Export credit agency UK Export Finance (UKEF) will be supporting Brazilian contractor Ocyan's decommissioning drive with a US$7.5mn guarantee.

Export credit agency UK Export Finance (UKEF) will be supporting Brazilian contractor Ocyan's decommissioning drive with a US$7.5mn guarantee.

After initial discussions with UKEF, Ocyan onboarded Scottish business Maritime Developments Ltd in 2022 who would take care of the equipment needs for the decommissioning project in Brazil. This was made possible using the UKEF grant which helped Ocyan procure financing from ABC International Bank to successfully set off the MDL deal. The grant will be applicable on a reimbursement basis, boosting its access to working capital.

Charlotte Wiltshire, European Head of Wholesale Banking, ABC International Bank plc said, "We are delighted to continue our support of UK businesses in conjunction with UKEF, leveraging off Bank ABC Group’s MENA and international footprint. This is an important milestone transaction, promoting the UK’s expertise in the oil and gas decommissioning and renewable energy arena. Bank ABC is looking forward to enabling similar energy transition projects in future."

A subsea pipelaying specialist from Aberdeen, MDL's wheeled horizontal lay system technology will be deployed by Ocyan to remove hundreds of kilometres of subsea cables and pipes from defunct FPSO oil and gas rigs in Brazilian waters.

Andrew Blaquiere, MDL Managing Director, said, "MDL is known worldwide for our forward-thinking technology that enables challenging scopes to progress on time and on budget, and this delivery to a Brazilian indigenous company is proof of that. Our engineering studies identified limitations with existing technology on the market when it came to recovery capability from deep waters like those in Brazil. The alternative for these operations would be to use a specialist construction vessel, resulting in high cost and scheduling challenges.

"In a true MDL ‘We Build Innovation’ style, we put our heads together, brainstormed alternative approaches – and delivered the Wheeled HLS. As a result, the client – and the Brazilian market – gained a cost-effective way to kit-out a vessel of opportunity to handle high loads and tackle recovery projects – this way enabling more sustainable end-of-life operations."

The first-ever overseas grant from UKEF also stands to benefit more than 70 Scottish businesses which are responsible for the entirely local MDL model.

Private equity investors Buckthorn Partners and One Equity Partners (OEP) have acquired Acteon Group, an international offshore energy infrastructure services businesses, in a move to develop the organisation’s capabilities in key markets.

The two entities have announced a significant injection of investment that will be used to improve Acteon’s standing with suppliers and customers. The company has been active since 1989 and now provides specialist engineering, services and technologies across all phases of the offshore lifecycle in 14 countries worldwide.

A key focus of this new occurrence will be placed on developing the organisation’s capabilities across survey, foundations, moorings, decommissioning, and consulting engineering services in support of the offshore renewable offshore oil and gas sectors.

“Acteon’s products and services are key to the energy transition in constructing, maintaining and supporting offshore energy infrastructure,” remarked Rob Willings, Partner at Buckthorn. “We are very pleased to acquire Acteon and its market-leading capability in managing offshore renewable, and offshore oil and gas infrastructure. Our ownership will bring stability to the business, and investment and expertise to grow and develop the company.”

Alongside the investment, the senior ranks of Acteon have been bolstered by the appointment of Brice Bouffard Chief Executive Officer. Brice brings a wealth of business experience highly relevant to Acteon and its key segments.

Helix Energy Solutions has announced the extension of its decommissioning contract with Trident Energy do Brasil Ltda.

The contract extension is for an additional 12 months and in direct continuation of the current contract. The extension is expected to begin in the fourth quarter of 2024 at rates in line with the improved well intervention market. The original contract commenced late 2022 offshore Brazil in the Campos Basin and utilises the Siem Helix 1 riser-based well intervention vessel and a 10K Intervention Riser System. Helix is providing fully integrated plug and abandonment well services through its Subsea Services Alliance partner SLB as well as project management and engineering services.

Helix and Siem Offshore have signed six-year charter extensions for both the Siem Helix vessels, with the Siem Helix 1 term extending through December 2030 and the Siem Helix 2 term extending through December 2031. The Siem Helix vessels are purpose-built advanced well intervention vessels capable of performing a wide range of subsea services including production enhancement, well decommissioning, subsea installation, offshore crane and Remotely Operated Vehicle (ROV) operations, offshore construction and emergency response.

