Marcelo Victor Tomaz De Matos, Plug and Abandonment (P&A) Advisor at Petrobras, will deliver a session on the company’s P&A updates and future plans at the Offshore Well Intervention Latin America 2022 (OWI LATAM), which will be held in Rio, Brazil from 18-19 October 2022.

Marcelo Victor Tomaz De Matos, Plug and Abandonment (P&A) Advisor at Petrobras, will deliver a session on the company’s P&A updates and future plans at the Offshore Well Intervention Latin America 2022 (OWI LATAM), which will be held in Rio, Brazil from 18-19 October 2022.

The speaker will outline Petrobras’ decommissioning forecasts to prepare for the upcoming wave of P&A activity. During the session, attendees can also expect to have access to the company’s P&A activities and performance results in subsea wells to take away best practices in mitigating future liability.

The presentation by Marcelo will also let attendees discover Petrobras’ P&A R&D roadmap, current challenges, and new techniques and technologies that can be applied to upcoming campaigns.

The presentation by Marcelo will also let attendees discover Petrobras’ P&A R&D roadmap, current challenges, and new techniques and technologies that can be applied to upcoming campaigns.

OWI LATAM is South America’s one-stop shop to gain first-hand knowledge from the world’s leading decommissioning and P&A experts as well as a hub for insightful sessions on new technologies.

To view the full programme click here:

https://www.offsnet.com/latam/conference-brochure

Or reach out to the details below:

Rachael Brand

Project Manager

T: +44 (0) 20 3409 3041

e:

Well decommissioning specialists Well-Safe Solutions have signed an agreement to plug and abandon (P&A) 14 wells on the United Kingdom Continental Shelf (UKCS).

The deal is the first scope agreed for the Well-Safe Defender semi-submersible rig, which the company purchased in June 2022. The project, for an undisclosed value, will see the rig mobilising in March 2023 for approximately 250 days of work.

Neil Ferguson, Operations Director at Well-Safe Solutions, said, “This is a very exciting time for our teams, with a little over a month between Well-Safe taking ownership of the Well-Safe Defender and the signing of this contract with our latest client.”

According to the company, the Well-Safe Defender is currently undergoing a host of efficiency enhancements as part of its integration into the business as well as the completion of its recertification ahead of mobilisation in March 2023.

Gavin Robinson, Commercial Manager at Well-Safe Solutions, said, “We are delighted to assist our client, a leading European operator, with meeting their decommissioning obligations on these historic fields. Like the Well-Safe Guardian and Well-Safe Protector, the Well-Safe Defender is a dedicated decommissioning asset converted from a drilling rig. Clients benefit from a greatly reduced carbon footprint and quicker mobilisation times as a result, as no virgin steel is required for a new-build rig.”

“In addition to the clear economic benefits of this approach, we expect this work to generate approximately 60 new positions offshore, with several supporting roles also required onshore. This will take the total estimated headcount in Well-Safe to 330 people in early 2023,” Gavin added.

The contract announcement is the latest in a summer of growth for Well-Safe Solutions, which previously announced a well decommissioning contract with Ithaca Energy as well as a capital funding boost of more than US$59mn (£50 million) by new and existing investors.

Allseas has celebrated yet another major offshore milestone after completing the removal of Repsol Norge’s 30,000 tonne Gyda platform in a matter of days.

Pioneering Spirit delivered the platform’s jacket to Asker Solutions’ disposal yard in Stord, Norway, less than 48 hours after removing it from the southern Norwegian Sea. The latest job for vessel’s jacket lift technology is one of the heaviest ever, but well within the 20,000 tonne lift capacity.

The jacket was set down directly onto the quayside and reunited with it decommissioned drilling and production topsides. Aker Solutions expects to recycle around 98% of the facilities.

Split across two campaigns, Pioneering Spirit completed the removal, transport and load-in to the disposal yard of the entire Gyda platform, its 32 conductors and template in 12 days.

