At the COSCO Shipping Shipyard in Nantong, China. Jan De Nul Group has launched the Voltaire, a next-generation offshore jack-up installation vessel for offshore renewables and decommissioning.

This vessel will be the second and largest jack-up vessel in Jan De Nul’s fleet and is due for delivery in H2 2022. Voltaire is built to transport, lift and install offshore wind turbines, transition pieces and foundations. The main crane with a capacity of over 3,000 tonnes will enable it to construct the current and future generation of wind farms at sea. Voltaire is ready for the future of offshore renewables, and will also be available to the oil and gas industry for the decommissioning of offshore structures.

The Voltaire is a jack-up vessel fitted with a high-tech jacking system. Four giant legs of 130 metres support the vessel to achieve stable working conditions at unsurpassed water depths up to 80 metres and with an elevated load of 16,000 tonnes. Compared to Jan De Nul’s other jack-up vessel Vole au vent, this new vessel has almost double the deck space.

Innovative design

The highly innovative main crane will be fitted with a Universal Quick Connector (UQC), developed by Huisman, and leveraging the expertise of Jan De Nul’s operational and engineering teams. The result is a innovative UQC, that will deliver a major step change in safer offshore lifting activities.

In common with Les Alizés, the Voltaire is equipped with a highly advanced dual exhaust filter system, removing up to 99% of nanoparticles from emissions using a diesel particulate filter (DPF) and reducing the NOx emissions and other pollutants by means of a selective catalytic reduction system (SCR) to levels in accordance with EU Stage V regulation. Together, these vessels will be the first two seaworthy installation vessels in the world with an extremely low carbon footprint.

InterMoor has been awarded a key contract with Chevron Thailand Exploration and Production, Ltd. (Chevron) for the disconnection and removal of Single Point Mooring (SPM) Buoy 1 and 2 in the Gulf of Thailand.

InterMoor will provide project management, engineering, procurement, as well as offshore execution for the decommissioning of the floaters. The campaign is expected to commence once necessary endorsements are in place.

For the execution of the project, InterMoor will be utilising a variety of high spec vessels to carry out the decommissioning activities along with cutting tools and other auxiliary/associated equipment by Acteon product and service line brands, Claxton, Aquatic, Seatronics and UTEC.

InterMoor APAC General Manager Vin Bala commented, “While InterMoor continues to enhance our reputation as a major Transportation and Installation (T&I) service provider in the Asia Pacific region, one of our unique strengths has always been in the decommissioning of subsea assets. We are extremely honoured and proud to have been awarded this important project from Chevron and see this as a testament to our team’s capabilities and our long-standing tradition of safe, execution excellence in decommissioning work in the region.”

Pharos Energy plc, an independent oil and gas exploration and production company, has announced that the Hoang Long Joint Operating Company has successfully completed its 2021 TGT well intervention and development drilling campaign.

Ed Story, President and CEO of Pharos Energy, commented, "I am delighted to announce that the first phase of the infill development drilling programme in TGT has finished, with all four wells testing at rates in line with or ahead of pre-drill expectations. The campaign was completed ahead of schedule and under budget.

“The well intervention programme conducted earlier in the year also delivered rates above expectations. Together, these two operational campaigns have increased production capacity and will ultimately improve recovery from the field. They also support the further activity set out in the Full Field Development Plan designed to optimise field oil & gas recovery and a submission request for a five-year contract term extension.

The initial flow of the four development wells of 8,800 bopd exceeded the predicted combined initial oil rate of 5,650 bopd by 3,150 bopd.

Well interventions and a gas lift optimisation programme earlier in the year resulted in an initial TGT production gain of 3,200 bopd. The six wells with additional perforations showed a gain of 1,800 bopd, the four wells with water shut off gained 900 bopd and eight wells where demulsifier injection was applied gained 500 bopd.

The TGT field gross production rate on 17 November 2021 was 14,800 boepd, but would have been approximately 19,800 boepd without the impact of the compressor fault mentioned below.

The results of the drilling and intervention activity support additional opportunities as set out in the Full Field Development Plan (e.g. nine contingent wells and an extensive well intervention programme), which could support a TGT license extension request to December 2031.

The Hoang Long Operating Company Management Committee has also approved two additional TGT wells and 13 well interventions (ten firm additional perforations and three water shut-offs) in the budget for 2022 on 17 November 2021.

