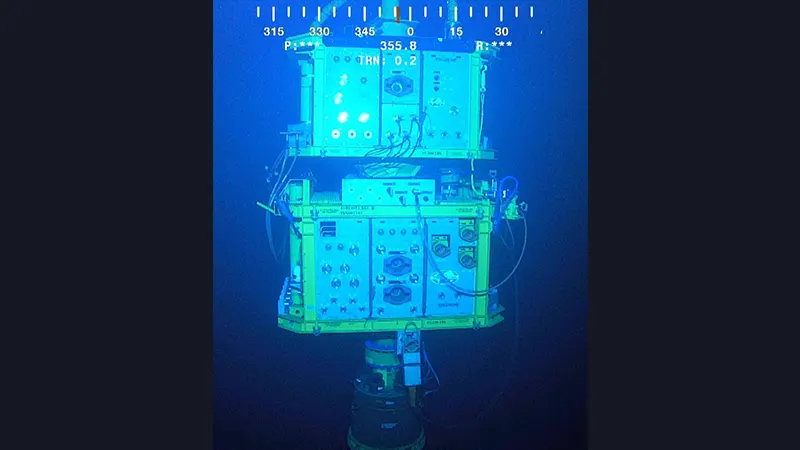

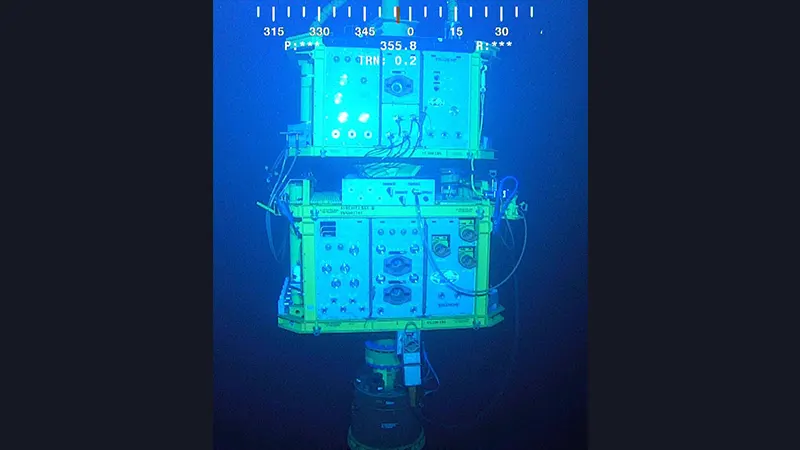

Houston-based subsea hardware and offshore service solutions, Trendsetter Engineering, has deployed for the first time its flagship Trident 20K Intervention System for Beacon Offshore Energy’s Shenandoah project in the Gulf of America

Houston-based subsea hardware and offshore service solutions, Trendsetter Engineering, has deployed for the first time its flagship Trident 20K Intervention System for Beacon Offshore Energy’s Shenandoah project in the Gulf of America

The deployment was initiated from the Deepwater Atlas for a two-well flowback operation at the Shenandoah site. The system was wet-hopped between wells, which not only helped to cut down operational costs but also several days of critical path rig time. The system is currently undergoing post-campaign maintenance by Trendsetter so that it is ready for further deployments.

The launch of the 20K Open Water Intervention Riser System (OWIRS) with its first deployment marks a milestone for Trendsetter.

The 20K intervention system enhances the company's fleet of rental intervention kits. It is the realisation of a groundbreaking innovation as it has been on the cards since the company's 2020 launch -- Trident 15K Intervention System. It was the result of dedicated research, development, engineering, design, assembly, and testing.

From exploration drilling through abandonment, Trendsetter Engineering offers solutions globally.

Register here for Offshore Network's global well intervention and decommissioning conferences.

In yet another move to roll back Biden-era legislation, The U.S. Department of the Interior (DOI) has announced it intends to revise the Bureau of Ocean Energy Management’s 2024 Risk Management and Financial Assurance for OCS Lease and Grant Obligations Rule.

In yet another move to roll back Biden-era legislation, The U.S. Department of the Interior (DOI) has announced it intends to revise the Bureau of Ocean Energy Management’s 2024 Risk Management and Financial Assurance for OCS Lease and Grant Obligations Rule.

