Decom Engineering (Decom), a provider of green decommissioning solutions, has executed three market-entry Australian contracts to strengthen its position within the Asia Pacific region.

The company was commissioned to supply and operate its chopsaw cutting technologies on behalf of a major operator in the Bass Strait alongside two other clients in Australian waters. Together, the contracts amounted to more than UK£500,000.

The decommissioning specialist performed three cuts on a 20’’ concrete weight coated carbon steel rigid pipeline as well as 25 cuts on a 13’’ in-filled flexible flow line jumper, with a 4.5’’ piggy back. This was achieved through the deployment and use of its C1-24 chopsaw at water depths of around 400 m. Meanwhile, another C1-24 chopsaw was utilised on assets in the country’s North West Shelf at water depths of around 500 m.

Decom Engineering Managing Director, Sean Conway, remarked, “The award of these three contracts by major operators is a clear signal that our commitment to the Australian decommissioning sector is being rewarded. With the extensive track-record Decom has established on projects in the UK North Sea, Africa and Asia, we judged that now was the right time for us to enter the Australian market and we are keen to be part of the sector’s journey to sustainability.”

The commitment to the country took the form of a significant investment in the region of UK£500,000 in order to establish infrastructure and relocate equipment and personnel to be reactive to local market demands. This decision was taken after the company recognised the remarkable opportunity that Australia presents, leading Decom to recognise it as strategic market for its future growth. This is also in line with a wider growth directive for the Asia Pacific market, with Decom investing upwards of UK£2mn to design and manufacture a nine-strong portfolio of chopsaws and supporting equipment (including control panels, spares and consumables) which have been used of projects throughout the region.

“We are excited to be kicking off three Australian projects in tandem and look forward to building a strong relationship with our customers,” Conway added. “As our reputation grows, we will replicate our AsiaPac model by investing in facilities, equipment and personnel in Australia, to provide cutting edge technologies which will assist contractors and operators looking for cost effective and environmentally sound decommissioning solutions.”

Following initial success, the company is aiming to introduce its Pipe Coating Removal (PCR) system to Australia in order to offer a full-service decommissioning option for redundant oil and gas steel pipes. The PCR strips steel tubulars of coating and transforms the pipe into a reusable product suitable for other uses.

Conway concluded, “To date our PCR system has processed more than 30,000 tonnes of steel tubulars from surplus prime and decommissioned oil and gas fields and we think that this is an offering which could introduce significant environmental and financial benefits to the massive Australian decommissioning sector.”

Cooper Energy Limited, an exploration and production company, has announced that the Helix Q7000 vessel has commenced work on the first well of the Basker Manta Gummy (BMG) decommissioning programme.

Although the company admitted that progress has been slower than anticipated, it is now making headway on the project with the Helix Q7000 – a purpose-built DP3 semisubmersible vessel from Helix Energy Solutions – now commencing work on the Basker-3 well after initially arriving late to the BMG field. The late arrival of the vessel resulted in Cooper Energy incurring more than three months of holding costs for the remaining contractor spread on the BMG programme and, in addition, more time was required during start-up activities due to factors such as loading of equipment and integration of the Integrated Riser System (IRS).

While Cooper Energy does not anticipate the start-up delays to impact the remainder of the project, the slow progress means re-forecasting of the programme for the remaining six BMG wells is required. As a result of this, the company has revised its mid-case cost estimate for the BMG decommissioning from AUS$193-198mn to approximately AUS$240-280mn. In order to keep this as low as possible, the company has indicated it will be applying learnings from the Basker-3 decommissioning work to the remaining wells. In addition, where possible, Cooper Energy and its contractors will aim to simplify the scope of decommissioning.

While the focus remains on executing the decommissioning programme safely and within the minimum time possible, the company has indicated there are certain risks retaining, including variables outside of the company’s control that could increase the total cost of the decommissioning programme.

Previously, the Helix Q7000 was at work offshore in New Zealand, conducting a decommissioning campaign on the Tui oil field. Click here to learn more.

BiSN, a provider of permanent downhole sealing solutions, has opened a manufacturing facility in Perth, Australia in order to increase its operational capacity in the Asia-Pacific region as well as creating several local jobs.

The decision to make the investment was driven by the growing demand for Wel-lok technology in the region. According to Paul Carragher, founder and CEO of the company, it is another step in its global expansion and builds on successful campaigns with operators in Australia and the wider region. Carragher added, “The Perth facility is one part of our commitment to rapidly support operators, allowing them to deploy Wel-lok technology for all intervention and P&A sealing applications.”

The Perth facility features full heater and bismuth-based alloy production, two major components of Wel-lok technology, as well as final assembly. It also provides a focus for regional business development and a field operations base. It will also boast a demonstration room to allow operators to view and get hands-on with Wel-lok and other technologies offered by BiSN. This will facilitate a collaborative environment for planning P&A, intervention and completion solutions.