One of India’s leading marine service providers, OCS Services Pvt. Ltd (OCS), has awarded Fugro a two year contract to support its asset integrity and corrosion management operations off the west coast of India.

One of India’s leading marine service providers, OCS Services Pvt. Ltd (OCS), has awarded Fugro a two year contract to support its asset integrity and corrosion management operations off the west coast of India.

Fugro has establish a reputation for offshore operational excellence and has cultivated a successful track record in India, both of which were taken into account when the contract was awarded. Fugro will help OCS deliver on ONGC’s Protective Coating of Process Platform Project 1 (PCPP1), an infrastructure project to maintain and refurbish 32 offshore platforms in 7 clusters.

For the first time in India, Fugro will provide survey Geo-data and positioning via remote support solutions controlled from one of its state-of-the-art remote operations centres (ROC). Fugro’s integrated digital solutions will allow OCS to identify debris, seabed features, and subsea pipelines and structures near Process Platform areas to protect the marine environment from future damage.

Remote support will also enable OCS to monitor their operations in real-time and thus enable early decision-making as the project progresses.

Sangram Dhote, Director at OCS, commented, “This collaborative approach will set a new standard to managing the safety of operations in the Mumbai High Field.”

Swaminathan Subramanian, Marine Asset Integrity Manager for Fugro in India, added, “We are very excited to be awarded this contract and are looking forward to collaborating with OCS on a successful project delivery that benefits from Fugro’s remote operations expertise and the highest safety standards.”

The project is expected to be completed by May 2023.

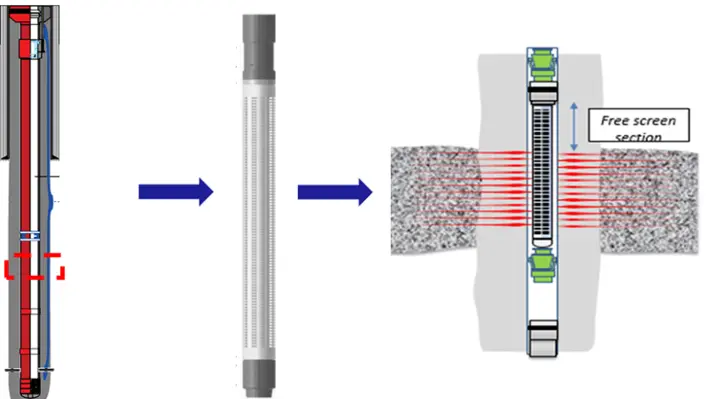

Brunei Shell Petroleum Company Sdn Bhd and AccessESP have successfully completed a trial project using GoRigless ESP System technology, a proprietary through-tubing deployment and slickline-retrieval technology for AccessESP high-performance permanent magnet motors and industry-standard ESP pumps.

David Malone, CEO, AccessESP, commented, “We appreciate the opportunity to demonstrate the reliability and effectiveness of our technology in offshore Brunei. Our system allows the operator to perform well cleanouts and boost production with less cost and reduced environmental impact.”

AccessESP delivers advanced technologies that help oil and gas operators reduce intervention costs, maximise well productivity, and enhance reservoir recovery rates by achieving the technical limit in ESP performance.

By avoiding the cost and complexity of a heavy workover rig required for traditional tubing-deployed ESP system interventions, millions of dollars of workover costs are avoided, greenhouse gas emissions are reduced, and recovery boosted.

TechnipFMC has announced its intention to acquire the remaining 49% of shares in TIOS AS, a joint venture between TechnipFMC and Island Offshore Management AS (Island Offshore) formed in 2018.

TIOS provides fully integrated Riserless Light Well Intervention (RLWI) services, including project management and engineering for plug and abandonment, riserless coiled tubing and well completion and intervention operations, and has serviced more than 740 wells globally since 2005.

The acquisition will accelerate the development of TechnipFMC’s integrated service model focused on maximising value to its clients.

The company will continue to utilise Island Offshore as the vessel provider for RLWI services.

Jonathan Landes, President, Subsea at TechnipFMC, said, “We are pleased to welcome TIOS wholly into TechnipFMC. This transaction brings into the company additional expertise that will maximise our capability to provide a complete range of well services globally to our clients in a rapid and economical manner.”

This announcement comes soon after the company released its Q2 2021 results, in which its subsea performance was particularly strong.

