The floating production storage and offloading (FPSO) vessels deployed for a significant deepwater gas development in the Turkish area of the Black Sea will be equipped with titanium stress joints (TSJ) over the next two years

The floating production storage and offloading (FPSO) vessels deployed for a significant deepwater gas development in the Turkish area of the Black Sea will be equipped with titanium stress joints (TSJ) over the next two years

The US$31mn deal has been bagged by precision engineering group, Hunting plc, who will be delivering six TSJs as part of phase three of the major project. These TSJs, which will be arriving from the company's Subsea Spring business unit in Houston, Texas, are backed by patented 'Direct Pull-thru Tube' technology. The TSJs will be used on the second and third vessels serving the project.

Hunting is also serving the phase two development contract that was reached last year, with completion awaited in 2026. The back to back awards have generated US$51.6mn in revenue for the company.

Speaking of the latest contract, Jim Johnson, Chief Executive, said, "Our continued success in the Turkish area of the Black Sea demonstrates the international demand and strength of Hunting's titanium stress joint product offering. This order continues the Group's run of success deploying this product line into key offshore regions including the Black Sea, Guyana, and the Gulf of Mexico.

"Our revenue opportunities have also been expanded with the acquisition of FES in June, which forms part of our 2030 Strategy to target revenue from the longer cycle segment of the industry, which is less impacted by short-term commodity price volatility."