To facilitate removal of the jacket, the structure’s 24 foundation piles were cut below seabed level. Main hoist blocks suspended from the Jacket lift system (JLS) beams were connected to pre-installed rigging and the entire structure lifted and aligned with the lifting beams. As the jacket was vertically fabricated and installed, the structure could not sustain loading in the horizontal position during transport.

The solution of transporting the jacket in a near-vertical (60%) position, with interface supports and grillage made delivery of the complete jacket to the yard possible. Pioneering Spirit only requires days in the field to remove entire platforms and subsea facilities, eliminating the need for multiple trips and a support fleet. Saving time and reducing vessel operations to a minimum significantly reduces the vessel’s emissions footprint.

“Our mission at Allseas is to remain a frontrunner in the offshore energy market by pioneering ground-breaking technology to meet the industry’s ever-changing needs,” said Allseas President Edward Heerema. “The Gyda platform removal strengthens our reputation as a game changer in the industry. Again we have shown that Pioneering Spirit provides a significantly faster, safer, more efficient and sustainable option for the removal and installation of offshore facilities.”

The world’s largest construction vessel will now mobilise for further heavy lift commitments. These include further jacket removals, as well as installation of a major offshore wind transmission station and jacket in the German North Sea that will supply clean electricity to tens of thousands of homes.

In what has been a busy year for Pioneering Spirit, the vessel has already lifted and transported more than 90,000 tonnes of decommissioned and new offshore facilities for the offshore energy industry in 2022, deploying both its Jacket lift and Topsides lift systems.

The Offshore Well Intervention Latin America 2022 (OWI LATAM), which will be held in Rio, Brazil from 18-19 October, will host a presentation by Matthew Vick, Senior Subsea Wells Engineer from bp.

Attendees will have the exclusive opportunity to learn about the company’s riserless intervention campaigns in the Gulf of Mexico.

Vick will review the broad scope of well access equipment that can be utilised from a single vessel, including mechanical wireline, hydraulic via TRT, hydraulic via well service jumper hose and hydraulic via stimulation choke insert.

During the talk, he will explore an overview of the planning and execution of the campaign including well access, well integrity restoration, well surveillance, well stimulation and protection, and fishing.

OWI LATAM allows you to access new regulations and innovative LWI technologies to develop a best practice intervention strategy for production, integrity and P&A projects.

You can view the full programme here:

https://www.offsnet.com/latam/conference-brochure

Or reach out to the details below:

Rachael Brand

Project Manager

T: +44 (0) 20 3409 3041

e:

With around 32% of wells suffering from well integrity issues globally (according to a previous estimate from the Society of Petroleum Engineers), CRA-Tubulars is preparing to enter the market with its Titanium Composite Tubing (TCT) technology to provide a unique, cost-effective and reliable solution that will help tackle this constant headache for operators.

Speaking to Offshore Network in an exclusive interview, Joost de Bakker, CEO of CRA-Tubulars, noted that while this issue has consistently been a thorn in the side of operators around the world, it is one that has been somewhat swept under the rug or at least not given the attention and investment it deserves. Traditionally, capital has been spent on short term, cheaper solutions and then the life-cycle is dealt with as it comes – with tubulars often replaced every couple of years. Now, however, this narrative is changing and many large oil companies are starting to change their philosophy to be more prepared early on and spend less on their wells in late-life.

“Volume wise, populations are increasing and wells are producing less. Because of this, the strategy of working over wells is becoming more unmanageable. In addition, HSE considerations are pushing companies to be more responsible when managing their assets from both a human and environmental perspective,” de Bakker remarked.

CRA-Tubulars’ TCT addresses these issues by offering a robust and highly corrosion-resistant solution for the global oil country tubular goods (OCTG) market. The product offers corrosion-free completion (titanium) with carbon fiber and aerospace epoxy superior tri-axial strength of the OCTG. It is API-5CT and NACE MR0175/ISO 15156 compliant, has a max operating temperature at 140⁰C and an 18,000 PSI burst. This cost-effective solution therefore offers significant advantages of the more traditional duplex or nickel alloy tubulars which are susceptible to corrosive elements and Stress Cracking Corrosion (SCC).