The Helix Producer I (HPI) contract has also been extended by one year, to 1 June 2025. Since 2016, the HPI, a ship-shaped dynamically positioned (DP2) floating production unit, has been located at Green Canyon Block 237 producing oil and gas through the existing Phoenix Field subsea infrastructure. The vessel is designed to produce hydrocarbons and export to shore via pipeline or tanker.

Scotty Sparks, Helix’s Executive Vice President and Chief Operating Officer, stated, “We are pleased to announce that Helix has successfully executed these contract extensions, reflective of improving market conditions and increased demand for Helix’s assets and services.”

In a recent update on the SPS-88 well from the Bauna Project site in Brazil, Karoon Energy said that it will install a lightweight intervention vessel (LWIV) to start an intervention process so that the impacted well can be brought back to production.

Production from the SPS-88 well was first affected in November 2023 due to the formation of hydrates owing to an equipment failure in the gaslift dehydration unit of the floating, production, storage and offloading (FPSO) platform. Of the 12 subsea wells from the area that are joined to the Altera&Ocyan-operated FPSO via flowlines, two Patola wells were bought online last year. While the company closely worked with the FPSO operator, and had the faulty equipment successfully replaced and topsides issues resolved to remove the hydrates by circulating fluids, a mechanical blockage in the gas lift valve still obstructs the well's production capacity.

The obstruction has led the company to decide upon undertaking a 20-day intervention process by LWIV that will cost it approximately US$5-10mn. Subjected to engaging a LWIV and ancillary services and equipment, the company noted on its latest statement that this work will be initiated on the fourth quarter of 2024.

As highlighted on its statement, the intervention work will reflect on Karoon's production costs as it will swing between the range of US$10.5-15.0 per boe for the year from the previous US$9.0-14.0 per boe. While the Bauna FPSO comes with a storage capacity of 631,000 boe, the intervention plans has also led it to lower its last year production goals to stand around 9.0mn boe.

Leading institutional investor in the global energy and infrastructure sectors, EIG, has entered into definitive agreements with Novonor S.A. and the Brazilian Development Bank (BNDES) in order to acquire Ocyan Participações S.A.

Ocyan is a Brazilian-based solutions provider to the offshore oil and gas industry that boasts a 23-year track record of delivering for the sector, including in the operation of subsea and decommissioning projects. It is the only operating in the floating production storage and offloading (FPSO) industry and currently operates four offshore units through a joint venture with Altera Infrastructure.

R. Blair Thomas, EIG’s Chairman and Chief Executive Officer, remarked, “I have known and respected Ocyan for decades. The company’s resilience and the strength of its business have helped it overcome significant economic headwinds while maintaining a healthy balance sheet, positioning Ocyan for long-term growth. Brazil is home to over 25% of the global FPSO fleets, and we believe the future market dynamics for oil and gas infrastructure in Brazil are very favourable, underscoring our dual commitment to supporting growth and development in this important region while creating value for our investors. We are also excited to support Ocyan’s ventures in the renewables space to help drive the energy transition forward.”

EIG is looking to finalise the takeover to the tune of US$390mn, continuing its history of investment into the South American country – it has invested more than US$2bn there since 1998. As the latest example of this, the acquisition of Ocyan reflects the company’s comprehensive Brazilian strategy focusing on infrastructure supporting deepwater crude oil production, responsible decommissioning activities and renewables / low-carbon projects.

Roberto Prisco Paraiso Ramos, Ocyan’s Chief Executive Officer, remarked, “Ocyan has built and operated more than US$4bn of drilling rigs, pipelaying support vessels and FPSOs, alone or in joint ventures, always enjoying the very strong support of its shareholders and Novonor. This acquisition does not impact current contracts and operations with our clients and suppliers. This is another important chapter in our history and one that will undoubtedly create new opportunities for Ocyan.”

Offshore Network’s latest Global Well Intervention Report delves into the highly-prosperous global market and analyses the growth of operators utilising well intervention practices as the focus across the industry is shifting towards end-of-life activities and reaching environmental targets.

