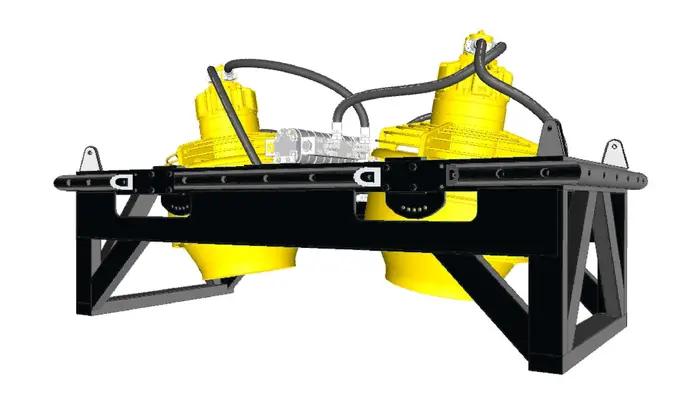

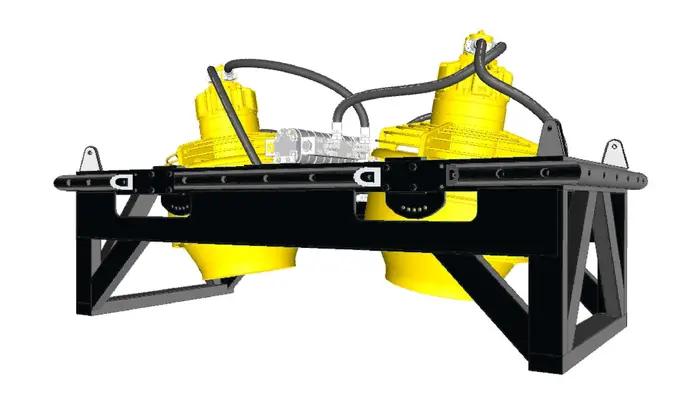

In a unique case study, Thunder Cranes has explained how it provided lifting support for coiled tubing operations in offshore Dubai, UAE, with cranes designed for portable use and ease of assembly & disassembly on offshore installations.

During planning for the coiled tubing operations it was determined that there was insufficient space to accommodate all of the coiled tubing equipment on the platform deck that was located directly over the wells identified for intervention.

As a result Thunder Cranes needed to make use of an adjacent platform, located 50 feet away, and so the company designed a lifting plan using two cranes and both platforms to carry out the lifting support required for the project.

For the purposes of the case study, they were named "Platform A" and "Platform B" and the company provided a summary of the steps carried out:

• Using the existing platform jib crane Thunder Cranes lifted the component parts of the 20 ton crane (TC20) from supply vessel to Platform A.

• Once TC20 was rigged up and load tested it then lifted the component parts of the 90 ton crane (TC90) from supply vessel to Platform A.

• After the TC90 was rigged up it rigged down the TC20 and lifted all of the TC20 components from Platform A to Platform B.

• TC20 was then rigged up on Platform B.

• TC90 was able to pick up the coiled tubing reel, with a long enough boom to be able to hook to the coiled tubing pipe and pull it over from one platform to another to be run through the injector.

• Over on platform A, working in tandem with the TC90, the TC20 lifted, rigged up, and helped support the coiled tubing injector.

In the case, the company rigged up and load tested two days within seven days thank to the TC clamping method, the modular design of the cranes, and the highly experienced staff.

In the project, TC20 and TC90 cranes enabled the coiled tubing work to begin ahead of schedule and was a safe & cost effective solution compared to alternative methods.

Jordan Whyte, Head of Commercial & Business Development at Gulf Marine Services (GMS), explained to Offshore Network how the company is facilitating more efficient heavy well intervention operations to save time and costs.

In the Middle East, attention is firmly fixed on increasing production. While the energy transition has threatened to shake confidence, key players have reaffirmed their faith in the oil and gas market in the years ahead by looking to increase production – Saudi Arabia’s Aramco has signalled its intention to increase oil production to 13mn bpd (up from 12mn bpd) and ADNOC is aiming to boost capacity to 5mn bpd (up from 4mn bpd).

Within the region, Whyte explained, one of the most favoured ways of increasing production is to workover existing wells using the likes of jack-up barges to re-stimulate wells in shallow waters. It is for this reason that of the 12 barges GMS currently has in the Middle East, around half are presently engaged in some form of well service operations (there is another barge in the North Sea working in renewables).

“Covid-19 dramatically delayed a lot of contracts of course but, subsequently, these have been reactivated. Now it is in overdrive, driven by these production targets and allied to the large population of existing shallow water platforms; the simplest and most efficient ways to reach these is by using jack-up barges. While we are not downhole engineering experts, we are the medium to carry out these operations and currently have high utilisation levels due to the production boom,” Whyte said.

GMS’ Evolving Capacity

Standing apart in GMS’ fleet is the Evolution self-propelled, self-elevating well intervention barge which was commissioned back in 2017. Fitted on board is the bespoke cantilever workover system, delivered in collaboration with Norwegian-based Dwellop.