The opening of the facility will remove the barrier of lead times due to shipping from the US or UK which can be prohibitive for operators and their intervention needs. “By opening a facility in Perth, it allows us to be more responsive to the needs of operators in Australia,” said Adrian Weiss, BiSN Senior Vice President of Operations. “The new facility is a continuation of BiSN’s commitment to increasing our global capability. We have listened to our clients in this region, and we are responding to help them seal safer and protect forever.”

The announcement follows the appointment of a new Regional Business Development Advisor in the Australian city, revealed earlier this year. Andy Vigor, the new appointment, boasts extensive experience in the industry having held roles in the Middle East and Asia Pacific regions. Now with BiSN, he is supporting customers both in Australasia and throughout the wider region.

Vigor surmised, “With the geographical size of the Australasia and the Asia Pacific region, response time and the ever-increasing cost of logistics is critical to our customers. We can now provide customized, engineered products and solutions locally, which will assist BiSN in its efforts to achieve service excellence for all of our regional customers.”

McDermott, a fully-integrated provider of engineering and construction solutions to the energy industry, has been awarded an engineering, procurement, removal and disposal contract by Santos for the full removal and disposal of the Campbell platform structure.

The platform is part of the Varanus Island Hub offshore Western Australia. McDermott has agreed to provide project management and engineering services for the removal and transportation of the platform topsides, structure and associated items to an onshore facility. There to be dismantled and disposed.

Mahesh Swaminathan, McDermott's Senior Vice President, Subsea and Floating Facilities, remarked, “Our successful, proven track record of project delivery spans the entire energy value chain. This decommissioning award reflects the commitment we share with Santos to timely, safe, and environmentally responsible removal of infrastructure at the end of its operational life cycle. We look forward to continuing to be part of delivering their sustainability commitments while also contributing to the circular economy for a lower carbon future.”

The contract is regarded as ‘sizeable’ by McDermott, being between US$1mn and US$50mn. The project management and engineering will be conducted by the company’s team in Perth with support from Indonesia and Malaysia. It represents the fourth decommissioning contract executed by McDermott in the country in the last two years.

The Offshore Well Intervention Australia 2023 Conference was carried out earlier this month as a host of industry experts and key stakeholders in the offshore community arrived in Perth for two days of engrossing seminars, presentations, panel discussion and (of course) extensive networking.

There were many highlights from the conference which provided an extensive ranging of talking points for those in attendance. A presentation by a NOPSEMA representative was an early point of interest which provided an insight into where the Australian regulator saw gaps in technology within the industry and what are the requirements for bringing new technology into the fold.

Attendees were also invited to hear how ExxonMobil has been creating a culture of innovation and improvement, where biases can be challenged and leadership teams are more receptive to new ideas. The ExxonMobil presenter noted and reviewed why this culture is so important and how it can help in upcoming campaigns as every participant’s ideas are valued, allowing for the continuous development of techniques and ideas to complete projects efficiently and effectively.

