Designed particularly for geothermal energy applications, Halliburton Company's latest product range includes the GeoESP lifting pumps, distinguished with features such as advanced submersible borehole and surface pump technology.

Designed particularly for geothermal energy applications, Halliburton Company's latest product range includes the GeoESP lifting pumps, distinguished with features such as advanced submersible borehole and surface pump technology.

Developed by an in-house service called Summit ESP, these pumps cater to fluids transportation challenges. They are characterised by a unique high-flow inlet design that protects it against solids, minimises power consumption, and effectively tackles scale formation.

Keeping harsh environment in mind, these pumps have been designed with the durability to withstand temperatures up to 220°C (428°F). It is capable of resisting any range of scale, corrosion, and abrasion. With standardised pump dimensions, it is suitable for various geothermal well conditions.

In another digital innovation to geothermal well management, the Intelevate data science-driven platform generates real-time diagnostics and rich visualisations of 'smart' field data. This system improves well operations, extends system run life, minimises shutdowns, reduces energy consumption, and increases production.

"With increased global focus on low carbon energy sources, we are using our many decades of geothermal production expertise to help our customers maximise safety and improve efficiency. Our GeoESP lifting pumps build upon our current system to minimise power usage and help push the boundaries of what is possible with more complex well designs," said Greg Schneider, Vice President - Artificial Lift, Halliburton.

Working for a prominent energy company, offshore lifting solutions provider Thunder Cranes offered mobilising its small-footprint, portable modular crane on a small supply vessel to the work site.

Working for a prominent energy company, offshore lifting solutions provider Thunder Cranes offered mobilising its small-footprint, portable modular crane on a small supply vessel to the work site.

After reaching the site, it can be rigged up, load tested, and prepared for lifting operations, all in a day, rather than going with the costly option of a barge or vessel crane, which can also render ineffectual.

While the project involved challenges from limited deck space to heavy lifting requirements, Thunder Cranes was well-equipped to tackle them with its compact, hydraulic powerpack/prime mover, TC20 stiff leg crane with a 60-ft boom length, and a 'self-lifting' package of TC's proprietary.

The choices of equipment and services by Thunder Cranes were reached post a thorough assessment of the client's lifting requirements, platform drawings, general specifications, and project timelines. This was followed by a site visit for verification, which became the basis for practical solutions.

The energy company required solutions with their offshore coiled tubing operations that involved the lifting of their CTU equipment onto their offshore platform which only had a small jib crane of 1.8-ton capacity, while the coiled tubing reel itself weighed 16 tons. Thunder Crane's modern approach with its portable-modular crane technology instead of the traditional large vessel or barge crane helped its client to optimise their logistics and enhance project uptime, while maintaining a high level of safety and cost-effectiveness.

The European Investment Bank (EIB) has provided a loan to Eavor Technologies to support the commercial-scale geothermal heating project in the German state of Bavaria.

The European Investment Bank (EIB) has provided a loan to Eavor Technologies to support the commercial-scale geothermal heating project in the German state of Bavaria.

Eavor will implement its closed-loop technology, Eavor-Loop, for the first time at commercial scale in the Bavarian town of Geretsried with the help of EIB’s loan of close to €45mn. The loan comes with a guarantee by the European InvestEU programme.

The project is co-financed by Japan Bank for International Cooperation, ING Bank N.V., and Mizuho Bank Ltd, and is insured by Japan’s Export Credit Agency, Nippon Export and Investment Insurance. It qualifies as a green loan in accordance with the Loan Market Association’s Green Loan principals. The combined support amounts to €130mn. The project is also being developed with the additional support of a €91.6mn grant from the EU Innovation Fund.

The Eavor-Loop will provide heating to households and businesses in Geretsried. In addition, an on-site power station will convert the geothermal heat into electricity. Eavor intends to start heat delivery by 2026, and the Eavor-Loop has started developing a second project in Germany to supply 15-20% of the demand of district heating in Hanover.

Nicola Beer, EIB Vice President, said, “The Eavor-Loop supports the transition to a carbon-neutral energy system in Germany and helps the country to get independent form fossil fuels, while adding to energy security for the people and businesses.”

