Island Drilling Company has announced the successful completion of its recent contract with Tullow Oil.

Island Drilling Company has announced the successful completion of its recent contract with Tullow Oil.

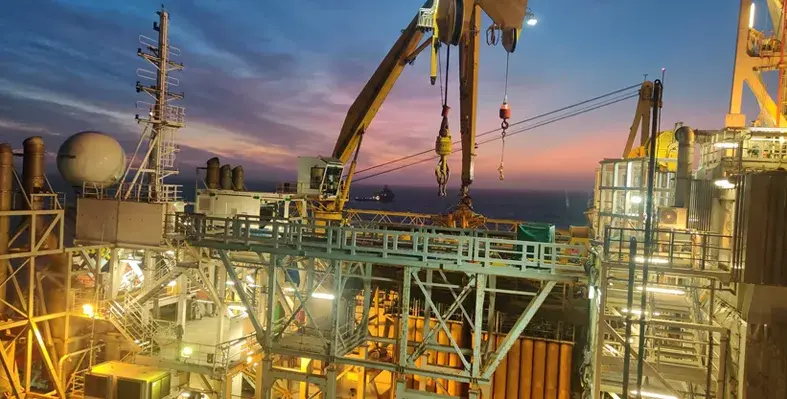

The operations, conducted in Mauritania over a period of three months, were carried out in water depths ranging from 208 meters to 1200 meters using dynamic positioning (DP) alone.

Throughout the project, all health, safety, and environmental (HSE) standards, and key performance indicators (KPIs) were achieved. The plug and abandonment (P&A) operations were completed within the planned timeframe and under budget, reflecting the efficiency and effectiveness of the collaboration.

The feat was achieved through the company's 'one team' approach by excellent cooperation between its offshore and onshore segments.

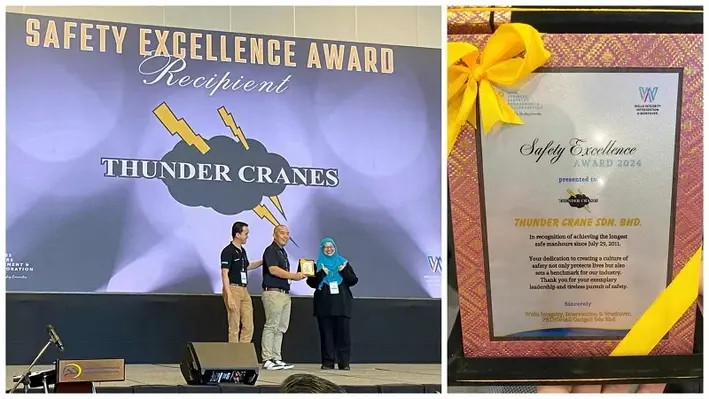

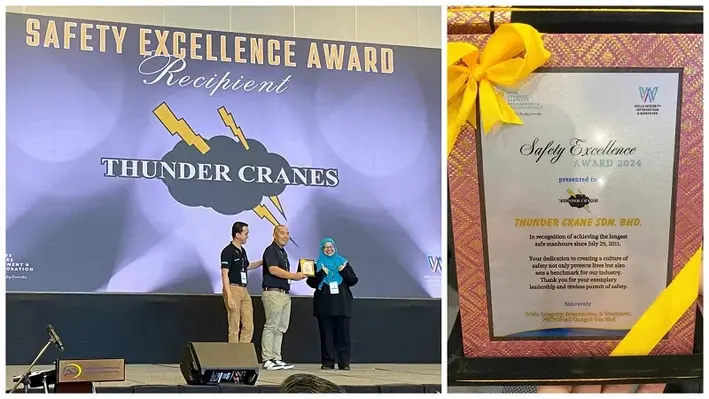

Thunder Cranes, a provider of portable-modular cranes and specialised lifting solutions for the offshore oil and gas industry, has been awarded the Safety Excellence Award by Petronas Carigali Sdn Bhd (PCSB).

The accolade pays tribute to the work Thunder Cranes has undertaken with PCSB since 2011, recognising its outstanding commitment to safety. This is proven by the fact it has achieved the longest safe manhours in operating with PCSB’s well integrity, intervention and workover department over the past 13 years.

In receiving the award, PCSB management thanks Thunder Cranes for its dedication to creating a culture of safety that “not only protects lives but also sets a benchmark for our industry.”

Across all of its offshore operations in Malaysia with PCSB, Thunder Cranes has accumulated 1.69mn LTI-free manhours over 4,759 days of operations since 2011.

Thunder Cranes has certainly been making waves in recent months, having just proven its worth in a Gulf of Thailand decommissioning project. Discover the full story by clicking here.