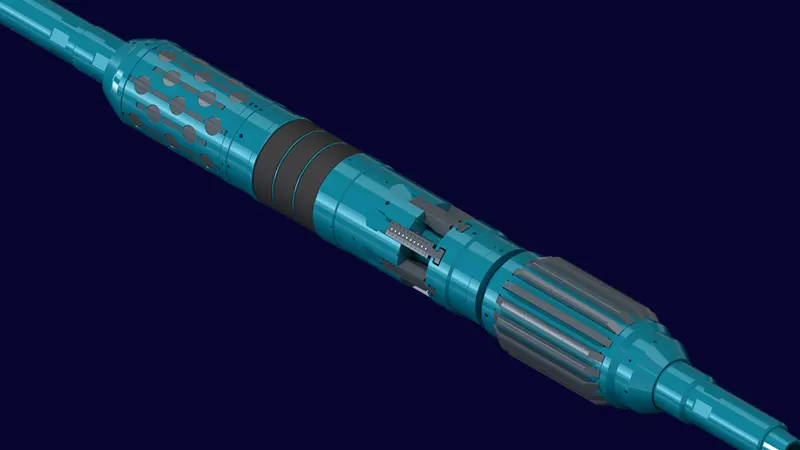

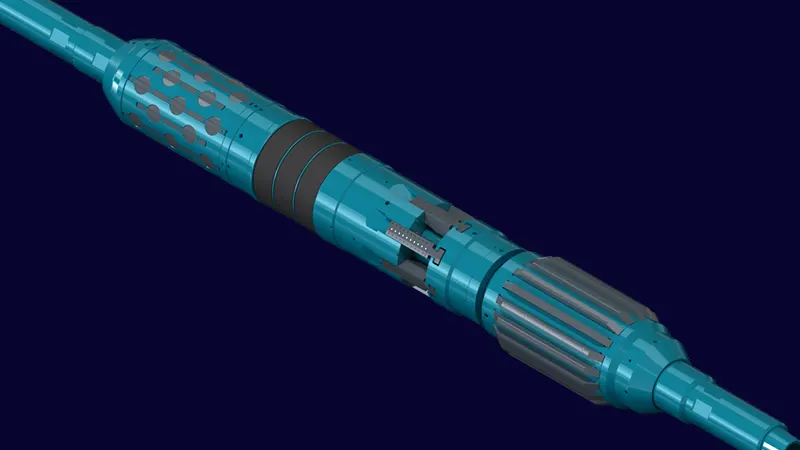

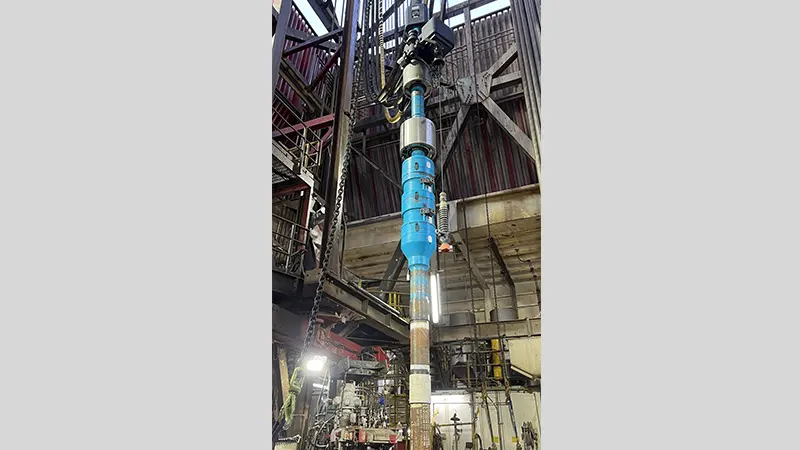

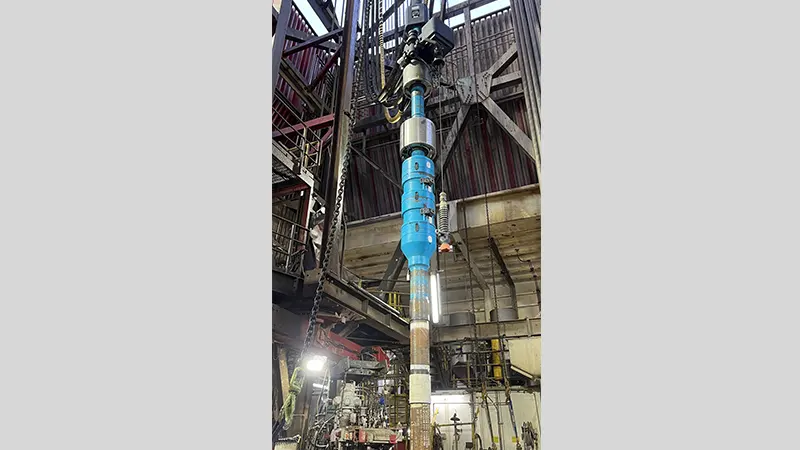

Expro has launched its most advanced BRUTE High-Pressure, High Tensile Packer System to date.

Expro has launched its most advanced BRUTE High-Pressure, High Tensile Packer System to date.

This new system is built to perform in extreme deepwater well conditions, handling the highest differential pressures in the industry. It allows operators to set higher in the wellbore, helping save rig time, reduce operational risks, and meet regulatory requirements more easily.

A key part of this launch is the BRUTE Armor Packer, a major step forward in Expro’s BRUTE range. This system offers unmatched strength and flexibility, with the ability to fully support 20k deepwater projects. When paired with the BRUTE 2 Storm Valve, it forms the most highly rated Storm/Service Packer and Valve combo available in the market, according to the company.

This latest technology was first used in a high-spec 20k deepwater project in the Gulf of America for a major energy company. In April 2025, Expro successfully deployed the 12.25” BRUTE Armor Packer System rated to 12,850 psid. The test confirmed the system's ability to handle extreme downhole pressures, proving its reliability in demanding offshore settings.

Following this success, Expro also introduced a new 20”/22” BRUTE Packer System. This tool was designed to overcome previous challenges faced by retrievable mechanical packers in large casing sizes. Traditional systems often struggle with tight internal diameters in subsea wellhead housings and casing adapters. Expro’s new packer offers double the expansion of standard systems, improving casing isolation for testing, suspension, and squeeze operations—without limiting performance.

In June 2025, the new 20”/22” packer was successfully used in a major offshore campaign in the Gulf of America. It passed through tight wellhead areas and expanded fully in a larger ID section below. The system achieved pressure integrity on the first try, confirming its ability to reduce rig time and risk while improving efficiency.

Jeremy Angelle, Vice President of Well Construction at Expro, said,“This launch sets a new standard for deepwater packers. The BRUTE system offers top-level pressure and tensile performance with unmatched adaptability. It proves Expro is leading the way in supporting the future of 20k offshore developments. We're not just meeting the industry's toughest standards – we're defining them.”

