ballast modules for an offshore energy project in the United Arab Emirates.

The contract is with a leading international engineering, procurement, and construction (EPC) contractor. Under the agreement, Tekmar will design and manufacture its polyurethane cable protection system, with work beginning immediately and final delivery scheduled for the first quarter of 2026.

Richard Turner, CEO of Tekmar Group, said, “We are delighted to partner again with this major customer on a significant energy project. This award reflects our strong presence and track record in the Middle East and underpins our position as a market leader in supporting customers with high-quality engineered asset protection technology."

He added, “This contract is also an important marker as we translate our healthy pipeline to good quality orders and build the platform for sustained growth for 2026 and beyond.”

Earlier this year, Tekmar also announced a contract for the supply of bespoke subsea infrastructure technology for a pipeline project in the Middle East, though the exact location has not been disclosed. In August, the company secured two offshore grouting contracts in Qatar, valued at approximately $1.6 million, to support subsea infrastructure inspection, maintenance, and repair (IMR) campaigns.

HIMA Group, the global safety automation expert, is setting new benchmarks for functional safety in the offshore industry. The company is showcasing its expanded portfolio, which combines decades of expertise with next-generation digitalisation to enhance safety, security, and efficiency across oil and gas, offshore wind, hydrogen, and carbon storage operations.

With Sella Controls and Origo Solutions now part of the HIMA Group, operators and contractors benefit from powerful synergies and a broadened offering that covers the entire safety automation value chain. Together, the group is delivering unmatched consulting, engineering, and project execution expertise across conventional and renewable offshore projects.

At the heart of HIMA’s portfolio is its independent open safety platform, which integrates hardware and software on a single technology base. Certified by TÜV, Lloyd’s Register, Bureau Veritas and DNV, the platform enables functional safety, OT security, and compliance with international standards, while also driving process efficiency and improving plant availability.

Under its #safetygoesdigital strategy, HIMA is accelerating the transition toward digitalised safety lifecycle management. This includes innovative tools like Safety Lifecycle Digitalisation (SLD) Cockpits, which use dashboards and data-driven monitoring to optimise productivity, streamline compliance, and improve safety outcomes.

HIMA Group's solutions are employed all over the world, but especially in the Middle East through the HIMA Middle East division located in Dubai.

The group’s proven solutions extend from high-integrity pressure protection systems (HIPPS) with Planar 4 technology for critical offshore applications, to turbomachinery control solutions with SIL3 compliance and advanced load-sharing capabilities. Origo Solutions’ SCADA+ platform brings flexible control and visualisation across wind, hydrogen, and oil and gas plants, now further enriched by HIMA integration. Meanwhile, FLOWorX® delivers comprehensive pipeline management and leak detection with high sensitivity and real-time monitoring, also suitable for hydrogen applications.

Other highlights include SafeHMI, a new approach to safe plant operations with inherent safety features and digitalised management of change. These developments reflect HIMA’s vision of building a future where digitalisation strengthens safety and resilience across the offshore sector.

By uniting the expertise of HIMA, Sella Controls, and Origo Solutions, the group is shaping the future of functional safety in offshore operations and reinforcing its position as a trusted partner for energy companies navigating both traditional and renewable transitions.

EnerMech has been awarded a two-year extension to its existing contract with Dubai Petroleum, continuing its role in delivering crane maintenance services across the operator’s offshore assets in the Middle East.

EnerMech has been awarded a two-year extension to its existing contract with Dubai Petroleum, continuing its role in delivering crane maintenance services across the operator’s offshore assets in the Middle East.

The original agreement, which began in 2022, included an optional extension clause that Dubai Petroleum has now activated. Under this renewed commitment, EnerMech will carry on providing both planned and corrective maintenance, deploying dedicated personnel across multiple offshore locations.

The extended scope also involves additional on-call services, as well as onshore repair and refurbishment of crane components. This includes sourcing spare parts and offering engineering upgrades for outdated or obsolete equipment—ensuring ongoing operational safety and efficiency.

The United Arab Emirates and the broader Middle East remain a key strategic focus for EnerMech. The company has significantly strengthened its footprint in the region through a number of recent contract wins, all aligned with its long-term goal of expanding services to local energy sector clients.

“We are ambitious in our aims in the Middle East and the extension of this contract is material evidence of the fine work that our regional team has undertaken for Dubai Petroleum over the initial phase of work.