Meeting market demand

Explaining the company’s history, de Bakker said, “We were officially founded in 2019, however, this is a natural succession from a team of inventors and engineers who have been working in this field for more than 20 years. Composite and non-metallic tubulars have been developed a lot over the last 20-25 years but one area that could never be truly tackled was downhole corrosion due to direct contact with a reservoir and the corrosive elements such as CO2 and chlorides for example. Composite materials are not very good at performing as a barrier in this context and meeting the standards of barrier philosophies, hence the design with a Titanium liner acting as a permeation barrier to overcome this. The idea for our company and product came out of decades of experience and an intent to rectify this.”

CRA Tubulars are therefore fast-tracking the TCT to commercialisation as a replacement for nickel alloys which are traditionally used for the most challenging well conditions globally.

“At this point in time we have built and tested prototypes. Based on that and modelling we can build on the decades-long experience of defence and aerospace development because we are using the same materials that have been used for aerospace applications – essentially we have repurposed aerospace technology and turned it into a tubular form to meet the requirements of the harsh downhole conditions in oil and gas, CCUS and geothermal wells.

“We therefore do not need to test extensively ourselves as it has already been proven how the materials interact and perform in similar conditions (in terms of temperature and pressure) to how we are using them in downhole solutions. You could almost say that we have patented a fighter jet in tubular form for downhole applications and using it to meet the demands of the oil and gas community.”

With the prototypes been built and tested to extreme conditions, the next step is certification. For this, the company has found an international operator who is supporting it financially and technically in taking the product through this process. In addition, CRA Tubulars is working with several partners to do field testing by putting pieces of TCT in their completion strings. By doing so, the company hopes to build confidence in their product to ultimately benefit the community when the first commercially presentable product is supplied (which is expected by the end of the year).

Looking ahead to this time, de Bakker discussed what markets the company will first be targeting. He said, “At the moment, we are very much looking at competing directly with the nickel alloy market. This is a market worth several billions of dollars in sales per year and when you break these down you can see the majority of oil and gas nickel alloy use is in the Middle East (it covers about half the global market because of the high volume of wells and often very sour conditions). However, we don’t want to stick to that area alone.”

While the critical market is oil and gas corrosive belts, de Bakker suggested, there are also new areas such as carbon capture storage (CCS) which the TCT could thrive in. “Many oil and gas companies are looking to use their old assets for this purpose and the CO2 and other elements could prove problematic for nickel alloys and carbon steel pipes. We are getting a lot of interest from companies in this market who are looking to build their future CCS portfolio, predominantly from North America, Western Europe and Australia.”

In recognition of this, de Bakker noted that the company has recently been awarded a Shell GameChanger contract for certifying TCT for applications in CCUS. The funding is for applications in CCS and Hydrogen. A representative from Shell GameChanger commented, "The Shell GameChanger programme offers the Shell organisation and the industry a reliable and cost effective alternative to conventional technology and contributes to an affordable and reliable low-carbon energy system – CRA Tubulars is part of this with their TCT technology."

Perfect timing

It appears that TCT could not be hitting the market at a better time. First and foremost, the economic squeeze caused by the pandemic is forcing oil and gas companies to pay closer attention to their finances. TCT in the long-term will save capital as the long-serving solution will mean wells can continue to produce for longer and at higher rates without requiring workovers.

Additionally, as de Bakker explained, because of the global political instability, the price of competitor product metals (such as nickel) has dramatically increased whereas CRA-Tubulars’ product markets are much more stable.

“Finally, in the Middle East there is a general push for developing a broader supply chain. A steel plant can cost up to US$150mn for nickel alloy products whereas a factor for ours, capable of producing 50 wells worth of material per year, would cost around US$8mn dollars. For competitors therefore it is more likely that manufacturing locations will be set up and distributed across the world (which brings additional costs and can take a long time) whereas we can have manufacturing fragmented where it is needed. This is very attractive from an in-country value perspective.”

Coming to the market

While de Bakker aims to bring a commercially presentable product to the market by the end of the year, he warned this is not a fixed point and, after that, volume manufacturing is of course a complex process and take time to deliver.