The rule increased the financial assurance requirements for offshore operators to ensure they meet their decommissioning obligations and was designed to “better protect the taxpayer from potentially bearing the cost of facility decommissioning and other financial risks associated with OCS development, such as environmental remediation.”

This rule was challenged by the Republican-led states of Louisiana, Mississippi and Texas and oil and gas industry groups, who argued that it would result in "potentially existential consequences" for small and medium-sized companies, although a federal judge earlier this year rejected their bid to block the rule. According to the DOI this rule was estimated to increase financial assurance requirements for offshore oil and gas operators by US$6.9bn in additional bonding, costing businesses an additional US$665mn in premiums each year.

The Trump administration intends to develop a new rule that will supposedly cut costs and red tape and free up billions of dollars for American producers to use to explore and produce oil and gas in the Gulf of America while protecting American taxpayers against high-risk decommissioning liabilities, according to the DOI statement.

“This revision will enable our nation’s energy producers to redirect their capital toward future leasing, exploration, and production all while financially protecting the American taxpayer,” said DOI Secretary Doug Burgum. “Cutting red tape will level the playing field and allow American companies to make investments that strengthen domestic energy security and benefit the Gulf of America states and their communities.”

The Department expects to finalise the rule this year, and will welcome public comments on the proposal.

The Bureau of Ocean Energy Management will continue to require all operators on the Outer Continental Shelf to provide financial assurance for their decommissioning obligations.

In a contract with Shell Offshore, innovative solutions provider, CRP Subsea, will be supplying crushable foam wrap (CFW) for the Whale deepwater development situated 200 miles south of Houston in the Gulf of America

In a contract with Shell Offshore, innovative solutions provider, CRP Subsea, will be supplying crushable foam wrap (CFW) for the Whale deepwater development situated 200 miles south of Houston in the Gulf of America

The contract covers one well-set to be delivered by Q3 2025, followed further by the generation of four additional well-sets over the year. Each well-set are made of 1,798 CFW quadrants, each one metre in length. Other components include installation equipment, such as adhesive (one tube per two quadrants), adhesive dispensing guns, tie wraps, and Spanset straps.

An engineered syntactic foam, CFW comprises of a thermoset resin and hollow glass microspheres (HGMS). Once installed around the inner drill casing, it is immersed in the annulus fluid. As pressure within the annulus increases, the CFW will collapse at a pre-determined pressure and temperature combination, as dictated by well conditions. This controlled collapse allows for the expansion of annulus fluid, dispersing potentially destructive pressure build-up.

Andy Smith, Head of Sales, said, "It’s fantastic that Shell has chosen us to support this exciting deepwater project. We’ve been manufacturing and deploying crushable foam wrap for decades, helping to protect wells around the world. This contract is a great validation of our team’s expertise and dedication to delivering high-quality solutions for the industry."

The CFW will be produced at the company's Skelmersdale facility, once project engineering begins shortly.

Click here to know more about Offshore Network's well intervention conferences.

One of the Gulf of Mexico’s leading late-life decommissioning specialist, Promethean Energy, has completed the decommissioning of offshore orphaned wells in the Matagorda Island lease area.

One of the Gulf of Mexico’s leading late-life decommissioning specialist, Promethean Energy, has completed the decommissioning of offshore orphaned wells in the Matagorda Island lease area.

Steve Louis, SVP of Decommissioning at Promethean, said, “Our team is incredibly proud to have completed this critical work efficiently, safely and ahead of budget. By integrating our expertise, technologies and strategic partnerships, we have demonstrated that decommissioning can be both cost-effective and environmentally responsible.”

The project began with drone inspections, safety preparations and detailed well diagnostics, leading to the lower and upper P&A of the wells. Promethean’s approach aligns with its commitment to leveraging cutting-edge technology to ensure safe and responsible end-of-life asset management.

Clint Boman, Senior Vice President of Operations, commented, “We are advancing standards at Matagorda Island and providing a replicable model for similar projects worldwide. Our focus is – and always will be – raising standards for safety, efficiency and innovation in decommissioning across our industry. For example, we implemented visual intelligence tools to manage safety risks associated with ageing offshore infrastructure addressing a long-standing industry challenge.”

Ernest Hui, Chief Strategy Officer of Promethean Energy, concluded, “Building on our strong execution performance, our strategy is to continue identifying synergies with other asset owners, fostering collaboration, and developing sustainable decommissioning campaigns that drive efficiency across the industry."