“Our lifting solutions service line personnel are renowned for delivering safe, efficient operations which provide our customers with industry leading capabilities and I commend them for achieving this strategically important extension,” said Charles ‘Chuck’ Davison Jr., EnerMech CEO.

The extension reflects both Dubai Petroleum’s confidence in EnerMech’s capabilities and the company's growing reputation for delivering safe, high-performance lifting solutions. With a focus on quality service, safety, and technical expertise, EnerMech continues to build strong partnerships within the offshore energy sector.

As the region pushes forward with infrastructure upgrades and asset integrity improvements, EnerMech’s continued presence positions it as a trusted service provider supporting critical offshore operations in the Gulf.

Halliburton has announced the launch of SK Well Pages, a new addition to its Summit Knowledge (SK) digital ecosystem, aimed at transforming how electric submersible pump (ESP) operations are managed.

This integrated platform enhances decision-making and production optimisation through the use of AI, machine learning, and advanced data analytics.

Part of Halliburton’s wider strategy to digitise oilfield operations, SK Well Pages provides a unified workspace tailored for ESP and HPS (horizontal pump systems) operations. It consolidates engineering, manufacturing, and real-time operational data to offer a complete, up-to-date view of performance. The platform also introduces automated workflows, improving both quality control and operational efficiency.

Designed with usability in mind, SK Well Pages includes customisable dashboards that offer clear visualisations of pump performance, surface sensors, and production trends. This enables proactive real-time monitoring and supports faster, more informed decision-making.

The platform is fully integrated with Halliburton’s advanced digital tools, including SpyGlass, for accurate pump sizing, and the Intelevate platform, which provides remote monitoring and control. Intelligent alerts, predictive models, and trend analysis help reduce downtime and extend equipment lifespan.

Greg Schneider, vice president, Artificial Lift, Halliburton, said, “We provide customers with advanced digital tools that give them clarity and control to make confident decisions. The Summit Knowledge digital ecosystem with SK Well Pages is a powerful step forward in the journey of how we deliver digital innovation for superior ESP optimisation.”

With SK Well Pages, Halliburton continues to drive innovation in artificial lift technology, offering oilfield operators a smarter, more connected way to optimise production.