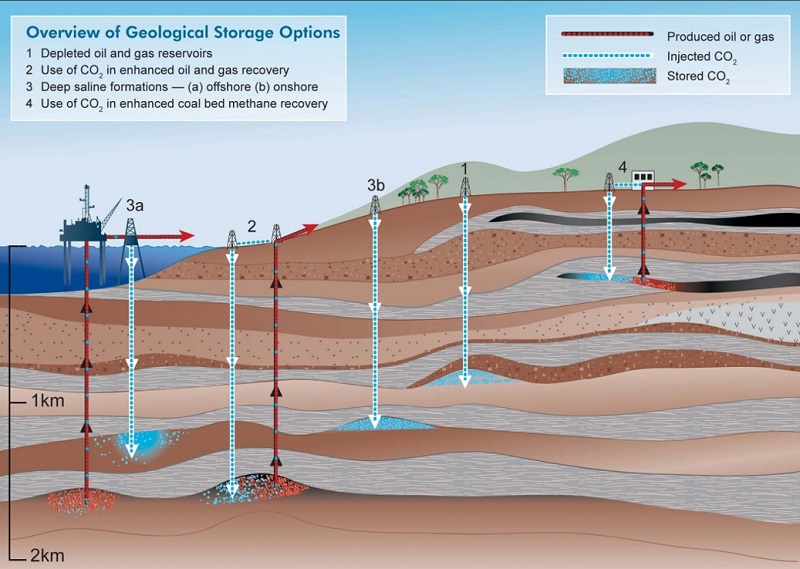

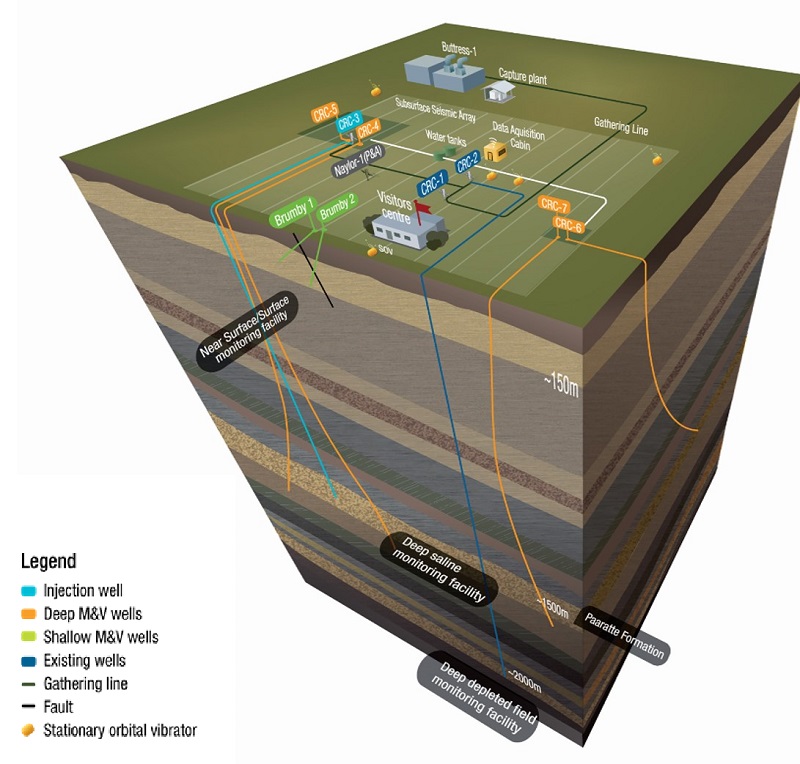

Then, in a memorable panel discussion that was described by a later presenter as one of the most memorable on the subject he had ever seen, participants from CCS Energy, NOPSEMA, Asia Pacific Energy Solutions and CO2Tech sat down to provide their thoughts on the CCS market in Australia. In the session, the speakers provided a detailed insight into the challenges and opportunities posed by the CCS market in the region, what are the advantages and disadvantages of repurposing ageing wells for CO2 storage, and how regulatory pressures are shaping the environment. Read more about what was said in the session here: https://offsnet.com/content/australia/meeting-emission-reduction-targets-through-ccs

Stringing the two days together was a myriad of presentations from technology providers and service providers outlining how their solutions were ready to support Australia’s offshore community for its well intervention requirements. In this vein, on the exhibition floor stood the likes of TAM International, Oilenco, Impact Selector and WELLVENE ready to display their wares to the gathered delegates. The onsite representatives provided some thoughts to Offshore Network on how their organisation was perceiving the Australian market:

Alastair McGregor, Business Development Manager at TAM International, remarked, “For Australia I think there's a lot of potential growth. The legislative, government and regulatory bodies have perhaps worked against themselves somewhat and lobbyists have perhaps been able to derail some projects that actually didn't have a lot of risk but were perceived as high risk.

“However, we have definitely seen a massive uptick in the whole P&A space but also routine well intervention here. P&A is definitely a major part of what we do and plugs and packers are integral to some of the operations around P&A. We are also seeing a bit of an uptick in people understanding how to apply them in the drilling phase as well. But, overall, P&A is definitely a large scope of what we do and is a large area of growth for us here.

“We've attended a few OWI AUS now and this one has certainly been very engaging with regards to the attendees; people definitely want to connect and learn a bit more about each other. We like to participate at events like this because it allows us to talk to more people and engage with them individually. There has definitely been a lot of interest in having those conversations during this event and I think we have at least four or five new leads from this conference.”

Colin Mackie, Country Manager at WELLVENE, said, “The main changes over the last six years for our company in Australia has been utilisation of equipment that is tried and tested in remedial intervention and utilising them in the P&A space. There has been more focus from operators on robust barriers and making efficiencies in deploying those barriers, which is where we've been able to help. As you go through P&A operations you have to consider every possible obstacle you may encounter on these older wells and try and plan contingencies that are efficient yet allow for the unknown, the fact that we are a smaller and more flexible company allows us to provide solutions a lot faster when the unknown does occur, and have a short turnaround on equipment that is bespoke to that particular problem. I think that will remain a big part of what we do in Australia over the next 10 years as well as the building of core products.

“Major growth areas for us as a company over and above the P&A and remedial intervention market would be service, we have some new technologies that allow for significant efficiencies in the Intervention space, and we are keen to work alongside the operators and indeed the contracted service companies to improve the safety and overall efficiency of interventions going forward.