Inching closer towards its goals to hit 300,000 net barrels per day of oil equivalent from the Gulf in 2026, Chevron Corporation has started production from the Ballymore subsea tieback in the deepwater Gulf of America.

Inching closer towards its goals to hit 300,000 net barrels per day of oil equivalent from the Gulf in 2026, Chevron Corporation has started production from the Ballymore subsea tieback in the deepwater Gulf of America.

The latest in a series of Chevron projects to start up last year, the company expects to produce up to 75,000 gross barrels of oil per day through three wells tied back three miles to the existing Chevron-operated Blind Faith facility.

“Ballymore is an example of how we are leveraging technology and driving efficiencies to help produce affordable, reliable energy from the deepwater Gulf of America, one of the lowest carbon intensity oil and gas producing basins in the world,” said Brent Gros, Vice President, Chevron Gulf of America. “Ballymore, which was completed on time and on budget, brings additional production online without building a new standalone offshore platform. This reduces our development costs and is expected to drive higher returns for shareholders.”

A prominent leaseholder in the Gulf, Chevron is keen on exploring further growth opportunities in the basin. Since last year, the company has started production from its industry-first Anchor project and non-operated Whale project and has been prioritising water injection to boost output at its operated Tahiti and Jack/St. Malo facilities.

Estimated potentially recoverable resources at Ballymore are 150 mn barrels of oil equivalent gross over the life of the project. Ballymore is located in the Mississippi Canyon area in around 6,600 feet (2,000 m) of water, about 160 miles (260 km) southeast of New Orleans. The development is Chevron’s first in the Norphlet trend of the Gulf.

The major's subsidiary Chevron USA Inc is operator of the Ballymore project with 60% working interest, along with TotalEnergies E&P USA, Inc who owns 40% working interest.

Decom Engineering, subsea cutting specialist and provider of green decommissioning solutions, continues to expand globally, winning contracts for its subsea cutting solutions in the Gulf of Mexico and elsewhere.

Decom Engineering, subsea cutting specialist and provider of green decommissioning solutions, continues to expand globally, winning contracts for its subsea cutting solutions in the Gulf of Mexico and elsewhere.

The company won contracts v.alued at more than £2 million (US$2.7 million) in the first quarter of 2025, including a chain cutting scope in the Gulf of Mexico in which it will deploy its new ultra-light and neutrally buoyant C1-16 chopsaw to cut studless mooring chains.

Offshore Brazil a 300-day campaign will see two C1-16 chopsaws cutting multiple link mooring chains of up to 142mm diameter, while a project due to start offshore Nigeria will involve tender cutting and flexible riser cutting scopes.

Decom Engineering’s range of cold cuttings Chopsaws can perform “clean cuts” through 2-46” materials and which can operate in the harshest working conditions, including subsea. The cutting saws are a cost-effective, snag-free alternative to diamond wire saws and hydraulic shears, and can be deployed on pipes, drill pipe, conductors, umbilicals, chains, wire rope and more.

Decom recognised the need to devise neutrally buoyant integration for its cutting tools when it was last year commissioned to assist with the removal of 30” conductors - with flexible risers inside - on the Brent Charlie platform in the UKCS. Due to the seabed conductor layout and restricted 3 metre width access, Decom’s C1-32 chopsaw had to be neutrally buoyant in seawater and easily manoeuvreable with a single ROV. Weighing approximately 6,700kg in air but only 50kg in seawater and with a blade diameter of 2,100mm, the C1-32 assisted with the cutting of 40 multi-string conductors, many with the added challenge of loose internal strings.

Decom Engineering commercial director Nick McNally said, “By analysing past campaigns in challenging environments including the Indian Ocean and the North Sea, we have fine-tuned our designs to perform seamlessly in extreme conditions.

“The development and integration of enhanced blade technology such as replaceable tips, custom deployment frames, and increased operational flexibility ensures that our tools are equipped to handle even the most demanding offshore operations with precision and reliability.

“On several projects we have been asked to assist on structural removal scopes after other cutting technologies have proven not to be capable, and this contingency role is now moving Decom into a position where we are becoming the first choice on larger and more complex scopes.”

Other solutions offered by Decom include a pipe coating removal machine which it says is the fastest and greenest process on the market. The cold process is capable of removing multiple coating types from decommissioned or surplus pipelines. The pipelines can then be repurposed and deployed in a number of sectors, for example piling and construction, which returns value to the client while decreasing the carbon footprint compared to using new steel.

