North America

- Region: North America

- Topics: Geothermal

- Date: Apr, 2023

Geothermal Technologies (GTI), a company dedicated to developing clean energy, has filed for drilling permits with the Division of Water Resources in the State of Colorado, US.

GTI is seeking to drill geothermal wells for the purpose of generating utility-scale electricity in the Denver-Julesburg (D-J) Basin. GTI’s proprietary GenaSys Geothermal Energy Harvesting System ushers in the latest generation of geothermal technologies. When coupled with advanced Organic Rankine Cycle (ORC) power generation technology, GTI’s innovative system enables the efficient extraction of geothermal energy in geographic regions around the globe that have been out of reach using conventional approaches.

“This is an important step forward in our plans to construct a first-of-its-kind geothermal power plant in the D-J using GTI’s proprietary suite of technologies,” said J. Gary McDaniel, CEO of GTI. “We are excited about the potential that exists in Colorado for the development of advanced geothermal power. GTI has calculated that the thermal prospect in the DJ Basin has over 5GW of geothermal energy that can be harvested using our technology. Our field development plan for generating power indicates we can install up to 400MW of baseload electricity production.”

Jim Hollis, President and COO of GTI, added, “Our GenaSys technology promises to make geothermal baseload power both low in cost and truly scalable – locally, regionally, and globally. We plan to begin by constructing a small 5MW power plant in the D-J basin and then scale from there.”

- Region: All

- Date: Apr, 2023

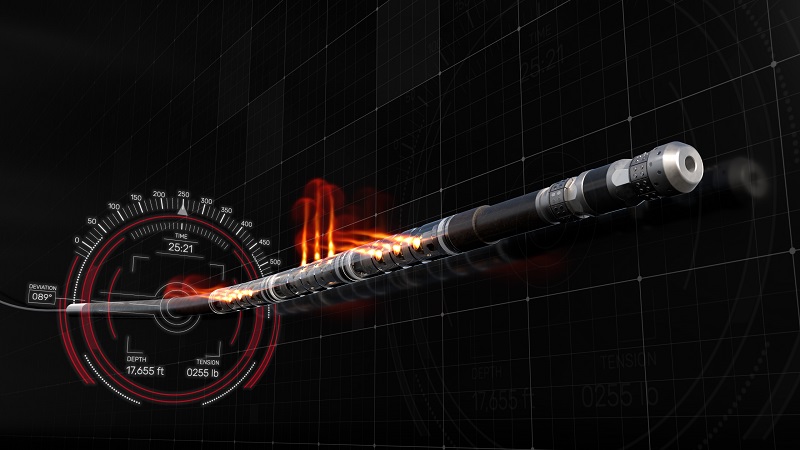

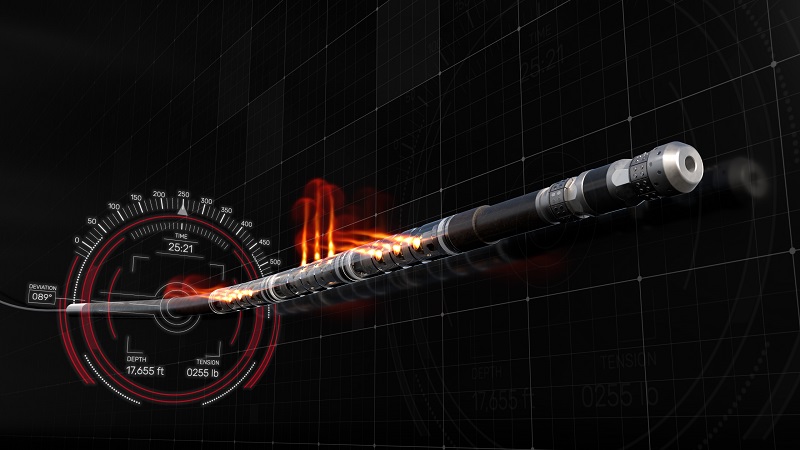

Halliburton, a leading provider of products and services to the energy industry, has announced the implementation of the Auto Pumpdown service within the company's hydraulic fracturing business which enables wireline and pump automation during unconventional completions operations.