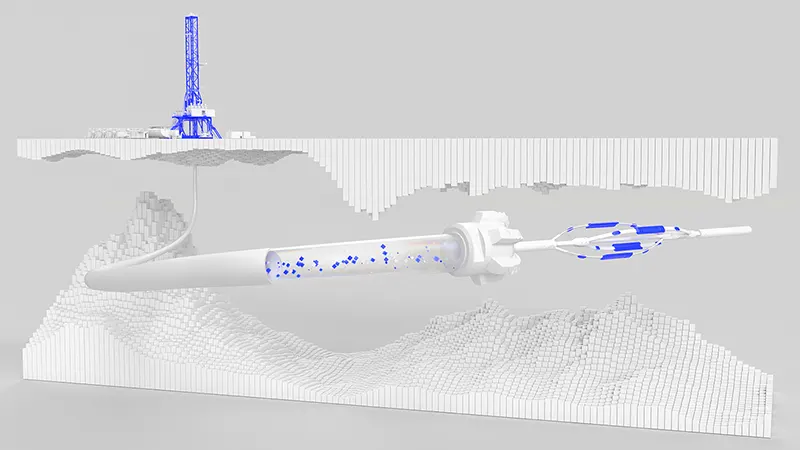

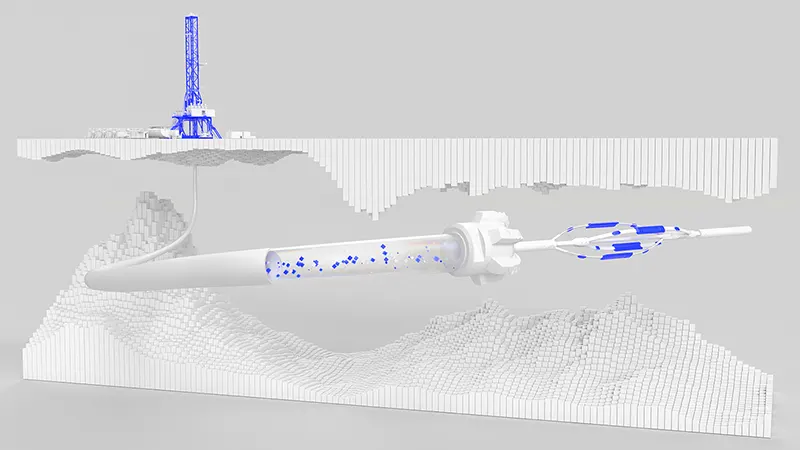

Expro, a global provider of energy services, has achieved a significant breakthrough in its international operations with the successful delivery of the world’s first fully remote five-plug cementing operation in Saudi Arabia. This marks a major step forward in the company’s strategic expansion across the Middle East and showcases its dedication to innovation, safety, and advanced engineering in the well construction space.

Expro, a global provider of energy services, has achieved a significant breakthrough in its international operations with the successful delivery of the world’s first fully remote five-plug cementing operation in Saudi Arabia. This marks a major step forward in the company’s strategic expansion across the Middle East and showcases its dedication to innovation, safety, and advanced engineering in the well construction space.

The landmark operation was carried out using Expro’s Generation-X Remote Plug Launcher (RPL) and the SkyHook cement-line make-up device—two proprietary technologies designed to automate complex cementing processes. This fully hands-free system enabled a multi-stage cementing job to be completed without any red-zone entry or man-riding operations, setting a new benchmark for operational safety and remote performance in the field.

This latest achievement builds on Expro’s initial cementing job in the Kingdom, completed in January. That successful operation laid the groundwork for rapid growth in the region, culminating in the delivery of this more complex five-plug job in May. Both operations reflect Expro’s deliberate progression from market entry to technology leadership, highlighting the scalability, precision, and reliability of its automated cementing solutions in high-demand environments.

The recent five-plug operation involved cementing a 9-5/8” casing in a high-pressure gas well—the longest of its kind in the field. All five components were pre-loaded into the modular Generation-X RPL in a controlled environment and launched remotely at the well site with high accuracy. This significantly reduced rig time, eliminated high-risk manual tasks, and improved cement placement and zonal isolation-critical factors in maintaining long-term well integrity.

“Our entry into Saudi Arabia is more than just geographic expansion – it’s about transforming cementing operations through advanced engineering,” said Jeremy Angelle, Vice President of Well Construction at Expro. “This breakthrough showcases our Generation-X and SkyHook technologies as world-class innovations that drive measurable safety and efficiency gains.”

Additional deployments of these technologies across the region have further validated their performance, with one customer achieving cement displacement rates of up to 13 bpm through the top drive—delivering cleaner wellbores, quicker casing-to-cement transitions, and shorter wellbore static times.

“Both the Generation-X launcher and SkyHook system were designed with safety, control, and field adaptability in mind,” Angelle added. “To see them deliver such strong results in a new region is a proud moment, and a signal of what’s possible as we grow our well construction capabilities globally.”

Expro continues to invest in expanding its footprint in Saudi Arabia and beyond, aligning its offerings with evolving customer needs in oil, gas, and geothermal markets. With proven success and growing demand, its remote cementing solutions are now poised for wider global adoption.

Saudi Arabia’s ADES International Holding has signed a deal to acquire rival offshore rig operator Shelf Drilling in a transaction valued at US$379.8mn.

The deal, subject to shareholder approval and other closing conditions, is expected to complete in the fourth quarter of 2025.

Once finalised, the combined entity will operate 83 offshore jack-up rigs, including 46 premium units, across key shallow-water basins worldwide, with a total backlog of US$9.45bn as of 30 June 2025.

ADES anticipates achieving annual operational cost synergies of US$40mn-50mn over the medium term and plans to settle Shelf Drilling’s existing debt obligations. The company also said it would work to optimise the new group’s capital structure and operational efficiency.

Dr. Mohamed Farouk, CEO of ADES, said, "Over the past years, we have unlocked new geographies and deepened our strategic reach. With this landmark transaction, we reinforce our position as a market leader in shallow-water offshore drilling, offering superior services to our client base alongside enhanced scale, asset quality and operational reach.

“As part of the transaction, we will add 33 jackups and a dedicated, experienced workforce, supporting expansion into additional regions and further strengthening our global footprint.”