Addressing a challenging deepwater permanent abandonment operation in the Gulf of America (GOA), Oilfield Service Professionals (OSP), along with Lee Energy Systems (LES), initiated the PerfPro Perf & Squeeze method to overcome the limitations that arise out of mechanical blowout preventer (BOP), posing an obstacle to conventional cut-and-pull operations for the 14.15” casing string. In case explosive perforative guns needed deployment, a lot of uncertainty centred marred casing centralisation, giving rise to potential risks of unintentional perforation across multiple casing strings.

Addressing a challenging deepwater permanent abandonment operation in the Gulf of America (GOA), Oilfield Service Professionals (OSP), along with Lee Energy Systems (LES), initiated the PerfPro Perf & Squeeze method to overcome the limitations that arise out of mechanical blowout preventer (BOP), posing an obstacle to conventional cut-and-pull operations for the 14.15” casing string. In case explosive perforative guns needed deployment, a lot of uncertainty centred marred casing centralisation, giving rise to potential risks of unintentional perforation across multiple casing strings.

There were also other challenges concerning high-risk lower marine riser package (LMRP) interventions, which could introduce debris into the well, leading to costly extended work scopes.

The Bureau of Safety and Environmental Enforcement-approved PerfPro Perf & Squeeze method offered an innovative low-risk solution to these challenges. The single-trip Perf & Squeeze method was implement by OSP and LES to leverage its safer, faster, and cost-effective alternative to conventional approaches. The package comprised NEXUS High-Pressure/High-Tensile Packer, Gator Perforator, CatchPro Dart/Ball Catcher, and BarrierPro Hydra-Set Bridge Plug with Scraper System.

The PerfPro Perf & Squeeze method altogether eliminated the need for LMRP intervention, leaving the potential well debris issues out of the question. Without the rig, more than 24 hours were saved in terms of downtime. The method provides assurance against explosive perforating guns to avoid unknown casing centralisation. It ensures access to the 14" x 22” annulus above the 16” TOL, enabling placement and verification of two critical zonal isolation barriers. It executed rapid planning, testing, and deployment, including a pre-job perforation test on 14.15” casing to confirm operational feasibility.

The PerfPro Perf & Squeeze approach saved operators more than US$1mn in operational cost savings while enhancing safety and efficiency . It has the potential to redefine primary P&A approaches.

To know more about the global well intervention scene, click here.