The Auto Pumpdown service controls fluid pumps and a wireline unit as a single, fully automated, closed-loop system to maximise Halliburton’s plug and perforating performance and efficiency. The system executes operations to plan and optimises equipment operation for improved consistency.

The service enhances operations by automating tasks previously prone to human inconsistencies and reduces risk by providing prompt feedback to dynamic downhole conditions. These improved consistencies create more efficient operations and reduce required fluids for tool conveyance.

Chris Tevis, Vice President of Wireline and Perforating, Halliburton, commented, “Halliburton’s Auto Pumpdown service ushers in a new era of intelligent plug and perf operations that reduce risk while redefining the level of efficiency and consistency we provide our customers. The service reinforces our leadership in unconventional perforating services by minimising variability in operations, which helps avoid unnecessary and costly well interventions and simultaneously improves efficiencies.”

Multiple perforating crews in North America currently use Auto Pumpdown service. Here, it has demonstrated improved operating efficiencies, reduced fluid requirements, and reduced risk of unnecessary well interventions.

Halliburton will implement Auto Pumpdown service on its North America fleet through 2023 and beyond.

- Region: All

- Topics: Geothermal

- Date: Apr, 2023

Onshore seismic acquisition and imaging experts, STRYDE, has enabled five new geothermal projects in Q1 of 2023 with the supply of its low-cost seismic technology, with a further five contracts for scheduled to commence during Q2.

Onshore seismic acquisition and imaging experts, STRYDE, has enabled five new geothermal projects in Q1 of 2023 with the supply of its low-cost seismic technology, with a further five contracts for scheduled to commence during Q2.

The global contracts, equating to a six-figure sum, will see the company’s technology deployed across the US, Middle East and Europe.

Two of the ten contracts include nodal equipment supply and seismic data processing for STYDE’s largest geothermal project to date in the Middle East, as well as a European survey that was constructed alongside a geological research centre in Belgium. Five of the seismic surveys have already commenced, and all ten are expected to be completed by the summer of 2023.

Nick Tranter, STRYDE’s Business Development Manager for New Energy, said, “Within the renewable energy space, STRYDE presents a cost-effective and reliable solution to help geothermal operators de-risk investment decisions, with high-resolution seismic data.”

Mike Popham, STRYDE CEO, commented, “I am proud to have STRYDE play a part in supporting the energy industry transition towards net-zero. Our technology has proven to be a key tool in propelling more than 20 geothermal projects to date, by providing an economically viable solution for understanding and monitoring the subsurface.”

- Region: North America

- Topics: Geothermal

- Date: Mar, 2023

Razor Energy Corp. in conjunction with FutEra Power Corp. has announced the successful construction, commission and operation of its co-produced geothermal power project in Swan Hills, Alberta.

Razor Energy Corp. in conjunction with FutEra Power Corp. has announced the successful construction, commission and operation of its co-produced geothermal power project in Swan Hills, Alberta.

The project combines an Organic Rankine Cycle (ORC) Turbine, which captures geothermal heat from the production fluid, and a Natural Gas Turbine (NGT). Both the ORC and NGT have grid interconnections which enable direct sales of electricity to the Alberta grid, and both systems have been running in a steady state while optimisation efforts are being made in order to reach the designed capacity.

Razor produces and injects large volumes of hot production fluid on a daily basis as part of its ongoing conventional oil and gas operations, and FutEra capitalises on that by capturing the geothermal heat energy from the fluid and using it to generate power with zero greenhouse gas emissions. The co-production element of the project means there is no new surface land footprint as the project utilises existing assets such as processing infrastructure, producing wells, produced water reinjection system and an operating gathering and distribution system.

In addition, the co-production approach enables Alberta’s fledgling geothermal industry to develop alongside the powerhouse of Alberta’s world-class oil and gas operations.

Justin Reimer, CEO of Emissions Reduction Alberta, said, “Alberta has long championed the geothermal industry. It is exciting to watch an idea for a pilot project grow into an industry-scale, commercial operation. This made-in-Alberta solution ushers in a new era of clean energy that will spur an entirely new industry in the province that taps into our existing oil and gas resources and expertise.”

FutEra’s next phase of the project will see the addition of solar, and potentially carbon capture, with the objective to create a net negative carbon emitting traditional oil and gas asset.