“As a company that is established in Australia already, OWI AUS allowed us to reconnect with some people that we don’t necessarily get to see on a regular basis that have flown in for the event and meet some of the overseas service companies that are coming in to try and introduce their products into our market. It has allowed us to share our story of growth in Australia over the last six years. Furthermore, it allows us to showcase our understanding of Australian market to the clients and operators that are here.”

David Fisher, Business Development Manager at Oilenco, commented, “Oilenco have a strong track record in the North Sea and have been completing abandonment workscopes in this space since 2018. As Australia is becoming increasingly active in this area, we recognise that our technologies are transferable to this market.

“The OWI AUS conference provided us with the opportunity to showcase not only our capabilities but for attendees to see first-hand some of the projects we have completed. From safety valve remedial projects for well intervention workscopes to creating well-barriers for multi-well campaigns for an abandonment workscope. But also, how we deal with the unexpected, creating bespoke solutions to solve parted tubing challenges as an example, and our ability to manufacture, design and engineer these solutions to meet the specific challenges our clients face. It also allowed us to demonstrate how we can become an extension to a project team, with early engagement sometimes being the difference between getting a solution and getting the right solution. When speaking with operators they recognise how our solutions can support their needs.

“From the work we have completed in Australia so far, the feedback we have been getting from clients is very positive, so we look forward to continuing to support this region.”

Steve Irvine, Region Manager Australia-New Zealand-PNG at Impact Selector International, surmised, “This last year has been pretty slow because there's been a lot of projects been pushed back due to various factors such as the regulator and the government just told him things back a bit. So it has been a bit slow but I think it appears that it is going to fruition next year and in the years ahead. This is because these plans will likely now get passed and the major operators are getting their EPs together and better than they have been. So I would say I am optimistic for the future in this region, especially in regards to P&A which appears will be the next big thing here with lots of projects kicking off for that. So that will certainly be a focus for us.

“OWI AUS 2023 was very much what we wanted to happen. The audience was very much in our own line of business, which is good and it has been a while since I've been to conference which has had the right people as this did.”

At the recently concluded Offshore Well Intervention Australia 2023 conference held in Perth, a panel of industry experts convened to explore the outlook for the CCS market in Australia.

Together, they considered the ambitious goal of significant emissions reduction by 2030 and how the industry can overcome the time constraints by implementing CCS projects, what opportunities exist or could be put in place to facilitate industry stakeholder collaboration, and how can the industry share knowledge to accelerate CCS adoption and address common challenges effectively.

In the session, Diego Vazquez Anzola, CCS Specialist at APES Energy Evolution, explained, “Acceleration can indeed benefit from industrial and governmental collaboration. Collaboration is important and necessary, but it is not indispensable.

“There are those who point at regulations, or sometimes the lack of them, as the reason for the slow progress of CCS projects in Australia. Australia has the opportunity to not reinvent the wheel and analyse closely the history of other successful projects in other jurisdictions. The few successful commercial scale CCS projects around the world, in or nearing execution, were matured in various timeframes. However, those projects with the most compressed maturation timelines have common denominators, which, contrary to the general belief, are not particularly technical.

“The acceleration of CCS projects around the world has been attained by prioritising simplicity in storage development planning, with phased and calculated strategies for growth and scalability. Furthermore, acceleration has been truly attained by having first a clear understanding of the value generating models, with clear strategies on revenue generation and maximisation. This is indispensable.

“It is when commercial models are clear that industrial collaborations thrive – with a solid strategy towards job creation and workforce re-skilling and with regulators incentivising an environment of knowledge sharing and communication that naturally results in simpler and more streamlined approval processes.

“In summary, industrial and governmental collaboration and knowledge sharing would indeed be beneficial for acceleration. However, commercial clarity is what enables true collaboration towards acceleration.”

Adding his voice here, Jason McKenna, CCS Strategic Advisor at CO2Tech/CO2CRC, commented, “If I had to choose one word to describe the goal of achieving significant GHG emissions reductions by 2030, it would be ‘challenging’. In Australia, the LNG and gas industries are likely to be the first movers as the capture component is already built in to the CCS value chain. The rate limiting step for significant emissions reductions is likely to be the development of cost-effective large-scale capture technologies for the hard-to-abate sectors. In terms of storage, depleted fields may offer reduced project development timelines in comparison to green-field saline aquifers by avoiding the need for lengthy appraisal programmes and the possible re-use of existing infrastructure.

“Currently, there seems to be more of a competitive rather than a collaborative environment amongst the oil and gas companies in terms of access to geological storage. There is the possibility for the Australian CO2 storage capacity to be ‘over-subscribed’ at the moment due to the number of gazetted GHG permits. It would be disappointing to see a number of individual small-scale CCS developments fail the commerciality test (i.e $/tonne) to the detriment of more commercially efficient hub-scale collaborative CCS developments.