Doug Pferdehirt, Chairman and CEO of TechnipFMC, commented, “Subsea inbound orders of US$2.8bn in the first half of the year were strong. We continue to see a healthy list of prospects and remain very confident in our full-year guidance for Subsea orders of more than US$4bn. Furthermore, growth in 2022 is supported by an increasing set of opportunities.

“We believe that offshore will continue to play a meaningful role in the total energy mix. We are building partnerships in support of new energy, leveraging our differentiated technologies, and capitalising on our integrated project execution and expertise as the subsea architect.”

At the virtual Offshore Well Intervention Asia Pacific Conference, an expert panel discussed how a growing emphasis on collaboration is complementing the shift to integrated services which is unlocking value for both operators and service providers.

At the virtual Offshore Well Intervention Asia Pacific Conference, an expert panel discussed how a growing emphasis on collaboration is complementing the shift to integrated services which is unlocking value for both operators and service providers.

Commenting on the rise in integrated services, Scott Deacon, Subsea Intervention Lead, Baker Hughes, opened the session by stating, “This is a growing area in the light well intervention space and it is also growing in the plug and abandonment (P&A) space as well. To have integrated solutions allows us to collaborate and support each other and brings cost effective and efficient solutions for operators.”

Chin Siang Tan, Senior Services Manager at Baker Hughes, added, “When we go into discussions with operators, they are much more open to the idea of us putting things together in a customised package and it is a very wide range of offers we are talking about now. Not just hardware but things like digital, software, remote surveillance etc are really striking interest in the conversation with operators now.”

“The scope of these integrated services is not just defined by operators but as a service contractor we have a responsibility to integrate and support not just within ourselves but outside our capabilities. Working with key subcontractors well help provide a bigger range of coverage and exercise the flexibility to customise solutions and provide the best project value for operators.”

Ankesh Nagar, lead engineer Petroleum Engineering & Surface facility North East India, Cair Oil & Gas, said, “Looking at a decade of our discrete services we realised there were some slippages on key contracts and projects which was ultimately due to some discrete contracts unable to deliver in the right spirit of the project. We as a group thought that when we moved into integrated solutions for both OPEX and CAPEX we would be able to take care of that aspect and improve on delivery. This is exactly what we saw when we took this step from 2015 onwards. Now we have multiple, regional, integrated service contracts for drilling as well as drilling and testing integrated services. We have found that even if you have projects over large areas you can still manage the delivery of them with leaner teams and achieve objectives of your business plans.”

Muhamad Zaki Amir Hussein, Well Intervention Specialist, Petronas MPM, noted that while it can be more messy for smaller providers to merge with others in order to offer these integrated services, generally the advantages far outweigh the associated challenges. He said, “For services providers this can align and focus your resources rather than having separate businesses developed for different service lines and having to manage separate contracts and performance levels. Having a single contract is more efficient and gives them more room to work in terms of economic of scale.”

Collaboration

The growing popularity of integrated services, combined with the Covid-19 restricted climate, has put a much greater emphasis on collaboration, with most service providers and operators now considering this a far greater part of their business model.

Deacon said, “Collaboration has been highlighted as the way forward and I think it is key for industry especially through the times we have just had. Service providers need to work together, operators need to work together. By looking outside of the business you can utilise other solutions which may be the best solution for the operator.”

Commenting on how his company has expanded this aspect, Nagar said, “We do an annual workshop with not only the service companies who have done work with us but also discrete and more niche services present as well. Then, when we project a need for a solution, there is already a good networking platform for these niche companies to showcase their potential so they can ultimately become part of the integrated service solution. Since our objective is to get a good quality output it is important to ensure there is good collaboration not just between us but also on their end as well. At the end of the day good communication and good collaboration equals good delivery of projects.”

Zaki added, “I agree there are great opportunities for smaller service providers with standalone solutions to learn through collaboration. There is great potential for syndication, experience and resource sharing across these service providers via collaboration for integrated solutions. As for collaboration among operators, there are more opportunities for this especially for bigger packages like workover and subsea work where mobilisation costs are high.”

“Bigger mobilisation and higher spread rates with subsea and workover packages require more economic of scale. Hence we try to find synergies and encourage collaboration across operators for this in the form of joint tenders or farming into an existing, awarded contract.”

