Bhagwan Marine has partnered with Linch-pin to deliver the Thevenard Island Offshore Decommissioning Project contract for Chevron Australia.

Bhagwan Marine has partnered with Linch-pin to deliver the Thevenard Island Offshore Decommissioning Project contract for Chevron Australia.

With special focus on environmental sustainability, the retirement project involves safe removal and the repurposing of nine offshore platforms as reefs.

While Bhagwan Marine will be supplying the marine and diving spreads, Linchpin will cover engineering aspects and deploy skilled construction personnel.

A major win for Bhagwan Marine, the offshore services provider is aiming a seamless and successful execution of the project for Chevron. The company is confident of its expertise and ability to deliver complex projects of this nature.

SLB and Ormat Technologies have entered into a strategic collaboration to develop integrated geothermal projects which reduce the associated risks while improving overall economics and ensuring long-term reliability.

SLB and Ormat Technologies have entered into a strategic collaboration to develop integrated geothermal projects which reduce the associated risks while improving overall economics and ensuring long-term reliability.

The integrated offering will provide developers with a comprehensive suite of solutions, including exploration and resource assessments to power plant commissioning and operation.

Both SLB and Ormat will provide operators with traditional and next-gen geothermal solutions, such as enhanced geothermal systems (EGS) and advanced geothermal solutions (AGS), with SLB obtaining a license of Ormat’s ESG patent.

The collaboration combines Ormat’s expertise in geothermal fields and project development, power plant design, manufacturing, operations, and engineering, procurement and construction capabilities with SLB’s expertise in reservoir characterization, well construction, completions and production technologies.

Irlan Amir, Vice President of Renewables and Energy Efficiency for SLB, said, “Geothermal energy represents a significant opportunity for the energy transition, providing clean, baseload renewable power. By combining our expertise with Ormat’s, we can help customers unlock the full potential of geothermal resources and accelerate the deployment of this sustainable energy source.”

Paul Thomsen, Vice President of Business Development at Ormat Technologies, commented, “Ormat’s world class geothermal development and technology expertise perfectly complements SLB’s significant reservoir knowledge and well construction technologies and expertise. Together, we can deliver more projects, offering exceptional value to our developers and contributing to a cleaner energy future.”

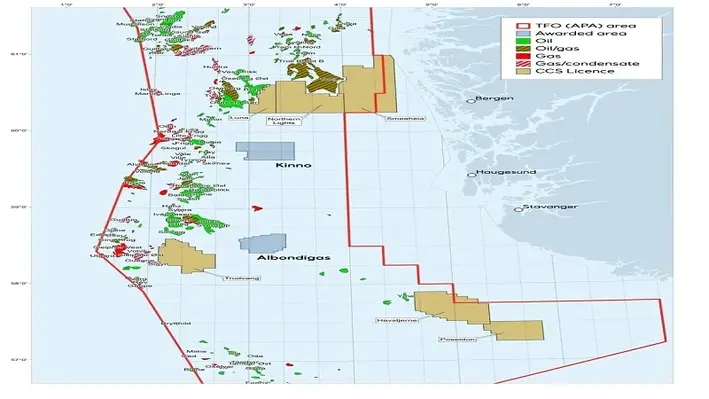

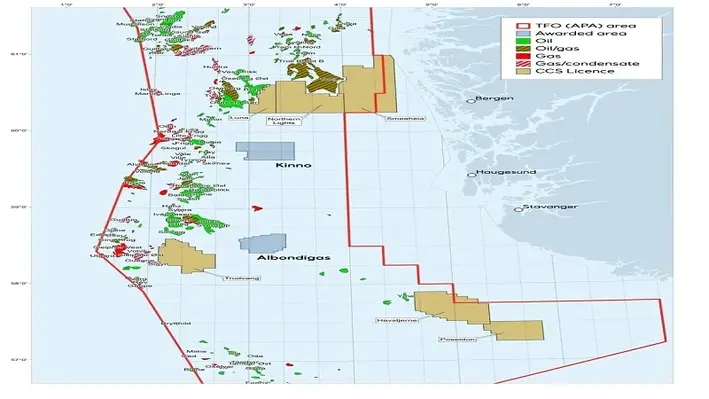

The Ministry of Energy has awarded Equinor the Albondigas and Kinno licenses in the North Sea for CO2 storage development.

The Ministry of Energy has awarded Equinor the Albondigas and Kinno licenses in the North Sea for CO2 storage development.

