Saudi Aramco has deepened its long-standing relationship with the United States by signing 17 new memoranda of understanding and agreements worth more than US$30bn, marking another significant step in its strategy to broaden global partnerships and support long-term growth.

Saudi Aramco has deepened its long-standing relationship with the United States by signing 17 new memoranda of understanding and agreements worth more than US$30bn, marking another significant step in its strategy to broaden global partnerships and support long-term growth.

These latest commitments span a wide range of sectors, from liquefied natural gas (LNG) and advanced materials to financial services and industrial supply chains, reinforcing Aramco’s position at the centre of global energy and technology collaboration.

The new deals build on the company’s earlier announcement in May 2025, when Aramco unveiled 34 MoUs and agreements with a combined potential value of around US$90bn. Together, the partnerships announced this year now approach an impressive US$120bn, reflecting a sharp expansion of its collaborative pipeline with American companies.

A major emphasis of the new agreements lies in LNG development. Aramco signed an MoU with MidOcean Energy linked to potential investment in the Lake Charles LNG project on the US Gulf Coast. The company is also assessing opportunities for cooperation with Commonwealth LNG on its liquefaction project in Louisiana, including discussions involving potential LNG and gas purchases through Aramco Trading. These moves highlight the Saudi energy giant’s increasing interest in global LNG markets as demand continues to evolve.

Aramco also strengthened ties with leading US suppliers such as SLB, Baker Hughes, McDermott, Halliburton, NESR, KBR, Flowserve, NOV, Worley and Fluor. These agreements reflect ongoing requirements across the company’s upstream and downstream operations, ensuring continued access to essential materials, engineering services and procurement support.

In the field of advanced materials, Aramco extended its existing MoU with Syensqo to examine opportunities for localising the production of carbon fibre and composite materials, a sector seen as increasingly important for industrial innovation and lightweight manufacturing.

Financial services were another key focus. Wisayah, Aramco’s investment arm, entered into asset management and investment agreements with Loomis Sayles, Blackstone and PGIM, while Aramco reached a strategic partnership with J.P. Morgan centred on cash account management.

Amin H. Nasser, Aramco President and CEO, said,“Since the 1930s, US firms have played a major role in supporting the company’s success… We expect the multi-billion dollar MoUs and agreements announced today to act as a springboard for further progress, strengthening Aramco’s longstanding legacy of collaboration with American counterparties and unlocking new value creation opportunities that promote innovation and growth."

Expro has officially completed its acquisition of Coretrax, marking a significant milestone in the growth of both businesses.

The acquisition will allow Expro to expand its portfolio of cost-effective, technology-enable well construction, well intervention and integrity solutions, while Coretrax will be able to accelerate its technology application globally.

John Fraser, CEO of Coretrax, highlighted how this acquisition marks the start of a “brand-new chapter” for the company by uniting with Expro to expand its capabilities: “Completing this agreement means both organisations working in sync to take on the most complex well challenges. We are proud of our innovation-led approach, strong customer base and performance history as we join forces with Expro to create greater value for customers around the globe.”

Michael Jardon, Chief Executive Officer at Expro, added, “We expect the acquisition to accelerate the growth of Coretrax’s innovative, high value-adding drilling optimisation, well integrity and production enhancing technology solutions by leveraging Expro’s global operating footprint.”

As the oil and gas industry is increasingly seeking sustainability, well intervention remains an obvious choice.

According to Jenny Feng, Supply Chain Analyst, Rystad Energy, operators will look to "ramp up production from existing fields, and well interventions will be a vital piece of the puzzle. As a quick, efficient, and cost-effective method of maximising existing resources, interventions are going to be a hot topic in the years to come." As per the research body’s prediction last year, spending on interventions stands close to nearly US$58bn. With sustainability the focal point, this amount sets the bar for a surge in the coming years as the number of wells ready for intervention is projected to reach 17% by 2027, equating to a total 260,000 wells globally.