“Another area of collaboration to facilitate timely project development timelines is early and regular engagement with stakeholders, particularly NOPTA and NOPSEMA. CCS is an emerging industry globally and regulators will likely have more confidence to provide timely project approvals if they feel informed and engaged at key project milestones.”

Ageing Wells for CO2 Storage

On exploring the advantages and disadvantages of repurposing ageing wells for CO2 storage, Vazquez Anzola continued, “It is well known that engineers prefer to build from scratch rather than modify existing tools, machines or gadgets. Well engineers around the world concur that newly built wells result in the most effective and safest designs.

“On the other hand, general perception dictates that reutilising infrastructure, including aged oil and gas wells, is the simplest and the most cost efficient solution for CO2 storage development plans that can be matured in the shortest time frame. This is not always the case, and it is rarely the case for scalable CO2 storage hubs.

“Although injecting CO2 in depleted fields is a valid option for commercial scale CCS projects, especially in early phases for CO2 storage hubs, this does not come without technical challenges and can result in extremely complex and/or expensive solutions.

“Traditional oil and gas professionals need to soon understand the concept of ‘permanent storage’ when commerciality of CCS projects is directly dependent on demonstrating to authorities, regulators, shareholders, and the market in general, that every molecule that has been injected is expected to remain sequestered for centuries. A small percentage of leakage after 100 or 200 years or more is considered acceptable in various jurisdictions. The general expectation is that by then, CO2 sequestration would not be as necessary to tackle global warming as it is today.

“As a consequence of these radically different timeframes, risks of loss of containment and mitigation plans embedded in the much needed Measure, Monitoring and Verification (MMV) plans of any CO2 storage project directly affect the design and material selection of future P&A campaigns, as well as all steps required for transforming other infrastructure for CO2 manipulation, conditioning and transportation.

“In a nutshell, initial scale and future scalability of the future CO2 storage hub determines whether or not depleted fields are suitable options. Long term containment risks need to be managed in a cost-efficient but also pragmatic fashion founded on a thorough understanding of these containment risks, their likelihood and their consequence severity.

“However, even when legacy wells are not re-used as CO2 injectors or monitors, they may need to be abandoned more adequately as they will eventually be exposed to the CO2 pressure and/or saturation plumes. The challenge reaches its peak when some of the riskiest legacy wells abandoned years ago following traditional O&G standards, might not even be accessible for adequate re-abandonment. Costs but most importantly containment risks determine whether or not a specific storage site is adequate to the required CO2 injection scale. This is of particular importance in depleted fields.

Picking up this thread, McKenna added, “The perceived advantages of using legacy petroleum wells (and legacy petroleum facilities for that matter) are reduced project timelines and reduced cost (CAPEX). However, this perception may be a false economy as retrofitting a brownfield development may not deliver on these perceived benefits and may pose increased safety risk. Furthermore, the operational efficiency (up-time) and OPEX costs (well interventions and facility maintenance) for brownfield developments may offset and negate any commercial benefit over a greenfield CCS development. There is the added risk of extended monitoring periods post-injection to achieve site closure and relinquish liability for the storage site. A key technical risk I foresee for legacy wells is related to the thermal shock the wells may experience from Joules-Thomsen cooling effects when high pressure CO2 is injected into pressure depleted reservoirs or when a CO2 injection well is shut-in and there is a pressure drop in wellbore.

“There also seems to be somewhat of a double standard developing between greenfield versus brownfield CCS developments. Well designs for greenfield developments are generally being built with several layers of redundancy to ensure well integrity over geological time. In contrast, well integrity issues related to legacy wells which were designed for a completely different purpose may be seen through ‘rose coloured’ glasses by some operators.”

Regulatory and environmental pressures

Across all the issues discussed at OWI AUS, a common thread throughout was the impact of regulatory and environmental pressures and this held true when it came to CCS. On reaching this topic, the panellists sought to understand how these were reshaping and influencing the CCS landscape and what strategies operators can adopt to proactively address the concerns in their future campaigns.

Providing his perspective here, Vazquez Anzola noted, “Communication is key. The operator should provide the regulator with a holistic perspective of how their CCS projects would not only help their own decarbonisation plans, but also how they fit into a deeper and wider plan that not only results in net-zero or even negative emissions, but is directly linked to value generating models that would positively impact the community.

“A key role of the regulator is to ensure that no industrial activity causes irreversible harm to natural resources, flora and fauna as well as human life.

“When the operator genuinely seeks guidance from the regulator to enable a project that visibly generates value (and revenue) for everybody, all pieces start falling into place and true collaboration enables quality projects adhering to the highest safety and environmental standards.”