- Region: All

- Topics: Integrity

- Date: Mar, 2023

Halliburton Company has introduced the RockJet family of reservoir-optimised shaped charges for the optimisation of downhole performance.

Halliburton Company has introduced the RockJet family of reservoir-optimised shaped charges for the optimisation of downhole performance.

The RockJet family of charges was developed at the Advanced Perforating Flow Laboratory at the Halliburton Jet Research Centre using real rock under downhole conditions, and are the first charges to be certified using the American Petroleum Institute’s new perforation witnessed test protocol.

The charges allow for operators to enhance well productivity by providing optimum reservoir connectivity through deeper formation penetration and a larger perforation tunnel diameter downhole. They help increase production and improve well productivity by improving reservoir contact through deep and clean tunnels which extend beyond the damage zone.

When tested at downhole conditions, the RockJet charges delivered 22% higher penetration and an 83% increase in area open to flow.

Chris Tevis, Vice President of Wireline and Perforating services, Halliburton, said, “The RockJet family demonstrates our commitment to develop innovative technologies that drive increased production for our customers. In the perforating business, optimising penetration depth and flow area is the key.

“A lot of companies may have charges that are tested on the surface, but how they perform in downhole conditions is difficult to prove. By following the API’s new test protocol, we can provide our customers with confidence that the RockJet charges, custom engineered at JRC’s Advanced Perforating Flow Lab, will perform downhole.”

- Region: All

- Topics: Integrity

- Date: Mar, 2023

UTEC, a geo-services brand in Acteon’s data and robotics division, has launched ‘iSite Subsea’, a cloud-based platform which gives users an intuitive 360° visualisation of subsea assets and data.

It is developed from UTEC’s iSite collaborative virtual asset and data management platform and is specifically designed to meet the needs of the offshore renewable energy market and oil & gas subsea asset owners. Through iSite Subsea, users can source, view, manage and report on seabed, survey and asset data using a single secure cloud-based interface, enabling interrogation and comparison of data over time, remotely, 24/7 and without specialist software knowledge. Ultimately, this helps to reduce costs, lower risk, enhance health and safety, and deliver better informed decisions.

The new platform facilitates the digital delivery, throughout the lifecycle of a subsea asset, of geophysical, geotechnical, structural integrity monitoring, inspection, and maintenance surveys. It is designed to give developers and contractors access to the data they need to plan, evaluate, execute, and solve safety, environmental and risk scenarios. The end-to-end service delivery ensures that the latest data sets are always available to all users and eliminates the risk of double handling, incomplete data entries, multiple versions, and lost data/information.

“Energy customers have been using iSite to drive safety and efficiency, reducing costs on their above-water assets for more than 10 years,” said Paul Smith, Managing Director, UTEC. “We are now bringing the advantages of our product to the subsea market as a dedicated tool. iSite Subsea development has been driven by our customers’ needs. It is designed to help them reduce the time and costs associated with multiple visits, lower risk and achieve significant health and safety improvements through smart data management and interrogation tools that inform decisions.”

- Region: Gulf of Mexico

- Topics: Geothermal

- Date: Mar, 2023

Global leader in well integrity and production optimisation, Coretrax, has successfully delivered its DAV MX circulation sub; a solution which will cool an estimated 400⁰C geothermal well bottom hole temperature by nearly 200⁰C in the US.

Global leader in well integrity and production optimisation, Coretrax, has successfully delivered its DAV MX circulation sub; a solution which will cool an estimated 400⁰C geothermal well bottom hole temperature by nearly 200⁰C in the US.

The solution was deployed during a planned closed-loop geothermal well project by a US operator, where the estimated bottom hole static temperature was 400⁰C. Operating at temperatures this high poses a high threat of equipment failure, so an effective and reliable ‘staging’ method was required in the hole to cool down the temperature-sensitive measurement while drilling (MWD) technology.

Staging is common practice for high temperature wellbores to prevent MED failures which normally involves pumping conventionally through the drill bit to cool the BHA. However, this method can result in the motor rotating the drill bit, causing possible damage in the cased and upper granite section as well as damage to the tech itself, meaning a more reliable method is required.