To view the full session, follow the link below:

https://www.youtube.com/watch?v=1mPcYhTsBfE

At the Offshore Well Intervention Asia Pacific Conference attention turned to Indonesia as representatives from Pertamina Hulu Mahakam, Harbour Energy and TGT Diagnostics discussed the market trends in the region and what best practices and new technologies are being considered to optimise campaigns.

Sakti Dwitama, Head of Wells Studies at Pertamina Hulu Mahakam, stated that in Mahakam the well intervention business was very heavy. Across the more than 2,000 producing wells the company maintains around 5,000 operations are carried out each year with around thirty units (be that coil tubing, E-line, slickline, etc) being used on a daily basis. Yet this market is not without its challenges. Most obviously, as all panellists agreed, was the disruption caused by the Covid-19 pandemic which has caused immense logistical issues for mobilising teams to safely perform well intervention operations. As Hubert Menard, Asia Pacific Business Manager at TGT Diagnostics, added, this has been problematic for operators and service companies alike and has required some real forward thinking in terms of resource management to accommodate for quarantining etc.

The other major challenge has been the economic situation in Indonesia where the low oil price (although it is returning) and poor exchange rates has required some frugal planning from operators. The Indonesian government, in order to boost the economy and wean the country off of its reliance on exported oil has targeted the production of 700,000 barrels of oil per day for this year 2021 (up from the current production figure close to 700,000) to push on to 1,000,000 by 2030. This will be a tough task and the panellists discussed the role of well intervention within this.

Sakti said, “In a way I see this as an opportunity for well intervention. In Mahakam there has been a steep decline in production, especially gas, and so there will be an increase in well intervention activities in order to achieve the national objective. We also want to get more efficient and to optimise this and we are seeing more and more rig activities getting taken over by rigless vessels.”

“However, this decline in production will not be stabilised if we only rely on existing wells. So while we do intervention to maintain a smooth baseline we need to balance it with the development of new wells. Last year we drilled about 300 new wells across the nation, to achieve the national target this year we are aiming to drill about 600. This will be maintained throughout the next few years so that we aim to be drilling around 1,000 wells per year.”

Athur Simatupang, Well Service Engineer at Harbour Energy agreed with this sentiment. At Harbour Energy, he noted, the main goal is to maintain gas production and by utilising intervention methods such as acidisation, perforation etc they hope to increase and maintain the gas production from their fields and help the government reach its target. He also noted intervention strategies were of more importance due to the increasing costs associated with drilling new wells. Companies in Indonesia are having to look to deeper waters to explore and develop new reservoirs which is much more challenging and requires more expensive equipment. While his company is looking to drill new wells in order to increase production, well intervention is being used to sustain and maintain it.

Data Management

In order to stay on top of which wells require production enhancement, precise and effective data acquisition and data management is key. As Menard noted, “The digital transformation is something that every operator and service provider needs to go through even though each has different objectives and initiatives relating to this.”

Sakti noted that in his company an in-house digitalisation platform (in use since 2007) captures all the historical data acquired from assets and allows them to get a better understanding of their wells in order to optimise and more efficiently manage their operations. Athur added that one of the most important uses of this data for his company was to allow them to manage, coordinate and plan the activities of all departments more effectively, so they could identify shared targets and strategies. In an age where making the most of resources is paramount, ensuring all departments are working together in this way can achieve substantial cost savings for the company.

In order to acquire this data, the panellists noted a growing trend of moving away from E-line operations, with many companies instead relying on other methods such as slickline. While doing so does not allow for real time data to be acquired, it has major benefits in regards to mobilisation and potential cost savings.

Menard noted that E-line has a much bigger footprint and unless urgent real-time data acquisition was required, in his companies experience it is often much more fruitful to use other methods such as slickline which requires much less equipment and is much lighter. Because of these advantages to ease of mobilisation, it can be a much better option especially for smaller platforms. Additionally slickline is often needed anyway to perform jobs such as removing safety valves etc and bringing in E-line would most add another logistical problem if another crew was required.

New technology

After touching upon digitalisation the panellists moved onto other new technology trends that are shaping the well intervention industry. Sakti bridged the gap to data by noting that the advancements of AI combined with big data will push companies to be much more efficient and could optimise campaigns through things such as predictive analytics. There are also new solutions emerging in the realm of sand control, a “common enemy” in Indonesia, which would allow operators to move away from traditional methods such as gravel packs which are becoming less economically suitable –especially for marginal wells.