Middle East and North Africa's (MENA) eagerness to take up intervention activities is well evident as companies such as Coretrax is showing increased interest in the fossil fuel-driven region. “The Middle East is a key growth area for Coretrax... As operators remain focused on maximising recovery efficiently and sustainably, our expandable technology is ideally placed to support this demand," said John Fraser, Coretrax CEO, while marking the company’s first deployment of ReLineWL straddles in 2022 for a major Saudi operator.

In another multi-year contract in the Middle East signed as recently as October 2023, the well integrity and production optimisation leaser will be delivering production enhancement across a multi-well campaign. It will also be supplying expandable tubulars to support brownfield optimisation. With advanced tools such as ReLineMNS and ReLineHYD expandable casing patches under the brand name, the company will effectively help isolate trouble zones and stimulate production on the operator’s existing wells.

Companies from the region are leveraging artificial intelligence and machine learning (AI and ML), and coming up with groundbreaking digital innovations in the intervention space. AIQ's autonomous well control solution called RoboWell that has been deployed by ADNOC in its North East Bab (NEB) assets remains one such instance. Expro, which is an active player in the MENA region, has come up with a tool called Galea, which is a completely automated well intervention system that can perform a variety of slickline operations, offering easy alternative to conventional methods.

The Middle East and North Africa Well Intervention Outlook attempts to reflect on these industry developments, as OWI MENA 2024 gears up to return in Abu Dhabi from 17-18 September.

Well integrity and production optimisation specialist Coretrax has strengthened its portfolio after acquiring a complementary suite of well intervention technology from Wireline Drilling Technologies.

The significant investment has expanded Coretrax’s offering. Since completing the acquisition, the firm has signed a global route to market agreement with a supermajor to support its well intervention requirements internationally and secured additional work in the Middle East with an existing client.

The company has already integrated the new assets and software, which include wireline pump units, drilling units and tractor modules into its existing technology portfolio. The additional equipment boosts Coretrax’s current well integrity offering, enabling the business to access and address damaged wellbores, and support highly deviated wells more efficiently.

John Fraser, CEO at Coretrax, said, “This investment demonstrates our continued drive to enhance and improve our services, positioning Coretrax as a full turnkey solution for

all wellbore entry and remediation operations. The additional technologies have integrated seamlessly into our portfolio of tools and are supporting several new contracts including a global supermajor and an ongoing long-term project in the Middle East.

“As the industry remains focused on extracting maximum recovery from existing wells, demand for wireline applications has increased as operators realise the cost and sustainability

benefits they bring across well intervention, frac plug drilling, well conveyancing and lateral drilling. Our recent investment will undoubtedly open up new markets for the business and we are excited about the opportunities this will bring.”