The first of a series of turnkey floating production storage and offloading vessels (FPSO) has been delivered by Seatrium for deployment in Brazil's prolific Buzios field, operated by the country's national oil company, Petrobras

The first of a series of turnkey floating production storage and offloading vessels (FPSO) has been delivered by Seatrium for deployment in Brazil's prolific Buzios field, operated by the country's national oil company, Petrobras

Following an extensive period of integration and commissioning works, the delivery was marked by a sailaway ceremony at the company's Singapore yard as Seatrium celebrated the occasion as a significant and timely milestone. Once it arrives at the Buzios field, the company will conduct the final phase of offshore commissioning works. When it becomes operational, the technically equipped P-78 FPSO will boost national oil production while advancing job creation locally. Driven by an eagerness to promote local content development for Brazil with work-force training and lpong-term skills enhancement, the company has primarily executed its activities in the Brazilian shipyards.

Seatrium has previously delivered FPSOs, floating production units, floating storage regasification units, drilling rigs and accomodation vessels that have contributed to Brazil's vast energy infrastructure while serving Petrobras' projects.

"We take great pride in delivering the first of the series of engineering, procurement and construction (EPC) FPSO to Petrobras. As a leader in providing sustainable offshore energy and infrastructure assets, Seatrium is committed to supporting Petrobras in their efforts to reduce carbon emissions from their floating production units. Our long-standing partnership with Petrobras in their decarbonisation journey spans five other FPSO projects, each showcasing innovative sustainability features. We look forward to building on our strong track record of performance, leveraging our seamless One Seatrium Global Delivery model to continue delivering safe and high-quality vessels that meet the evolving demands of the industry," said Chris Ong, Chief Executive Officer, Seatrium.

Identified as Petrobras 78 (P-78), the vessel will support the development of the world's largest deepwater project that promises a production capacity of 180,000 barrells of oil per day (bopd), 7.2 million cubic metres (mcbm) of gas per day, and a storage capacity of 2 million barrels of oil.

“The FPSO P-78 is more than just the largest and most complex unit ever built for Petrobras — it is a testament to how far we’ve come. This vessel embodies the highest standards of construction and commissioning quality, integrating a wealth of new specifications and hardearned lessons from the Replicantes and Cessão Onerosa FPSO series. In many ways, the P-78 is the culmination of over 15 years of Petrobras’ legacy in building and operating FPSOs in the Pre-Salt region — a legacy now sailing into the future,” said Renata Baruzzi, Executive Officer for Engineering, Technology and Innovation, Petrobras.

While covering projects for Petrobras in Brazil, Seatrium follows their One Seatrium Global Delivery Model, which advances fostering partnerships with industry stakeholders for project delivery across the globe. This has earned the company experiences of fabricating topside modules to the weight of 54,000 mt across its shipyards in Singapore, China and Brazil.

The Department of the Interior has updated its guidelines for states applying to federal programmes specialising in the cleanup of orphaned oil and gas wells.

The Department of the Interior has updated its guidelines for states applying to federal programmes specialising in the cleanup of orphaned oil and gas wells.

The revised guidelines mean two federal grant programmes have been updated: the US£780mn Orphaned Wells State Matching Grant Program and the US$1.93 billion Orphaned Wells State Formula Grant Program.

The revisions eliminate non-statutory requirements and reduces the burdens placed on state grant recipients, including removing the requirement that states conduct pre- and post-plugging methane measurements; recognizing the discretion states have in identifying and plugging orphaned wells; and eliminating the Department’s post-award environmental review and approval process.

Acting Assistant Secretary of Policy, Management and Budget, Tyler Hassen, said, “States know their land and their needs best. By cutting unnecessary barriers, we’re helping them clean up old wells faster, protect communities and support energy development.”

Eva Vrana, Deputy Assistant Secretary for Policy and Environmental Management, commented, “These changes make it easier for states to get to work. States can move more quickly to plug wells and reduce environmental risks.”

The updated guidance supports the Trump’s administration initiatives to prioritise the USA’s energy independence and cut regulations. By giving the states more flexibility and speeding up plugging efforts, DOI is helping to achieve this goal.

The Fram Sor development project offshore Norway will undergo engineering, procurement, construction and installation (EPCI) work in line with a significant contract signed between the project operator, Equinor, and offshore projects enabler, Subsea7.