Continuing the discussion, McKenna added, “With respect to NOPTA approvals, there is an additional approval required for CCS projects in comparison to petroleum developments. This relates to approval from the Responsible Commonwealth Minister (RCM) for any Key GHG Operations (ie seismic surveys, geotechnical surveys and drilling wells). The guidance provided for these approvals is three months for NOPTA review and one month for RCM approval. If the GHG activity overlaps an existing petroleum title, the GHG Operator is required to demonstrate there will not be a ‘A Significant Risk Of A Significant Adverse Impact’ (SROASAI) on a discovered or undiscovered petroleum resource or an associated increase in costs to develop the resource.

“To facilitate timely approval of a Key GHG Operation, it is preferable for the overlapping petroleum titleholder to agree in writing that there is no significant risk posed by the GHG activity. However, if such agreement cannot be achieved, the RCM can form an independent view of the SROASAI assessment. This additional approval and the requirement to engage with overlapping titleholders has the potential to increase project development timelines. There is also the possibility that CCS proponents may have to declare force majeure if they cannot obtain RCM approval to undertake the activities related to their permit commitments. The unfamiliarity of the regulator to approve a Declaration Of Identified Storage Formation (DISF) and subsequent Injection License may increase uncertainty in project timelines for early adopters of CCS technology.

“Brownfield developments may suffer from project delays related to achieving approval of safety cases to from NOPSEMA to re-use legacy petroleum infrastructure. In terms of environmental approvals, the recent litigation against NOPSEMA approvals for petroleum activities poses similar risk for CCS activities. Furthermore, the CCS industry may be seen by activists as extending the life of the fossil fuel industry.

“I agree with Diego that communication is pivotal. A strategy of early and regular engagement with stakeholders who have high interest and high influence is Stakeholder Management 101. Education will also be a key enabler for the public acceptance of CCS technology.”

Woodside Energy, an Australian petroleum exploration and production company, has safely and successfully lifted the 83 m-long Nganhurra Riser Turret Mooring (RTM) onto a barge off the North West Cape in Western Australia.

Following the successful lift, the RTM is now transitioning to the Australian Marine Complex (AMC) near Perth. Upon arrival, it will be cleaned and deconstructed for recycling and reuse – more than 95% of the RTM is expected to be eligible for this.

In a world-first, the heavy lift vessel Heerema Aegir, with three supporting tugs, lifted the 2,500 tonne RTM onto a 120 m barge where it was secured ahead of its journey to the AMC. Woodside has presented the removal as a demonstration of its abilities to manage activities in the sensitive marine environments where it operates.

The Nganhurra RTM brought subsea production lines from the Enfield oil field to a floating production storage and offloading facility. Enfield ceased production in November 2018 and the RTM is being removed as part of decommissioning activities at the field, which also includes the permanent plugging and abandonment of 18 former production wells.

The decommissioning concept for the Nganhurra RTM was matured over more than two years of careful planning and detailed engineering, undertaken in conjunction with a range of specialist contractors.

In-field preparatory activities included remote operated vehicle inspections, removal of redundant equipment and installation of a purpose-built lifting point.

Following an assessment of the forecast weather and sea-state, the remaining mooring lines were cut, and the RTM was towed to a sheltered location to ensure the lifting operation could be executed safely. After the RTM is unloaded at AMC, it will be cleaned of marine growth and deconstructed for recycling and reuse opportunities, supporting local employment and contracting opportunities.

The Maritime Union of Australia (MUA) has launched a report produced alongside the Macquarie University’s Centre for Energy and Natural Resources Innovation and Transformation calling for a major shakeup in government policy and regulation for the dismantling, processing, recycling and disposal of offshore oil and gas infrastructure.

The Maritime Union of Australia (MUA) has launched a report produced alongside the Macquarie University’s Centre for Energy and Natural Resources Innovation and Transformation calling for a major shakeup in government policy and regulation for the dismantling, processing, recycling and disposal of offshore oil and gas infrastructure.

The report focuses on the decommissioning processes of offshore infrastructure and the necessary next steps once the structure are removed.

MUA’s Assistant National Secretary, Adrian Evans, said, “Australian maritime workers built and maintained our offshore oil and gas industry throughout the latter decades of the 20th Century, and with our eyes set firmly on the need to decarbonise our economy and diversify our renewable energy supplies the MUA is advocating for a sustainable and clean withdrawal from offshore oil and gas that includes the comprehensive removal and recycling of the massive volume of disused offshore equipment.”

The MUA and the Centre for Energy and Natural Resources Innovation and Transformation have examined Australia’s international and legal obligations and domestic laws relating to the decommissioning and disposal of the offshore infrastructures and have identified gaps in the legal framework, analysed best practice in mature jurisdictions and provided a series of recommendations for the development of the Australian government’s policy.