All the panellists stressed their companies were not afraid to utilise new technology and insisted that their doors were open for new viable ideas which could optimise their operations. Sakti said, “In Mahakam we are open to trying out new technologies and there are plenty of new products and techniques being implemented and trialled on our wells. The first step is to get to know each other, then we can have a tech day or forum to see what you have in your toolbox. From there we can discuss how to move forward in more detail, perhaps offer a scenario and understand how this technology will help and what benefit we can gain.”

Athur added, “Every year we do a new tech presentation for all out contractors but, not waiting for that, our door is always open and you may contact us directly. Of course in the Indonesian market everything is about low price but we are happy to have a discussion to see if we can insert the product into our applications.”

To listen to the full session, follow the link below:

https://www.youtube.com/watch?v=KpZeA629gtU

On day three of OWI APAC, attention turned to optimising production enhancement strategies as host Sohan Harkesh Singh, Asset Performance Solution Commercial Manager – Asia, Schlumberger, was joined by representatives from EnQuest and South East Asia Hibiscus to consider the best way to capture value from this “low hanging fruit”.

On day three of OWI APAC, attention turned to optimising production enhancement strategies as host Sohan Harkesh Singh, Asset Performance Solution Commercial Manager – Asia, Schlumberger, was joined by representatives from EnQuest and South East Asia Hibiscus to consider the best way to capture value from this “low hanging fruit”.

As the panellists agreed it was critical to have an efficient workflow for any production enhancement programme, Khairul Riza bin Zainul Riza, Well Services Engineer, Hibiscus, took the opportunity to explain the process at his company whereupon they split intervention into two – routine and non-routine. The first, routine, is slickline only which is being worked 365 days a year. There is an overall plan of when work should be starting but it is updated as they go along when new opportunities are identified which can slot into the sequence. Such dynamic processes can help save time as if an opportunity to implement a solution can be identified with crew currently working on a remote jacket, turnaround will be much faster than if they need to return to it at a later date.

Non-routine, as Riza continued, is for more complex well entry and typically involves some sort of support vessel with a crane. This is for anything beyond slickline such as coil tubing. Planning is done far in advance (6-8 months) with opportunities continually identified for the following year.

Mohd Farid Mohd Talib, Wells Engineer, EnQuest, said that his company had an almost similar workflow to cater for most of the 362 strings in the Seligi field with OSV throughout the year where the team works in integrated systems between Subsurface, Ptech, Wells Team and also the Operation department. This process is started from a field reservoir workshop a year in advance to develop initial IWR target inventories by applying efficiency on online integrated system Well Request Forms (WRF). Farid noted it was vital to monitor large well inventories as much as possible to consider whether they were in a first time, routine, non-routine, easy to moderate, complex or very complex requirement of intervention. The company assesses what they can gain from intervening on categories of production enhancement/idle well recoveries (PE/IWR), data acquisition (DA) and also well integrity (WI) issues with the intention to protect the baseline of EnQuest within approved UEC (cost allocated) and overall chance of success (CoS) as well as justifying their well plan throughout the year to meet on the annual production KPI target.

Sohan added, “We have dedicated production enhancement workflows and we try to do this in an integrated fashion. We try to engage with the operator from the start to ensure there is alignment on delivery as this is very important and try to use digital technology where possible to help us deliver overall solutions much quicker. In some examples, digital workflows can fast track workflows by 90%.”

Production enhancement challenges

Turning to the challenges and inhibitors of production enhancement, Riza noted that in North Sabah, where some Hibiscus assets are located, one of the biggest difficulties is actually bad weather which comes round twice a year (mid and end). This can make activity planning extremely difficult with limited periods for operations. This is combined with the fact that resources must be shared with other departments internally, such as crew, living quarters, supply vessels etc. Such problems highlight the importance of dedicated and efficient workflows even more.

The panellists also noted that well intervention activities have been severely limited by the occurrence of oil price drops which can disrupt the economic planning. Farid said, “Right now it is not economical for us to have E-line at the moment so we are opting instead to optimise the services of the IIWR/IWS integrated contract for coil tubing and slickline. We have managed to use it to fulfil all our objectives without neglecting on company annual barrel gain KPI targets. With this we perform on our objectives to redo baselines, check on adhoc active well requirements, perform our yearly well intervention campaign for PE/IWR and DA, and also perform well repairs for WI, etc. This strategy has allowed EnQuest to achieve on its targets for top efficiency, fast turnaround and allows for cost optimisation to deplete remaining reserves.”