This unit skids hydraulically from the main deck of the barge out of the back end for the best part of 50 ft; has a light weight drilling derrick that comes complete with top drive system; and has a high level of automation such as a pipe handling system that will pick pipe up off the deck and feed into the top drive before running in hole. There is also an automated iron roughneck on board and everything is run from a driller’s cabin on the side of the unit so that pipe can be tripped in and out of the well at significant speeds (up to 1,000 ft an hour). Below the deck is also a full Mud System with everything normally associated with a drilling rig; enhancing the vessel’s capacity.

Whyte remarked, “In a sense it is very similar to a jack-up rig but it is a hell of a lot lighter and thus can skid out over a platform much faster (typically only 30 minutes). There is some transverse movement which means we can also skid left to right in order to workover adjacent wells without having to necessarily move the barge itself. When we do have to skid back, rig down and move elsewhere, we can typically do so and be ready to work at another location within 24 hours. This is significantly faster than a jack-up rig for example which can take the best part of two to three days and even more if the weather is poor. Not to mention the fact no tug-boats are required to get it to the next location due largely to our clients comfort operating Evolution in DP-2 mode when approaching platforms. As a result, the Evolution can workover up to three or four times as many wells per year compared to a typical non-propelled drilling jack-up in any given field.”

“We are trying to bring down the costs of all brownfield workover operations and the Evolution offers flexibility and cost saving due largely to the superior marine efficiencies.”

The Evolution was purpose built for P&A and workover scopes but can also perform some drilling operations. Whyte noted that it is really only limited by the amount of tubular piping that can be carried on deck (and a few others such as top drive torque capability and hook load) and the 200t crane on board means it even has the ability to remove small jackets although that has not been done to date.

In once case study provided by GMS, the Evolution was contracted by an Arabian Gulf NOC for a well intervention scope covering various operations. The barge jacked up alongside a similar vessel to transfer well services equipment (which was moved across and commissioned in a record two days) before sailing to the platform tower, jacking up and deploying the cantilever system. The unit was ready to commence operations with three hours (saving 90% rig time) and rig up of well services equipment was completed in 31 hours (achieving 15% time saving). Following this, rig down of well services and preparation for the barge to move was completed in just 14 hours.

On the Horizon

Currently the Evolution is performing legacy work for Qatar Energy (QE) on a field which was previously operated by Occidental Petroleum for around 25 years. The former owners used a more traditional method of workover which QE continued until GMS suggested that the Evolution would be more efficient. In the 18 months since then, the Evolution has been proving its worth and this is without even reaching its full potential.

“In truth we are not even at the stage where we are using Evolution at 100% of her capability but we are certainly working towards that. As it gets more tried and tested and both the crew and client gains confidence, we will be more prepared to tackle more difficult workovers and remediation projects. But it is fair to say that, so far, it is going well and QE appreciate the marine efficiencies being achieved,” Whyte noted.

Pushing, the Evolution to greater heights is just one of the targets on the horizon for GMS, Whyte continued. The company has recently taken a big step in its digital journey by signing a contract to install an enterprise resource planning system which will provide the company with an interconnected system across its operations, giving it the ability to upgrade internal procedures; integrate vessel operations, maintenance, procurement and inventory control, alongside crew and payroll management; and centralise data for better visibility. Whyte surmised that while it will not be fully up and running for a couple of months yet, the company has already started to feel the benefits (most notably in the real-time communication between offshore and onshore) which is a promising sign for the digital road ahead.

Another exciting development is through the delivery of a lighter cantilever system which the company is looking to push across the line for commercial use. This is, as it says on the tin, a lighter version of the system which can be used for all well services which do not require tubing to be pulled from the well.

Whyte said, “It can skid out just as far and can be retrofitted to existing vessels. There is a lot of interest from NOCs for this and we are looking for more opportunities for the cantilever system and its lighter cousin. As the rig rates continue to rise and move away from barges, we think our offerings will become increasingly more attractive to operators for both heavier and lighter workover operations.”

Finally, Whyte concluded by noting that the company is keeping an eye on other regions for which its fleet could be deployed with regard to well service and workover operations.

“West Africa is finally waking up to well servicededicated barges; in the North Sea there is some increased activity in terms of P&A; and there is interest from regions such as Asia and Australia to bring in some of our barges. The Evolution is capable of operating anywhere with water depth of around 70m and has proved herself in other regions such as the North Sea before,” Whyte continued.

“We put no barriers on where we work as long as the economics work out. That being said, such is the boom and demand here that, at the moment, we are very focused in the Middle East region. The Evolution itself has been working in Qatar for the last two years and fingers crossed we expect her to continue there for some time.”

OWI ME 2022

GMS will be speaking further on this at OWI ME 2022 on the 28-29 March 2022 in Dubai, UAE. Register here or reach out to Rachael Brand on the details below for more information:

Rachael Brand

Project Manager, Offshore Network

t: +44 (0) 20 3409 3041

e:

Unity, one of Europe’s largest providers of well integrity solutions, has launched a new range of compact technologies to solve common industry challenges and support Unity’s surface well integrity, shallow intervention and well decommissioning services.

For offshore operations, the new products reduce well bay space requirements, simplify and accelerate offline mobilisation and reduce person on board, cost and risk. Due to these efficiencies, the products all offer between 50-75% savings in OPEX.