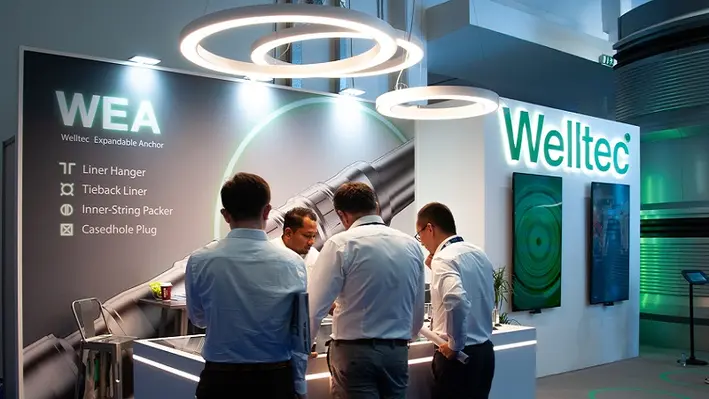

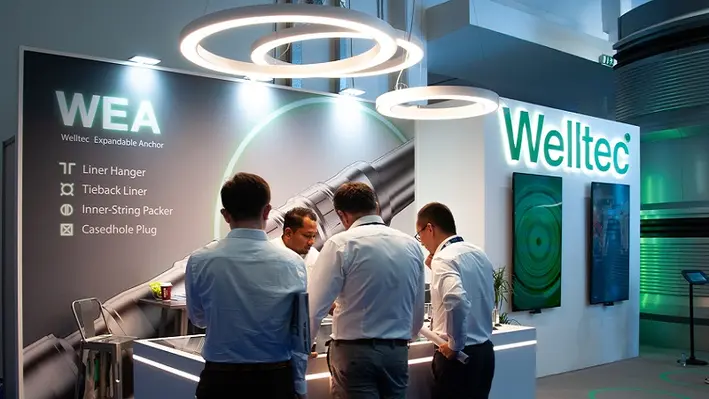

Welltec sees great prospects in the Middle East for its recently launched Welltec Expandable Anchor (WEA).

The Welltec Expandable Anchor (WEA) was a key focus at the company’s stand at ADIPEC 2023, where Completion, Intervention, and New Energy & Climate Technology solutions were showcased, all with optimisation and efficiency as core design principles.

Engineered and rigorously tested over the past couple of years, the WEA is a 4-in-1 life-of-well completion system for anchoring in cased hole. Firmly rooted in proven metal expandable packer technology, it provides industry-leading reliability, efficiency, and flexibility, as explained by Kevin Wood, Sales Director for Completions in the Middle East.

“The WEA has three key benefits. It is reliable, with essentially no moving parts; it’s basically a metal expandable sleeve that is secured onto a casing. It is efficient, as it is slimline and full bore, so operators can circulate fluids or cement at high rates compared to other products. It can also be rotated when run in hole making for efficient installation in deviated and challenging wells. And it is flexible; one particular size of WEA can cover multiple casing grades and we can also add or take away modular parts, depending on the environment in the well.”

The product is available in a full range of sizes, with key completion applications as a liner hanger, tieback liner, inner-string packer, and casedhole plug. All versions of the product are qualified to the API 19LH V1 standard and are fully compatible with Welltec’s Metal Expandable Packer (MEP) portfolio.

The WEA clearly addresses a market need, as illustrated by several installations taking place immediately after qualification, with a requirement from one Middle East operator for product delivery within eight weeks. Facilitated by its in-house design and manufacturing capabilities, Welltec was able to deliver the solution in seven weeks.

Prospects in the region are very encouraging, Wood said, “ADIPEC has been big for us; we signed a two-year call-off contract with ADNOC Onshore for the WEA technology which can address several of the challenges they face on some wells.

“The products covered under the call-off agreement are for the prevention of sustained casing pressure – this is annular casing pressure that can makes its way back to surface, a challenge which has cost the industry around US$75bn since 2009,” he continued. “Around 35% of wells globally exhibit gas pressure in the annulus, and the only way to deal with that is to flare it off, or vent it off, both of which are harmful to the environment. That’s where this anchor and our technology come in. It’s a life-of-well solution, providing a barrier in the well. It’s important that when a well comes to the end of its life, it is decommissioned correctly. The problem with cement is that over the life of the well it expands and contracts, which creates leaks through the cement. Using the Welltec Annular Barrier, which the anchor is incorporated with, gives you a fully qualified barrier that you can abandon above, thereby future-proofing the well for abandonment.”

This in effect helps reduce emissions. The emissions reduction angle certainly chimes with ADIPEC’s central theme of decarbonisation. Wood stressed the company’s commitment to the energy transition, which is “in our DNA – it’s not just a buzzword for us”. He explained that Welltec is playing a key role in Project Greensand, which involves the long-term storage of CO2 by injecting it into depleted reservoirs in Denmark. To support this, and similar projects, Welltec’s New Energy & Climate Technology segment has already constructed an advanced testing facility in Denmark that enables full-scale downhole components to be tested against real-world CO2 well-type environments including high pressures, temperatures, and flow rates.

“The test loop and background to Project Greensand have opened up a lot of conversations here, especially with COP28 coming up,” he said.