Riza agreed and added that Hibiscus has had to scale down plans quite a bit as well as deferring campaigns (such as a coil tubing from last year to this). His company, too, has noted that E-line is no longer economic and has instead turned to performing operations with memory tools and performing perforation jobs on slickline instead. Yet, despite this, they have encountered a fair bit of success with reworked campaigns, such as three fishing jobs which were successfully completed recently, two of the aforementioned perforation jobs and two saturation logging jobs. There is one more perforation job planned for this year after saturation logging results were received last year.

Best practices and new technology

Sohan switched the conversation by asking the panellists to explain the best practices for carrying out production enhancement, especially in the challenging times the industry is going through. For his part, he said, “Schlumberger is increasingly being more focused on the development of new digital technology as enablers for production enhancement. You may be familiar with the buzz word WPO [well portfolio optimiser] which we have designed to improve production enhancement workflows to reduce time take for data gathering to selecting & ranking well candidates. This allowed a client to reduce the time taken to rank their candidates from four months to two weeks.”

Sohan also focused on new technology providing real time surveillance, powerful analytics and more which allow for predictive insights to help make better, more informed decisions. Farid added that at EnQuest, they are always open to trying new technologies and opportunities to perform more efficient well operations as long as they are economically viable, before opting for workover or drilling options, and have sharing benefits to develop more knowledge between all parties involved. They encourage and challenge contractors to become the leaders of the job, sharing KPI achievements on subsurface proven alignments mechanisms and sharing their technical expertise with the EnQuest crew so that they can perform better on the solution in the future. EnQuest is also always looking forward in order to share their experience for proven and clear direction on integrated workflows (IIWR/IWS) and for technical solution sharing on new technology for man-made gas shut offs that have been planned for the first time in the world.

Riza said, “One thing we do well is achieve cost saving through sharing resources via integrated planning with other departments. When one of them needs an additional vessel (such as a supply vessel), we look at what campaigns everyone has going on to see if we can share it out so we each do not have to acquire one separately.”

“Also, early planning and preparation is critical. We plan 6-8 months in advance for heavier activities. That is key to achieving most of our targets. It allows us to communicate up front early our entire annual plan to contractors so that they can align their resources in a timely manner to our requirements. In that way no one is caught off guard.”

The panellists also touched upon other best practices such as adapting multi-skilled personnel. For instance, at Hibiscus a slickline equipment mechanic is routinely mobilised to service and check the slickline equipment offshore but now they are multi-skilled as a slickline assistant also so they can form part of the slickline operating team. Not only does this save value but also reduces the need for additional people to be mobilised, which is especially important during Covid-19.

To hear more from the panellists including further discussion on best practices and procurement models, follow the link below:

https://www.youtube.com/watch?v=QMZvLeiv5p4

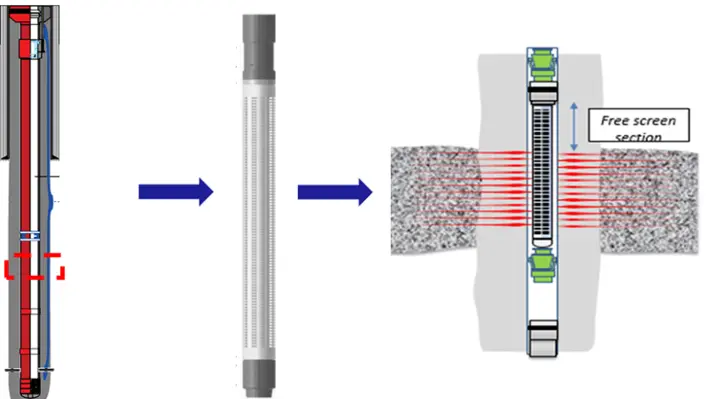

Presenting in a virtual webinar, Bhargava Ram Gundemoni, 3M Global Solutions Specialist Ceramics & Glass, Ceramic Sand Screens, showcased how operators can enhance their production from marginal fields through the use of ceramic sand screens. Using a case study to highlight how an Operator in Asia achieved a 70% cost saving compared to chemical sand consolidation methods, Ram presented the technology and application detail.