The OWI Global Awards is returning on 14 November to gather the offshore community for a celebration as the very best in global well intervention excellence are recognised for their outstanding contribution to the industry.

Sponsored by Welltec, the 2024 edition will be held at Union Kirk in Aberdeen, Scotland, with 11 winners picked out from a wide roster of exceptional entrees. Tickets are available now and can be acquired by clicking here.

Those in attendance will have the opportunity to network with peers from the offshore community and will share in the celebration of the 2024 champions selected from the categories of:

•Best Project Outcome: Organisations that have completed an industry leading project;

•Best Example of Collaboration: Two or more organisations that have collaborated to achieve ground-breaking outcomes;

•Best Example of Digital Innovation: Trailblazers in digitising processes or solutions;

•Best Example of Downhole Innovation: Organisations with excellent well intervention technology at a subsurface level;

•Best Example of Well Integrity Innovation: Organisations with an exceptional well integrity solution or service;

•Best Example of P&A Innovation: Organisations that have a solution, technology or completed a project which signifies the best in P&A;

•Best Example of Subsea Intervention: Organisations with first-class well intervention operations in waters over 1,000+ feet deep;

•Best Example of Platform Intervention: Organisations with an outstanding project on the well head;

•Energy Transition Pioneer of the Year: Organisations spearheading the transition to greener energy through the services and tooling they offer;

•Intervention Champion of the Year: Organisations that are market leaders in the well service industry;

•Jørgen Hallundbæk Lifetime Achievement Award: An individual who has made an exceptional contribution to the well intervention community throughout their career.

With a plethora of submissions being received, the daunting task of determining the finalists from the talented entry pool and, ultimately, selecting the category winners was given to an experienced panel of judges. Industry experts from ADNOC, EGPC, ENI, Petronas and more acted as arbitrators, independently assessing and scoring each entry to determine which submissions had gone the extra mile. As such, the official 2024 finalists who are in with a chance of claiming a trophy in Aberdeen are:

TAQA, an international company offering leading well solutions for the energy industry, has revealed the next-generation inflow control system.

The M4 Inflow Control System dictates the flow of undesired fluid (such as water and gas) and avoids any binary (open/close) effect that can result in instability or even stop production. Enabling operators to optimise their reservoir performance while sustainability managing fluid production, the new system excels in controlling water in ultra-light and light applications and enhances gas production control, providing stability and flexibility in diverse reservoir conditions.

“With the largest portfolio of inflow control systems more than 20 years of inflow control devices expertise, the M4 Inflow Control System represents the pinnacle of our innovation so far,” remarked Mojtaba Moradi, subsurface engineering manager of TAQA. “This new generation offers water control by gradually reducing inflow as water production increases, avoiding premature well shut in.

“Its main benefit is precision control based on reservoir production. The device allows operators to maximise output without risking shutting wells in, so they can manage production continuously and efficiently, which translates into obvious financial benefits.”

According to TAQA, the M4 Inflow Control System technology incorporates an advanced pilot control system that is super sensitive to density, making it suitable for a wide range of oil types, including ultra-light, light, medium, and heavy oils. It also features advanced multi-phase control, allowing the device to perform independently of its orientation in the wellbore.

TAQA also offers a ‘plug and play’ integration with its full portfolio of inflow systems and has been built to optimise performance in all types of wells in all reservoir types. Additional operational features such as last-minute capacity change, and the ability to circulate to the bottom have also been incorporated into the design.

Although not limited to any oil viscosity, so far, the system has demonstrated excellent performance with oil viscosities as low as 0.5cP tested together with water to define the operating and control points at various water cuts. A full qualification matrix of debris, erosion and cycle testing has also been completed.