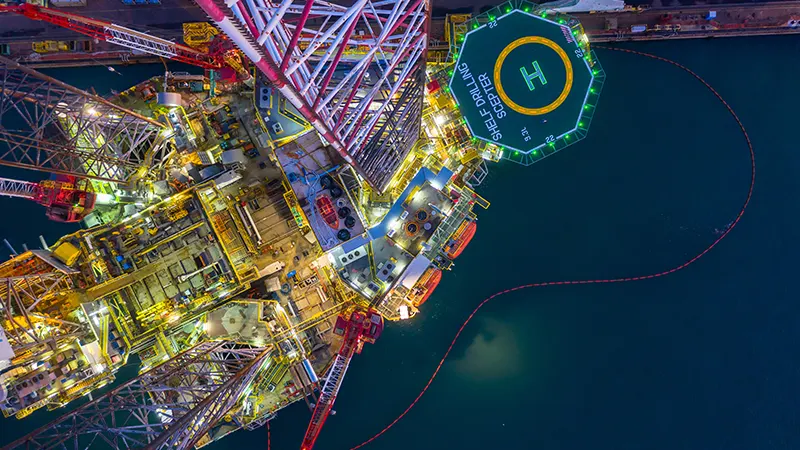

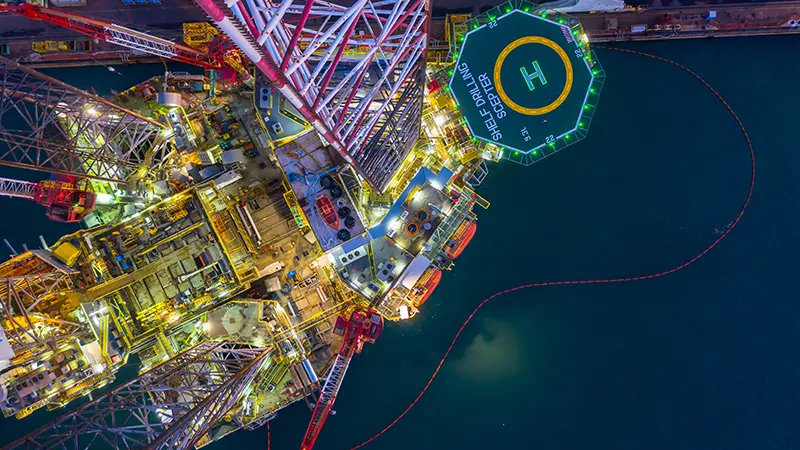

The Sparta deepwater development in the United States will be spearheaded by Subsea7 as the project's operator Shell Offshore Inc onboarded the subsea engineering and construction company for a sizeable contract, ranging somewhere between US$50-150mn.

The Sparta deepwater development in the United States will be spearheaded by Subsea7 as the project's operator Shell Offshore Inc onboarded the subsea engineering and construction company for a sizeable contract, ranging somewhere between US$50-150mn.

The contract mandates Subsea7 to oversee the transportation and installation of a floating production system (FPS) at Garden Banks block 959, which is located off the southeastern coast of Louisiana at water depths of up to 1,635 metres. The company's team have initiated project management and engineering activities from its office in Houston, Texas, aiming to start offshore operations in 2027.

Craig Broussard, Senior Vice President for Subsea7 Gulf of Mexico, said, “We are proud to continue our collaboration with Shell in the US, building on past projects, including the recent Vito development. We look forward to playing a key role in the successful delivery of the Sparta project.”

Partners involved in the Sparta project has conducted studies to find an estimated, discovered recoverable resource volume of 244 mn barrel of oil equivalent (boe), and is aiming to extract as much as 90,000 boepd. It is Shell’s 15th deep-water host in the Gulf of Mexico. Speaking of the project, the company's Integrated Gas & Upstream Director, Zoe Yujnovich said it "demonstrates the power of replication, driving greater value from our advantaged positions”. It is “aligned with our commitment to pursue the most energy-efficient and competitive projects while supplying safe, secure energy supplies today and for decades to come”.

To know more about Offshore Network's global well lifecycle conferences, click here.

A US federal judge struck down a vast lease sale for drilling rights in the Gulf of America, casting doubt over future oil well interventions in the region.

According to various news reports, the judge ruled that Lease Sale 261, held by the Biden Administration, violated environmental regulations, halting activities across more than 283,280 sq km of federal waters.

Organised by the Bureau of Ocean Energy Management (BOEM), the sale had auctioned off approximately 6,475 sq km for US$261.7mn.

The oil and gas lease sale was located in Gulf waters off the coast of Louisiana, and could threaten the survival of the endangered Rice’s whale species, according to environmental groups.

Statistics have placed the number of whales to just below 100 individuals.

Companies such as Chevron, ExxonMobil, and Shell secured leases aimed at boosting production in the Gulf, which supplies 14% of US crude oil, according to the US Energy Information Administration. However, environmental organisations, including Earthjustice and Sierra Club, challenged the sale, claiming it disregarded climate change consequences and risks to the endangered Rice’s whale.

The judge's decision hinged on the National Environmental Policy Act, finding that BOEM failed to properly evaluate the greenhouse gas emissions tied to future oil and gas output. The judge highlighted potential dangers from vessel strikes and noise pollution caused by drilling, deeming BOEM’s environmental analysis inadequate.

The ruling disrupts plans for oil well interventions and new subsea developments. Those projects are now in jeopardy, with the industry awaiting a resolution that could involve a revised review or cancellation of the leases entirely.

Associated Press added that The American Petroleum Institute, or API, an oil and gas trade association representing more than 600 firms and a party to the Gulf Coast case, said it is evaluating its options after this week’s ruling.

Negotiations to determine next steps are underway, but the immediate impact is clear, as billions in investments and planned interventions in the Gulf hang in the balance, leaving operators scrambling to adapt.

As the legal wrangle continues, the ruling underscores the growing tension between energy demands and environmental protection, with the Gulf of America at the centre of the debate.