Beginning the presentation, Ram stated that marginal fields can pose a variety of challenges to operators which can have disastrous economic and HSE consequences if not properly operated. For one of the field/assets in Asia, Operator A had to contend with low reserves, ranging from just 0.05BCF to 2BCF natural gas production per reservoir zone; high operational costs due to offshore and near shore delta locations; complex geography such as stacked thin-bed reservoirs and unconsolidated and poorly sorted sand distributions; and the fact that hotspotting erosion is often a high risk. Many of these are common challenges that operators must overcome, which they must do in a safe and cost-effective way. It is for this reason that selecting the right sand control completion is absolutely imperative.

Traditional Sand control

Operator A was struggling to achieve economic viability for their fields. Previously, it had used traditional methods of sand control for their marginal fields such as multi-zone single trip gravel packs, chemical sand consolidation, or metallic stand-alone screens. The operator had found that such approaches each had drawbacks relating to high cost (often related to additional rig time being required due to the increased complexity), HSE risks (especially using chemicals), loss of productivity before the reservoir life had been depleted, increased chance of hotspotting and difficulty achieving sand mapping due to wide reservoir sand facies. All these led to higher capex, longer payback times and generally lower returns.

Technology unlocks application scope through material change

To economically unlock marginal well production across the field, new sand control technological advancements needed to be considered. Operator A therefore selected the 3M ceramic sand control solution to enable a standardised field wide approach.

The solution featured a much simpler design with ceramic rings (with spacers on one face) stacked on top of each other to create v-shape gap openings to enable any particles stuck to be pushed into the tubing. The rings were stacked onto a base pipe with two end caps with a pin and box connection on each side which was then covered by a metallic shroud for protection during transportation and downhole running. This was a monobore completion approach which addressed the complex geography of heterogeneous reservoir sand properties by having one solution and was easily installed via a slickline rigless deployment. Ceramic parts were chosen due to their excellent corrosion and erosion resistant properties.

Across the field, 13 installations were implemented and all achieved sand-free production rates. Max production achieved was 4.4mmscfd with 36ft/s insitu velocity of gas (Vg) at perforation hole which was the reservoir production limitation compared to 13ft/s when using sand consolidation method in the past. Additionally, the operator reported the successful implementation of stand-alone screen application for volume shale (Vsh) greater than 35% with further deployments currently being made to address expansion of the application scope to Vsh less than 35%.

Operator A achieved a 70% cost saving compared to chemical sand consolidation methods. Further enabled simplified approach, optimising right through drilling to completion with lower capex, faster ROI and higher production rates achieved the fast and simple deployment (only five and a half days) enables the execution of a higher number of reservoirs per year, it was successfully proven to safely retain and control post frequent restart of wells and it addressed the challenge of erosion and hotspotting. Ram also noted that the solution met the full lifetime of each reservoir which, in these cases, ranged from six to nine months with no failure of the sand control.

Offshore Network took the opportunity to speak with Ram in order to understand this innovative technology in more detail:

Do any specialist personnel need to come out to deploy the solution or are you able to direct this?

It is a simple Stand-alone screen design which can be run like an industry Stand-Alone Screen deployment. 3M provides guidelines for handling and run-in hole (RIH), for the Operators and Service provider. 3M can support well on paper (WOP/IWOP) to onshore support as identified.

How compatible is the ceramic solution with different types of cables?

In terms of deployment, ceramic sand screen has already been successfully deployed on wireline, slickline, coil tubing and on a pipe. This offers operators flexibility and cost-effective approach in deployment to meet the operational and application needs.

Can you give some more details relating to the cost saving which can be achieved?

By using ceramic stand-alone screen deployment via slickline unit, Operator A mitigated the need of coil tubing, pumping of chemicals, time required for deployment and curing of chemicals. Operator A calculated this saving contributed 70% against the chemical sand consolidation methodology.

There are other cases globally, where operators have benefited from running 3M Ceramic Sand Screen as a stand-alone system which has demonstrated faster returns on investment to cover the costs. Ceramic sand screens offer an alternative downhole sand control methodology as a simple Stand-alone screen method, which enhances production improvement, operational simplicity and reduced HSE

How much this solution has been utilised in Asia and how has Covid-19 affected this?

This technology was first introduced in the field in 2010 and, since then, we have more than 110 deployments globally with the majority of them (more than 50%) in Asia.

Covid-19 really disrupted the market, with project sanctioning taking longer, and higher focus on cashflow.

Do you imagine this technology will become more widely utilised in the future?