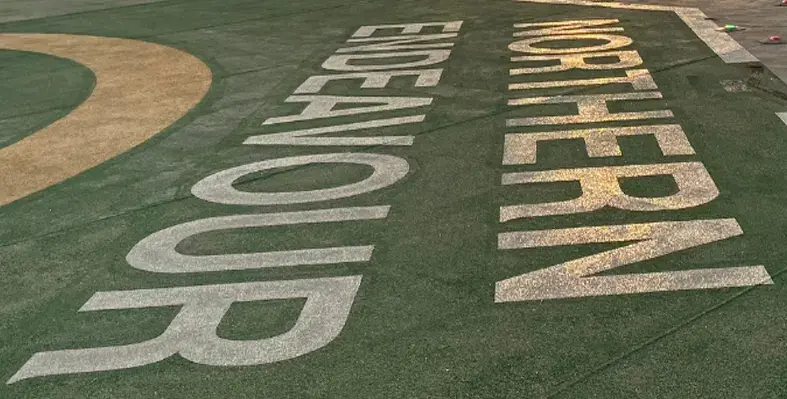

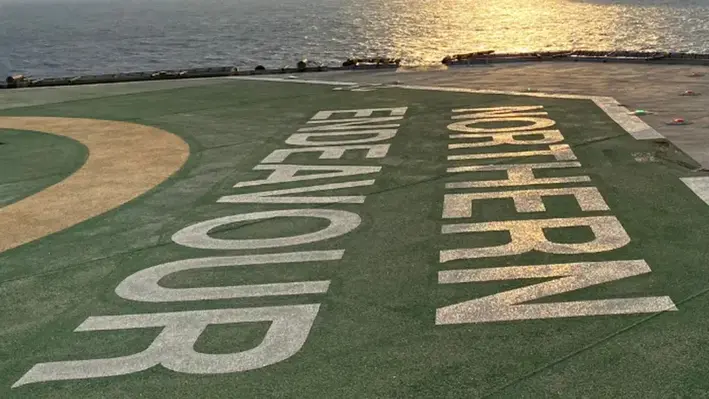

With a commitment to recycling the Northern Endeavour floating production storage and offtake (FPSO) vessel in a safe and environmentally sound manner while achieving value for money, the Australian Government has released a request for tender (RFT) to find a supplier to recycle the vessel.

With a commitment to recycling the Northern Endeavour floating production storage and offtake (FPSO) vessel in a safe and environmentally sound manner while achieving value for money, the Australian Government has released a request for tender (RFT) to find a supplier to recycle the vessel.

As works are underway to prepare the FPSO for a safe disconnection from the subsea infrastructure, the Government is seeking proposals from organisations to recycle the FPSO and manage the disposal of hazardous waste. This also includes the recycling of any furniture, fixtures, equipment, victuals or other on-board items. The FPSO will be towed to the ship recycling facility of the successful tenderer.

All FPSO recycling activities must comply with relevant regulatory requirements. This includes relevant safety, environmental protection and maritime regulations across international conventions and agreements, domestic legislation and regulations, and state legislation and regulations.

Interested parties must ensure registration to submit proposals through the AusTender website only. All requirements must be addressed in the RFT documents which are accessible on AusTender.

The Department of Industry, Science and Resources is holding industry briefing sessions for interested parties. There will be three separate briefings focussing on the commercial, financial and technical aspects of the RFT. To register for the briefings, participants can email the contact officer at

Submissions of the RFTs will close on 29 November 2024.

The Department of the Interior has announced the Bureau of Land Management's approval of the Fervo Cape Geothermal Power Project in Beaver County, Utah.

The Department of the Interior has announced the Bureau of Land Management's approval of the Fervo Cape Geothermal Power Project in Beaver County, Utah.

The project will use innovative technology to generate up to 2GW of baseload power that, if fully developed, is enough to supply more than two million homes. This approval marks the BLM's green-light for nearly 32GW of clean energy projects on public lands, including 42 projects approved under the Biden-Harris administration. The BLM is also proposing a new categorical exclusion to facilitate geothermal energy resources confirmation on public lands.

“Geothermal energy is one of our greatest untapped clean energy resources on public lands,” said Principal Deputy Assistant Secretary for Land and Minerals Management, Steve Feldgus. “Today’s actions are part of the Department’s work to deliver on new opportunities, new technologies, and new solutions in geothermal energy that support the Biden-Harris administration’s commitment to create jobs, economic growth, and clean carbon-free electricity for communities throughout the West.”

“The BLM is committed to supporting the responsible growth of geothermal energy on public lands,” said BLM Director Tracy Stone-Manning. “We need all the tools in the toolbox to reach a clean energy future, and this proposed categorical exclusion will be helpful in accelerating the process of locating new geothermal resources.”