Mich-Elle Myers, MUA Assistant National Secretary, commented, “Offshore energy projects have provided generations of members with rewarding and fulfilling work building and maintaining the infrastructure that powers our economy. That’s not going to change with the shift to offshore renewable projects, and as older oil and gas projects wind down and come offline we have a collective obligation to remove and dispose of these installations thoroughly and sustainably.”

The recent 'Decommissioning and Abandonment Australia 2023' conference held in Perth saw many insightful presentations from a distinguished list of speakers. On the legal and regulatory side, Ben Adamson, a lawyer from HFW, an international law firm specialising in offshore energy and maritime law, provided a diverse audience with an in-depth dive into Australia’s offshore decommissioning regime.

The recent 'Decommissioning and Abandonment Australia 2023' conference held in Perth saw many insightful presentations from a distinguished list of speakers. On the legal and regulatory side, Ben Adamson, a lawyer from HFW, an international law firm specialising in offshore energy and maritime law, provided a diverse audience with an in-depth dive into Australia’s offshore decommissioning regime.

Ben kicked off his presentation with a briefing on the international framework relevant to decommissioning, which is driven primarily by United Nations Convention of Law of the Sea (UNCLOS) and the International Maritime Organisation (IMO). He then transitioned his presentation to discuss Australian legislation designed to enforce local decommissioning obligations. Of particular interest were his comments comparing and contrasting various national regulatory regimes, which appear to vary significantly between countries and offshore regions.

Ben pointed out that nothing in the Australian offshore oil and gas industry happens in a vacuum. An overlay of international laws and conventions exists that will continue to have a real effect on how Australia regulates the large pipeline of decommissioning work set to take place over the next two decades.

Revamped regime

The most important parts of the Australian offshore decommissioning regime are set out in the Offshore Petroleum and Greenhouse Gas Storage Act 2006 and its various regulations. Parts of the Act relevant to decommissioning underwent a major overhaul in 2021 to make the legislation fit for purpose and to respond, in part, to an unfortunate series of events where the decommissioning of an Australian FPSO and associated offshore field fell at great cost to the Australian taxpayer following the insolvency of the titleholder.

As Ben set out, the Australian government appears anxious to avoid a repeat of such events. The central pillar of the revamped Australian decommissioning regime is that titleholders must maintain and repair all structures, equipment and property brought into a field. Once the structure, equipment or property is no longer in use, titleholders must remove it. If the current titleholder is not available, or is unable or unwilling to undertake decommissioning, the Australian government has the power to bring former titleholders (as well as a range of other parties) back to decommission the offshore asset.

Trailing liability

The most important and topical of the changes to Australia's offshore decommissioning regime is what Ben described as trailing liability. Common in some other offshore jurisdictions around the world, trailing liability means that the government has the power, as a last resort, to 'call back' a past titleholder to remediate the environment or remove property. In that context, Ben raised some pertinent questions such as what would or could occur if at some distant point in the future a plugged well began leaking oil. Who will (or should) be brought back under a trailing liability regime to remediate it? Is it fair to force a former titleholder to decommission a well where that titleholder was at some point operating the field, but was otherwise not responsible for drilling or plugging the well?

In addition, Ben canvassed a number of other as-yet unresolved aspects of Australia's new decommissioning laws that arise from trailing liability. For example, what is the fair approach regarding small-percentage titleholders that form part of a joint venture comprising the titleholder? In the event that a former titleholder must decommission an asset, should they be entitled to tax breaks? Further, as Ben put it, can titleholders ever get a 'clean break' from a field after legitimately divesting their interest, if the spectre of trailing liability exists in perpetuity? As Ben concluded, current Australian decommissioning laws do not fully address these tricky issues, as well as a host of other issues raised by the new regime.

The second important point under the new Australian framework is that surrender of titles can only occur with the consent of the regulator. If a titleholder has not done the necessary decommissioning and the field is nearing the end of its life, Ben pointed out that with the passage of the amendments to the legislation, it will be difficult for the titleholder to transfer title, especially to a more speculative entity attempting to extract profit from an aging field.

In light of the major overhaul to Australia's decommissioning laws, Ben's opinion was that the most interesting aspect of Australia's updated decommissioning regime is how the regulator will manage its growing regulatory burden while upholding Australia's decommissioning obligations under international law. This is a complex and involved area that will evolve over time.

Increased accountability from titleholders

In terms of the role the Australian oil and gas regulator plays, the revamped decommissioning regime hands the regulator a new arsenal of powers to enforce titleholders' decommissioning obligations. Broad powers now exist to monitor and if necessary, intervene to stop, changes to the control of a titleholder, and passage of title from one titleholder to another.