Assessments issued by Rystad Energy suggest that 17% of the world’s wells will undergo intervention processes by 2027, accounting for 260,000 wells globally. Spending within this market has already seen a surge and is likely to amount to US$58bn by the end of 2023, representing a significant growth of 20% since 2022. Climate consciousness has played a predominant role aiding the growth as mounting pressure is building across the industry to limit environmental footprints, with global companies seeking to make intervention an integral pillar within their business strategies.

In November 2023, COP28 witnessed Saudi Arabia launch its landmark Oil and Gas Decarbonisation Charter (OGDC) wherein 50 companies who represent 40% of the global oil and gas market thus far have signed up to the global pact to speed up climate action initiatives and are committed to become net-zero by 2050. However, it is not just the call for fast environmental action that is driving the intervention market, but the global increase in energy demand is also playing a vital role. According to the International Energy Agency, annual oil demand is expected to grow from 285.7 mboe/d in 2021 to 351 mboe/d in 2045, with oil set to retain a 29% share in the energy mix.

Increasing production rates is still a major priority across the industry, and a factor that must be balanced with the growing need to minimise carbon footprints. Well intervention practices are proving a key avenue that companies across the globe are turning their heads to, from expediting resources from the more veteran regions like the North Sea and the Gulf of Mexico to introducing more of these practices to ‘newer’ regions such as the Middle East and West Africa.

Shell has awarded a sizeable contract to Subsea7, a subsea engineering, construction and services company serving the offshore energy industry, for the decommissioning of subsea infrastructure offshore Brazil.

The infrastructure in question is that associated with the FPSO Fluminense in the Bijupirá and Salema fields of the Campos Basin, at 700 m water depth.

Yann Cottart, Subsea7 Brazil Vice-President, remarked, “Twenty years ago, Subsea7 installed the flexibles and umbilicals for Shell’s Bijupirá and Salema fields and, two decades later, we’re proud to be one of Shell’s chosen contractors to take part in the completion of this field’s life cycle.”

The scope of work for Subsea7 includes the disconnection, recovery and disposal of 10 flexible risers, three umbilicals and nine mooring lines.

The works in question are expected to get underway in December 2023.

Expro, a provider of energy services, has expanded its portfolio of cost-effective, technology-enabled services and solutions within the subsea well access sector by completing the acquisition of PRT Offshore.

Based in Houston, US, PRT Offshore is the only company to provide a complete Hook-to-Hanger solution which enables comprehensive well completions, interventions and decommissioning services from surface to subsea.

In completing the acquisition, Expro expands its portfolio within the subsea well access sector in the North and Latin America. On the other hand, it will help accelerate the growth of PRT Offshore’s surface equipment offering in Europe, sub-Saharan Africa and Asia Pacific.

Michael Jardon, Expro Chief Executive Officer, remarked, “This is an exciting day for both PRT Offshore and Expro as we strengthen and expand our subsea well access technology offering while continuing to deliver value to our customers across the life of their wells.

“Our subsea well access portfolio has a well-established global footprint, especially in the ESSA and APAC regions. We believe this will offer significant growth opportunities for PRT Offshore in these attractive markets. Simultaneously, Expro plans to leverage PRT Offshore’s strong position in deepwater offshore well completion and intervention across the NLA region to provide integrated solutions to our customers.”

PRT Offshore President, Patrick Place, added, “We are looking forward to embarking on this next phase of our journey with Expro. This agreement is an exciting development for PRT Offshore as we integrate our technology, solutions, and expertise with Expro’s market-leading subsea well access portfolio.

“We are excited to continue our best-in-class responsiveness and service quality, as well as leverage the resources of a more robust platform. Our employees, vital and valued, are at the forefront of this transaction, and we are committed to fostering their growth and success in this new chapter. Building on the foundation we have created, this acquisition will open new opportunities for growth, innovation, and success for our company, customers, and employees.”

Petrobras has welcomed the arrival of the floating production, storage and offloading (FPSO) vessel Sepetiba for future work on the company’s giant Santos Basin offshore Brazil.

Petrobras has welcomed the arrival of the floating production, storage and offloading (FPSO) vessel Sepetiba for future work on the company’s giant Santos Basin offshore Brazil.