Considered important building blocks for developing the Norwegian Continental Shelf into a leading area for CO2 storage in Europe, each of the licenses are expected to have a storage capacity of 5 million tons of CO2 annually.

"We are very pleased to see the Norwegian authorities have made new CCS storage acreage available for exploration and that we have been awarded these two licenses. We see that demand for CO2 storage is increasing in several countries, and it is crucial to bring forward new CO2 storages quickly, so that we can offer industrial solutions that can support large scale decarbonisation of hard-to-abate industries in Europe," said Grete Tveit, Senior Vice President for Low Carbon Solutions in Equinor.

Equinor expect 4-8% real base project returns for its early phase CO2 storage business, and further value uplift potential when commercial markets are developed.

Equinor is maturing a ship-based solution and a massive pipeline to connect industrial emissions in Europe with storage opportunities at the Norwegian Continental Shelf. The planned pipeline named CO2 Highway Europe will have capacity to transport 25-35 million tons of CO2 per year from Belgium and France.

The Albondigas and Kinno licenses will serve as additional storage opportunities to the Smeaheia storage license which was awarded to Equinor in 2022. Smeaheia will be used as the anchor storage for this pipeline development.

Equinor is also about to complete the first phase of the Northern Lights CO2 transport and storage facility together with Shell and Total Energies. It will be ready to receive CO2 by the second half of this year.

"Scale-up of CO2 transport and storage is essential to meet the interest and demand for this type of services. Gaining access to more CO2 storage capacity aligns well with our ambition of having 30 to 50 million tons of CO2 transport and storage capacity per year by 2035," said Tveit.

Driven by a framework agreement signed with Woodside Energy (Senegal) BV, ocean services provider DeepOcean will be supervising subsea inspection, maintenance, and repair (IMR) services for the Sangomar field offshore Senegal, West Africa

Driven by a framework agreement signed with Woodside Energy (Senegal) BV, ocean services provider DeepOcean will be supervising subsea inspection, maintenance, and repair (IMR) services for the Sangomar field offshore Senegal, West Africa

“We have extensive experience from similar IMR operations offshore West Africa, but this is our first project offshore Senegal and with Woodside. We look forward to being Woodside’s subsea IMR supplier here over the coming years and to demonstrate our competence and extensive pool of specialist subsea tools and underwater assets,” said Øyvind Mikaelsen, CEO of DeepOcean.

Driven by 24 subsea wells and associated subsea systems that comprises of wellheads and subsea trees, in-line tees, manifolds, flowlines and risers, flowline-end terminals, and umbilicals, the project demands long-drawn services from DeepOcean. Its scope of work will include project management, engineering, and execution of subsea services such as inspection, survey, intervention, and maintenance, as well as additional services such as underwater inspection of FPSO (UWILD) and standalone ROV operations. The Norway-based provider will be supported by a Senegalese service company called Teranga Oil and Gas Services SARL.

“Sangomar is a large and impressive field development, with extensive subsea infrastructure. Our aim is always to inspect and maintain it as effectively as possible, thereby keeping costs and operational disturbances to a minimum for Woodside,” said Mikaelsen.

A project of strategic importance, the Sangomar oil field is supported by investments from the Africa Finance Corporation.

The UK National Geothermal Centre (NGC) has been launched to accelerate the UK geothermal sector and enhance the role it can play in decarbonising the UK’s future energy mix.

With funding from the Net Zero Technology Centre (NZTC), Durham University, SHIFT Geothermal, and The Reece Foundation, the NGC aims to support research and innovation, develop expertise and drive the creation of a policy, regulation and investment framework which enables geothermal advancement. It will drive collaboration between government, industry, and academia, promoting the integration of geothermal energy into the future renewable energy mix as a low carbon option for heating homes and industries, and power generation.

The geothermal sector has the potential to meet 10GW of the UK’s projected heating demand and 1.5GW of the anticipated electricity demand by 2050. Geothermal expansion could create 50,000 jobs for the future and result in an annual reduction of 10 million tonnes of CO₂ emissions.

Nigel Lees, chair of the NGC, said, “The launch of the National Geothermal Centre today represents a significant step in realising the opportunities that geothermal energy provides the UK. For several decades there has been a growing and meaningful contribution to our understanding of geothermal potential in the UK, yet we remain in the nascent stages of development with pockets of knowledge and expertise.

“The Centre will embrace and build on this, working collaboratively with all stakeholders to ensure a common understanding of the opportunities and challenges whilst giving a consistent voice and advocacy to fully unlock the geothermal potential in the UK and play a crucial part in the delivery of our net zero ambitions.”