Nevertheless, the CEO is excited for the future and paid homage to his incredible team which has helped get TCT this far, and will no doubt help drive it in the future. Our founder has been in the composite business for more than 20 years and has built a team of shareholders which have a diverse field of experience. We have tried to attract the best in the field – for instance, our carbon fibre expert has a PHD in carbon fibre technologies and has worked extensively in the oil and gas industry for carbon fibre technology in downhole applications.”

De Bakker concluded with a nod to partners which he noted were incredibly important to how the company does and will work. “Independent parties have expertise and the critical structure that we, as a start-up, are lacking and will help accelerate commerciality for our benefit and the benefit of the end users.”

As demonstrated in September last year when the company received the global SPE ATCE rising star award for start up and new technology, CRA Tubulars is offering an innovative product that has the potential to offer so much value to operators. As a result, there is little doubt that many are keeping close watch of the company’s progress towards commercialisation and that it will lack suitors for potential partnerships in the future.

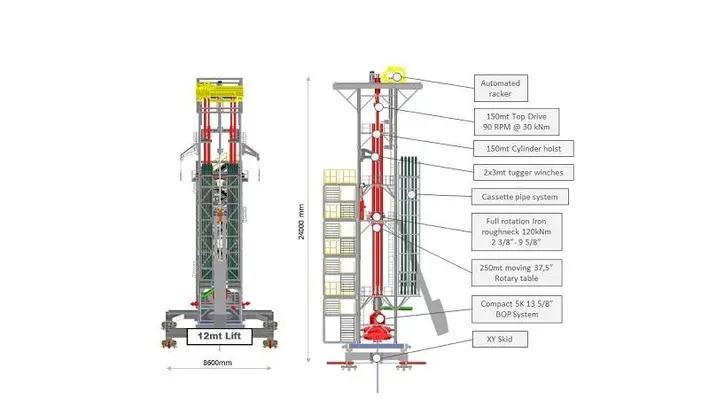

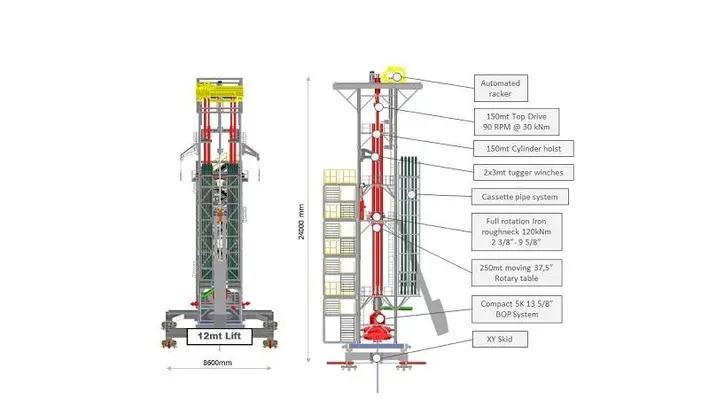

To fill a glaring gap in the decommissioning market, Voll Marintek Limited is pioneering the HWU-150 Lean Machine, a dual jack lifting system with key advantages over rigless operations and MDR to deliver significant cost, risk and climate benefits for the industry.

Dennis Vollmar, CEO of Voll Marintek Limited, spoke to Offshore Network to discuss his innovative solution in detail and explained how he identified this opening in the market.

“So we realised there was a gap by knocking on doors really. We had deep interactions with different operators, service providers and contractors and realised there was space for something new.

“It comes down to knowing well conditions. Wells which are coming to the end of their life are usually decades old and in this time the way data is collected has changed. In many cases you don’t even know which revision is the most updated one. In these cases, you have two options: either a customised approach with the deployment of specialised workover units for each subtask or use a rig.”

There are drawbacks to both. In the former, rigless workover units require intensive planning, a detailed knowledge of well integrity and, due to their simplicity and dependency on crane support, they are highly vulnerable to unforeseen events and weather conditions. Rigs on the other hand have more capacity and can simplify the planning and execution phase, but generally have a very high spread cost and carbon footprint.