The application of Coretrax’s DAV MX delivered significant time savings while maintaining well integrity and improving safety. Estimated bottom hole temperatures were reduced from the estimated 400⁰C to 210⁰C. The tool was deployed with the Split Flow Dart, which allowed a limited flow through the motor and drill bit, reducing the rotations per minute while delivering high flow rate to effectively cool the BHA and borehole.

John Fraser, Chief Executive Officer, Coretrax, said, “The geothermal market has experienced significant growth in recent years in response to global environmental objectives and Coretrax already has a tangible track record in supporting these developments globally. Our range of downhole circulation tools are ideally placed to support the high temperatures and complexities of geothermal wells.

“The latest project is a strong example of how technology which has traditionally been applied to oil and gas operations can support this expanding sector to address the most complex well challenges while delivering enhanced reliability and greater efficiencies.”

The downhole circulation tool can be used across a wide range of applications including hole cleaning, displacements, lost circulation material spotting and blowout preventer jetting, among others.

- Region: All

- Date: Feb, 2023

Intelligent Wellhead Systems (IWS), a supplier of digital technologies that improve oil and gas well completion operations, has welcomed Shiblee Hashem to the executive management team as Vice President of Operations.

In his new role, Hashem will lead the growing operations team, including the regional managers and US facilities teams, and work closely with the COO to drive the company’s transformational strategies to meet financial goals.

Hashem brings more than 25 years of oil and gas consulting and operations management experience and throughout his career, he has worked closely with some of the largest independent and national oil companies in Europe, the Middle East, Asia, North and South America, and North, East and West Africa. Drawing upon this extensive experience, he offers a diverse professional background in both executive and technical management. Prior to joining IWS, he held senior management positions with AccessESP (a Baker Hughes Company) and Halliburton.

The new member of the executive management team belongs to the Project Management Institute (PMI) and the US Gulf Coast Section of the SPE. He is currently serving as the Program Chairperson of the SPE’s Bangladesh Section.

Based in Houston, Hashem reports to Steve Sinclair-Smith, Chief Executive Officer of IWS.

Hashem commented, “Safety and efficiency have always been part of the IWS mission. As the company grows in 2023, our focus is on delivering the highest service quality while maintaining safe and efficient operations.”

In other news, Pason Systems has increased its non-controlling investment in IWS through the acquisition of outstanding common shares of IWS for an aggregate purchase price of US$7.9mn and an agreement to invest up to US$25mn in preferred shares of IWS.

There was also cause for celebration when the company’s inVision Digital Valve Control technology received a Special Meritorious Award for Engineering Innovation (MEA) in the Digitalization category from Hart Energy.

- Region: North America

- Topics: Geothermal

- Date: Jan, 2023

As the focus on environmental sustainability has never been more prevalent across all industries than it is right now, the race is on to find long-term renewable solutions to the climate crisis. Operators across the globe are trying to make their innovations in the oil and gas industry as green as possible, but that is not an easy stepping-stone to overcome.

As the focus on environmental sustainability has never been more prevalent across all industries than it is right now, the race is on to find long-term renewable solutions to the climate crisis. Operators across the globe are trying to make their innovations in the oil and gas industry as green as possible, but that is not an easy stepping-stone to overcome.

Geothermal energy could be the answer so many are looking for. It is a method of clean energy which bridges the gap between the oil and gas industry and renewable energy sources in order to reach net zero. The US has already increased federal funding by millions of dollars in 2022 alone to widen the scope of geothermal projects up and down the country, tapping into the underutilized potential beneath our feet.

A key area of interest within the geothermal industry is that of repurposing end-of-life oil and gas wells. Geothermal companies can turn these assets back into active wells, only producing a slightly different end-product, negating the need for decommissioning services and the associated costs. Operators can turn their liabilities into profitable assets at a quarter of the cost while producing green energy.

In spite of the benefits associated with geothermal, there are a number of issues holding the industry back from becoming a mainstream alternative. For one, the extortionate upfront costs associated with starting geothermal projects from scratch prove a wall too vast to climb in most instances, as well as the technological challenges that present themselves when working with temperatures of this calibre.

Nevertheless, advanced methods and technologies are working at mitigating against the challenges posed by geothermal extraction, using expertise from the oil and gas industry to finesse already existing drilling equipment in order to marry the industries together to be able to harness a green energy source born from an oil well.

More Articles …

Page 7 of 17

Copyright © 2024 Offshore Network