FPSO Sepetiba is currently undergoing technical procedures before it will be taken to the Mero field within the Santos Basin later this year. The FPSO is capable of producing up to 180,000 barrels of oil and 12mn cubic metres of gas per day, with production expected to begin in Q4 2023.

Sepetiba, which was delivered to Petrobras by SBM, is the second definitive FPSO to be installed in the Mero field, the third largest by volume of oil in place (VOIP), out of all four systems in place. The four units together will have the capacity to produce up to 720,000 barrels of oil per day.

The combined Mero field is operated by Petrobras in partnership with Shell Brasil, TotalEnergies, CNPC, CNOOC and Pré- Sal Petróleo S.A – PPSA.

Expro has announced it has entered into a definitive agreement to acquire the offshore services provider, PRT Offshore, in a bid to expand its portfolio of cost-effective technology services and solutions.

Expro has announced it has entered into a definitive agreement to acquire the offshore services provider, PRT Offshore, in a bid to expand its portfolio of cost-effective technology services and solutions.

Upon closing of the transaction, which is expected in Q4 2023, Expro will enhance subsea services within the North and Latin America (NLA) region, and accelerate the growth of PRT Offshore’s surface equipment offering in Europe and sub-Saharan Africa (ESSA) and Asia Pacific (APAC) regions.

Based in Houston, Texas, PRT Offshore is the only company to provide a complete Hook-to-Hanger solution, enabling comprehensive well intervention and decommissioning services from the surface to subsea. The unique system allows customers to access the wellbore safely and efficiently while reducing on-board personnel.

Michael Jardon, Expro Chief Executive Officer, said, “Expro is committed to investing in innovation and technology to differentiate our services and solutions offering. This strategic acquisition is exciting for both Expro and PRT Offshore as we strengthen and expand our subsea well access technology offering and continue to deliver value to our customers across the life of their wells.

“Our subsea well access portfolio has a strong and established international presence, particularly across ESSA and APAC. We believe this will provide significant opportunities to expand PRT Offshore’s presence in these attractive regions. Similarly, Expro will leverage PRT Offshore’s strong position in deepwater offshore well completion and intervention throughout the NLA region to deliver integrated customer solutions.”

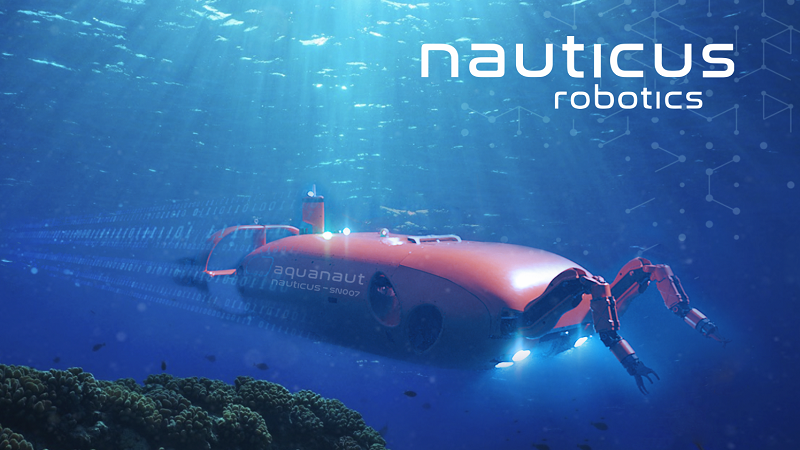

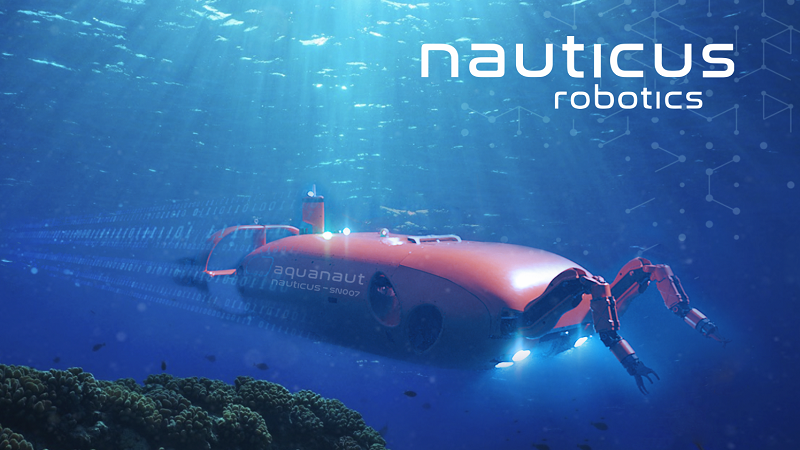

Nauticus Robotics, a developer of autonomous robots using artificial intelligence for data collection and intervention services, has been awarded a contract by Petrobras to deploy its autonomous subsea robot, Aquanaut, to support the company’s offshore activities.

