TechnipFMC has announced its intention to acquire the remaining 49% of shares in TIOS AS, a joint venture between TechnipFMC and Island Offshore Management AS (Island Offshore) formed in 2018.

TIOS provides fully integrated Riserless Light Well Intervention (RLWI) services, including project management and engineering for plug and abandonment, riserless coiled tubing and well completion and intervention operations, and has serviced more than 740 wells globally since 2005.

The acquisition will accelerate the development of TechnipFMC’s integrated service model focused on maximising value to its clients.

The company will continue to utilise Island Offshore as the vessel provider for RLWI services.

Jonathan Landes, President, Subsea at TechnipFMC, said, “We are pleased to welcome TIOS wholly into TechnipFMC. This transaction brings into the company additional expertise that will maximise our capability to provide a complete range of well services globally to our clients in a rapid and economical manner.”

This announcement comes soon after the company released its Q2 2021 results, in which its subsea performance was particularly strong.

Doug Pferdehirt, Chairman and CEO of TechnipFMC, commented, “Subsea inbound orders of US$2.8bn in the first half of the year were strong. We continue to see a healthy list of prospects and remain very confident in our full-year guidance for Subsea orders of more than US$4bn. Furthermore, growth in 2022 is supported by an increasing set of opportunities.

“We believe that offshore will continue to play a meaningful role in the total energy mix. We are building partnerships in support of new energy, leveraging our differentiated technologies, and capitalising on our integrated project execution and expertise as the subsea architect.”

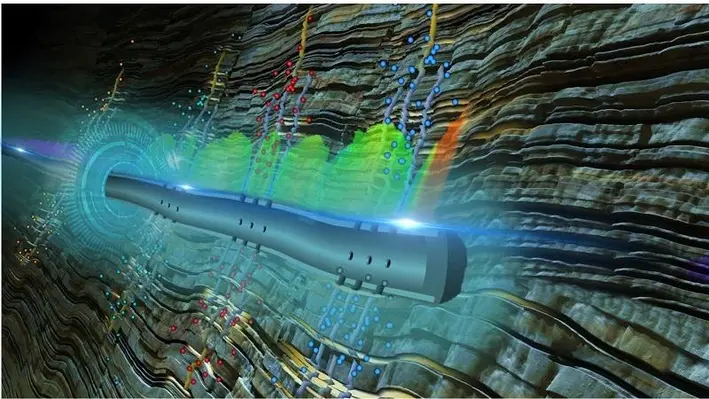

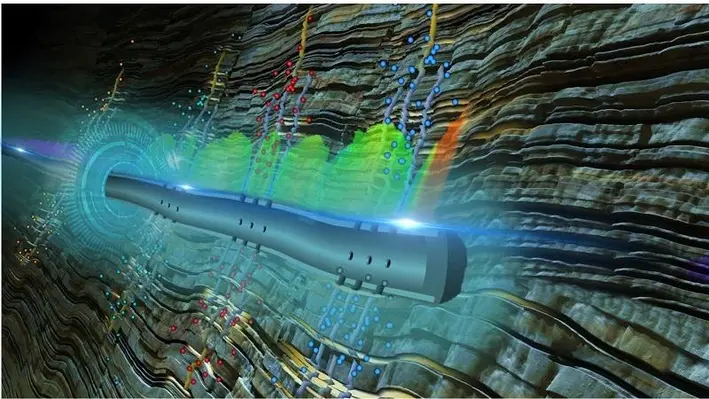

Halliburton has launched ExpressFiber, a single-use fibre optic cable that offers accurate, direct subsurface measurements, including cross-well communication, at a price point that enables fracture monitoring on every well pad.

Halliburton has launched ExpressFiber, a single-use fibre optic cable that offers accurate, direct subsurface measurements, including cross-well communication, at a price point that enables fracture monitoring on every well pad.