Now, a change of ownership at the level of the titleholder is firmly within the regulator's grasp. Ben stated that players in the market can expect the regulator to act should it conclude, for example, that the entities taking control of a titleholder are not suitably resourced or experienced, or do not have the appropriate financial backing to carry out decommissioning. Before concluding his remarks about the new Australian regime, Ben reiterated that the trailing liability laws and powers to intervene in changes to control of the titleholder do not directly apply to contractors, employees, banks or customers.

The second part of Ben's presentation was a practical discussion on what a typical decommissioning contract may look like from a risk management perspective. He prefaced the discussion by setting out the typical options presented to those engaged in work offshore: either transfer risk, or accept it, insure against it, and price it in. Although decommissioning is a highly specialised undertaking, in Ben's view, the major themes and principles underlying contracts typically found in the offshore oil and gas sector would be relevant for offshore decommissioning contracts.

The offshore industry is a unique environment and there have been, over a long period of time, contractual terms developed that deal with the unique risk and liability issues faced in the offshore setting. Ben was clear that the typical knock-for-knock indemnity arrangements so common in the wider offshore and maritime world would likely be retained in decommissioning contracts, because these terms allowed contracting parties to either transfer risk, or assume it and insure against it.

Dealing with waste

Perhaps the biggest difference between typical offshore contracts and decommissioning contracts is how waste is dealt with. This aspect of Ben's presentation was directed to those in the audience who are preparing to deal with the vast volume of waste equipment, assets and material that is expected to be generated over the coming decades as Australia tackles its offshore decommissioning task. The big questions in this space are: what is to be done with the waste (some of it clearly hazardous) and crucially, how risk and title in the waste may be transferred between contracting parties. Ben recounted the difficulty his clients experienced exporting Australian offshore oil and gas waste overseas. As a final parting word, he challenged those present to develop local, home-grown waste disposal alternatives to avoid the issues arising in sending Australia's hazardous waste overseas.

The STORM-WORK was designed specifically for offshore industrial work activities and was very well received by offshore operators across industries – heavylift, decommissioning, oil & gas, and offshore wind. ConocoPhillips in Australia is using the customised enlarged version of STORMWORK while the standard units have been employed in multiple projects throughout Europe, among others, with Seaway7.

The design, safeguarding both the workers inside the basket and the assets worked on thanks to the soft-touch features and contoured shape, is praised by users worldwide. The small footprint and light weight allow for improved manoeuvring, while the highly durable, low-maintenance materials used ensure long unit lifespan.

“The unit is excellent for accessing areas with obstacles and tight landing spaces," comments a STORM-WORK user from Boskalis. Reflex Marine’s innovative work basket design has been recognised by industrial engineering body LEEA with an award in the Safety category confirming the outstanding crew protection features and safety benefits.

STORM-WORK is available for purchase and hire and can be customised to meet the required size and capacity.

C-Kore Systems has announced the successful completion of a decommissioning campaign offshore Western Australia.

C-Kore Systems has announced the successful completion of a decommissioning campaign offshore Western Australia.

The campaign was completed using C-Kore Sensor Monitor units to interrogate the wellhead pressure and temperature sensors on the oilfield. With their automated test routine, the Sensor Monitor units repeatedly tested and data-logged the information, allowing the operator to complete the campaign swiftly and safely.

Cynthia Pikaar, Sales & Marketing Manager for C-Kore, said, “It is fantastic to be working on this project in Australia. With an increasing number of orders for our Sensor Monitor tools, operators understand the value of our testing tools offer, automating and data-logging results. We look forward to working in Australia again on the next campaign.”

C-Kore Systems has a range of subsea testing tools used globally for decommissioning, fault-finding and new installation campaigns. The tools can be operated without the need for C-Kore personnel to be present, providing rapid feedback. The systems offer significant operational savings to testing campaign with the simple, accurate and reliable deployment.

Relatively stable oil prices and a growing global oil demand is creating favourable dynamics for the oil and gas community in the near-future, however uncertainty is rife over how long this will last as the race to meet the Paris Agreement 2050 target intensifies.

While this is raising questions over further drilling activity offshore Australia, it is suggesting a promising future for the country’s well intervention market as operators seek to squeeze the last drops of oil out of existing assets and perform end-of-life work in preparation for the substantial decommissioning task ahead. At the same time, the offshore carbon capture and storage space is garnering significant interest and marks another tantalising frontier that is receiving Government backing.

Read Offshore Network’s full report to understand the background and nuances of Australia’s offshore well intervention market as well as the potential challenges (such as labour shortages and vessel availability) which threatens to stifle it.

Page 4 of 9

Copyright © 2025 Offshore Network