The new technology range includes a compact dual-bore xmas tree isolation system, a compact valve removal tool and a compact shear-seal valve. The products complement Unity’s existing Surface Intervention System (SIS), the first product in this compact technology range. It is already delivering multi-functional operations such as inspection, plug setting, milling and xmas tree removal, at reduced cost and improved efficiency compared to wireline or coiled tubing intervention. The SIS is the most compact of its type on the market with a footprint of around 2 sq ft, requiring only two technicians to operate.

The new dual-bore xmas tree isolation system has a footprint of just 1.5 sq ft with an operating height of only 6 ft above the well cap. It can be mobilised and deployed rapidly for shallow plug setting, particularly suited to support and reduce the cost of P&A operations. It can be deployed offline without the need for traditional intervention equipment, saving around 60-75% or more per well. Time savings from rig-up to rig-down are in the order of two to three hours compared to two to three days for wireline or coiled tubing interventions and the system is quickly and easily moved between wells.

The valve removal tool is also designed for use in cramped well bays and delivers an impressive, industry leading, 1,200 ft/lbs torque with optional hydraulic operation without the associated space normally required for such operations. Its rental price is around 60% lesser than similar products.

The new compact shear-seal valve is designed to reduce the weight and geometry of intervention pressure control equipment. It utilises a hydraulically actuated ram but is 50% lighter and 30% smaller than the next closest comparable product. It is rated to cut slickline, wireline, SIS rods and coiled tubing and is modular in design, allowing dual redundant stack-up configurations. Its compact size and reduced weight improve handling and help to reduce concerns over structural integrity on late-life assets.

Gary Smart, CEO at Unity said, “Unity is engaged in long term contract work on over 1,000 wells around Europe, the Middle East and Africa. Our investment in this new compact technology range has followed on the back of significant contract wins over the last 18 months, which have highlighted several common technical challenges faced by the industry, particularly in the late-life, P&A and well decommissioning market. We are very excited to be offering such an impressive step-change in savings and technical advancement to the market.”

D&A GOM 2022

Innovative technology for decommissioning and related operations will soon be on display at D&A GOM 2022, arriving in Houston, Texas, on 18 May. At this event, the offshore community is set to reunite face-to-face to discuss the challenges and opportunities marking decommissioning and abandonment in the region, listen to sessions delving into current complex situations and network to help each other optimise their strategies. To find out more, download the brochure: www.offsnet.com/da-gom/conference-brochure

Or contact:

Joseph Watson

Project Manager

Offshore Network Ltd.

t: +44 (0) 20 3409 5720

e:

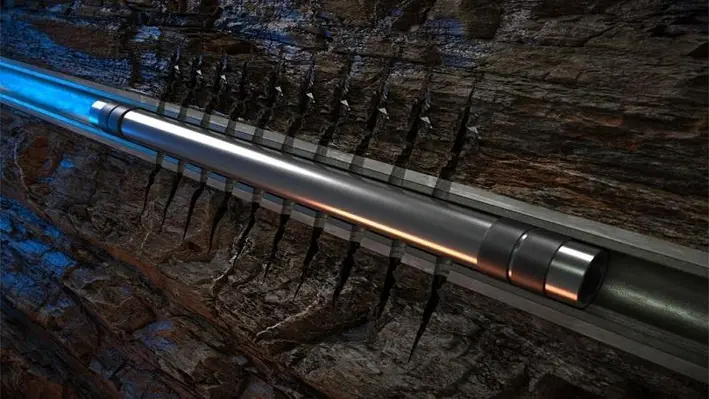

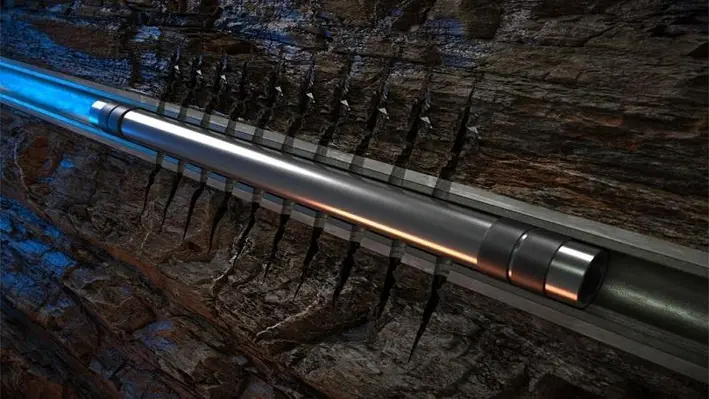

ReLineWL, the expandable technology designed to unlock greater commercial value by maximising production from existing wells, has been successfully deployed in the Middle East for the first time by developers Coretrax.

The global well integrity and production optimisation leader’s ReLineWL is a one-trip, wireline deployed straddle system to address common well integrity issues.

It is proven to deliver a 700% greater flow area when compared to traditional straddles, securing safety and sustainability benefits by reducing the number of onsite personnel required to complete the work.

Introduced in the Middle East for the first time, ReLineWL was deployed to support a major Saudi operator when water ingress on a producing well led to decreased oil recovery. Two ReLineWL 28ft straddles were deployed on e-line, enabling the operator to isolate several perforation intervals to shut off water production zones.