Understanding and optimising well and fracture interference is a significant challenge that operators face today. ExpressFiber uses distributed acoustic sensing (DAS) to acquire a direct measurement of micro seismic, strain, and temperature unlike other cross-well monitoring techniques that provide indirect estimates.

ExpressFiber, paired with Halliburton’s intelligent fracturing and subsurface monitoring services, provides real-time actionable insights of fracture growth and well interference, allowing operators to improve completions designs and gain overall capital efficiency. It can be pumped downhole in offset wells within a couple of hours, and can be installed any time before or during the fracturing operation. ExpressFiber is designed to withstand downhole conditions for the duration of the stimulation treatment before degrading, and has no impact to subsequent fracturing operations in offset wellbores.

Michael Segura, Vice-President of Production Enhancement, commented, “When it comes to direct measurement of the subsurface, fibre is the most direct and trusted sensor of choice, but traditionally it has been expensive and complex to install. Our innovative fibre portfolio transforms fracture monitoring from an application reserved for science wells to a routine solution for regular use on more wells across your asset.”

Through a five-year agreement for North America unconventionals, ExpressFiber will be enabled by FiberLine Intervention (FLI), a wellbore surveying technique from Well-SENSE Technology Limited.

As the Offshore Well Intervention West Africa conference draws near, Offshore Network spoke to David Carr, Senior Vice President – Helix Well Ops (UK) Ltd. to gain a preview of the well intervention market and appetite in the region, and the latest on Helix’s activities there.

As the Offshore Well Intervention West Africa conference draws near, Offshore Network spoke to David Carr, Senior Vice President – Helix Well Ops (UK) Ltd. to gain a preview of the well intervention market and appetite in the region, and the latest on Helix’s activities there.

The Q7000 continues to shine

Carr began by discussing the Q7000, a DP Class 3 semisubmersible well intervention vessel that arrived in Nigerian waters for its pilot project at the start of 2020. Carr stated, “The first operator was an international major in Nigeria with whom we had scheduled to conduct a five well campaign. We had a new vessel, a new crew, a new well access package and we were working in a new country, and yet we completed the campaign around 25 days quicker than expected.”

“This vessel has been operated since it’s inception as a fully integrated package, utilising the services of Schlumberger, our partner in the Subsea Services Alliance.”

“During the last well, the pandemic hit, so unfortunately we had to return to Tenerife, however we continued conversations with Total, Chevron and Shell in Nigeria over Teams. Before the end of last year, we mobilised the vessel again and completed a five well campaign for Total and one for Chevron. In the last few weeks, we have begun a campaign for SNEPCo which is from five to seven wells. It is most likely we will finish the current campaign in early Q4 2021 and stack the vessel in a nearby port before recommencing operations in January 2022. After that, we are in discussions with two other major operators and a potential third to keep Q7000 in country, so we will be doing projects there next year as well.”

“After these projects are completed, the Q7000 will move on to Australia, but to do so we go right past Angola. We are in discussion with a couple of operators to do some work in the country during the second half of next year before moving on,” Carr added.

Carr also took time to explain how the Q7000 crew is rotated in the wake of the pandemic by noting that before members were rotated monthly but now, due to Covid quarantine rules, they do six week stints away from home in order to isolate. He noted that the company has been massively helped by their policy of utilising local content ‒ around 65% of the Q7000’s crew is Nigerian, and those crew do not have to go through international protocols, just Helix’s.

Carr added, “Nigeria is a very good place for local talent. The offshore oil industry has been established in the country for more than 40 years, so in terms of getting quality wireline, deck, or downhole service crews, the region is well supplied. We comply with the local content rules in the country, enforced by the Nigerian oil regulator (NAPIMS), but we don’t just comply by hiring cooks and cleaners, etc. Instead we hire and train DP officers, junior vessel engineers and more. All of the Schlumberger’s crew are Nigerian. We had nearly 30 Nigerian crew members fly to Singapore before the Q7000 set sail, so they knew the vessel, procedures and safety protocols well before arriving in West Africa.”