Voll Marintek, therefore, has developed the Lean Machine, a multipurpose unit to fill the void between these two options.

“The Lean Machine is basically a hybrid solution between a hydraulic workover unit (HWU) and a modular drilling rig (MDR). It combines the main features of a HWU such as fast assembly, lightness, compactness and only requires a small footprint in addition to the benefits of MDR such as drilling, milling, making pipe connections respectively handling different pipe types conventionally and in a safe manner.”

The dual jack lifting system is a modular adaptable multipurpose unit which has the capacity to be upgraded with additional features so that it can be customised for each project and adapted to various interfaces. It consists of different modules designed to cover a specific P&A task which can be stacked on top of each other, extending the previous operational envelope of the complete system (this is called ‘The Happy Meal’). This means it can be upgraded with existing modules at the offshore location to perform sequential tasks instead of mobilising specialised equipment for each subtask or oversized workover rigs.

The operator can choose the options required based on additional costs for each contingency as desired always keeping integrated costs in mind. Importantly, the compactness of the 10 ft container footprint and the lightness of each module (around 12 mt) allow its assembly on a skid beam substructure, heave compensation platform or in a derrick structure of an existing rig.

Explaining the benefits of the system, Vollmar commented, “Cost and risk are the main drivers here. When looking at costs for an operation you want to see exactly the expenditure that will be incurred. Often this is not possible without an extensive preparation phase and even then unforeseen circumstances can occur – which is why rigs are often used.

“What we are doing is to see how we can make the whole process lean. So when you know the potential work scopes you need to perform you can configure the machine to it but, if you have the eventuality of making adaptations (maybe to enhance the operational envelope or even downsize it), you can do that in the field and this is where costs can be significantly reduced.”

Vollmar claimed that the deployment of the modular adaptable unit to tackle challenges within the P&A and decommissioning space will enable the highest potential cost savings available. The faster pipe recovery system alone allows cost savings of US$1mn per well based on a five day execution phase reduction. A global operator has already performed a preliminary total cost analysis in comparison to conventional solutions and identified a cost reduction above 30% for his 100 well campaign.

The high cost of a rig is also mirrored in its high carbon footprint, a somewhat neglected but increasingly pressing concern for the oil and gas industry. HWU’s of course have an advantage here, but poor weather, unforeseen events and the mobilisation of additional equipment to cover all P&A phases can bring down operational efficiency and extends the time duration for a P&A campaign– which is not a problem for the Lean Machine.

Mounting market interest

While still at the start of its journey, the Lean Machine is already attracting attention and suitors which is driving it steadily towards commercialisation.

“The interest in regard to decommissioning is operators who see themselves as delay asset management companies and want to change or look at game changers to reduce the cost of decommissioning,” Vollmar remarked.

“There is also interest beyond decommissioning in production enhancement, for example. As the oil and gas prices increases, we need to look at solutions which reduce costs and simplify the process. Usually, you can collect wells with the same well challenges which only require wireline (for example) for a campaign. Then you need to get a certain threshold to justify the costs to mobilise other equipment. Our approach gives you the advantage as it is multipurpose and has all this included. You can combine now all the different well interventions and justify the cost much easier, which obviously increases the recovery factor of mature fields.” The wide application range simplifies wireline, side track drilling, coiled tubing, ESP runs, conductor pulling, life well interventions or slot recovery operations. On top, the dual jacking system reduces operational time by almost 40% and its offering a hoisting capacity up to 250mt.

For the next steps on its promising journey, Voll Marintek will be conducting a FEED study in September 2022 for which they have been granted a significant grant by Innovate UK. The company will look at different potential well designs which would require P&A and test the technical, commercial and operational feasibility of the Lean Machine against them. Over the course of the study, further engineering and optimisation of the solution will be undertaken.

“We are already receiving interest from operators to manufacture the system and offer it at a rental rate. The idea here would be we manufacture the system, rent it out and then provide maintenance and support when needed,” surmised Vollmar.