Following encouraging results from extensive surveys, INPEX Corporation has decided to go ahead with exploratory drilling for geothermal energy development in Shibetsu Town, Hokkaido, Japan.

Following encouraging results from extensive surveys, INPEX Corporation has decided to go ahead with exploratory drilling for geothermal energy development in Shibetsu Town, Hokkaido, Japan.

Since its nomination in the process of the 'Selection of Operators for the Musadake Region Geothermal Survey' in Shibetsu Town in 2020, INPEX has been conducting surface and geophysical surveys as well as drilling operations in the Sempo area northwest of Mount Musadake in the western part of Shibetsu Town. It took a positive turn as the company came across geothermal resources from the site, which can potentially actualise its net zero ambitions while expanding its clean energy business in Japan.

INPEX aims to accelerate its geothermal initiatives by tapping into the technologies it cultivated through oil and natural gas development. The company has plans to proactively engage in energy landscape development to help

realise a net zero carbon society while fulfilling its responsibilities for the stable development and supply of energy.

Norwegian energy producer Equinor will deploy Emerson's suite of Roxar downhole monitoring tools to achieve optimal results from the Rosebank oil and gas field offshore the United Kingdom.

Norwegian energy producer Equinor will deploy Emerson's suite of Roxar downhole monitoring tools to achieve optimal results from the Rosebank oil and gas field offshore the United Kingdom.

With an estimated capacity of more than 300 million barrels of recoverable oil resources, the Rosebank field is considered a significant asset in meeting the UK’s energy security requirements. The first phase of the Rosebank field development will involve a refurbished, electrification-ready floating production storage and offloading vessel connected to a subsea production system. Startup of the Rosebank field’s first phase is planned for 2026-2027.

Emerson's advanced well completion monitoring systems enable advanced oil recovery techniques, optimise reservoir performance and verify well integrity in real time. A challenging task amid harsh environment conditions, the Roxar integrated downhole network technology provides an uninterrupted coverage of pressure and temperature data from active wells, which leads to safe operation, production optimisation and well integrity maintenance.

SLB, a global technology leader in the energy sector, has marked 55 years of operations in Angola where it played a vital role in supporting and developing the country’s energy landscape.

The milestone was celebrated at a grand gala event in Launda where distinguished guests were in attendance. This included Angola’s Secretary of State for Petroleum and Gas, H.E. José Alexandre Barroso, who took the opportunity to applaud SLB for its longstanding collaboration and support towards the country’s socio-economic development.

By leveraging its global footprint and extensive experience and providing its advanced technology solutions, the company has helped the country to optimise its oil and gas production. This has been vital to its continued development as oil and gas currently represents 96% of the country’s exports. At the present time, therefore, ensuring that energy production remains at a low-cost and as clean as possible has been described as vital for the nation’s future, and SLB remains committed to this end and driving energy innovation for a lower-carbon future aligned with these needs.

“55 years ago we took our first steps in Soyo-Zaire with the first log for Petrofina,” commented SLB managing director, Central, East and Southern Africa – Miguel Baptista. “Today, we have grown our foundation in Angola based on our core values of people, technology and performance. We have built on this by growing partnerships, igniting capacity and increasing local spend; providing opportunities to local businesses, investing in infrastructure and growing our revenue contribution. We will remain steadfast in the next 55 years and more to come; combining our expertise, resources, and vision, to make significant strides in shaping a sustainable energy future for Angola.”

Energy technology company Baker Hughes has announced a significant order from Petrobras for workover and plug and abandonment (P&A) services in pre- and post-salt fields offshore Brazil.

Energy technology company Baker Hughes has announced a significant order from Petrobras for workover and plug and abandonment (P&A) services in pre- and post-salt fields offshore Brazil.

The multi-year project is set to begin in H1 2025. Baker Hughes’ integrated solutions portfolio will aid with the deployment of wireline, coiled tubing, cementing, tubular running, wellbore intervention, fishing, and geosciences services across all of Petrobras’ offshore fields. The agreement also includes Baker Hughes’ remedial tool, completion fluids and production chemicals.

Maria Claudia Borras, Executive Vice President, Oilfield Services & Equipment at Baker Hughes, said, “Baker Hughes brings to this important project a comprehensive technology portfolio, a deep understanding of localisation, and a rich history of working in Brazil.

“Flawlessly integrating these capabilities will be essential to the success of the project. Our expertise in integrated solutions is the foundation for efficiently taking energy forward in Brazil.”