Collaboration

Helix has established a strong relationship with NAPIMS by providing opportunities for local Nigerian engineers, and imbuing them with transferable work skills to remain in the region. This relationship is essential when finding new opportunities for their vessels.

As Carr explained, “We speak to all the operators in the region, but not necessarily at the same time. NAPIMS does though, because it has an interest in increasing production for the whole of Nigeria. NAPIMS allows these operators to spend OPEX money on well intervention and they encourage this type of work to be taken up.”

“Additionally, each operator is ultimately aiming to increase production for themselves, whereas NAPIMS is trying to do it for the whole country. Through collaboration and discussions on where campaigns can fit in together they can all do this more effectively, but it is the NAPIMS that is the glue to bind them all together.”

Carr also added that Helix are not the only LWI service company working in the region and highlighted that while his company competes with many others, all are keen to see success continue within the segment. He commented that the last thing he wants is for them to have a bad job and that some of them are doing fantastic work ‒ such as Oceaneering who are working with BP in Angola currently.

The challenges and opportunities of West Africa

The success of the Q7000 in Nigeria has shown that there are opportunities to be found in the region, and by operators communicating and attracting such vessels to the region they have the chance to enhance well production and increase the well life of the rapidly ageing subsea wells located there.

However as Carr noted, the region can be a challenging place to operate. He said, “What typically kills well intervention work in West Africa is the transit cost of the vessel all the way from Europe or Gulf of Mexico (GOM). If you want to use a vessel in West Africa, you will probably have to sail it from the North Sea, which is very expensive. When we brought the Q7000 here, we agreed to pay for mobilisation but we needed to get a guaranteed amount of work to recoup this cost. Again, this is where collaboration between operators becomes necessary. When operators discuss and work out how the vessel will be utilised, it provides the opportunity to remain in the region longer.”

A promising future?

It is no secret that sub-Saharan Africa will have one of the oldest average ages of wells in the coming years, and as energy demand increases in line with the population, well intervention is predicted by many to have an important role in the region’s future. Weighing in on this subject, Carr said, “Nobody predicts the price of oil will reach such a height that exploration to replace reserves will be high on the agenda of many operators. As we know, companies like Total, Shell, BP are making big transitions into renewable energy and they will not want to be putting masses of capex into new exploration and development.”

“They are going to have to maintain their reserves by managing the wells they have; essentially, well intervention is going to have to be a big part of this. Unfortunately, the obviousness of that statement does not always translate into money being spent.”

“Adding to this, the well interventions that we (and our competitors) are doing now are reactive ‒ fixing things that are broken. What we need is a more European model of proactive work. Going into wells that are producing and making them more efficient. Doing well intervention earlier in their life so that they can maximise economic returns and continue production for many years to come.”

Rig vs riserless

One hot topic that has been debated in the region is the use of riserless over riser-based solutions for well intervention activities, with some touting the former as the answer to West Africa’s ageing well problem.

Carr took a more measured approach and commented, “There is an impression in the market that riserless equals cheap and at times this may be true. But we find that in the deep waters of West Africa, with the complexity and lack of supply chain in the area, sometimes it is less practical. With the riser vessels there is more contingency which leads to better outcomes in a place with less predictable wells. One of the criticisms of riser-based is it takes long to deploy the system and get onto the well, this is true if it is only deployed once. However, Helix often does multi-well campaigns and have the ability to deploy the system once, before hopping over to the next well and not recovering it in-between. In such cases it is every bit as fast as a riserless package.”

“At the end of the day it is going to be a combination of the two, and our intention is to have both capabilities in the region. In fact, in the future our intention is to bring one of our large monohulls from Brazil to be permanently stationed in West Africa. Our vessels (Siem Helix 1 and Siem Helix 2) currently in Brazil have each done more than 50 jobs each in deep water and complex geologies so they should be well suited. With those vessels we anticipate we can have riserless and riser-based capabilities. If we can get a minimum commitment from one or more of the operators in the region this will come to fruition,” Carr concluded.