Compared to traditional tools, the ReLineWL’s outer diameter (OD) allowed the system to pass through restrictions before they were expanded and set at almost 7,000ft. The tool delivered a large post-expansion inner diameter, providing maximum production conduit to surface over conventional options.

The well was successfully brought back online with a 31% reduction in water production and additional oil production of 1,400bbls/day. With the requirement for surface water management also reduced the application also significantly reduced the operator’s carbon footprint.

John Fraser, Chief Executive Officer of Coretrax, commented, “The Middle East is a key growth area for Coretrax and the first deployment of our ReLineWL in the region is a significant milestone for the business as we continue to enhance our technology portfolio to support the most complex well integrity challenges. As operators remain focused on maximising recovery efficiently and sustainably, our expandable technology is ideally placed to support this demand.”

Available in various CRA materials, the tool can be configured to smart completion products such as autonomous inflow devices (AICDs) to enhance production by selectively eliminating gas and water production and provide a comprehensive workover solution.

The RelineWL has a high expansion ratio of 75% and is designed for stackability creating a longer, integrated straddle to be deployed, without losing ID. This also allows operators to gain access below if well intervention is required at a later date.

“The ReLineWL already has a proven track record in North America and I’m excited to see this successfully deployed in the Middle East for the first time. As we head into 2022, we already have a healthy pipeline of projects in the region and look forward to working closely with our customers to transform current well performance and deliver greater operational efficiencies,” Fraser continued.

Tony Branch, a former President of Weatherford’s Regional Operations, will lead Westerton Access, an industry leader and technical innovator in the provision of subsea and topside inspection solutions, and the recently-launched Westerton SplashZone Integrity Specialists (WSIS), a company specifically formed to tackle the highly corrosive and problematic area immediately above and below the water line.

The companies are part of the wider Westerton portfolio, which includes Westerton’s fishing and intervention service.

Robin Porter, Founder of Westerton, said, “We are pleased to have Tony on board, and look forward to working with him. He is experienced in executive leadership roles and has led companies through transitional periods, including the launch of new product lines, so his skillset is well-suited to the newly structured Westerton group of companies.

“He has a proven track record in merging different operations into one cohesive team and I am excited at the prospect of increased growth and collaboration we will see across our specialist companies.”

Branch, who has more than 30 years worth of experience in the industry, commented, “I am excited to be joining a talented, dynamic and client focused team with a strong technical offering. The business has a strong foundation, and I am looking forward to working with the team to help deliver results for our valued clients.

“Building on our recent and successful expansion into the Middle East, we have further growth aspirations, both in terms of geography and the size of the organisation, and I look forward to playing a part in that, along with the rest of the team. Our Access and WSIS services both solve significant problems, not only in our traditional industry of oil and gas, but also in other sectors such as offshore wind."

Branch added, "All structures that are in the ocean are subject to harsh operating conditions and need to be inspected and repaired, regardless of whether they are oil and gas platforms or a wind farm. These assets need to be inspected quickly, efficiently and more cost effectively than traditional vessel-based services currently offer, and with the skills, technology and experience we possess, that is something we are more than capable of doing, saving operators money.”

The appointment of Branch comes after the company has expanded its footprint in the Middle East with new offices in Dubai.

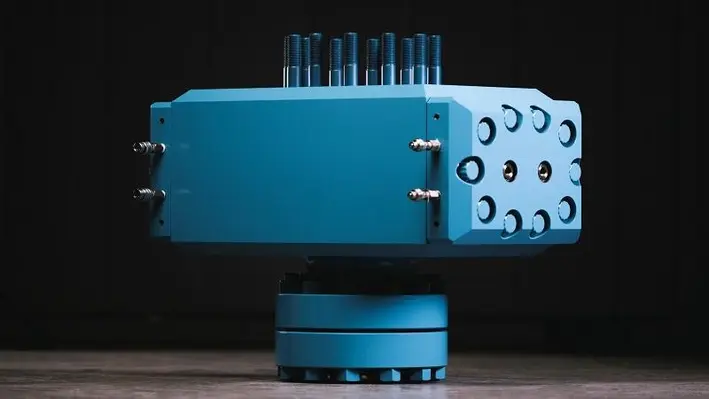

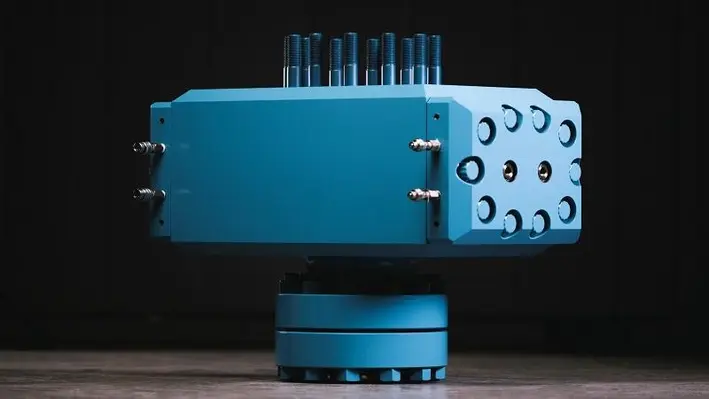

Expro has launched Galea, the world’s first fully autonomous well intervention system, designed to maximise production while reducing intervention costs, HSE risks and environmental impact.