Elsewhere in the Middle East, Welltec is active in Qatar and Saudi Arabia, the latter of which provides a manufacturing hub supporting regional activity, and keeping lead times to a minimum. Wood commented that this has been a “huge success”, and expansion of the hub is on the cards. “We can not only deliver quickly compared to our peers, we can also manufacture in the region.”

As far as future product development goes, Welltec has a couple of technologies in the field-trial phase. One is the Isealate Springblade Patch, a unique relining and repair solution for downhole applications. The first in-field deployment successfully took place in Europe in October.

“We also provide a service that can radially expand an existing casing string: the Saturn Expander. This can be utilised in wells where there is casing pressure,” said Wood.

“It expands the casing, compresses the cement on the outside, and cures any microannuli or leaks you might have.

“These solutions are coming to fruition now, and there is a lot of interest in the region, particularly given that many wells here suffer from casing pressure.”

SLB, a global technology company, has released its Q2 2023 results revealing the part intervention and stimulation activities are playing in the business growth.

The company reported a revenue of US$8.1bn, representing a 20% increase year-on-year. SLB CEO Olivier Le Peuch commented, “I am very pleased with our second-quarter results, which reflect significant growth in the international markets, particularly in the Middle East & Asia, and offshore. North America revenue also grew sequentially benefiting from our agility across the most resilient basins and market segments, although the rig count in the area declined. As the upcycle continues to unfold, we are excited about the opportunities for our business, with international- and offshore-led growth fueling strong pretax segment operating margin expansion and cash flows as highlighted in this quarter’s results.

“Compared to the same period a year ago, international revenue grew 21%, outpacing North America which increased 14%. Year on year, revenue grew 20% and pretax segment operating margin expanded 240 basis points (bps), representing the tenth straight quarter that we have increased our pretax segment operating margin year on year. This was driven by the international markets, where we posted our highest year-on-year incremental margin in the last three years, demonstrating the earnings power of our operations in these markets.”

Breaking this down, the company noted that reservoir performance revenue grew 9% sequentially due, primarily, to increased intervention, stimulation and evaluation activity internationally. Profitability improved mainly due to higher activity and improved operating leverage across intervention and stimulation with new technology deployment contributing to margin expansion, particularly in Saudia Arabia, Qatar, Europe & Africa and Mexico.

The Middle East & Asia was a particularly strong-performing region for the company with a 10% increase sequentially driven by double-digit revenue growth in Saudi Arabia, Egypt, UAE, Kuwait, China and India. SLB attributed to higher drilling, intervention, stimulation and evaluation activity here, both on land and offshore. Saudi Arabia was a particular hotspot for higher stimulation and intervention activity. Reservoir Performance grew 23% year-on-year, primarily down to higher intervention and stimulation activity led by the Middle East & Asia.

The company also highlighted how it had experienced increased intervention and stimulation activity in Argentina which helped offset the lower revenue recorded in Mexico.

This year’s OWI Middle East and North Africa (OWI MENA 2023) conference promises to be grand affair as sights are set to broaden the format and shine the spotlight towards operators in the Gulf and North Africa equally.

This year’s OWI Middle East and North Africa (OWI MENA 2023) conference promises to be grand affair as sights are set to broaden the format and shine the spotlight towards operators in the Gulf and North Africa equally.

With the tagline of this year’s conference being ‘future-proof your intervention projects to exceed environmental targets and optimise well programmes by utilising transformative digital and downhole technologies’, OWI MENA is the only place to offer key learnings to the well intervention community in order to the build the best roadmap for future growth.

Constantly evolving and growing, OWI MENA 2023 boasts the largest roster of speakers to date, with 20 operator speakers set to lead discussions on key topics such as market status, sustainable well programmes, well integrity, innovative technologies and end of life. Speakers include representatives from ADNOC, Shell, bp, Aramco, and many more.