Aquanaut will be used in Petrobras’ deepwater production field using supervised autonomy for infield inspection services. The contract, one of the largest of its kind to date, consists of approximately two months of subsea inspection and expands Nauticus’ growing international presence to South America.

The fully-electric Aquanaut carries an array of multi-spectral perception sensors that allow the robot to detect, classify, inspect, and act upon subsea infrastructure using its pair of manipulators without direct operator control. This method provides significant cost and greenhouse gas emissions reductions over conventional methods.

Nicolaus Radford, CEO of Nauticus, commented, “A contract with another worldwide leading operator for Nauticus speaks to the state-of-the-art technologies of our autonomous robots as we further penetrate the global markets. The market opportunity for Nauticus in offshore Brazil is significant, as it is one of the world's most active offshore energy basins; we are pleased to enter this market through a world class operator.

“We competed through a rigorous tender process with many well-respected industry competitors to earn this business with Petrobras and eagerly await the deployment of our assets to validate our capabilities. We continue to build our robust pipeline of opportunities, giving us confidence to execute on our mission and deliver long-term value to shareholders.”

Brazil has posed itself as one of the key drivers in the Latin American market that is driving the region's growth in the international oil and gas game. A net oil importer until 2014, Brazil has become the top producer in Latin America in 2016, and since then has enjoyed uncontested leadership in the region. While this represents a great opportunity for the region’s oil and gas sector, from the operators to service providers supporting them, there is a looming decommissioning wave on the horizon.

Brazil has posed itself as one of the key drivers in the Latin American market that is driving the region's growth in the international oil and gas game. A net oil importer until 2014, Brazil has become the top producer in Latin America in 2016, and since then has enjoyed uncontested leadership in the region. While this represents a great opportunity for the region’s oil and gas sector, from the operators to service providers supporting them, there is a looming decommissioning wave on the horizon.

The global oil market has been witness to many ups and downs since the advent of the Covid-19 pandemic. Far from stability, it has weathered a persistent conflict in eastern Europe; re-emergence of Covid-19 in China; major, consecutive price cuts by OPEC+ nations, and a global uptake on renewable activity. The IEA, however, has indicated that oil demand would remain steady until it reaches a peak in the mid-2030’s at 103mn bpd before beginning to plateau. It predicted that despite the global energy mix changing to accommodate the surgence of renewable practices coming to the forefront, fossil fuels will still hold a 60% share within the energy game until at least mid-century.

The Ministry of Mines and Energy (MME) in Brazil has big plans on drawing investment to the country's petroleum sector. It will be focusing on the various ways to drive exploration in frontier areas and call for investments in mature, as well as marginal, economic fields. Owing to these ambitious goals, there is a dual opportunity for both greenfield development and production enhancement through well intervention.

Besides the active role of Petrobras on advancing the country’s oil and gas industry, new players are also emerging as the state-owned Brazilian Petroleum Company has been passing on its mature assets to several entities from BW Energy to Trident over the last few years. Petrobras itself has plans to decommission 26 of its floating platforms, with the P-32 asset scheduled to begin the process this year.

On the other hand, high marketed utilisation rates of offshore rigs, especially in Latin America following the eastern European conflict, led to a supply chain gridlock. While many operators are considering collaboration between companies in order to use the same vessel for their respective assets, logistically, that process could also present challenges.

Another challenge in the well intervention industry lies in tackling the high costs involved in the process. This has resulted in the popularity of a slightly more fresh-faced method – riserless light well intervention (RLWI). Used instead of heavier vessels, this has the potential to significantly reduce cost of operations and minimise environmental impact – an increasingly pressing concern for operators.

Page 5 of 10

Copyright © 2025 Offshore Network