Sign up for West Africa's leading well intervention conference to hear more on reducing costs, overcoming logistical challenges, increasing well performance and the future of the market: https://offsnet.com/owi-wa/register

Frank's International (Frank’s), a global oil services company that provides a broad and comprehensive range of highly engineered tubular running services, tubular fabrication, and specialty well construction and intervention solutions, has received the inaugural 2021 Most Valuable Partner (MVP) Award from a major operator in recognition of its work in Guyana.

This award recognises Frank's work in helping their customer meet important operational goals both safely and efficiently. Frank's Tubular Running Services, Cementing and Well Integrity teams developed a customised solution involving multiple casing technologies, which eliminated the need to alternate tools and accommodated different casing types.

The solution enabled faster run times and removed the need for personnel to enter the hazardous red zone. Frank's first-rate operational planning and execution led to a record-setting casing string run, with a total of five hours saved and zero rejected connections with a fully nationalised night crew.

Specifically, the MVP award recognises the following categories and achievements:

-Safety, Security, Health and Environment (SSHE) Excellence: recognised as strong leaders and contributors in pre-tour and rig-floor meetings

-Reliability: excellent Non-Productive Time (NPT) performance demonstrating 99.8% up time

-Adaptability and Proactivity: onshore personnel engaged early and effectively collaborated

-Truly Working as a Partner: offshore personnel consistently demonstrated commitment to supporting activities on the rig outside of their base work scope.

"Congratulations to our Tubular Running Services, Cementing, and Well Integrity teams, including local crew members in Guyana," said York McCauley, Frank’s Senior Operations Manager, Caribbean. "These talented and dedicated team members consistently demonstrate operational excellence both onshore and offshore. This award is a testament to their hard work and dedication to delivering superior value, safety, and efficiency to our partners. We appreciate their outstanding contributions to Frank's operations."

Michael Kearney, Chairman, President and Chief Executive Officer, added, "Innovating to help our customers and going above and beyond is what distinguishes our talented team at Frank's. Thank you to our employees for living our core values of Safety, Integrity, Innovation, Diversity and Excellence every day."

A report published on Reportlinker.com, titled ‘Well Intervention Market by Service, Intervention, Application Well Region – global Forecast 2026’ has suggested that the global well intervention market is projected to reach US$9.3bn by 2026, up from US$7.6bn in 2021.

This growth represents a steady CAGR of 4.2% with the main driver being the growing need to maximise product potential of mature oil and gas fields. This increasing demand for offshore and subsea well intervention could off excellent opportunities for service companies offering such services.

Fast growth

The report continues by breaking down this market growth and suggests that the horizontal well segment, by well type, is projected to dominate the global well intervention market due to the increasing horizontal directional drilling activities to optimise production from wells. Such wells are expensive when compared to vertical wells, but they are often preferred due to their efficiency in increasing oil field production and their ability to access subsurface reservoirs that are not directly accessible from above.

The offshore segment

By application, the offshore segment is expected to be the fastest growing market from 2021-2026 as companies have been exploring offshore locations for oil and gas production owing to the fact that offshore locations have a large number of untapped reserves.

Despite fluctuating oil prices, the application of offshore well intervention services is expected to rise, attributed to the increasing deep and ultradeep water drilling and production activities and an increase in the number of maturing subsea wells.

North America dominates market

According to the report, North America represents the largest and the fastest-growing region in the well intervention market and is expected to dominate the global well intervention market between 2021 and 2026. The region has the largest shale reserves, which makes it a lucrative market for drilling activities and for oilfield service providers.