“Today’s announcement delivers immediate and compelling value to our shareholders, reflecting both the strength of our business and the dedication of our employees. Over the past 13 years, Shelf Drilling has built a resilient company with an outstanding safety track record and a reputation for operational excellence.

“This transaction unites two highly complementary organizations, and we are confident that the combination will unlock the full strategic value of our global fleet and operations. We look forward to working closely with the ADES team to ensure a seamless and successful integration,” said Greg O’Brien, CEO of Shelf Drilling.

NMDC Energy, a leading EPC (engineering, procurement, and construction) service provider for onshore and offshore energy industries, has officially started fabrication activities at its advanced facility in Ras Al-Khair, Saudi Arabia. The commencement of steel cutting signifies the start of full operations, reinforcing the company’s commitment to supporting Saudi Arabia’s industrial growth and energy development goals.

NMDC Energy, a leading EPC (engineering, procurement, and construction) service provider for onshore and offshore energy industries, has officially started fabrication activities at its advanced facility in Ras Al-Khair, Saudi Arabia. The commencement of steel cutting signifies the start of full operations, reinforcing the company’s commitment to supporting Saudi Arabia’s industrial growth and energy development goals.

The Ras Al-Khair yard, covering 400,000 square metres, is situated in the strategically important Ras Al-Khair Special Economic Zone. Designed to support both offshore and onshore projects, it has an annual fabrication capacity of 40,000 tonnes. The facility is equipped with advanced automation, digital tools, and provides comprehensive services including fabrication, rigging, modularisation, and maintenance for complex energy infrastructure.

With an investment of AED 200 million, NMDC Energy has created a safe, modern, and sustainable workspace aimed at reducing emissions and aligning with Saudi Aramco’s and the Kingdom’s energy sector needs.

Mohamed Hamad Almehairi,Chairman of NMDC Energy, said, “The start of fabrication in Ras Al-Khair is a significant step in our regional expansion. With over 51 years of experience, NMDC Energy is proud to bring its proven expertise to Saudi Arabia. This yard is not just an operational asset—it’s a strategic investment supporting industrial growth, local capability, and regional transformation.”

Currently, nine offshore jackets are in production for long-time client Aramco. This milestone enhances NMDC Energy’s presence in the Kingdom and aligns with Saudi Arabia’s Vision 2030 by adding new industrial capabilities. To support operations, over 1,800 skilled staff will be relocated from Abu Dhabi to ensure top-quality standards and seamless project execution.

The Ras Al-Khair facility plays a central role in NMDC Energy’s localisation efforts. The company has already reinvested billions of riyals into Saudi Arabia and aims to increase its iktva (In-Kingdom Total Value Add) score to 39% by 2025 and 51% by 2028.

Ahmed Al Dhaheri CEO Eng. said, “This facility underlines our commitment to supporting Saudi Arabia’s localisation agenda and delivering high-scale, complex projects. With decades of expertise, NMDC Energy is ready to support national industrial ambitions and energy infrastructure needs.”

As a key tenant in the Ras Al-Khair Special Economic Zone, NMDC Energy contributes to trade, job creation, and long-term investment in the region. The company plans to use the yard’s full potential to drive innovation and strengthen the energy and manufacturing sectors across the Gulf.

SLB has acquired Stimline Digital AS, a leading well intervention software company.

SLB has acquired Stimline Digital AS, a leading well intervention software company.

Stimline Digital’s IDEX platform provides operators features powerful visualisation capabilities and enables a collaborative environment to optimise the planning and execution of well intervention operations. Powered by AI, the application enables operators to efficiently standardise digital workflows through all phases of interventions, from planning through to real-time execution and post-job analysis.

The IDEX platform will be integrated with SLB's data environment and advanced intervention applications for planning and modelling, providing operators with the ability to create intelligent, data-driven workflows and thus ensuring greater consistency, efficiency and performance for well interventions.

“With 80% of global production expected to come from mature fields by 2030, innovative digital technologies are needed to improve the success rate and economics of interventions,” said Frederik Majkut, president, Reservoir Performance, SLB. “Through this acquisition, we aim to scale adoption of the IDEX platform as an agnostic ecosystem to help the industry standardise cumbersome planning and execution processes. We will also integrate it with our technology stack and domain expertise to provide our customers with well intervention performance assurance.”

The MENA region could potentially be a strong market for SLB’s strengthened well intervention capabilities, given the prevalence of mature fields and the focus on EOR activities.