Galea replaces larger, conventional and more labor-intensive wireline rig-ups for a range of slickline operations such as solids removal, plug setting/pulling and logging surveys. It can be configured in a variety of operating modes to suit a range of applications onshore and offshore.

Max Tseplic, Expro’s Vice-President of Well Intervention, explained, “Galea maximises production while reducing operational overheads by using an intelligent, autonomous system to perform a variety of slickline operations.

“Frequent, routine interventions typically involve significant manpower and equipment, which are costly. Planning these operations is often restricted by the availability of hardware and crew. The environmental impact of regular interventions, and the movement of vehicles and equipment, are also significant, as is the HSE risk to crew in travelling to and from well sites and performing operations.

“Galea eliminates these challenges by removing the movement of people and equipment to the well site for each intervention. Remote control and 24/7 monitoring reduce HSE risk and allow production to continue in inaccessible areas. The reduced environmental impact of using Galea helps asset managers comply with environmental regulations.”

In fully autonomous mode, Galea deploys a tool string into the well either at regular intervals or as defined by the well conditions. In semi-autonomous mode, Galea performs a pre-programmed intervention sequence, initiated locally or remotely. A small, self-contained intervention package permanently located at the well site eliminates the need for a wireline unit or truck.

In manual mode, Galea enables quick rig-up intervention compared to conventional operations. When not in use, the system occupies a fraction of the well site or deck-space required for a standard slickline winch unit and PCE package.

Galea also has several fail-safe features to ensure containment and eliminate potential wire-breaks during operations.

Expro Group Holdings International Limited (Expro) has reported its financial and operational results for the three and six months ended June 30, 2021 with total revenue for Q2 2021 standing at US$176.3mn, compared to revenue of US$156.3mn in Q1 2021, an increase of 13% sequentially.

Expro Group Holdings International Limited (Expro) has reported its financial and operational results for the three and six months ended June 30, 2021 with total revenue for Q2 2021 standing at US$176.3mn, compared to revenue of US$156.3mn in Q1 2021, an increase of 13% sequentially.

The company’s net loss for Q2 2021 was US$8.4mn compared to a net loss of US$20.4mn for Q1 2021. Adjusted EBITDA of US$26.3mn increased 58% sequentially, driven by higher revenue, a more favourable activity mix and lower corporate costs.

Mike Jardon, CEO of Expro, commented, “Expro delivered solid performance in the second quarter as our broad portfolio of services, global operating footprint and continued cost and capital discipline enabled us to effectively manage and mitigate ongoing industry headwinds related to the pandemic.”

Intervention leads the way

Jardon continued, “Thanks to the hard work, expertise and commitment of our talented employees, as well as our leading technology platform, we continued to advance our capabilities and deliver differentiated services and solutions that safely enhance our customers’ operational efficiency and improve the sustainability of both Expro’s and our customers’ operations.

“For example, Expro employed its unique CoilHose intervention system to initiate production by unloading heavy completions fluids from a highly deviated well in Asia. This solution successfully delivered both time and cost efficiencies to the client. Additionally, the compact system footprint and associated ease of logistics resulted in a significant improvement in the environmental impact of the operations as compared with traditional solutions.”

“Also during the second quarter, we achieved an industry first by deploying our unique Octopoda annulus intervention system to a depth of 300 metres in the C annulus of a well in Latin America. This system successfully introduced a plug in the annulus which restored casing integrity and enabled production to be safely resumed from the well. We are very excited about the potential of Octopoda as it will allow customers to, cost effectively restore well integrity, resume production and reduce fugitive gas emissions from wells,” Jardon added.

“In recent years, the majority of Expro’s business has been driven by our customers’ production optimisation efforts and their operational expenditures more so than their drilling-related activities and capital expenditures. As a result (and despite the possibility of continuing headwinds related to the pandemic), we currently expect at least modest revenue and margin momentum for Expro over the next couple of quarters, driven by an overall increase in international activity, and positive trends in well testing and production services and well intervention and integrity services, in particular. Beyond the next couple of quarters, an expected recovery in offshore development across geographies reinforces our confidence that Expro is well-positioned for sustained growth, which we believe will be driven by increasing demand for subsea well access services and more complex well construction services, respective strengths of Expro and Frank’s International with whom we announced a definitive merger agreement on March 11, 2021.”

Regional breakdown

The company report noted that their operations in Asia Paciifc were particularly strong primary driven by higher subsea, completion and intervention services revenue in Brunei and Australia. In Brunei, Expro is in the start-up phase of a multi-year well intervention campaign, while in Australia, results benefitted from a generally higher level of customer activity and higher well testing services revenue.

Revenue in MENA was driven by higher subsea, completion and intervention services in Qatar and Algeria. The year-over-year decrease in MENA revenue was primarily driven by lower well testing services revenue in Algeria and Egypt as a result of lower activity levels, partially offset by increase in subsea, completion and intervention services revenue from a new project in Qatar.