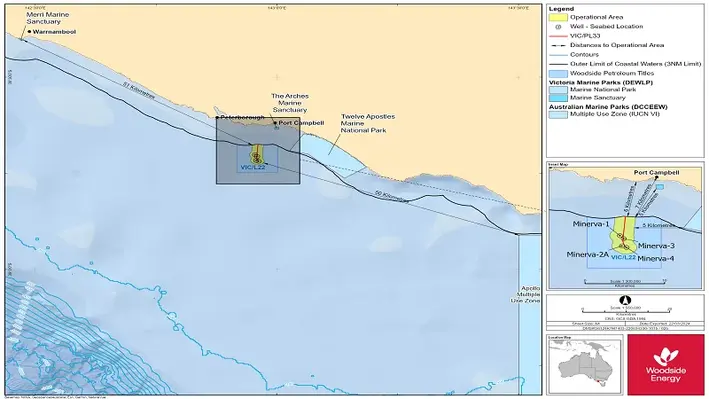

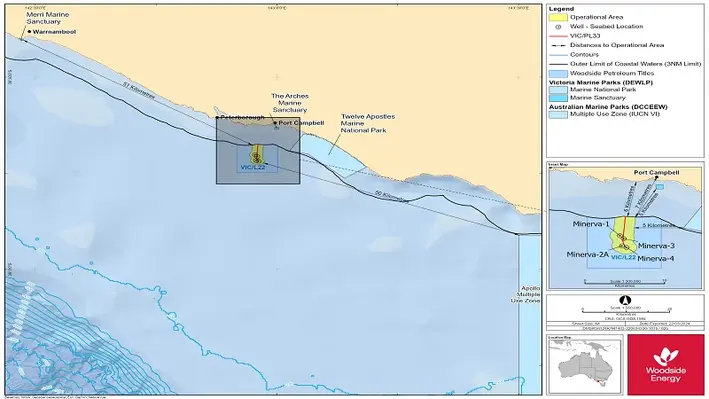

The National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA), the Australian Government’s offshore energy regulator responsible for health and safety, well integrity and environmental management for offshore oil and gas, has accepted Woodside Energy’s plans to decommission the Minerva Field.

The field, previously operated by BHP Petroleum, is located in Commonwealth waters with the wells laying approximately 11 km southwest of Port Campbell in water depths of approximately 50-60 m. Woodside plans to remove all subsea infrastructure and equipment from the seabed associated with the Minerva development. According to NOPSEMA, activities covered by the decommissioning include:

• Ongoing field management activities (inspection and monitoring) for the Minerva subsea and well infrastructure until decommissioning;

• Removal of the Minerva gas pipeline bundle in Commonwealth waters. The pipeline comprises of approximately 4.9 km of 10-inch concrete coated rigid-steel flowline, bunded with an electro hydraulic umbilical and two 2-inch steel chemical injection lines and stabilisation materials;

• Removal of Minerva subsea infrastructure within VIC-L22 in Commonwealth Waters comprising of five inline pipeline structures, five tie-in spools, and associated equipment and stabilisation material.

Equipment removal activities are planned to commence as early as Q4 2024 and require approximately three to five months, subject to vessel availability and weather constraints.

The plans for the decommissioning were submitted to NOPSEMA earlier this year. Click here to learn more.

New Zealand-based Contact Energy has reached a major commissioning milestone with its new Te Huka 3 geothermal power station as it has synchronised and provided power to the national grid for the first time.

New Zealand-based Contact Energy has reached a major commissioning milestone with its new Te Huka 3 geothermal power station as it has synchronised and provided power to the national grid for the first time.

At full capacity the power station will run at 51.4MW which equates to enough renewable energy to power the equivalent of 60,000 homes. During a three week testing period with Transpower, approximately 15MW will initially be fed into the grid before gradually increasing.

This period will be followed by formal generator compliance testing to Transpower’s system operator code requirements to confirm Te Huka 3 can provide electricity to the grid efficiently and safely.

Contact’s CEO Mike Fuge said “This marks a huge moment for the team at Te Huka 3, who have, for the past two years, worked tirelessly from the initial ground-breaking on site to building a fully operational renewable power station.

“[Te Huka 3] is a significant demonstration of our ability to invest, build and deliver world class assets for the benefit of all New Zealand.”

Once Transpower’s tests are completed, Contact will carry out further performance and reliability testing before the site is expected to become fully operational by the end of the year. One of the tests will include a 30-day reliability run to confirm that Te Huka 3 can run continuously and reliably at 51.4MW over a month-long period.

Fuge continued, “It is a really exciting time for geothermal energy. It has often been the unsung hero of power, but now it is really coming into its own as it plays a crucial role in New Zealand’s transition away from fossil fuels while helping to keep the lights on.”

Saipem, a global leader in the engineering and construction of major projects for the energy and infrastructure sectors, has signed a MoU with Geolog and Ignis H2 Energy to develop advanced technological solutions and conduct feasibility studies for new geothermal plants.

The two companies are specialised in the geothermal sector; Geolog is a leader in the evaluation of geological formation and drilling solutions, while Ignis H2 Energy expertise lies in geothermal resource acquisition, exploration and development. Saipem has moved to utilise the experience of both companies as it aims to develop advanced solutions that can enable a greater use of geothermal energy. In particular, the company is interested in next-generation geothermal energy systems, offshore geothermal energy, and the conversion of oil & gas wells.