While Europe is the launch pad, it is clear that Vollmar has no intention of shackling his ambitions to this region, but instead envisioned the Lean Machine being rolled out across the globe.

“This solution has been developed through niche market research and I looked at a lot which are not currently provided for with a sufficient solution. For example, Australia and Brunei have a lot of wells in four to five metres water depth which you cannot enter with normal jackups. So you need to engineer something which is light, compact and could be added to any vessel of opportunity. But, at the same time, you don’t want to make any large vessel modification. So companies have been looking at lift barges to put a cantilever on but this is not economical or would only be so with a contract for 5-10 years as, again, you need to make modifications. It would be much easier to have something light and compact which could be put on top of the wellheads and even deployed by a jacking barge (or between two).”

“In Asia and Africa, people did not really think about workovers and so you often find wells with a production facility incredibly close. Workover equipment is only feasible if you look really deeply into interfaces and have the time and resources to do it. The Lean Machine could really help here and can be easily adapted depending on how much space is available at location.”

While it was clear that Vollmar is very much ready to take on the world with the Lean Machine, for now it is time to build the foundations. After the start of the FEED study, the next steps for Voll Marintek will be building alliances, manufacturing and testing and field trials before commercialisation – currently targeted in 2024/25. Without doubt, however, there will be many in the industry following this progression with great interest.

Following its success in the Gulf of Thailand, Decom Engineering (Decom) has secured two contracts worth more than UK£300,000 in the North Sea and offshore West Africa, strengthening their reputation as a leading provider of decommissioning services.

The northern Irish company had designed and developed a range of cold cutting saws which are deployed on a variety of energy sector decommissioning projects which require pipelines and associated infrastructure to be safely removed.

The UK Continental Shelf contract is a conductor recovery and removal project deployed topside on a vessel and Decom’s C1 Chopsaw is expected to complete eight cuts on behalf of a global offshore contractor. Separately, Norwegian-headquartered subsea and offshore wind farm contractor Havfram have commissioned Decom to carry out cutting operations on a ROVCON connecter in water depths of up to 800 metres off the coast of West Africa.

Both projects were secured following a series of technical trials at JFD Global’s testing tank and the National Hyperbaric Centre in Aberdeen, and they follow the successful completion of two phases of another international workscope offshore in the Gulf of Thailand in which Decom’s chop saws performed hundreds of cuts on piping of up to 16” diameter.

Decom Engineering Managing Director, Sean Conway, commented, “The successful completion of a strategic project offshore Thailand and our imminent mobilisation on workscopes in the North Sea and Africa, demonstrates that our technology is gaining traction with energy companies and contractors who have technically challenging requirements on a range of international decommissioning projects.

“Recent technical trials in Aberdeen have proven our cutting technologies can operate safely in deeper waters and that they are preferable to rival solutions where accessibility to subsea infrastructure is an issue.

Steven Gibson, Senior Engineer with Havfram during testing, remarked, “The potential of Decom’s saw to cut the heavy grade material we are going to be cutting through on the West African seabed, the speed of the cut, and the ability to position it in a very restricted space, were the driving factors in awarding this workscope.”

Decom opened up a new base near Aberdeen at the start of 2022 to be located closer to potential North Sea clients and the policy appears to be paying off following this most recent contract award.

Conway added, “We will continue to invest in infrastructure and to build our asset portfolio to ensure we are positioned to be able to respond to more technically challenging projects as the global decommissioning sector continues to grow.

“Our R&D and engineering teams are currently working on new chop saws which are capable of handling piping of up to 36” diameter in anticipation of potentially winning other contracts in the second half of this year.”

Helix Energy Solutions Group has completed the acquisition of all the equity interests of the Alliance group of companies which will expand its decommissioning presence in the Gulf of Mexico.

The acquisition will also advance the company’s Helix’s environmental, social and governance (ESG) initiatives by responsibly supporting the end-of-life requirements of oil and gas projects.