According to the US Energy Information Administration, in 2017, the region had 307.9 trillion cu/ft of shale reserves, out of which only 18.6 trillion cu/ft have been produced in the same year. Thus, the vast potential from the shale reservoirs has been attracting more drilling operations in the North American oil industry. Profitable drilling activities are likely to create enough opportunities for well intervention operations.

Halliburton Company, in their Q2 2021 results, have pointed to an increase in well intervention activities as partially responsible for their growth in revenue and suggested that a multi-year upcycle may be unfolding.

The company’s Completion and Production revenue in Q2 of 2021 was US$2bn, an increase of US$178mn, or 10%, when compared to Q1, while operating income was US$317mn, an increase of US$65mn, or 26%. These results were driven by increased activity across multiple product service lines in North America land, higher cementing activity in the Eastern Hemisphere and Latin America, increased completion tools sales in the Middle East, the North Sea, and Latin America, as well as higher well intervention services in regions such as the Middle East, Africa and North America.

Drilling and Evaluation revenue for Halliburton in Q2 of 2021 was US$1.7bn, an increase of US$78mn, when compared to Q1 of 2021, while operating income was US$175mn, an increase of US$4mn. These results were due to improved drilling-related services and wireline activity across all regions, along with increased testing services in the Eastern Hemisphere.

Jeff Miller, Chairman, President and CEO of Halliburton, said, “Halliburton’s Completion and Production division margin reached three-year highs, while our Drilling and Evaluation division margin outperformed expectations, setting both divisions up for robust margin growth this year.

“The positive activity momentum we see in North America and international markets today, combined with our expectations for future customer demand, gives us conviction for an unfolding multi-year upcycle.”

Coretrax, a global well integrity and production optimisation leader, has moved to new regional headquarters as the business gears up for further growth and has supplemented by strengthening its senior leadership team.

New facilities for a new era

The company has consolidated its European headquarters into a new facility at Badentoy industrial estate, Aberdeen, which boasts 70,000 sq ft of offices, warehouse and yard space to support increased business demand across the region.

In the Middle East, following a period of sustained growth, Coretrax has doubled the size of its headquarters in Dubai, United Arab Emirates (UAE), after moving into a new DMCC office space in the city and an operations hub in Abu Dhabi.

Expanding the leadership team

Coretrax has appointed Keith Bradford as the new EARC Regional Manager, to be located at the new facility in Aberdeen. Bradford has more than 25 years worth of experience in the industry and joins the company from Varel Energy Solutions where he was most recently Region Director. Prior to this, he held the role of General Manager with Downhole Products. He will be responsible for leading Coretrax’s expansion across Europe, Africa, Russia and Caspian.

In the Middle East, Murray Forbes has been appointed as Vice President of Sales and Marketing, also bringing more than 25 years’ experience in well operations, technical support and product development. Forbes held several senior positions at major oilfield service companies and was most recently global sales director at Welltec. He will work closely with Coretrax’s global senior leadership team to drive and enhance the company’s current technology offering.

Forbes is supported by Bob Murdoch who has been appointed as Eastern Hemisphere Expandables Operations Manager. Boasting more 30 years’ experience in technical operations, Murdoch joins the firm from Halliburton where he was operations manager – liner hangers. He will be responsible for leading Coretrax’s fast-growing, expandable technology range in the Middle East and Asia Pacific.

Emile Sevadjian has also been appointed as Vice President of Expandables Engineering, having joined from Halliburton.

Kenny Murray, Chief Executive Officer at Coretrax, commented, “Our new, larger offices in Aberdeen and Dubai are a significant milestone for the business as we gear up for further expansion in the next 12 months. Despite the challenges that the Covid-19 pandemic has presented, we are continuing to see increased demand for our technology and this is testament to the high-quality service our people consistently deliver.