Commissioner for Climate Action, Wopke Hoekstra, commented, “Once again, we see how valuable the work of the Innovation Fund is through the funding it provides for cutting edge projects that lower emissions. Today, thanks to €45mn investment by the European Investment Bank and €91.6mn from the Innovation Fund, we are supporting the innovative geothermal technology Eavor-Loop in Bavaria, Germany.”

Daniel Molk, Executive Vice President Europe Operations, concluded, “We are impressed and honoured that, after the EU Innovation Fund, the European Investment Bank is now also co-financing our project in Geretsried. Europe has recognised that the Eavor Loop is a scalable key technology for achieving climate neutrality and significantly more energy security on this continent."

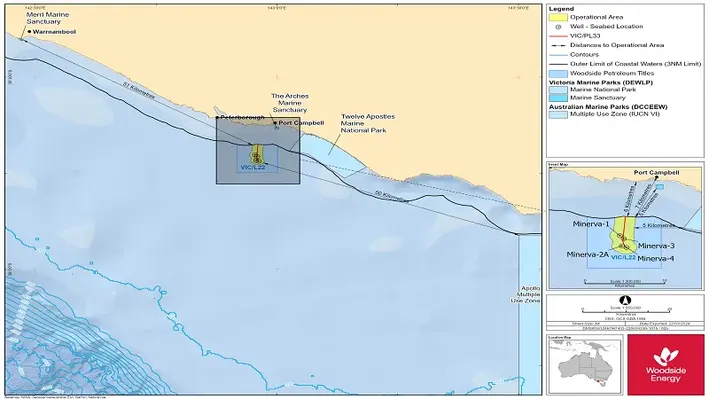

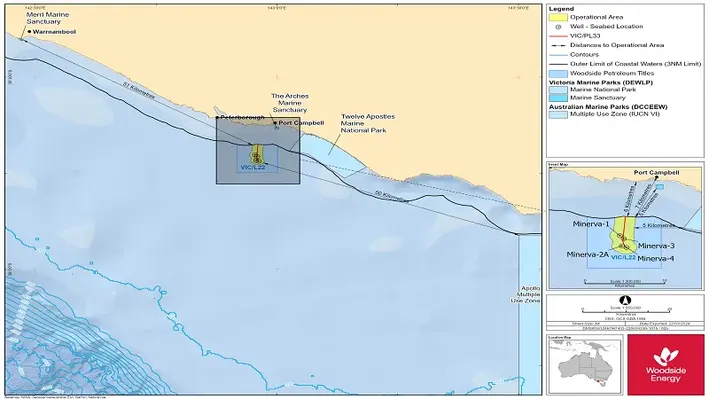

Woodside Energy has prepared and submitted an experts-consulted, final environment plan (EP) to the National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA), in accordance with the requirements of the Offshore Petroleum and Greenhouse Gas Storage Act 2006 and Environment Regulations.

Woodside Energy has prepared and submitted an experts-consulted, final environment plan (EP) to the National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA), in accordance with the requirements of the Offshore Petroleum and Greenhouse Gas Storage Act 2006 and Environment Regulations.

In the capacity of a titleholder under the Offshore Petroleum and Greenhouse Gas Storage (Environment) Regulations 2023 (Commonwealth), Woodside has proposed to undertake decommissioning activities within offshore petroleum production licence VIC/L22 and pipeline licence VIC/PL33.

It will include the removal of approximately 5 km of pipeline bundle and associated equipment, well tie-in infrastructure, and Minerva-2A wellhead and guide base that make up the Minerva subsea infrastructure.

As planning activities are well in progress, a rig has been secured for plug and abandonment in the Minerva field through a rig consortium with other titleholders in the region.

Keeping with the Environment Regulations, Woodside's EP has attempted to identify and describe the probable environmental impacts and risks that may arise during the end-of-life operations. It has worked out a process of appropriate management controls to reduce impacts and risks to a level that is ‘as low as reasonably practicable’ and acceptable. It defines Environmental Performance Outcomes (EPOs), Performance Standards (PSs) and Measurement Criteria (MCs) to ensure minimum adverse impact.

Woodside is planning the plug and abandonment of the Minerva-1, Minerva-2A, Minerva-3 and Minerva-4 wells (in accordance with a separate Minerva Plug and Abandonment EP), and removal of property in VIC/L22 and VIC/PL33 (under this EP).