As per the MoU, the three entities have agreed to carry out joint studies on unconventional geothermal energy such as terrestrial heat sources difficult to access as well as on offshore geothermal energy.

Saipem will lead the feasibility study of geothermal plants, by assessing the technical solutions currently available in the market and identifying potential technological gaps. Geolog and Ignis will contribute to the assessment of geological formations and drilling solutions, as well as the analysis of geothermal resources availability.

Oil Spill Response Ltd (OSRL), the largest international industry-funded cooperative dedicated to supporting its members in preparing for and responding to oil spills, has marked another step in its rebranding efforts through the reveal of its newly designed logo.

Encapsulating OSRL’s core values of safety, collaboration and innovation while reflecting its commitment to future aspirations, the new logo is part of the company’s wider rebrand which also includes a refreshed mission and vision.

“We wanted a brand that not only reflects our 40 years of leadership but also positions OSRL for the future,” remarked Darren Waterman, Engagement Director. “The new identity stands as a symbol of our unwavering commitment to safety, innovation, and collaboration.”

The new logo, which was conceived through an extensive brand review, will be gradually rolled out across all company touchpoints, including its website, social media channels, training materials, and operational equipment.

“We are proud to introduce a brand that honours our rich legacy while looking toward the future,” commented Vania De Stefani, CEO. “This new logo is not just a visual change; it’s a reflection of OSRL’s evolution and our ongoing dedication to our members and the industry.”

The brand rollout will continue throughout 2025 to ensure a sustainable approach minimising waste.

The Bureau of Safety and Environmental Enforcement (BSEE) has awarded a contract and first task order for the decommissioning of eight orphaned pipelines in the Matagorda Island lease area.

This move comes as part of the Biden-Harris Administration’s concerted efforts to address legacy population and will see work take place in the area which is located around 12 miles off of the Texas coast.

On 4 September, BSEE awarded a five-year indefinite delivery/indefinite quantity contract to Chet Morrison Contractors, LLC, to conduct on-site pipeline decommissioning activities. This was closely followed, on 12 September, by the award of the first task order under the contract, for the Matagorda Island Areas.

“With this award, BSEE advances to the active pipeline decommissioning phase of the Matagorda Island area project,” remarked Kathryn Kovacs, Interior Deputy Assistant Secretary for Land and Minerals Management, who leads BSEE. “The funding provided by the Bipartisan Infrastructure Law is crucial to BSEE as we tackle orphaned infrastructure on the Outer Continental Shelf, which presents a serious hazard to safety and the environment.”

The project will reduce pollution risks and improve offshore safety by decommissioning infrastructure that could interfere with navigation, commercial fisheries, and other current or future ocean uses.

These awards the year are the latest in a series that has seen action take place in the Matagorda Island lease area. Last year, BSEE awarded contracts for the decommissioning of nine orphaned wells there in a bid to address the urgent decommissioning needs. This included securing wellheads, decommissioning pipelines with hazardous materials, and preparing the site for permanently sealing the wells.

This has been part of the Bipartisan Infrastructure Law which allocated US$250mn to clean up well sites in national parks, national forests, national wildlife refuges, and other public lands and waters. Nearly US$150mn has been disbursed over the past three years.

PT Pertamina Power Indonesia (Pertamina NRE), PT Pertamina Geothermal Energy Tbk (PGE) and France-based clean hydrogen technology venture Genvia have signed a MoU to collaboratively develop green hydrogen production through the integration of advanced solid oxide electrolyser (SOEL) technology with geothermal heat resources.

The agreement includes the technical and economic study of the use of Genvia’s advanced high-temperature SOEL technology to reduce energy consumption in green hydrogen, and will be conducted at one of PGE’s geothermal sites.

The collaboration will leverage PGE’s geothermal expertise and Pertamina NRE’s broader clean energy portfolio, including renewables, green hydrogen, battery storage, electric vehicles and carbon businesses.

John Anis, CEO of Pertamina NRE, said, “We at Pertamina NRE are very enthusiastic about the collaboration with Genvia, which we believe will significantly accelerate the development of green hydrogen in Indonesia. This collaboration underlines our commitment to explore innovative solutions to achieve more cost-effective hydrogen production and maximise Indonesia’s green energy potential, such as geothermal.”

Florence Lambert, CEO of Genvia, commented, “Through our collaboration with Pertamina NRE and PGE, we see great potential in combining Genvia’s advanced technology with Indonesia’s abundant geothermal resources to drive a sustainable energy future. By exploring the potential of high-temperature SOEL technology, we aim to unlock new efficiencies in green hydrogen production.”

Page 49 of 118