After taking on board client feedback, there is a huge appetite within the community to hear from North African operators, and this year there is a dedicated spotlight session for the region. OWI MENA 2023 will also exhibit two networking sessions, three breakout workshops and more than 12 demos in the Innovative Technology Showcase Hall in order to further promote collaboration between delegates. 40% of attendance will be from major, independent or national operators, as well as 35 % from expert technology providers, meaning there is ample opportunity to expand individual networks.

For more information and session details, the full brochure can be downloaded here. Any questions regarding the conference please reach out to Rachael Brand at

Despite geopolitical developments such as the fresh Covid-19 wave in China and the outbreak of war in eastern Europe, there are positive indications that an assured oil and gas demand coupled with a stable oil price are setting the stage for a prosperous future for the Middle East’s well intervention industry.

From the explosion of Covid-19 in early 2020 to the Autumn of 2022, global uncertainty unsettled the stability of the oil and gas industry and led to wide fluctuations for the oil price. Within this period, the price ranged from as low as US$21.44 (WTI) to as high as US$122.11 per barrel (WTI) before settling at around the US$80 mark at the end of 2022. As the industry heads deeper into the new year, many commentators are bullish that, partly due to cuts to production by OPEC+, the oil price will stabilise and could even surpass the US$100 mark once again – Morgan Stanley, for instance, has forecasted the Brent oil price to hit as high as US$110. More conservatively, the EIA has suggested the Brent crude oil spot price will average at US$92, which is still a healthy number for those working within the industry.

The EIA has also indicated that while oil demand will remain lacklustre in Q1 2023, it will begin to regain meaningful momentum in Q2 2023 and is likely to go beyond 2019 levels in the process. From a longer-term perspective, OPEC’s 2022 World Outlook 2045 has identified fossil fuel’s continued prominent role within the energy industry for the next two decades and forecasts oil retaining a 29% share in the global energy mix by 2045 with gas holding 24%.

These trends spell happy reading for the oil and gas companies operating within the Middle East and North African region who will have to continue working to increase oil production over the years to meet blossoming demand. However, the environmental concerns have not passed them by and most operators within the region are also incorporating stringent climate objectives to help mitigate their emission output.

So how will these organisations balance the tightrope of greater production and less climate impact? Well, while a number of initiatives are being pursued to help reduce emissions to justify further drilling, one answer lies in well intervention which offers production rate enhancement without the need for further wells to come online. Indeed, with the oil price looking so healthy, there is expectations that the region’s intervention market will rapidly grow over the short- to medium-term as operators have the cash to explore the option. There are more than 10,000 offshore wells throughout the region (on top of the onshore well count that is much higher), according to Rystad, and these have an average well life of 16-21 years, above the global average of 10-15 years. Well intervention, which offers the opportunity to revamp the production rates of ageing, flagging wells, is therefore emerging as an attractive solution to tick all boxes.

Read the full, free-to-read report, including an exploration of the factors shaping business objectives from those operating within the well intervention market.

Thunder Cranes, a leading provider of portable, modular, offshore rental cranes with a dynamic lift capacity ranging from 2 to 60 tons, has re-opened its operations in the Middle East with a base in the United Arab Emirates.

The company’s temporary installation cranes are designed to be versatile and adaptable, with a number of tie-down scenarios, on-deck placement configurations, and boom-length options to choose from.

The cranes allow clients to efficiently and cost-effectively support P&A, well intervention, facility engineering and decommissioning jobs, without compromising safety, time, and performance.

Previously Thunder Cranes had operated in the region with a base in Dubai from 2009 to 2019. The newly re-opened office and yard facility will enable Thunder Cranes to more effectively serve the UAE and Middle East moving forwards.

Dinesh Arumugam, CEO of Thunder Cranes, said, “As a market-leading provider of portable-modular offshore rental cranes, Thunder Cranes is committed to helping customers in the UAE and across the region with cost-effective and efficient lifting solutions to support offshore projects.”