Woodside's scope of decommissioning activity as mentioned in the EP is focussed in Commonwealth waters in the Otway Basin approximately 7 km south-southwest of Port Campbell, Victoria, where the Minerva subsea infrastructure is in approximately 55–59 m water depth at lowest astronomical tide (LAT). The operational area is thus defined as a 1,000 m radius around the subsea infrastructure, wellheads, and the gas production pipeline (the pipeline) within Commonwealth waters.

Spread over 24-hours per day, and seven days per week, Woodside believes the decommissioning activities might take up to 90-120 days, and completion is not anticipated before 30 June 2025.

Export credit agency UK Export Finance (UKEF) will be supporting Brazilian contractor Ocyan's decommissioning drive with a US$7.5mn guarantee.

Export credit agency UK Export Finance (UKEF) will be supporting Brazilian contractor Ocyan's decommissioning drive with a US$7.5mn guarantee.

After initial discussions with UKEF, Ocyan onboarded Scottish business Maritime Developments Ltd in 2022 who would take care of the equipment needs for the decommissioning project in Brazil. This was made possible using the UKEF grant which helped Ocyan procure financing from ABC International Bank to successfully set off the MDL deal. The grant will be applicable on a reimbursement basis, boosting its access to working capital.

Charlotte Wiltshire, European Head of Wholesale Banking, ABC International Bank plc said, "We are delighted to continue our support of UK businesses in conjunction with UKEF, leveraging off Bank ABC Group’s MENA and international footprint. This is an important milestone transaction, promoting the UK’s expertise in the oil and gas decommissioning and renewable energy arena. Bank ABC is looking forward to enabling similar energy transition projects in future."

A subsea pipelaying specialist from Aberdeen, MDL's wheeled horizontal lay system technology will be deployed by Ocyan to remove hundreds of kilometres of subsea cables and pipes from defunct FPSO oil and gas rigs in Brazilian waters.

Andrew Blaquiere, MDL Managing Director, said, "MDL is known worldwide for our forward-thinking technology that enables challenging scopes to progress on time and on budget, and this delivery to a Brazilian indigenous company is proof of that. Our engineering studies identified limitations with existing technology on the market when it came to recovery capability from deep waters like those in Brazil. The alternative for these operations would be to use a specialist construction vessel, resulting in high cost and scheduling challenges.

"In a true MDL ‘We Build Innovation’ style, we put our heads together, brainstormed alternative approaches – and delivered the Wheeled HLS. As a result, the client – and the Brazilian market – gained a cost-effective way to kit-out a vessel of opportunity to handle high loads and tackle recovery projects – this way enabling more sustainable end-of-life operations."

The first-ever overseas grant from UKEF also stands to benefit more than 70 Scottish businesses which are responsible for the entirely local MDL model.

AGR has been awarded a contract by geothermal energy supplier Innargi for the provision of technical consultancy for three appraisal wells being drilled in Aarhus, Denmark.

AGR has been awarded a contract by geothermal energy supplier Innargi for the provision of technical consultancy for three appraisal wells being drilled in Aarhus, Denmark.

Through the contract, AGR will provide wellsite geology and drilling supervision over the Aarhus wells as the company boasts extensive experience in well and reservoir engineering for geothermal wells. AGR has previously supplied software solutions for managing geothermal drilling time and costs for projects throughout Germany and Austria.

Lene Thorstensen, Manager Operations and Wellsire Geology at AGR, said, “Our team has a track record of managing drilling of more than 200 wells in the North Sea. The Aarhus project is a great example of valuable competence transfer from the oil and gas industry to renewable energy sources.”

Innargi aims to bring clean and reliable district heating to Europe through geothermal energy, and the Aarhus plant project provides a stepping-stone to achieving that goal. The geothermal plant, if everything goes accordingly, will become the EU’s largest geothermal district heating system. A 6,000 horsepower drilling rig has been set to drill 2.5 km into the ground to extract the heated water, with heat delivery set to begin in 2025. The system is projected to provide 20% of Aarhus’ district heating upon completion.

The UK-based decommissioning specialist Decom Engineering's intellectual property (IP) has passed a 'strength test' following an intellectual asset review of its pipeline cutting saw technology and Pipe Coating Removal (PCR) tools by global IP experts Inngot.