“Our new senior appointments each bring substantial knowledge and experience to the business which will be vital as we implement our ambitious growth strategy. As the industry continues to focus on driving operational efficiencies and responsible oil recovery, we are ideally placed to support operations at all stages of the well lifecycle. We already have a healthy pipeline of work moving into the remainder of this year and I look forward to expanding our footprint across the oil and gas and renewable sectors in the coming months.”

The Abu Dhabi National Oil Company (ADNOC) have announced an investment of US$763.7mn in integrated rigless services across six of its artificial islands in the Upper Zakum and Satah Al Razboot (SARB) fields to support its production capacity.

ADNOC Offshore has issued three contracts to Schlumberger, ADNOC Drilling, and Halliburton after a competitive tender process which will help see the company support its production capacity expansion to 5mnbpd by 2030.

The scope of the contracts includes coiled tubing services with thru-tubing downhole tools, stimulation services, including equipment and chemicals/fluid systems, surface well testing services, wireline, and production logging services and tools, saturation monitoring, and well integrity.

Ahmad Saqer Al-Suwaidi, CEO of ADNOC Offshore, commented, “These contracts are an important contributor to ADNOC Offshore’s plans to build our production capacity to over 2 million barrels a day in the coming years to support the ADNOC Group’s smart growth strategy. The award follows a highly competitive bid process, which included a rigorous assessment of how much of the contract value would support the growth and diversification of the UAE’s economy through ADNOC’s In-Country Value Program.”

The six artificial islands covered by the awards are Asseifiya, Ettouk, Al Ghallan, and Umm Al Anbar in the Upper Zakum field and Al Qatia and Bu Sikeen in the SARB field.

Halliburton’s joy in the Middle East continues

ADNOC’s announcement came within days of Halliburton revealing it has also secured a contract to provide production chemicals and associated services for a large IOC in Oman. Halliburton will supply a full suite of customised products along with specialised services to support the in-field chemical treatments across the seven-year contract.

Miguel Gonzalez, vice president of Halliburton Multi-Chem, said, “We are excited to provide our production chemical expertise and management services to help our customer maximise their asset value in Oman. This collaboration aims to improve operational efficiencies and reliability by applying tailored solutions and close alignment between parties.”

Halliburton will manufacture key raw materials for the contract’s portfolio at the new Halliburton Saudi Chemical Reaction Plant. Opening at the end of 2021, the facility increases Halliburton’s capabilities to support Oman and the region.

The plant will have capabilities to manufacture a broad slate of chemicals for stimulation, production, midstream, and downstream engineered treatment programmes.

Following an initial agreement between the two companies in 2018, Equinor and Ardyne, a specialist downhole technology and services company for reducing rig time on well abandonment, slot recovery, workover, exploration and P&A operations have agreed a second joint industry project (JIP) to develop a unique well decommissioning technology to reduce the economic and environmental impacts of slot recovery and well decommissioning operations.

The UK£1mn project has been jointly funded by Equinor and Ardyne. Ardyne will manage all engineering, project management and onsite rig qualification testing before deployment for field trials.

TITAN RS

TITAN RS, which will be ready for commercialisation in 12 months, combines Ardyne’s field proven bottom hole assembly (BHA) systems with the new resonance tool to aid casing recovery by using resonance to reduce the pulling force required to free stuck casing. Successful trial wells have been completed recovering casing encased in settled solids.

The system uses the novel and highly effective application of resonance or vibration technology to allow longer sections to be pulled more quickly from settled material in the well. Ardyne has proved resonance to be highly effective in loosening settled material surrounding the casing, with an approximate 30% reduction in pull force required. The vibrations remain isolated downhole and are not transferred to the rig floor.

Compared to conventional rig systems, TITAN RS can provide up to 40% time efficiency savings for well abandonment, decommissioning and brownfield slot recovery projects through fewer runs and time downhole, with a resultant reduction in carbon emissions due to less rig time. The additional functionality means well clean up can be achieved as part of the recovery process without the need for additional trips in the well.