To support the project and help advance Latin America’s energy landscape, Baker Hughes will expand its Rio de Janeiro facilities to include coiled tubing and tubular running services to contribute to the growth of the Brazilian industry.

While Europe has often spearheaded geothermal progress and innovation, the past few years have played witness to a stagnated playing field as financial blockades and unclear legislation has somewhat slowed the project pipeline. However, after funding through both private and public channels continues to gain momentum, the region has the resources and drive to become a major market player within the geothermal market once again.

While Europe has often spearheaded geothermal progress and innovation, the past few years have played witness to a stagnated playing field as financial blockades and unclear legislation has somewhat slowed the project pipeline. However, after funding through both private and public channels continues to gain momentum, the region has the resources and drive to become a major market player within the geothermal market once again.

In January 2024, the European Union Parliament overwhelmingly endorsed a resolution that called for a new geothermal energy strategy to be implemented across the region. The resolution calls for an industrial alliance on geothermal energy, as well as the installation of an insurance programme to mitigate against financial risk. This endorsement is a huge step for the region and will hopefully provide reassurance and confidence in the market to warrant further investment.

However, while the parliamentary push is a step in the right direction, concerns are still being drawn around the commerciality of the commodity for geothermal, and the debate about whether the long-term payoff and associated risks are worth the investment.

With the above issues and more industry insights set to be discussed at the upcoming GTS EU 2024 later this year, including topics around expediting growth, new technology and scalability, enhancing the transition, attracting external stakeholders and commercial considerations, the bespoke outlook offers an alternative look into the pioneering industry.

Offshore Network has released an overview on the health, safety and environment (HSE) ecosphere in the Gulf of Mexico, with a primary focus on the challenges and opportunities faced by the region’s oil and gas sector.

With Environmental Resources Management indicating that 94% of health and safety function leaders are reporting increased expectations around health and safety in the years ahead, the HSE market is undergoing intense scrutiny. Operators in the region continue to grapple with some key challenges posed by the region and the nature of the industry including the Covid hangover, getting workers on board, ageing assets and of course evolving stringent regulations – a story kick-started by the events around the Deepwater Horizon disaster.

To combat these, stakeholders are engaging in a range of best practices and deploying new technologies in order to bring their workforce together and mitigate risk for their operations moving forward.

With pertinent issues in this environment set to be discussed at length at HSE GOM 2024 later this year (key topics include: safety culture, process safety, planning & preparation, technology & innovation, and environmental safeguarding) the report provides a refreshing perspective on the market ahead of doors opening in Houston.

An interdisciplinary joint project on geothermal development in Germany, AGENS has received a €44.4mn grant from the Federal Ministry for Economic Affairs and Climate Protection (BMWK), based on a resolution of the German Bundestag.

An interdisciplinary joint project on geothermal development in Germany, AGENS has received a €44.4mn grant from the Federal Ministry for Economic Affairs and Climate Protection (BMWK), based on a resolution of the German Bundestag.

Defined as the 'Demonstration of an adaptive, multilateral reservoir development for geothermal energy for seismicity and cost mitigation in the Upper Rhine Graben' that will be delivered over a span of five years, the AGENS initiative involves geopfalz, Institute for Geothermal Resource Management at ITB gGmbH, Johann Wolfgang Goethe University of Frankfurt am Main, Rhineland-Palatinate Technical University of Kaiserslautern-Landau, Ruhr University Bochum, geomecon GmbH, and the Technical University Bergakademie Freiberg.

In a sub-project of the AGENS that will be spearheaded by Stadtwerke Speyer GmbH-subsidiary Geopfalz GmbH & Co. KG in Schifferstadt city, Geopfalz will create 'Rhein-Pfalz' – the first deep geothermal duplicate, a basic building block for geothermal heat supply. This will ensure decarbonisation of the heat supply in Speyer and Schifferstadt, creating public awareness on sustainable living.

Reasearchers will also take into account the larger economic impact of the project.

With an allocation of €24.3mn, the project will look into a pioneering exploration technique, in which several side boreholes are drilled from a main borehole. The reservoir can be developed in a geomechanically and hydraulically optimised manner that reduces the risks of induced seismicity while increasing productivity.

A remaining funding of around €20.1mn will go to the other project partners.

Geo-Energie Suisse AG is an associate partner in the AGENS project. The project also involes the Federal Ministry of Education and Research (BMBF), which is supporting as part of the supplementary project LISAGENS with an additional funding volume of approximately €1.8mn to address questions of basic research.

Page 54 of 118