The UK-based decommissioning specialist Decom Engineering's intellectual property (IP) has passed a 'strength test' following an intellectual asset review of its pipeline cutting saw technology and Pipe Coating Removal (PCR) tools by global IP experts Inngot.

Decom's C1 range of chop saws has served major hydrocarbon producing regions, and its PCR machine is known for its sustainable and cost-saving credentials as they are capable of safely removing protective coatings from pipes for them to be repurposed in construction and other projects.

To protect its market advantage, Decom commissioned Inngot to report on the strengths of its IP as it ramps up protection in US, Canadian and European markets and in other key regions where its technology has been used, including Australia, Thailand, Malaysia and Brunei.

The report commissioned to Inngot on the strengths of Decom's IP read, “Decom Engineering has developed safe and effective pipeline cutting equipment for the decommissioning and maintenance of oil and gas pipelines and installations. The patent describes a cutting apparatus designed for versatile, efficient cutting of various materials both above and below sea level, which is useful in decommissioning industries.

“Cleanly cutting through 2" to 46” pipes, the C1 Chopsaw is a single-blade, cold-cutting saw that can be deployed and operated within the harshest working conditions, both onshore and subsea. It is fully certified to 2000m water depth, is customisable, and has blade reverse and hot stab integration capabilities.

“The patents focus on an adaptable, efficient cutting apparatus. The unique features, like multiple cuts per blade, fast cut times, and the use of water cooling systems for surface cutting, demonstrate the practical application of the patented technology, enhancing their marketability and potential for generating cash flows.”

Nick McNally, Decom Engineering Commercial Director, said that the company prioritises strengthening patent protection as an important step to gain an edge over competitors in diverse international markets.

He said, “We know our technology is market leading and of high value so it makes sense to put in place all the necessary protections to ensure we can make the most of the growth opportunities which present themselves.

“When a patent is granted, it prevents a third party from legally manufacturing, importing into, exporting out of, storing or using a patent-protected product in the territory where the patent is granted and valid.

“Working closely with Inngot, we have established the commercial value of our technologies and this has underlined the need to take a rigorous approach if we feel our designs and decades-long expertise is being compromised.”

An analysis by Inngot of Decom’s PCR machine technology, reads, “The patent outlines a comprehensive solution for the efficient removal of protective coatings from pipes. It addresses problems associated with existing methods, such as labour intensiveness, high costs, and environmental risks due to the release of toxic chemicals.

“The invention features a versatile tool carriage that supports various removal tools, including scrapers, sanders, and wire brushes. This adaptability allows for effective coating removal while maintaining energy efficiency. The apparatus is designed to ensure the structural integrity of the pipes, promoting their reuse and minimising environmental impact.

“This system's technological advancements, demonstrated by its ability to remove multiple coating types with 100% waste capture and converting pipes into usable products, make it a practical application of the patent. There is a direct relationship with the product, which has unique features that cater to a specific need in the market. This indicates a clear plan to use the patent to generate cash flows.”

The report also researched existing patents which have been lodged by potential competitors, adding, “The patent analysis was extended to examine the patenting activities of other entities in the same technological sectors so that the company’s position in the broader industry landscape can be assessed. This provides a holistic view that gives a deeper understanding of the company's innovation strategy and its financial implications, as well as identifying both potential competitors and potential acquirers of the IP.”

“The strength of our patented technology is underlined by the number of international projects we are currently engaged on and a strong pipeline of future work on the horizon and into 2025,” said McNally.

GreenFire Energy Inc. and Stoic Transitional Resources have announced a pioneering collaboration effort for innovative geothermal energy solutions.

GreenFire Energy Inc. and Stoic Transitional Resources have announced a pioneering collaboration effort for innovative geothermal energy solutions.

Through a cross-license agreement that covers GreenFire’s patented GreenLoop technology and Stoic’s patent-pending Flux Crossover, the companies will focus their efforts on repurposing existing oil and gas wells and non-productive geothermal wells to harness the potential of geothermal energy.

GreenFire’s Greenloop technology is a closed loop advanced geothermal system which provides solutions that assure the availability of resilient, sustainable and scalable geothermal energy for a range of applications, including power and direct use heating and cooling. The Stoic technology aims to enhance the GreenLoop performance.