Ardyne has calculated that, when considering a single well scenario, an average rig time saving of more than 78 hours can be achieved. This would equal 136 tonnes of CO2 avoided, 156.8 MW hours of electricity and 13,807 gallons of diesel.

Alan Fairweather, CEO of Ardyne, commented, “The process is proven. The ability to cut days off existing processes through the innovative use of resonance is compelling at a time when the industry is seeking to maximise efficiencies at every opportunity. The environmental benefits of reduced carbon emissions through less time required on site are clear.”

“Equinor has already identified wells offshore Norway for the commercial deployment of TITAN RS next year. We look forward to providing them with a unique and industry-leading method to reduce operational costs and carbon emissions.”

Pål V. Hemmingsen, Task Leader Low-cost P&A Equinor, added, “The benefits of TITAN RS match our ambitions to shape the future of energy. We have been impressed with Ardyne’s unique application of resonance as a force for good in reducing project time and carbon output associated with P&A and slot recovery operations. We look forward to full commercialisation of the system from this latest JIP with the company.”

The UK Oil and Gas Authority (OGA) has published a new cost estimate for offshore oil and gas decommissioning in the UK Continental Shelf (UKCS), suggesting that the total cost of decommissioning has reduced, spelling good news for both the industry and the Exchequer.

The report showed that the total cost of decommissioning UKCS offshore oil and gas infrastructure has reduced to UK£46bn, which is a projected saving of nearly UK£14bn. This marks steady progress towards the US£39bn by end-2022 target called for in the 2017 report.

Behind the decline

The UK£2bn reduction in the 2021 estimate is the result of continuous improvement and reductions in well decommissioning costs, driven by reductions in subsea P&A costs, cost estimating uncertainty and associated cost risk.

Expenditure in 2020 was impacted by Covid-19 and the low commodity price, contributing to a continuation of a plateau in the rate of cost reduction reported last year. While short-term forecasts show a recovery from this slowdown, commercial transformation remains key to meeting the cost reduction target.

There are positive signs that operators are embracing lessons learned from across the industry as well as embedding a culture of continuous improvement and setting ambitious best in class performance targets. This is helping drive the downward cost trajectory and, more will be needed to meet the target. At the same time however there remain some real inconsistencies in cost performance, reducing the overall improvement of the basin.

The majority of decommissioning cost is forecast to be incurred over the coming two decades, and the window of opportunity to identify and embed the necessary changes to drive the next step change in cost efficient decommissioning is immediate.

Achieving the cost reduction target

The OGA’s updated Decommissioning Strategy sets out the commercial transformation and strategic objectives required to deliver cost efficiency and achieve the UKCS cost reduction target of greater than 35%.

The 2021 Estimate notes that there are a number of opportunities to bring about further cost reductions, but it also highlights risks to continuing to bring down costs.

An average annual cost reduction of 6% has been delivered over the past four years. If this average is maintained, the 35% target remains achievable by end-2022.

Equinor Energy has opted to add additional well intervention work to the previously agreed work scope for the low-emission jack-up rig Maersk Intrepid at the Martin Linge field offshore Norway.

Maersk Intrepid is an ultra-harsh environment CJ70 jack-up rig, designed for year-round operations in the North Sea and featuring hybrid, low-emission upgrades. It was delivered in 2014 and is currently operating at Martin Linge for Equinor. The rig was initially contracted by Equinor for both drilling and accommodation activities and its scope in the region has been continually extended as the field has been developed.

Of the latest contract extension, the firm value is approximately US$10.5mn, including integrated services but excluding potential performance bonuses. The added well intervention scope has a firm duration of 31 days, which means that the rig is now contracted until February 2022.

The contract extension is entered under the Master Framework Agreement between Equinor and Maersk Drilling, in which the parties have committed to collaborate on technology advancements and further initiatives to limit greenhouse gas emissions. The contract with Equinor Energy AS contains a performance bonus scheme based on rewarding reduced CO2 and NOx emissions.