Owen Kratz, President and Chief Executive Officer of Helix, commented, “We are pleased to have completed our acquisition and added Alliance to the Helix family, which complements Helix’s existing deepwater abandonment offerings by adding shelf and facility abandonment capabilities and significantly enhances our position as a full-field abandonment services provider.

“The acquisition marks a meaningful step in our participation in the Energy Transition, and we are excited to welcome our new colleagues to the Helix family.”

Helix also announced that it has amended its existing asset-based revolving credit facility (ABL Facility). The amendment aligns with Helix’s Alliance acquisition, expanding the eligible credit line and establishing a link in its pricing to sustainability targets. The key features of the amendment include increasing the size of the ABL Facility to US$100mn and including ESG/sustainability-linked performance targets that may result in adjustments to commitment and borrowing rates.

Kratz continued, “We have increased the size of our ABL Facility to accommodate the increase in our expected borrowing base with the Alliance acquisition. We are also pleased to have included a sustainability-linked performance target that may reduce our fees under the facility and we are appreciative of the support from our bank group in this amendment.”

THREE60 Energy, a leading independent energy service company offering complete asset life cycle solutions, has acquired Fraser Well Management, a well and pipeline operator and well management specialist, in order to strengthen its wells credentials.

THREE60 Energy will become one of only two companies that can undertake the role as outsourced duty holder (installation operator), pipeline operator and well operator across the asset life cycle, further positioning the company as a strategic services partner.

Fraser Well Management’s services span the complete well lifecycle, both onshore and offshore, with comprehensive end-to-end well and pipeline operator solutions provided to customers across the world. The company also provides well management, decommissioning, specialist engineering, and commercial services, with sustainability as a key operational consideration.

All of Fraser Well Management’s personnel will transfer to the THREE60 Energy team.

Walter Thain, Group CEO at THREE60 Energy, commented, “The capabilities and expertise that Fraser Well Management has accumulated will greatly benefit the integrated solutions we offer our customers throughout the asset life cycle. We are immensely proud to have our new team members join THREE60 Energy, as we can continue to provide better energy together.

“As we continue to transition into sustainable and renewable energies alongside traditional means of energy production and storage, there has never been a more pertinent time to invest in the future of our business and our place in the energy supply chain.”

Lasse Hermansson, Managing Director at THREE60 Energy Norway, added, “The breadth of transferrable knowledge across THREE60 Energy is crucial for capitalising on the synergies across disciplines, and the addition of Fraser Well Management’s skills and people will greatly add to our expertise.

“This not only enhances our UK capabilities, but provides additional competencies and services to our Norwegian and global business. We are extremely excited about the acquisition and see a great cultural and collaborative fit with the excellent team at Fraser Well Management.”

Nick Ford, Managing Director at Fraser Well Management, remarked, “We have watched the rapid and sustained growth of THREE60 Energy alongside our own development and can see the synergies that the integration of Fraser Well Management’s service offerings combined with that currently provided by THREE60 Energy will provide our clients better solutions to their energy needs. This deal is a natural progression for our services and people, as both can continue to grow and expand under THREE60 Energy.

“As late life, CCUS and decommissioning play an ever more significant role, we are proud to be part of THREE60 Energy Group as the company delivers in these key areas.”

The Australian Government has contracted Wood, a leading consulting and engineering company, to oversee the first decommissioning phase of the Northern Endeavour FPSO facility in the Timor Sea.

The Northern Endeavour is a 274 m long FPSO, permanently moored between the Laminaria and Corallina oilfields, approximately 550 km northwest of Darwin in the Timor Sea. Production began in 1999 and peaked at 170,000 barrels of oil per day. In 2019, the facility was shut down by NOPSEMA after an immediate threat to health and safety was found at the facility. After owners Northern Oil & Gas Australia went into liquidation, it fell to the Government to maintain and ultimately decommission it.

Wood will work closely with the Department of Industry, Science, Energy & Resources (DISER) and contractors to ensure the safe, efficient and responsible initial phase of the decommissioning scope.

Ralph Ellis, Wood’s President of Operations across the Asia Pacific region, commented, “The responsible decommissioning of the Northern Endeavour FPSO is of great national interest, with safety, cost, and sustainability in sharp focus throughout.