In North and Latin America revenue sequential improvement in was primarily driven by higher subsea, completion and intervention services revenue in Argentina, reflecting a strong recovery in activity following Covid-19 related project delays in 2020, and higher well testing services revenue in Mexico and the Gulf of Mexico, which were largely offset by lower subsea, completion and intervention services revenue in the Gulf of Mexico from lower customer activity. The year-over-year improvement in segment revenue was primarily driven by higher well testing revenues in Mexico, higher subsea, completion and intervention services revenue in Argentina and Columbia.

At the Offshore Well Intervention Middle East and North Africa 2021 virtual conference, Neil Ferguson, Business and Sales Development Manager, Well Intervention and Integrity at Expro, demonstrated Expro’s two latest developments in well integrity developed to unlock value for operators.

At the Offshore Well Intervention Middle East and North Africa 2021 virtual conference, Neil Ferguson, Business and Sales Development Manager, Well Intervention and Integrity at Expro, demonstrated Expro’s two latest developments in well integrity developed to unlock value for operators.

Ferguson began by noting that it is an exciting time to be involved in well integrity, an area which is attracting more interest from the industry each year. At Expro, ten years ago the main focus of the Well Intervention portfolio was production optimisation, whereas now 50% of its portfolio is well integrity related. To this end, Expro has recently introduced two new technologies to add to their product offerings to serve this market.

Fibre Optics Enabled Slickline

As Ferguson continued, fibre optics is nothing new to the industry and has, for many years, been permanently deployed in wells to monitor wells and identify problems. However, having this installed from the start of the well’s production is, for one, very costly (could amount to around US$500,000) and can also cause problems down the line. For instance, if an operator is relying on these fibre optics 10-15 years after installation the equipment may not function as effectively, with the fibre darkening for instance, meaning operators may not get the correct results they need when they need them.

Expro, therefore have introduced Distributed Fibre Optics Sensing (DFOS) Slickline which is able to be deployed into a well using a standard slickline unit. The DFOS Slickline service means that an operator only needs to deploy the fibre optics when and where they need it, rather than having it permanently installed from the start of the wells life. Expro has the capability to retrofit the fibre into the well for a few hours, get the required results and then it can be redeployed onto the next well – a development with the capacity to optimise capex at the start of a well’s life and opex throughout its life. The DFOS Slickline is capable of diagnosing a range of issues such as tubing to casing leaks, flow behind casing, gas lift valve leaks, leaks at packers, leaks at casing shoes, sustained casing pressure and sand protection.

Ferguson said, “One thing our solution partners worked hard on is our ability to process data on site. Traditional fibre optic can generate terabytes of data per day – we didn’t want to just hand our customers a hard disk of this at the end of the job, so having visualisation and analysis on site was very important to us. Therefore, as part of our offering, we reduce and streamline the data so it is easier to transmit and interpret – we can reduce 2.5 terabytes of raw data into a 30mb manageable file.”

To emphasise the capabilities of this technology, Ferguson demonstrated its use in some case studies. For instance, in the North Sea, DFOS Slickline was used to assist a customer suffering from a tubing to annulus communication issue. The DFOS Slickline was rigged up on the well and took just over 1 shift to perform a survey, before being pulled out again. DFOS Slickline has two embedded fibres; one for distributed temperature sensing mode and the other for distributed acoustic sensing mode, with acquisition from both fibres occurring simultaneously. While the DFOS Slickline was being pulled out of hole the data processing and visualisation task began, the DTS data processing and visualisation task taking just one hour, with the DAS data processing and visualisation task taking just three.

The well integrity issue was swiftly identified as a side pocket mandrel having a faulty gas lift valve leaving the operator free to pursue remediation activities immediately, with the intervention equipment still rigged up onto the well. In this way a customer’s shut in well (which was costing around 2,000 barrels per day in lost production) was swiftly restored to production. Because the DFOS Slickline is so efficient, the operator can go from deployment to remediation in the same intervention and campaign.

Octopoda

Ferguson then turned to the Octopoda Well Integrity Solution, featuring offerings such as line plug services, sealant services and wellhead multi-tools. The crown jewel, however, is the annulus intervention (AI) service, this innovative technology enables intervention into a live annulus with a hose, this to remediate well integrity issues by the pumping of fluids and resins.

In one case study that Ferguson outlined, Octopoda AI was run into the annulus to remediate a fluid barrier. The customer had issues with plugged bleed-off line due to a high viscocity mud in the B-annulus. A subsequent influx of gas into the B-annulus caused a problem which resulted in the well being shut-in. It was estimated that a traditional lubricate and bleed operation would take around 12 months to complete, so the customer called Expro, who was able to design a tailor-made solution with a 6mm hose and tailor made well spring tool to enable intervention into the B Annulus.

To remove the sustained casing pressure, the annulus fluid was displaced with 1.5SG brine. During the operation the annulus intervention system was deployed to a depth of 49m depth below the B-annulus gate valve, a total volume of 40,000 litres of 1.5SG brine was pumped, there were no spills or incidents reported, and the operation was successfully completed with the well flow being reinstated in 25 days.

Octopoda AI can be used in a variety of applications including the removal of sustained casing pressure, spotting of resin for casing integrity remediation, corrosive fluid displacement, preparation for P&A operations and environmental and groundwater protection. Ferguson stated that some of the benefits included cost effective well recovery by restoring well integrity, efficient footprint and personnel requirements, rapid mobilisation of the technology, and a reduced requirement for a workover rig or heavy duty equipment.