The Fram Sor development project offshore Norway will undergo engineering, procurement, construction and installation (EPCI) work in line with a significant contract signed between the project operator, Equinor, and offshore projects enabler, Subsea7.

The EPCI development will comprise the inlaying of 53 kms of production, gas lift and water injection lines that will make up the vast body of subsea structures and flowlines. Alongside, the technical development will also include the installation of an umbilical system to support the front-end engineering and design in terms of an earlier contract reached in January.

The assembling activities to advance engineering and project management will be initiated from the company's Norway and United Kingdom bases before offshore installation work begins from 2026-2028.

The Fram Sor region sits 10-30 kms north of the Equinor-operated Troll C platform, which lies 70 kms north-west of Bergen. There are plans to connect the project to the existing Fram and Troll C infrastructure.

Erik Femsteinevik, Vice President for Subsea 7 Norway, said, “This award continues our long-standing collaboration with Equinor. The FEED study enabled Subsea7 to engage early in the field development process, optimising design solutions and contributing to the final investment decision. We look forward to working closely with Equinor to deliver the Fram Sør development safely and efficiently."

Contract is subject to authority approval of Plan for development and operations (PDO).

On Friday, 4 July 2025, Subsea7 announced it has been awarded a sizeable offshore contract in Egypt. The contract involves the engineering, procurement, commissioning, and installation (EPCI) of flexible pipelines, umbilicals, and other subsea components. These will connect new wells to existing offshore infrastructure through a tie-back system.

On Friday, 4 July 2025, Subsea7 announced it has been awarded a sizeable offshore contract in Egypt. The contract involves the engineering, procurement, commissioning, and installation (EPCI) of flexible pipelines, umbilicals, and other subsea components. These will connect new wells to existing offshore infrastructure through a tie-back system.

Subsea7 did not disclose the exact value of the contract but categorised it as "sizeable," typically meaning it falls between US$50mn and US$150mn.The project aims to support ongoing oil and gas developments offshore Egypt. Subsea7 will carry out project management and engineering from its offices in France, Portugal, and Egypt. These activities will begin immediately.

Offshore installation work is scheduled to begin in 2026. The project is expected to improve connectivity and efficiency in Egypt’s offshore energy sector. This contract adds to Subsea7’s portfolio of offshore work and strengthens its position in the Eastern Mediterranean region. The company continues to play a key role in delivering complex subsea infrastructure for global energy projects.

Subsea7 is known for its experience in subsea engineering and has successfully executed similar projects worldwide. This new contract highlights its ongoing relationship with operators in the Middle East and North Africa.The announcement reflects continued investment in offshore energy developments in Egypt, as the country seeks to increase production and improve infrastructure in its oil and gas sector.

Overall, the award marks another important step in Subsea7’s global operations and regional presence. David Bertin, Subsea7’s Senior Vice President GPC East, said: “Our early engagement has been instrumental in shaping a shared vision and delivering innovative, efficient solutions. This award is a testament to the strength of our collaboration, our proven track record, and our commitment to safe, high-quality execution. We are pleased to be able to support our client in enabling and executing such a strategically important project in Egypt.”

Two separate environmental incidents linked to ageing offshore assets off Western Australia (WA) could trigger further scrutiny into the industry’s decommissioning actions.

Two separate environmental incidents linked to ageing offshore assets off Western Australia (WA) could trigger further scrutiny into the industry’s decommissioning actions.

It follows revelations by independent news outlet, Boiling Cold, that Chevron had detected gas leaking at a recently-closed site on Barrow Island, which is now set for decommissioning, an article that was subsequently picked up by ABC News.

The US-based oil and gas giant ended production at the site, which sits 50 km north west of Karratha off the Pilbara coast, in mid-May.

A Chevron spokesperson later confirmed the leak to Boiling Cold.

“As part of detailed planning for the decommissioning of WA oil infrastructure, data analysis has indicated an environmental risk from the subsurface migration of hydrocarbons, primarily gas, to groundwater and the surface,” the spokesperson was quoted as saying by the independent news outlet, and later by ABC.

“We have informed relevant regulatory agencies, and we will work with them to develop a comprehensive investigation programme.”

The Department of Mines, Petroleum and Exploration is still investigating the leak, the ABC report added.