Yes, we are confident that this technology is a “game changer” in the way operators control downhole sand, whilst enhances productivity. Maersk Oil stated, “This technology has the potential to completely change the way mechanical sand control screens are being developed.”

Additionally, Operator A said the technology was an “eye opener" (post deployments and production successes in multiple wells) to safely tackle and push boundaries of shallow sandy reservoir production in a challenging economical context. Foreseeing wider applications in near future subsurface sand control…”

To learn more about 3M Ceramic Sand Screens visit: https://www.3m.com/3M/en_US/oil-and-gas-us/ceramic-sand-screens/

PTT Exploration and Production Public Company Limited (PTTEP) has announced yet another gas discovery from its first exploration well, Kulintang-1, in Block SK438, located off the coast of Sarawak, offshore Malaysia.

Phongsthorn Thavisin, CEO of PTTEP, disclosed that PTTEP, through its subsidiary PTTEP HK Offshore Limited (PTTEP HKO), commenced the drilling of Kulintang-1 wildcat well in Block SK438 in March 2021 and successfully drilled to a total depth of 2,238 metres in April 2021.

Block SK438 is located in the shallow waters, approximately 108 kilometres off the coast of Bintulu in Sarawak. PTTEP HKO is the operator with 80% participating interest while PETRONAS Carigali Sdn. Bhd. (PETRONAS Carigali) holds the remaining 20%. PTTEP expects to drill another exploration well in this block in the second quarter of 2021.

Block SK438 is adjacent to Blocks SK405, SK309 and SK311, SK314A, all of which are operated by PTTEP, with existing facilities nearby. The location, therefore, provides an advantage for future development including the potential for cluster development.

PTTEP’s Malaysian success story

This discovery is the latest of PTTEP’s continued success in Malaysia. Already this year the company discovered a significant oil and gas column of more than 100 metres from exploration well, Sirung-1, in Block SK405B; revealed a high quality gas reservoir from the Dokong-1 well in Block SK417; registered a new record for its largest ever gas discovery from the Lang Lebah-2 appraisal well in the Sarawak SK 410B Project; and announced the start-up of natural gas production from Rotan and Buluh deepwater fields of Block H which targets production capacity at 270 million standard cubic feet per day.

“The Kulintang-1 well adds to the consecutive discoveries PTTEP has made this year which demonstrate our significant exploration progress in Malaysia. The discovery highlights our strong partnership with PETRONAS and continuous efforts in applying new techniques and interpretation to identify opportunities in mature areas. We are determined to explore further and make more oil & gas discoveries in Malaysia to serve future energy demand,” said Thavisin.

Beacon Offshore and Claxton, the lead brand for the Acteon drilling and decommissioning business segment, have signed a master services agreement for the severance and recovery of more than 100 subsea wells in the Gulf of Thailand.

While detailed information of the agreement has so far been withheld, Sam Hanton, CEO of Claxton, stated, “The relationship with Beacon Offshore is a milestone for long-term collaboration in the region which was underpinned by significant effort and commitment by all parties.

“We are very excited about this project as it highlights Claxton’s rigless P&A capabilities and reflects the expertise of Claxton as a trusted partner in vessel-based decommissioning.”

Asia Pacific decommissioning

This is the latest agreement regarding decommissioning operations in Asia Pacific, a market which is expected to take off in the next few years largely due to the shared global desire to limit climate impact by ensuring abandoned wells are properly plugged and abandoned with infrastructure removed. While, traditionally, complicated government regulation and lack of experience has restricted such campaigns in the region, this problem is fast becoming too large to ignore, especially with a large number of fields approaching the end of their production life.

As Jean-Baptiste Berchoteau, Wood Mackenzie’s Asia upstream analyst, told Breakbulk last year, “With more than 380 fields expecting to cease production in the next decade, the magnitude and cost of work can no longer be ignored. Through learning from global decommissioning projects, the industry can adopt and adapt practices best suited for Asia-Pacific’s own set of challenges.”

Breakbulk noted that across the 380 fields there are 35,000 offshore wells, serviced by 2,600 platforms representing 7.5 million tonnes of steel and more than 55,000km of pipelines which will need to be retired in the forthcoming years – representing an enormous challenge which operators will have to deal with in order to meet their environmental commitments. Such a challenge, however, opens a very promising door for service providers such as Claxton who in the coming years will no doubt be called into action to conduct more decommissioning operations in this region.

Page 12 of 15

Copyright © 2026 Offshore Network