Abu Dhabi National Oil Company (ADNOC) has announced a US$1.17bn contract for the hire of thirteen self-propelled jack up barges to drive offshore operational efficiencies and support the expansion of its crude oil production capacity to five million barrels per day (mmbpd) by 2030.

Abu Dhabi National Oil Company (ADNOC) has announced a US$1.17bn contract for the hire of thirteen self-propelled jack up barges to drive offshore operational efficiencies and support the expansion of its crude oil production capacity to five million barrels per day (mmbpd) by 2030.

The five year contract was awarded by ADNOC Offshore to ADNOC Logistics and Services (ADNOC L&S). Over 80% of the award value will flow back into the UAE’s economy under ADNOC’s In-Country Value (ICV) programme, supporting local economic growth and diversification.

The 13 self-propelled jack up barges are multi-purpose assets that enable rig-less operations and maintenance with single point responsibility proved by ADNOC L&S, enabling efficiencies. The barges, which will be deployed across ADNOC’s offshore fields, are equipped to support a wide scope of operations, including project work, maintenance and accommodation.

Ahmad Saqer Al Suwaidi, ADNOC Offshore CEO, said, “This significant award to ADNOC L&S will help deliver our production capacity expansion in the offshore and directly support ADNOC’s strategic growth objective of 5 million barrels of oil production capacity by 2030. ADNOC L&S have a proven track record in the industry and their best in class expertise, together with the ready availability of the self-propelled jack up barges, will help us drive efficiencies and flexibility while cementing ADNOC’s position as a leading low cost and low carbon energy producer. Critically, the award enables very high ICV, which can stimulate new business opportunities to support the growth and diversification of UAE’s economy.”

Speaking on the contract, Captain Abdulkareem Al Masabi, ADNOC L&S CEO, said, “We are extremely proud to continue the decade’s long relationship between ADNOC Offshore and ADNOC L&S. We are committed to continuing to seize growth opportunities and deliver more value to ADNOC and this announcement is another milestone in that journey.”

The self-propelled jack up barges will be hired along with manpower and equipment. The barges will be utilised for rig-less well intervention and pre- and post-drilling operations, as well as for topside maintenance and integrity restoration activities at our offshore assets.

All requirements of the services have been unified in line with ADNOC’s approach of centralising procurement and operational logistics management. This provides ADNOC Offshore and its strategic partners with operational flexibility while enabling cost efficiencies and single point responsibility by ADNOC L&S.

The award underpins the continued investment and development at ADNOC Offshore and ensures the responsible acceleration of growth and greater value for the UAE, ADNOC and its strategic partners.

At the Offshore Well Intervention Middle East 2022 conference, representatives from BP provided a detailed case study on their successful rigless abandonment of a well in Block 61, Oman.

Aala Abbas, Wells C, I & I Engineer at BP, opened the session by explaining the background of the operation. She noted that the well was drilled back in 2016, targeting the Amin formation and appraising the northern concession of Block 61. The formation is of tight gas which required hydraulic fracturing to produce, and the well was intervened post D&C immediately where the targeted zone was perforated and break down was attempted. This, however, was unsuccessful and, after attempts were made to re-stimulate in addition to extensive testing, the decision was finally made to permanently abandon the well as part of the oil and gas ministry requirement.

“Conventionally, wells P&A jobs are performed via a drilling rig which is very efficient, has a low-risk profile, is fairly straightforward but costly,” Abbas commented. “Hence, we looked into different methodologies and benchmarked them against the rig option which was projected to take 11 days and a cost of one [given as a comparative figure].”

“The second methodology was a hybrid option where the rig and rigless would be used. It would entail killing the well via coiled tubing before setting a plug and cementing the wellbore via a rig. The P&A job was expected to take approximately 12 days of operation at a cost of 1.23. This is quite high but would save rig time.”

“The other option, and the one we selected, was P&A completely through rigless. The well would be killed via coiled tubing before the setting of the plug and perforation above it would be conducted via E-line. It would then be cemented in the wellbore via the cement unit. The total duration of this methodology was approximately 22 days, and the planned cost was 0.73 with zero rig time. There were, however, disadvantages in it being non-standard, relatively higher risk profile and it was the least experienced method.”