The incident follows a separate oil spill in May from facilities at Woodside’s Griffin field, about 58 km north-west of Exmouth, which is also set for decommissioning.

The National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA) is still investigating the spill.

The ABC report also cited Denise Fitch, chairperson of the environmental non-profit Cape Conservation Group based in Exmouth, questioning the industry’s commitment to the decommissioning process.

“There's no trust in their being capable of preventing oil spills,” she was quoted as saying by ABC.

“There have been, even in the last 12 to 18 months, a number of incidents where there have been spills and where decommissioning has caused issues or hasn't been done properly.”

The coiled tubing market is experiencing significant momentum, particularly in North America, due to increased offshore well intervention activities.

A recent report by Allied Market Research titled "Coiled Tubing Market" reveals that the global market was valued at US$3.0 billion in 2020 and is expected to grow to US$4.7 billion by 2030, registering a CAGR of 4.5% during the forecast period from 2021 to 2030.

Coiled tubing—long, continuous steel or composite tubing used in oil and gas operations—has become a key tool for offshore interventions. It offers flexibility, rapid deployment, and minimal surface footprint, making it ideal for offshore applications such as cleanouts, acidizing, fracturing, and stimulation. As operators seek to optimize well performance and prolong the life of maturing offshore assets, coiled tubing has emerged as a cost-effective solution for maintaining and enhancing productivity.

In North America, the presence of substantial offshore resources and a mature oil and gas industry has positioned the region as a dominant player in the coiled tubing market. The U.S. leads in offshore well intervention, supported by continued investment in deepwater and ultra-deepwater drilling. The integration of advanced coiled tubing technologies—such as real-time data monitoring, improved corrosion resistance, and enhanced injectors—has further strengthened its application in complex offshore environments.

Well intervention remains the largest service segment in the market, accounting for a significant share due to its widespread use in maintaining offshore production. Despite the advantages, offshore coiled tubing operations are challenged by high operational costs and equipment wear, especially in high-pressure, high-temperature wells.

However, these challenges are being addressed through technological innovation and automation. Leading oilfield service providers such as Halliburton, Schlumberger, Baker Hughes, and Weatherford are investing in research and development to improve equipment durability and operational efficiency.

With the increase in unconventional and offshore drilling projects, the North American coiled tubing market is poised for continued growth. The demand for safe, reliable, and sustainable well intervention services is expected to rise, reinforcing coiled tubing’s role in the future of offshore oil and gas operations.

The coiled tubing market is experiencing significant momentum, particularly in North America, due to increased offshore well intervention activities.

A recent report by Allied Market Research titled "Coiled Tubing Market" reveals that the global market was valued at $3.0 billion in 2020 and is expected to grow to $4.7 billion by 2030, registering a CAGR of 4.5% during the forecast period from 2021 to 2030.

Coiled tubing—long, continuous steel or composite tubing used in oil and gas operations—has become a key tool for offshore interventions. It offers flexibility, rapid deployment, and minimal surface footprint, making it ideal for offshore applications such as cleanouts, acidizing, fracturing, and stimulation. As operators seek to optimize well performance and prolong the life of maturing offshore assets, coiled tubing has emerged as a cost-effective solution for maintaining and enhancing productivity.

In North America, the presence of substantial offshore resources and a mature oil and gas industry has positioned the region as a dominant player in the coiled tubing market. The U.S. leads in offshore well intervention, supported by continued investment in deepwater and ultra-deepwater drilling. The integration of advanced coiled tubing technologies—such as real-time data monitoring, improved corrosion resistance, and enhanced injectors—has further strengthened its application in complex offshore environments.

Well intervention remains the largest service segment in the market, accounting for a significant share due to its widespread use in maintaining offshore production. Despite the advantages, offshore coiled tubing operations are challenged by high operational costs and equipment wear, especially in high-pressure, high-temperature wells.

However, these challenges are being addressed through technological innovation and automation. Leading oilfield service providers such as Halliburton, Schlumberger, Baker Hughes, and Weatherford are investing in research and development to improve equipment durability and operational efficiency.

With the increase in unconventional and offshore drilling projects, the North American coiled tubing market is poised for continued growth. The demand for safe, reliable, and sustainable well intervention services is expected to rise, reinforcing coiled tubing’s role in the future of offshore oil and gas operations.