“We are proud to have been selected by the Australian Government to represent their interests in the first phase of the field’s decommissioning journey. As Owner’s Team, we will leverage our unrivalled offshore decommissioning expertise garnered in mature basins across the world to support the successful delivery of this critical scope of work.

“We look forward to working closely with both DISER and the lead contractor on this important project.”

Abu Dhabi National Energy Company PJSC (TAQA), an integrated utility company in the Europe, the Middle East and Africa region, has announced the completion of safe and successful removal of the Brae Alpha West drilling rig and the Brae Bravo upper main jacket in the northern North Sea.

The operation, which was the latest in TAQA’s extensive UKCS decommissioning programme, involved the removal and transport of more than 12,000 tonnes of material from the Brae field in the UK North Sea.

The HAF Consortium, Heerema Marine Contractors and AF Offshore Decom, were contracted to execute the operation on behalf of TAQA.

The Heerema-operated Sleipnir semi-submersible crane vessel first removed the 1,000 tonne Brae Alpha Rig 1, in a single lift on 20 June.

Sleipnir then moved to Brae Bravo to remove the 11,000-tonne upper main jacket. This forms part of TAQA’s decommissioning obligations and follows the removal of the Brae Bravo topsides modules and flare bridge, jacket and tower last summer – one of the largest topsides removals in the UK North Sea.

Both Rig 1 and the Brae Bravo jacket have been safely offloaded at the AFOD Environmental Base in Vats, Norway, and are being processed with the aim of reusing or recycling 95% or more of the material, which is expected to be completed in 2023. The entire operation was successfully completed with zero health and safety incidents.

Donald Taylor, TAQA Managing Director for Europe, commented, “TAQA’s extensive late-life portfolio positions us at the forefront of decommissioning in the UK. By adopting valuable lessons learned during last year’s successful Brae Bravo topside removal campaign, we are continuing to develop our skills and capabilities supporting the transition from operations to removals and disposal.

“The coming years offers some of the most interesting challenges and opportunities for our workforce and wider industry. TAQA is proud to pioneer this change while maximising the value of our assets and playing a valuable role in the energy transition.”

Osbit, an offshore technology company, has delivered a new intervention tower system to FTAI Ocean which comprises 1,300 tonnes of equipment and stands at 40 metres tall.

The tower will enable riser and riserless based well intervention activities in water depths of up to 1,500 metres and integrates a series of innovations derived from the company’s extensive experience in developing well intervention and offshore handling equipment.

The tower’s vertical racking system reduces the need for well centre access, while maximising deck space with its small footprint. An active and passive heave compensated platform supports coil tubing, slickline and e-line operations, while safe personnel access is facilitated via an integrated walk to work system.

For riserless operations, the system has four guide wires and two pod wires integrated with the existing vessel crane which provides up to 250 tonne Safe Working Load (SWL) active heave compensation. The system’s deck skidding system minimises the need for crane lifts, increases the operating window, and enables equipment to be directly loaded into the well centre.

The tower was fabricated and assembled at Wilton Engineering Services in Teesside, UK.

Osbit Director Steve Binney, commented, “Completing this project is a huge achievement for Osbit, and we have worked extremely hard to deliver our largest and most technologically complex engineering system yet. As a team, we have overcome many obstacles to reach this important milestone, which shows not only our capability, but that of North East England, and our fantastic supply chain."

Project Director, Steve Bedford, added, “The delivery of this project is Osbit’s biggest milestone yet and is testament to the unbelievable efforts of the whole Osbit team, most of whom have made a direct contribution towards making this happen. This tower system is a prime example of how we work from first principles, combining our proven technology modules with fresh thinking to produce exciting engineering systems for the offshore world.

"It has also been rewarding to watch our team grow and develop as they supported this project’s development, and we are already applying this learning on to our latest projects and concepts for the offshore wind market. With the build complete, we are looking forward to providing further support to FTAI Ocean now that preparations are underway for transportation to Singapore.”

Page 83 of 118