In addition to its well intervention capabilities, the IDEX platform will enable teams to collaborate on and publish digital well operations procedures with full traceability and control, as well as supporting the real-time execution tracking of these procedures.

SLB, a global energy technology company, has launched the OnWave autonomous logging platform, a first-of-its-kind solution designed to improve the efficiency and safety of formation evaluation in all well conditions.

SLB, a global energy technology company, has launched the OnWave autonomous logging platform, a first-of-its-kind solution designed to improve the efficiency and safety of formation evaluation in all well conditions.

The OnWave platform operates without the need for a wireline unit or cable. Its cable-free design allows it to be deployed in less than half the time of traditional wireline systems. It also permits drill pipe rotation and mud circulation during operations, reducing the risk of stuck pipe incidents and boosting overall well safety.

“The OnWave platform marks the beginning of a new era in formation evaluation,” said Frederik Majkut, president of Reservoir Performance at SLB. “By streamlining how we gather high-fidelity measurements downhole, we are opening up key opportunities for our customers to integrate data-driven decision making into their workflows across the well life cycle — from exploration through to production and recovery, he added.

The platform can be used in any well trajectory and does not require an SLB crew onsite. It autonomously handles key downhole tasks that would normally need surface-based engineers, including data acquisition and quality control. Uniquely, it maintains continuous communication with the surface, confirming tool status and position in real time — something most wireless logging systems cannot do. This ensures data quality and avoids the need for repeat runs.

The OnWave platform has been deployed successfully in various regions, including the United States and the Middle East. In South Texas, it cut landing time to total well depth from hours to just 27 minutes, a 70% reduction compared to traditional methods. Data processed at the surface delivered high-quality petrophysical and acoustic insights, enabling better completion and stimulation design, and helping to derisk field development for the operator.

L&T Energy Hydrocarbon Offshore has received a substantial order from a major client in the Middle East.

The company made the announcement on 29 July, explaining that the order covers numerous offshore packages, including engineering, procurement, construction, and installation of offshore structures, as well as upgrades to existing facilities. The order is worth more than US$1.7bn, according to a press statement issued by the company.

L&T did not name the client or the country it will be operating in.

Calling it an 'ultra-mega' order, L&T said that its hydrocarbon offshore vertical helps the offshore oil and gas industry in a significant manner, and is the main provider of engineering, procurement, construction, installation, and commissioning (EPCIC) solutions.

With strong in-house engineering capabilities, cutting-edge manufacturing yards, and a dedicated fleet of marine vessels, L&T has a proven track record in both shallow and deep-water field development.

Over the last three decades, it has completed complicated projects requiring permanent platforms, subsea pipes and structures, brownfield renovations, and decommissioning.

L&T added that "this ultra-mega order demonstrates the speed and precision with which the Hydrocarbon Offshore business vertical delivers complex projects around the world while complying to world-class safety standards."

Larsen & Toubro is a US$30bn Indian multinational that specialises in EPC projects, high-tech manufacturing, and services across different regions.

In March this year, the company had bagged another ultra-mega project from QatarEnergy LNG.

Qatar had awarded L&T an offshore contract for the North Field Production Sustainability Offshore Compression Project (NFPS COMP), making it the largest single contract ever received by the company at the time.

The scope of work included the engineering, procurement, fabrication, installation, and commissioning of two offshore compression complexes, each consisting of large offshore platforms with compression and power generation facilities, living quarters, flare platforms, interconnected bridges, and other associated structures to be located approximately 80 km off the northeast coast of Qatar.

Commenting on the Qatari development, S.N. Subrahmanyan, Chairman and Managing Director – L&T had commented, “Securing QatarEnergy LNG’s Ultra Mega Offshore Contract – largest single order in our history, is a landmark achievement. This prestigious project strengthens our global energy portfolio while supporting Qatar’s energy security objectives. We look forward to setting new benchmarks in project execution that will reinforce Qatar’s position as a global LNG leader.”

The Middle East and Africa well intervention market, valued at US$2.4bn in 2024, is projected to reach US$4.6bn by 2034, driven by a 6.4% CAGR, fueled by the region's focus on ageing oilfields and rising energy demands.

These figures, published by Global Market Insights (GMI), also reveal that this growth is evident in recent activities across Saudi Arabia, the UAE, and Egypt, where advanced well intervention techniques are enhancing oil and gas production. According to GMI, the offshore segment in this industry is expected to grow by 7% between 2025 and 2034.