To read more about the report or explore insights from other regions, visit: www.world.einnews.com

Helix Energy Solutions has announced a new plug and abandonment agreement with ExxonMobil in the Gulf of America.

Helix Energy Solutions has announced a new plug and abandonment agreement with ExxonMobil in the Gulf of America.

The operator’s Louisiana-based shallow water abandonment group, Helix Alliance, has secured a three-year framework agreement for P&A services within the region.

Owen Kratz, President and Chief Executive Officer of Helix, said, “This agreement underscores our commitment to delivering high-value, fit-for-purpose decommissioning services. This agreement also demonstrates Helix Alliance’s position as a trusted partner for comprehensive offshore solutions, providing well intervention, diving, heavy lift, and marine support services on the US Gulf of America shelf.”

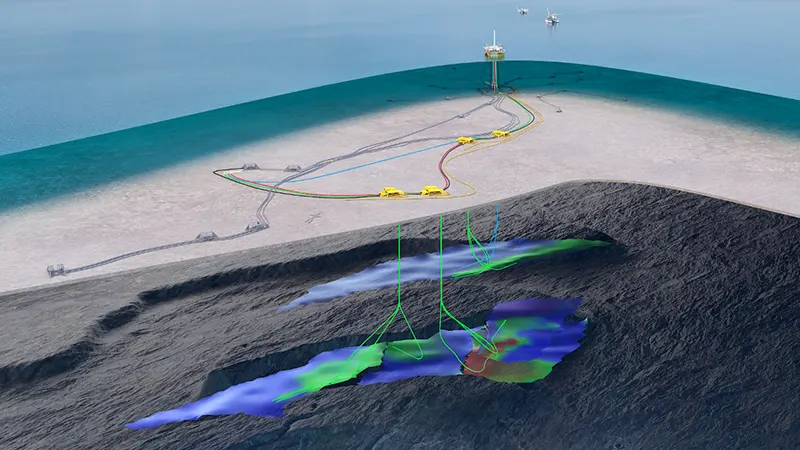

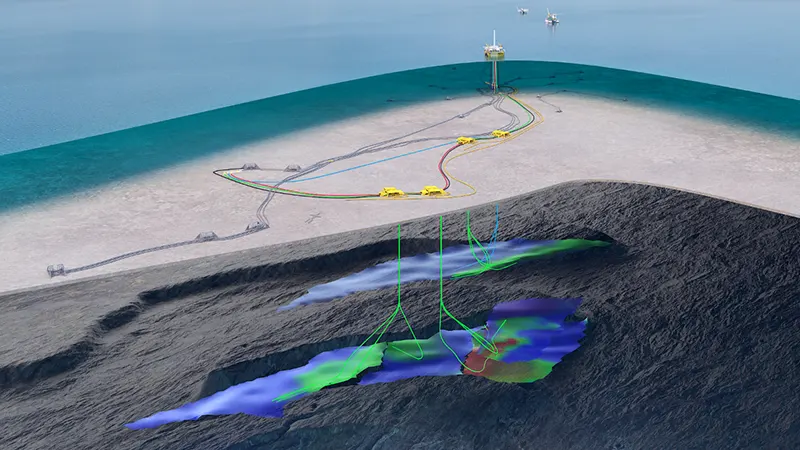

The Woodside Energy-operated Trion deepwater oil and gas development offshore Mexico will receive tubular running services (TRS) and cementing services from Expro to build the greenfield project

The Woodside Energy-operated Trion deepwater oil and gas development offshore Mexico will receive tubular running services (TRS) and cementing services from Expro to build the greenfield project

Before the project is ready for its first targeted oil in 2026, the three-year contract involves the deployment of Expro's well construction technologies, which are designed to deliver effective problem-solving from top drive to target depth. The comprehensive suite of services will involve TRS casing, drilling and completions, casing accessories, cement heads, and Expro's Skyhook system.

Set to be Mexico's first deepwater oil production facility, the Trion greenfield project will be supported by Expro to achieve maximum well performance optimisation alongside technical execution. Its approach will be backed by practices driving cost-effectiveness and operational reliability throughout the project lifestyle.