At the Offshore Well Intervention Conference, Middle East and North Africa 2021 host Tural Yusuboc, Senior Engineer of Well Integrity at ADNOC, was joined by an experienced panel to discuss the pressures shaping the well integrity market and the factors that will drive change for the discipline in the future.

At the Offshore Well Intervention Conference, Middle East and North Africa 2021 host Tural Yusuboc, Senior Engineer of Well Integrity at ADNOC, was joined by an experienced panel to discuss the pressures shaping the well integrity market and the factors that will drive change for the discipline in the future.

Briefly outlining its history, Fayez Issa, Group Well Integrity Advisor for ADNOC, commented, “Well integrity has gone through different stages. If you go back 30-40 years it did not exist, there was minimum knowledge. But then after many incidents and major catastrophes the knowledge of oil integrity has become a vital aspect of oil and gas. It changed a lot ten years ago after the events on the Macondo field in the Gulf of Mexico. Before, people could happily ask things like do we really need to log cement? Is it important to see variations? Do we need special requirements for a gas lift? Additionally, a lot of things were done at minimum costs. Now if a well is planned to last for thirty years it has to be designed to last that long, a change partially due to the environmental challenges and more stringent regulations.”

Nowadays well integrity is a much larger concern for the industry, emphasised by Neil Ferguson, Business and Sales Development Manager of Well Intervention and Integrity at Expro Group, who noted that Expro now has 50% of its portfolio dedicated to this discipline whereas 20 years ago it was just 20%.

Exemplifying why well integrity and surveillance is such an important topic in today’s world, Mustafa Adel Amer, Well Integrity Focal Point at BAPETCO, said, “Ten years ago BAPETCO started doing well integrity management systems which accelerated the building up of knowledge. But unfortunately after the crash in 2014 the company took the decision to save costs and stop things such as corrosion logs etc. Now after six years the company is going to pay more to fix the unknown causes of corrosion and will have to probe the wells.”

While the discipline has grown significantly over the last few decades, the panellists noted that there was still room for improvement. Ferguson, suggested that there was perhaps a bit of a disconnect from integrity as it was so often bound up as part of drilling and production. The participants suggested that if well integrity is kept within these departments it might not perform its role as effectively, but having well integrity as a separate entity within companies would empower it to do so.

Abandonment

Switching the conversation slightly, Ferguson turned the focus on well integrity related to abandonment. He said, “One of my concerns is how do we help customers safely abandon their wells when they need to stay abandoned. There is now an expectation that once abandoned, these wells stay that way forever. The next challenge is figuring out how to do best possible job to ensure integrity in not just in a well’s operating life but once it is abandoned also. I don’t think we will be able to just forget these wells once they are abandoned and there will be elements of risk that will continue to challenge the industry. We have a huge responsibility as we move forward as to what we categorise as well integrity.”

Abandonment remains a difficult topic for the industry as, at the bottom line, it does not return any profit. As the panellists noted, drilling wells is exciting as you then get the reward, but this is not the case with abandonment and so often it can be neglected. This is exemplified by Bloomberg projecting that more than 32 millions wells worldwide are no longer producing and awaiting proper abandonment.

To ensure these operations are carried out and, importantly, are done so in a proper way to ensure the integrity is not compromised, the panellists suggested that cost must be projected forward, so that operators can plan for these financial hit in advance rather than bear the brunt unexpectedly at the end of a well’s life. Additionally, more stringent regulations would ensure that abandonment would be a requirement, but of course the implementation of regulations varies from region to region. Ultimately, the panellists agreed, if there is an event relating to an abandoned well’s integrity, it could easily be a catastrophic event that will affect everybody, not just the local region. Therefore it is also the responsibility of the oil and gas industry, not just the regulators, to ensure the integrity and abandonments of wells is taken seriously and performed in an environmentally responsible manner.

The role of technology

The participants noted that technology has played, and will continue to play, a huge role in the well integrity sector and, in recent years, perhaps the most significant advancements have been made with AI and big data.

Ferguson said, “AI is used in just about everything else we do in day to day life, so why shouldn’t we use it to our advantage in our industry to give us a predictive view on well integrity issues. We are in the era of big data and digitalisation, and there is so much data to look at that is very easy to miss some key information. The capacity for AI to interpret data and predict well integrity issues in the future is a huge cause for optimism and I think it is going to be hugely important moving forward.”

Adel Amer commented, “One of the challenges of performing corrective actions was the unavailability of material. We had one well, for example, that had three failures and we couldn’t acquire the material to replace the faults for one and a half years. But just replying on a simple data model, we can plan ahead for such instances by seeing how many faults occurred in previous years to predict what material we will need in the future. I think more solutions like this are going to come up if we make data available to these smart minds.”

Although enormous strides have been made with digitalisation and AI the panellists noted that there were still areas for improvement which would greatly enhance well integrity capacity. For instance, Issa noted that while there is a lot of data being collected from various sources such as corrosion logs, cement logs etc, there was still not enough surveillance data being conducted. Improving this would only enhance the ability to predict issues and rapidly remediate them.