Managing Director at Eye-bot Aerial Solutions, David Palmerton, has analysed the current decommissioning ambit within the Gulf of America, the challenges posed by the vast scope of end-of-life work to carry out, and how robotics and data-driven technologies play an integral role in transforming the market.

Managing Director at Eye-bot Aerial Solutions, David Palmerton, has analysed the current decommissioning ambit within the Gulf of America, the challenges posed by the vast scope of end-of-life work to carry out, and how robotics and data-driven technologies play an integral role in transforming the market.

In the Gulf of America, a significant number of offshore oil and gas wells and platforms are overdue for decommissioning. According to the Bureau of Safety and Environmental Enforcement (BSEE), there are 1,366 offshore structures, with 273 having submitted decommissioning applications and 451 located on terminated leases, of which only 192 have pending decommissioning applications. These delays pose environmental risks, including potential leaks, structural failures, and threats to marine ecosystems as well as increased costs for operators and regulators.

The financial burden of decommissioning these structures is substantial, potentially reaching billions of dollars, with concerns that taxpayers may ultimately bear the cost if companies fail to meet their obligations. A significant portion of these wells are classified as orphaned or abandoned, meaning the companies responsible for their decommissioning no longer exist or lack the financial capability to carry out the required work.

Under regulations set out by the Interior Department, administered by BOEM and BSEE, operators are jointly and severally liable for decommissioning obligations. Even if a company transfers its lease to another operator, it remains responsible for ensuring that all abandonment and removal obligations are fulfilled. Operators must complete decommissioning within one year of lease termination or within three to five years of a structure becoming idle. However, with aging infrastructure and a backlog of overdue removals, BSEE has emphasised the need for proactive compliance throughout the life of a lease.

Given the magnitude of overdue decommissioning in the Gulf, oil and gas operators are turning to advanced technology to enhance pre-decommissioning inspections and streamline project planning. Drones, robotics, and AI-powered digital modelling are now at the forefront of assessing the structural integrity of offshore platforms, pipelines, and subsea infrastructure before decommissioning begins.

By deploying aerial and underwater drones, operators can conduct high-resolution LiDAR scans, ultrasonic inspections, and photogrammetry surveys without sending personnel into hazardous environments. These drone-based inspections provide real-time structural data, detecting corrosion, metal fatigue, and structural integrity risks before dismantling begins.

Simultaneously, AI-driven Building Information Modelling (BIM) and Simultaneous Localised and Mapping (SLAM)-based 3D mapping allow engineers to simulate decommissioning scenarios, optimise removal sequences and enhance worker safety.

The integration of data-driven decommissioning is reshaping offshore well abandonment practices, making projects safer, more efficient, and cost-effective. With thousands of overdue structures requiring removal, these technological advancements offer a critical solution for tackling the Gulf's growing decommissioning backlog.

The process begins with autonomous aerial and underwater drones conducting high-resolution scans of the platform. These drones are equipped with LiDAR, thermal imaging, and photogrammetry sensors, capable of capturing structural details down to the millimetre. The data collected is processed using SLAM technology, generating a real-time digital twin of the platform.

This BIM model provides:

For areas of the platform that are potentially unsafe for human entry, such as confined interiors or corroded sections, a quadruped robotic system is deployed. This autonomous robotic platform is equipped with a LiDAR camera, thermal sensors, and AI-driven navigation, allowing it to traverse hazardous environments, capture high-resolution scans and transmit critical data to the BIM model.

By integrating robotic mobility solutions, teams can inspect structural conditions without exposing personnel to risk, ensuring a complete and accurate dataset for decommissioning planning.

The digital twin model allows engineers to simulate decommissioning scenarios before physical execution, ensuring a safe and efficient process. Potential structural instabilities can be identified, allowing engineers to plan necessary reinforcement measures before deconstruction.

Key considerations for deconstruction planning include:

The decommissioning process is executed with robotic precision, leveraging drones, autonomous robotics and AI-driven modelling.

Some of the execution processes include:

A number of positive results can come from AI-driven decommissioning processes, including a 40% reduction in project time, enhanced worker safety, greater compliance with both regulatory and environmental standards, and increased material recycling and disposal.

As drone technology, AI-driven modelling, and autonomous robotics advance, offshore platform decommissioning is shifting toward zero-contact, data-driven precision. The integration of real-time digital twin modelling, predictive analytics, and autonomous robotic inspections marks the beginning of a fully AI-driven offshore decommissioning era.