Stoic’s Flux Crossover combined with the GreenLoop technology will enhance performance by optimising flow patterns, minimising parasitic heat loss and double heat transfer efficiency. The two companies announced a partnership last year for the development of geothermal projects through utilising abandoned wells in New Zealand and Canada.

Steven Brown, President of GreenFire Energy Inc., said, “We are pleased to be collaborating with Stoic Transitional resources. GreenFire Energy’s technology has the capability to economically repurpose idle geothermal wells and expand implementations in geothermal fields. Collaborating with Stoic’s technology will enhance performance and broaden GreenFire Energy’s solutions.”

Joe Tarrant, Co-Founder and Chief Commercial Officer at Stoic, commented, “Our commitment extends beyond innovation to fostering sustainable partnerships and empowering communities. Stoic’s pioneering approach to clean energy aligns perfectly with our mission, emphasising the value proposition for data centre customers.”

Organic Rankine Cycle (ORC) systems provider Turboden has collaborated with enhanced geothermal systems company Fervo Energy on advancing the Cape Station project.

Organic Rankine Cycle (ORC) systems provider Turboden has collaborated with enhanced geothermal systems company Fervo Energy on advancing the Cape Station project.

With an anticipated total project capacity of approximately 400 MW, the project is Fervo's largest commercial endeavour in the geothermal industry. Situated in southwest Utah, the project will be a prime source for 24/7 carbon-free energy production.

Turboden will provide the engineering and procurement of power plant equipment for the initial 90 MW phase of the project. This includes the installation of three generators with six ORC turbines.

"We are excited to collaborate with Turboden on our Cape Station project," stated Tim Latimer, CEO and Co-Founder of Fervo Energy. "With this partnership, the ORC industry enters a new age of scale necessary to meet the skyrocketing demand for around-the-clock clean energy."

Paolo Bertuzzi, CEO and Managing Director of Turboden, said, "Fervo Energy's commitment to advancing geothermal energy aligns seamlessly with Turboden's mission to drive sustainable energy innovation. Together, we are forging a path towards a cleaner, greener future. The success of this project, alongside other initiatives in North America, prompted Turboden to consider establishing a US-based office. This strategic move enables us to leverage the support of Mitsubishi Heavy Industries America, further enhancing our operations and presence in the region.”

It is not long now until the doors are set to open once again on West Africa’s leading well intervention conference, offering exclusive access to operator best practices, innovative technologies, exploration strategies and more.

It is not long now until the doors are set to open once again on West Africa’s leading well intervention conference, offering exclusive access to operator best practices, innovative technologies, exploration strategies and more.

This year’s instalment of the OWI WA 2024 conference will return on 28-29 May in the brand new location of Lagos, Nigeria, in the Sheraton Lagos Hotel. With the focus this year predominantly honing in on the combination of innovative well intervention technologies with strategic planning practices in order to optimise the performance of the ageing assets within the region, this event once again unties West Africa’s offshore community as they come together in a series of unique networking opportunities.

Featuring more than 30 expert speakers, 10 technology demos, and two technical breakout workshops, the conference promises to be an insightful and lucrative experience for all attendees. More than 200 decision makers are expected to attend, partaking in six dedicated networking events and engaging in a series of sessions covering key topics such as regional analysis, mature and ageing assets, strategic planning and management, and production optimisation.

This year, OWI WA 2024 has partnered with Women in Energy Network, an association dedicated to providing a platform for women who work across the entire energy industry chain in order to build confidence and enhance their professional progress.

For more information regarding OWI WA 2024, the full brochure can be downloaded here. For any additional enquiries please contact Jack Heffernan at

The Department of the Interior announced a final rule from the Bureau of Ocean Energy Management (BOEM) that makes the American oil and gas industry accountable to cover decommissioning costs of offshore platforms on the US Outer Continental Shelf (OCS).

The Department of the Interior announced a final rule from the Bureau of Ocean Energy Management (BOEM) that makes the American oil and gas industry accountable to cover decommissioning costs of offshore platforms on the US Outer Continental Shelf (OCS).