The rigless operation, once selected, was divided into four main stages. The first was to isolate the reservoir by pumping cement via coiled tubing covering approximately 530 metres from the well TD to above the pay zone. BP then tagged the cement to confirm its placement and quality via coiled tubing and, post tag, they displaced the well back to one SG before inflow testing the plug and pressure that up to 8,000 psi.

The next stage included setting a copperhead bridge plug across the packer to isolate the shallowest reservoir section and then pressure tested to 7,000 psi. Initially they ran with tubing punch but this was unsuccessful and so they ran with 2-7/8” perforating guns, perforating just above the packer to allow reverse circulation later for the cement job. The injection test was successful with a circulation rate of six barrels per minute.

Continuing the presentation, Sultan Al Abri, Wells C, I & I Engineer at BP, commented, “For the third stage we had to confirm that we had sufficient circulation of cement through the perforation and so, to stimulate that, we pumped a high viscous pill which confirmed the circulation and capability to receive cement through the perforations. After that, we reversed circulated the cement from the A-annulus up the tubing while applying positive pressure on the tubing to avoid having cement free-falling from the annulus. The cement was then given time to cure before running slickline tag to confirm the cement placement and the quality of the cement which was successful.

In the fourth and final stage, the tree was removed, and the tubing and wellhead were cut using a thermal cutter at the surface. The remaining void, from tubing to the annulus side, was pumped with cement using a cement unit with a PVC pipe. After the abandonment the barriers in place included cement across the Amin formation, 15K copperhead bridge plug across the packer depth covering the shallowest reservoir, cement in A-annulus from packer to surface, cement in B-annulus from 13 3/8” shoe to surface, and cement in 4 ½” by 5 ½” tubing from the copperhead bridge plug to the surface.

This was a non-standard operation for the company, and they therefore had some challenges. These included:

• An inability to establish circulation through tubing post tubing punch as the punch tool was not fit for purpose. To remedy that in the future they would select a perforation gun instead.

• Longer WOC duration as the shallowest section BHST was not incorporated into the lab test. In the future the company would therefore ensure lab tests would be performed in a more representative environment and the cement recipe would be optimised.

• Incorrect pumped cement volume due to on site pre-job recalculation using incorrect capacities. This could be avoided in the future by ensuring all changes to the programme are managed by MOC process.

• Inability to cut the tubing due to an inadequate gas weld cutter. The lesson learned from this was to use the plasma cutter for tubing cut.

“Despite the challenges, we delivered the abandonment job with an extra one day than planned but with a 27% less cost than initially expected. For individual service lines we had well testing delivered at about 90% of the planned cost at eight instead of ten days duration; slickline was conducted at the right cost but took an extra half day; coiled tubing was delivered at 65% the planned cost and ran for three and half days instead of five; cementing was completed at about 60% of the projected cost at approximately the same amount of time; and tree removal took the same amount of time as expected,” Al Abri concluded.

“The only service line that we exceeded the planned cost and duration was E-Line and that is attributed to the NPTs mentioned earlier where extra runs were required.”

At the Offshore Well Intervention Middle East 2022 conference, Mustafa Adel Amer, Senior Petroleum Production Technology Engineer and Well Integrity Management at BAPETCO, guided the audience through an expert case study focused on well production and methane abatement.

Adel Amer began by explaining the latest goals set out to reduce methane emissions whereby, at COP26, more than 100 countries signed the global methane pledge to cut methane emissions by 30% by 2030. Methane emissions are now at the centre of climate discussions and the abatement of them is, and will become, key to the competiveness of fossil fuels in the future.

The upstream sector, Adel Amer continued, is assumed to contribute around 80% of the methane emissions in the industry, with the majority of this coming from venting operations. Given the global desire to abate methane emissions, it is therefore of paramount importance for operators to reduce this without affecting production rates.