This article was authored by David Palmerton, Managing Director at Eye-bot Aerial Solutions.

D&A GOM, the world’s leading decommissioning conference, is all set to open its doors on 8 April in Houston!

D&A GOM, the world’s leading decommissioning conference, is all set to open its doors on 8 April in Houston!

The two-day event, held in partnership with Promethean Energy at Norris Conference Centers, Houston City Center, will provide an unmissable opportunity to gain exclusive access to the latest operator case studies, decommissioning strategies, regulatory insights and best-in-class technology to create long-lasting partnerships for upcoming abandonment campaigns. Delegates will also be able to get together with more than 600 decommissioning decision makers at dedicated networking events.

Leading operators including Apache, bp, Chevron, HESS, LLOG exploration, Petrobras, Promethean Energy, Shell and Woodside will share their decommissioning insights, along with other leading industry experts.

With environmental factors coming to the fore, the event will kick off with an opening presentation on the circular economy and decommissioning, followed by a panel session on reefing processes in Texas, Louisiana, Mississippi and Alabama and presentations focusing on platform reuse and recycling. This will be followed by sessions focusing on aspects of planning and execution of decommissioning projects, a highlight being presentations focusing on the challenges, learnings and success factors of the Chevron Genesis Spar removal campaign.

As a forum for the sharing of international expertise, the event will feature international decommissioning case studies and overviews from the North Sea, Australia and Brazil. A highlight will be a panel session on pipelines, where senior managers and directors from Offshore Operators Committee, bp, Woodside and Appache will discuss global approaches to pipeline removal. This will be followed by a case study from Shell focusing on the relationship between circularity and decommissioning and how these concepts were applied in an offshore field in Brazil.

All the latest technology advances will be covered, from Oilfield Service Professionals’ modular, high-performance drillable technologies for enhanced wellbore isolation and remediation to Rotech Subsea’s state-of-the-art CFE tools and pipeline grabs and Welltec’s advanced wireline intervention tools.

“Last year demonstrated how critical this topic still is with the community as 500+ delegates joined us in Houston from all over the world, as we discussed the pertinent issues within decommissioning and abandonment. We are confident we can build on the successful 2024 conference by ensuring that lessons learned and critical case studies are discussed in 2025,” said Joseph Watson, Lead Project Manager.

Featuring 600+ delegates, 20+ operator delegations, more than 40 expert speakers, 35 decom tech demos, three breakout technical workshops and eight bespoke networking sessions, D&A GOM 2025 promises to be an unmissable event in the region’s oil and gas calendar.

For further information see the website at https://events.offsnet.com/DA-GOM-2025#/ or get in touch with Joseph Watson at

Offshore decommissioning has been considered a growing and expensive issue in the Gulf of Mexico.

Several analyses conducted to estimate the costs of decommissioning infrastructure in the federal waters of the Gulf of Mexico have shown that it would amount to an estimated US$40bn to US$70bn. According to a 2024 report by the Governmental Accountability Office (GAO), out of a total of 8,000 wells and 1,600 oil and gas platforms, nearly 2.700 wells and 500 platforms are overdue for decommissioning. To be considered overdue, a platform needs to be unoperational on an active lease for more than 10 years or left standing with an inactive lease for well over a year. In case of the latter, the lease may have either expired, been relinquished or terminated.

Shallow and deep water wells are the two main types of wells located in the Gulf of Mexico. While shallow-water wells were initially developed by large oil companies, they were later sold to smaller companies over the years, that lacked the financial resources of major oil companies. Being of minimum economic value, shallow-water wells are often at a high risk of being abandoned by their operators. On the other hand, deepwater wells are newer and relatively more complex that shallow-water wells. Being larger and deeper makes them higher in economic value. Therefore, decommissioning these wells during their end-of-life stage is costlier when compared to shallow-water wells.

According to a report by Ocean Conservancy, decommissioning a deepwater well costs a whopping US$24mn, while a shallow-water well costs only around US$660,000. Currently, there are more than 1,600 active deepwater wells in the Gulf of Mexico, with the cost of decommissioning these wells estimated to exceed US$34bn. Considering subsea pipelines that are often left discarded on ocean floors, the exact cost of their removal has not been estimated, but is expected to have a high cost similar to deepwater well decommissioning.

Page 6 of 23

Copyright © 2026 Offshore Network