This announcement comes as a relief for American taxpayers who had to otherwise bear the brunt of the huge decommissioning liabilities if the oil and gas companies failed to meet them.

Updating 20-year-old regulations, the new law demands financial assurance requirements for the offshore oil and gas industry operating on the OCS. The Government Accountability Office (GAO) found that previous practices followed by industry operators on meeting decommissioning deadlines were not as clearly defined, exposing American taxpayers to bear the cost in the end.

The final Risk Management and Financial Assurance for OCS Lease and Grant Obligations rule amendments address these concerns and reduce financial risks associated with OCS development by substantially increasing the level of financial assurances that operators must provide in advance.

“The American taxpayer should not be held responsible when oil and gas companies are unable to clean up after their own operations. The Interior Department is committed to ensuring that the federal oil and gas leasing program is implemented fairly, with accountability and transparency,” said Secretary Deb Haaland. “This final rule updates, simplifies and strengthens outdated requirements to ensure that taxpayers are protected and current operators are held responsible for their end-of-lease cleanup obligations on the Outer Continental Shelf.”

“For far too long, the federal government has failed to follow through on measures to ensure accountability for oil and gas companies operating offshore,” said Principal Deputy Assistant Secretary for Land and Minerals Management, Dr Steve Feldgus. “Coupled with our recent announcement from the Bureau of Land Management, the Department is ensuring that we have a modern oil and gas leasing programme that protects taxpayers’ interests.”

“The offshore oil and gas industry has evolved significantly over the last 20 years, and our financial assurance regulations need to keep pace,” said BOEM Director Elizabeth Klein. “Today’s action addresses the outdated and insufficient approach to supplemental bonding that does not always accurately capture the risks that industry may pose for the American taxpayer – like financial health of a company or the value of the assets that the lessee holds.”

According to the new rules, BOEM will use a credit rating from a Nationally Recognised Statistical Rating Organisation or a proxy credit rating equivalent to access a company's financial strength. The bureau will also consider the current value of the remaining proved oil and gas reserves on the lease compared to the estimated cost of meeting decommissioning obligations. If the lease has significant reserves still available, then in the event of a bankruptcy, the lease will likely be acquired by another operator who will assume the plugging and abandonment liabilities.

Companies without an investment-grade credit rating or sufficient proved reserves will need to provide supplemental financial assurance to comply with the new rule.

BOEM believes that the industry will be required to provide US$6.9bn in new financial assurances to protect American taxpayers from assuming industry decommissioning costs. To provide industry with flexibility to meet the new financial assurance requirements, the bureau will allow current lessees and grant holders to request phased-in payments in a span of three years to meet the new supplemental financial assurance demands.

With the race to a net zero future continues to heat up across the globe, more eyes are turning towards geothermal methods as a suitable alternative for energy. While the US continues to dominate the word stage when it comes to geothermal production, there is a giant lying under the surface across the Asia Pacific.

With the race to a net zero future continues to heat up across the globe, more eyes are turning towards geothermal methods as a suitable alternative for energy. While the US continues to dominate the word stage when it comes to geothermal production, there is a giant lying under the surface across the Asia Pacific.

With Indonesia boasting a predicted capacity of 27GW, and both the Philippines and New Zealand ramping up their installed capacity year-on-year, APAC has become one of the key global players in the geothermal game, already producing 35% of geothermal generation worldwide.

However, the burning question that faces the region is do the myriad of issues presented by factors such as limited resources, a lack of governmental funding and a challenging topography to contend with mean that the colossal potential lying underground will have to remain as such, rather than be utilised as a fruitful source of energy?

As the majority of geothermal resources are associated with volcanic activity in high terrain, exploration projects become more challenging and require additional resources and infrastructure, such that the region may not have access to. Financial stability is also a crucial factor waging a war against the utilisation of geothermal energy throughout APAC as the resource is not necessarily a commercial viable option for many operators.

Nevertheless, measures are being put into place to mitigate against these challenges, with government policies changing to accommodate green energy funds and private sectors and investing higher sums into the industry, there is a hope of prosperous future.

The Asia Pacific Geothermal Transition Outlook attempts to analyse the key players within the region and outlines where the pitfalls and mitigations lay ahead of the inaugural GTS APAC 2024 conference in Jakarta from 9-10 July.

Page 56 of 118