Woodside and Expro go back a long way, with the latest partnership seeing the establishment of a new Expro hub in the region as Woodside manage operations from its Tampico shore base and office. This will also generate local employment and economic upliftment.

Jeremy Angelle, Vice President of Well Construction said, “With our extensive track record and a reputation as a trusted provider of TRS solutions, we are proud to play a key role in this world-class development. This contract win reflects not only the strength of our technical capabilities and commercial offering but also our legacy of supporting Trion exploration wells through Frank’s TRS and VERSAFLO TM systems.

"This project represents an exciting opportunity to showcase our innovative technologies on a historic deepwater development, and we look forward to building a strong, long-term partnership with Woodside in Mexico.”

The Trion field is situated in the Perdido Fold Belt, approximately 180 km off Mexico’s coastline in the Gulf of Mexico, in water depths of around 2,500 meters.

Click here to register for Offshore Network's international well intervention and decommissioning conferences.

A new natural gas discovery has been made at the “Pegasus-1” well, located in Block 10 of the Exclusive Economic Zone (EEZ) of the Republic of Cyprus.

The discovery follows the successful completion of drilling operations carried out by the consortium of ExxonMobil Exploration and Production Cyprus (Offshore) Limited, the operator, and QatarEnergy International E&P LLC.

Valaris, a global offshore drilling company that provides services to the energy industry, confirmed the discovery. The “Pegasus-1” well is situated approximately 190 km offshore, southwest of Cyprus. Drilling was conducted by the “Valaris DS-9” drillship, which safely reached a depth of 1,921 metres of water. The well revealed an estimated 350 metres of gas-bearing reservoir.

According to the government of Cyprus, further evaluation will be required in the coming months to assess the results of the discovery and determine the potential of the find.

This marks the second confirmed gas discovery in Block 10 by ExxonMobil and QatarEnergy. The first was the “Glaucus-1” well, announced in February 2019. That was followed by the “Glaucus-2” appraisal well, completed in March 2022, which confirmed the existence of high-quality gas-bearing reservoirs in the area.

Earlier this month, the President of the Republic of Cyprus, Mr Nikos Christodoulides, was briefed on the discovery. Present at the briefing were the Vice President of ExxonMobil, Mr John Ardill; the Minister of Energy, Commerce and Industry of Cyprus, Mr George Papanastasiou; and ExxonMobil Cyprus Country Manager, Mr Varnavas Theodossiou.

New Fortress Energy Inc, through one of its subsidiaries, has signed a five-year agreement for the deployment of the Energos Winter, a 138,250 m³ floating storage and regasification unit (FSRU).

The agreement marks a significant step in New Fortress Energy’s continued expansion into key liquefied natural gas (LNG) markets and reinforces its growing presence in the Eastern Mediterranean.

The company is working in partnership with the Egyptian Natural Gas Holding Company (EGAS) to support Egypt’s LNG infrastructure and energy import capabilities.

Under the terms of the deal, the Energos Winter will be stationed at EGAS’s LNG import terminal in Damietta, on Egypt’s northern coast.

This deployment represents New Fortress Energy’s second FSRU operating in Egypt.

The Energos Winter is expected to join the Energos Eskimo, which is already in service in the country, as early as August this year.

The addition of a second unit is anticipated to enhance EGAS’s import capacity and improve energy security for Egypt and the surrounding region.

“We are pleased to reinforce our relationship with EGAS by way of our deployment of a second FSRU to Egypt. This deal enhances NFE’s goals of providing reliable and cost-effective energy across the globe,” said Chris Guinta, CFO of New Fortress Energy.

“EGAS is pleased to strengthen its long-standing partnership with New Fortress Energy through the execution of a second Regasification Service Agreement. Under this agreement, NFE’s second FSRU, Energos Winter, will provide regasification services at the Damietta terminal, contributing to the security of natural gas supply for the Arab Republic of Egypt over the next five years,” said Yasseen Mohamed, executive managing director of EGAS.

New Fortress is a global energy infrastructure company which develops, owns, and operates a range of natural gas and LNG infrastructure, supported by an integrated fleet of vessels and logistics assets. Earlier this year, the company announced multiple agreements to supply gas to the Carribean region such as the Dominican Republic, Jamaica and Puerto Rico.

Page 1 of 94