In Saudi Arabia, the well intervention market is expected to reach US$510mn by 2034, propelled by extensive proven oil reserves and a focus on mature fields. In July 2024, Saudi Aramco announced discoveries in the Eastern Province, including two unconventional oil deposits, a light oil reservoir, and multiple gas fields, with the Al-Ladam field’s Ladam-2 well producing 5,100 barrels of very light Arabian oil and 4.9 million standard cubic feet of gas daily. These discoveries necessitate well intervention techniques like hydraulic fracturing and acid stimulation to optimise output from low-pressure wells and shale reserves, addressing the increasing presence of such assets.

In the UAE, ADNOC’s US$1.7bn contract awarded to ADNOC Drilling Company in May 2024 for 144 unconventional oil and gas wells is actively progressing this year. Well intervention services, including coiled tubing and wireline logging, are critical for maintaining well integrity and boosting production efficiency in these unconventional resources, reflecting the region’s shift toward complex geological challenges.

In Egypt, BP Egypt’s discovery of a substantial gas reservoir near its Temsah offshore operations in September 2024 spurred increased well intervention activities by July 2025. Companies deployed advanced logging services to assess reservoir changes and optimise production, driven by rising energy consumption and urbanisation. These efforts align with the region’s growing focus on deep and ultra-deep-sea explorations, where well intervention is essential for sustaining output.

Technological advancements are pivotal. In February 2024, Odfjell Technology opened a 10,000 sq m facility in Saudi Arabia’s Eastern Province, enhancing wellbore maintenance and intervention operations. By June 2025, this facility supported expanded drilling and intervention with new machinery and workforce growth. Strategic partnerships and mergers are also strengthening market positions, with companies investing in R&D for innovative intervention tools tailored to mature fields.

Government initiatives are fostering growth. Policies in Saudi Arabia and the UAE prioritise developing mature fields, with the zonal isolation segment expected to generate significant revenues by 2034. These efforts reflect a regional strategy to meet energy demands while extending the life of existing oil and gas assets through advanced well intervention techniques.

The newly rebranded MENA WELLS 2025 is set to bring together the Middle East and North Africa’s leading well operations professionals on 9–10 September 2025 at the Bab Al Qasr Hotel, Abu Dhabi.

The newly rebranded MENA WELLS 2025 is set to bring together the Middle East and North Africa’s leading well operations professionals on 9–10 September 2025 at the Bab Al Qasr Hotel, Abu Dhabi.

Previously known as OWI MENA, the event has been refreshed to cover the entire well lifecycle — from integrity and intervention to decommissioning and productivity — reflecting the evolving needs of the industry across both onshore and offshore assets.

This year’s agenda is packed with more than 25 expert presentations, 10 live technology demos, and five dedicated networking sessions, offering valuable insight and opportunities to connect. Delegates will also benefit from exclusive access to PDO’s Workover Journey Workshop and the IMCA Regional Meeting, making it one of the most comprehensive well-focused gatherings in the region.

Senior engineers, technical leads, and decision-makers from organisations including ADNOC, Petrobel, PDO, and EGPC will take the stage to share real-world case studies and practical lessons. Topics include advanced well diagnostics, expanding the use of glass plug and steel patch technologies, managing legacy assets, and improving diver safety during subsea decommissioning.

New sessions will also highlight how AI, data analytics, and next-gen materials are reshaping maintenance planning and enhancing long-term well integrity. Whether you’re involved in drilling, completions, production, or abandonment, MENA WELLS 2025 delivers timely, relevant content to help teams boost performance while meeting rising safety and sustainability expectations.

The event is designed to support collaboration and knowledge exchange — from the technology showcase hall to the VIP meeting area, where sponsors, operators, and solution providers can discuss projects and build strategic partnerships in a focused setting.

"It was an amazing conference where we learned about new technologies and some very good presentations on production optimization and plug and abandonment." said Muhammad Farooqn Zubair, Senior Completion and Workover Engineer, ADNOC.

Early bird rates are available until 8 August 2025, so now is the time to secure your place. For full information, download the brochure at https://events.offsnet.com/MENAWells2025#/Brochure

Page 3 of 12

Copyright © 2025 Offshore Network