At the virtual Offshore Well Intervention Asia Pacific Conference, an expert panel discussed how a growing emphasis on collaboration is complementing the shift to integrated services which is unlocking value for both operators and service providers.

At the virtual Offshore Well Intervention Asia Pacific Conference, an expert panel discussed how a growing emphasis on collaboration is complementing the shift to integrated services which is unlocking value for both operators and service providers.

Commenting on the rise in integrated services, Scott Deacon, Subsea Intervention Lead, Baker Hughes, opened the session by stating, “This is a growing area in the light well intervention space and it is also growing in the plug and abandonment (P&A) space as well. To have integrated solutions allows us to collaborate and support each other and brings cost effective and efficient solutions for operators.”

Chin Siang Tan, Senior Services Manager at Baker Hughes, added, “When we go into discussions with operators, they are much more open to the idea of us putting things together in a customised package and it is a very wide range of offers we are talking about now. Not just hardware but things like digital, software, remote surveillance etc are really striking interest in the conversation with operators now.”

“The scope of these integrated services is not just defined by operators but as a service contractor we have a responsibility to integrate and support not just within ourselves but outside our capabilities. Working with key subcontractors well help provide a bigger range of coverage and exercise the flexibility to customise solutions and provide the best project value for operators.”

Ankesh Nagar, lead engineer Petroleum Engineering & Surface facility North East India, Cair Oil & Gas, said, “Looking at a decade of our discrete services we realised there were some slippages on key contracts and projects which was ultimately due to some discrete contracts unable to deliver in the right spirit of the project. We as a group thought that when we moved into integrated solutions for both OPEX and CAPEX we would be able to take care of that aspect and improve on delivery. This is exactly what we saw when we took this step from 2015 onwards. Now we have multiple, regional, integrated service contracts for drilling as well as drilling and testing integrated services. We have found that even if you have projects over large areas you can still manage the delivery of them with leaner teams and achieve objectives of your business plans.”

Muhamad Zaki Amir Hussein, Well Intervention Specialist, Petronas MPM, noted that while it can be more messy for smaller providers to merge with others in order to offer these integrated services, generally the advantages far outweigh the associated challenges. He said, “For services providers this can align and focus your resources rather than having separate businesses developed for different service lines and having to manage separate contracts and performance levels. Having a single contract is more efficient and gives them more room to work in terms of economic of scale.”

Collaboration

The growing popularity of integrated services, combined with the Covid-19 restricted climate, has put a much greater emphasis on collaboration, with most service providers and operators now considering this a far greater part of their business model.

Deacon said, “Collaboration has been highlighted as the way forward and I think it is key for industry especially through the times we have just had. Service providers need to work together, operators need to work together. By looking outside of the business you can utilise other solutions which may be the best solution for the operator.”

Commenting on how his company has expanded this aspect, Nagar said, “We do an annual workshop with not only the service companies who have done work with us but also discrete and more niche services present as well. Then, when we project a need for a solution, there is already a good networking platform for these niche companies to showcase their potential so they can ultimately become part of the integrated service solution. Since our objective is to get a good quality output it is important to ensure there is good collaboration not just between us but also on their end as well. At the end of the day good communication and good collaboration equals good delivery of projects.”

Zaki added, “I agree there are great opportunities for smaller service providers with standalone solutions to learn through collaboration. There is great potential for syndication, experience and resource sharing across these service providers via collaboration for integrated solutions. As for collaboration among operators, there are more opportunities for this especially for bigger packages like workover and subsea work where mobilisation costs are high.”

“Bigger mobilisation and higher spread rates with subsea and workover packages require more economic of scale. Hence we try to find synergies and encourage collaboration across operators for this in the form of joint tenders or farming into an existing, awarded contract.”

To view the full session, follow the link below:

https://www.youtube.com/watch?v=1mPcYhTsBfE

Page 100 of 118