In pursuit of this, Adel Amer presented a case study from his company which focused on treating liquid loaded gas wells in a method that reduced methane emissions and saved significant money.

Adel Amer said, “Liquid loading in a gas well is the inability of produced gas to produce the entrain liquids from the wellbore. Over time, gas velocity decreases and liquids in the well will impact the lift performance that reduce or even stop gas production.”

“Turner discovered the liquid loading could be projected by a droplet model illustrating when droplets move up or down depending on the velocity relative to a critical velocity.”

Adel Amer explained that is common to use VLP to diagnose liquid loading where, in practice, critical velocity is generally defined as the minimum gas velocity in the produced tubing required to produce with low probability of liquid loading risk.

“With the Turner approach, the droplets accumulate in the large ID section but bubble flow takes place at the very low gas flow rate, you need very low gas rate usually at the far left end of the VLP curve. In many cases you don’t see the size of liquid columns that you would expect to balance the drawdown when the well is shut in for cycles.”

Mustafa, in his presentation, presented technical analysis showed that wells that operate in their unstable, hydrostatic dominated, part of their VLP suffer from increased liquid holdup along the entire well.

“We therefore need to focus on increasing velocity across the entire well,” Adel Amer remarked.

In order to do so BAPETCO showed a solution performed on an old well located in an onshore gas field with over 10 wells suffering from liquid loading and run under manual unloading cycles. The well chosen was an old one, beyond 17 years of operation, which had a five inch completion. The task was to end the cyclic behaviour of wells to increase production and eliminate methane emissions.

Considering the context of the field and the company in terms of near wellbore damage after well killing and the well integrity manual that mandate having operable sub-surface safety value in all gas wells, the best solution as Adel Amer said, “was to run a velocity string without killing the well while maintaining the sub-surface safety valve operable and without reliance on a snubbing unit.”

They began by conducting surveillance to select the best candidate wells through in-house developed python code that analyse reservoir data, production data, well history, and well integrity history to gain insightful analytics of the well integrity failure history, potential gain, clearance of the well etc. They then selected candidates and examined the potential in terms of possibility of success and expected gain.

Once done, they went to the PIPESIM to model the surface network and make sure production gains coming from fixing the intermittency of the gas wells would not be constrained by network capacity or connection with other high pressure wells in the network.

The modelling results indicated that inserting 2 7/8 inch completions reduced the risk of liquid loading over the completion string and maintained liquid loading velocity ration favorable for stable gas production.

In practice, to run the velocity string without killing the well, without snubbing units and while having operable sub-surface safety valve, the operating included:

• Rigless inspection of the existing five inch completion and settling an isolation packer with surge disk.

• Workover to run the 2 7/8 inch and set an upper packer below the sub-surface safety valve.

• Rigless coiled tubing to unload the brine and break the surge disk.

Adel Amer said, “This was completed successfully and the project converted the well from one with a fluctuation intermittent behaviour to a more stable state. The stability of production increased to 2.5MMSCF/D after applying the velocity string, up from a 1.5MMSCF/D the day before the project.”

The project helps to achieve various positive results including:

• Cost reduction: the cost of using workover rig to run the 2 7/8 inch tubing inside the existing 5 inch completion was only 10% of a snubbing unit with payback time of 5-6 weeks.

• Increased the gas production rate by 1.5 times and condensate production by 3.8 times.

• The monthly reduced GHG emissions per well is equivalent to 4.4mn miles of passenger vehicle emissions.

• Reduced workload on production operations from elimination of manual unloading.

• Maintained compliance with well integrity standards.

Abel Amer concluded, “We now have a new way of dealing with intermittent gas wells which is less expensive, does not kill the reservoir and maintains an operable sub-surface safety valve. Even though liquid loading is a dynamic process, using PIPESIM provided very useful clue to estimate the liquid loading velocity ratio which was among the main design parameters.”

Abel Amer can be contacted through his LinkedIn profile here.

Page 1 of 3