Another area of improvement is centred around data sharing. As noted, the more data available the easier it is to predict potential issues in the future and, while perhaps there is scope for acquiring more, collectively oil and gas operators hold a plethora of data from locations across the world. If companies were more visible with their data, it would enhance opportunities to rapidly remediate wells and ultimately capture value for operators.

“But this is something the industry is not keen on, sharing products and data. This hinders a lot of the opportunities that could be unlocked without really spending any money,” noted Adel Amer. “If we want to move forward in the digital era we need to exchange data and make data sets available.”

The Covid-19 effect

The panellists also turned to how Covid-19 had affected the well integrity discipline, noting that perhaps the most significant change, which will most likely last into the future, was the withdrawal on reliance from externals. For instance, Adel Amer noted that in Egypt typically the company orders a lot of materials from abroad but this was, of course, dramatically hindered by travel restrictions and so, instead, local companies began manufacturing more advanced equipment. There was also an emphasis on training to ensure that the expertise was available within companies rather than seeking it from exterior sources. Issa noted that in ADNOC the company has recently issued a well integrity e-learning which was mandatory not only for those related to the discipline but also drilling and operation etc to ensure all employees know what they should be looking for.

It was clear from the discussion that while the discipline of well integrity had taken great strides over the last few decades, things such as lack of surveillance and a reluctance to share data was holding it back. Addressing these obstacles would only enhance the field, which would ultimately lead to healthier wells with extended production lives capable of providing more value to operators and the industry.

SEAJET Systems has launched to the subsea intervention market to provide the ability for companies to own and operate the most advanced controlled flow excavation (CFE) technology without third party interference, providing a more flexible, cost-effective and efficient solution.

SEAJET Systems has launched to the subsea intervention market to provide the ability for companies to own and operate the most advanced controlled flow excavation (CFE) technology without third party interference, providing a more flexible, cost-effective and efficient solution.

Established by industry leaders Hector Susman, a pioneer of industry-leading excavation equipment, and Faisel Chaudry, who has more than 15 years’ experience in the sector with Rotech Subsea, Reef Subsea and James Fisher, SEAJET offers one of the most versatile CFE systems on the market. Developed by optimising existing CFE equipment, the company’s build-to-order technology introduces advanced hydrodynamic properties suitable for a wide range of applications and variable seabed conditions. SEAJET offers a tailored aftermarket support package to inspire client confidence to own, operate and maintain their own-in-house CFE equipment.

Chaudry commented, “We’ve launched SEAJET to meet the significant demand for cable trenching and de-burial in the rapidly growing offshore wind market. In addition, the use of CFE equipment continues to escalate in the inspection, maintenance and repair, decommissioning and salvage applications across oil and gas and marine sectors. Our unique mix of expertise in this specific area of subsea intervention provides customers with a solution they can trust.”

Susman added, “Having designed 95% of the CFE tools available on the market today, with the new SEAJET excavator, I have taken all lessons learned over that 25-year period and introduced the most advanced CFE system to date. Our technology has been optimised to work in the widest range of applications and soil conditions. We have honed the real sweet spot between flow and velocity, resulting in something others cannot offer – a flexible solution with enhanced performance and a business model that has efficiency built-in at every turn.”

Headquartered in Dubai, with operations in Europe and South East Asia, the company currently employs a team of seven people. Together, the senior management team has delivered more than 30 builds of MFE/CFE systems and execution of over 600 trenching/excavation projects globally.

The rate of technological advancements is advancing, and it is pulling the oil and gas industry into new realms of digitalisation, automation, AI and more. The field has become more competitive and yet, despite this, the latest innovation from Blue Spark Energy, the wireline applied stimulation pulsing technology (the BlueSpark tool) which has the potential to radically increase the efficiency of well intervention operations, stands apart.

In a virtual webinar, Blue Spark Energy representatives Todd Parker, CEO, and Chris Grahame, VP of Sales and Marketing, presented the technology, describing it as the future of environmentally responsible wellbore interventions.

As Parker explained, the engineers at Blue Spark Energy have utilised electrical energy in a third format outside of AC or DC, high pulsed power, for application within the well intervention sector. High pulsed power is the idea of taking electricity and compressing it to be released in a very short period of time. Returning to school physics, power equals energy over time, so by reducing the time taken, the power is much higher. By example, Parker demonstrated a test in the Blue Spark Energy laboratory which used the energy equivalent to two cell phone batteries and releasing it in microseconds to generate power in the hundreds of megawatts range. The company has taken this and built a device to take electrical energy, compress it and then produce a high power output for use in the well intervention sector.

Production enhancement

So what can this technology actually do? Well, as Parker continued, “The primary application of this technology is to return oil wells to optimal production by removing blockages that could cause disruptions. The BlueSpark tool, through repeated high power pulses, can effectively remove organic and inorganic debris in production zones and reopen perforations which have been plugged either immediately after perforation or as the well has matured.”

Already Blue Spark Energy has deployed this technology in hundreds of wells across the globe and returned with some incredibly promising results. Listing some of these examples, Parker stated that in one example in the Middle East, a customer used the BlueSpark technology for two remote wells and found that the high power pulses were just as effective as coiled tubing acidisation methods and was able to more easily target specific zones. Additionally, the small footprint and ability to rapidly mobilise to the remote location (due to the small amount of equipment and personnel required) meant the BlueSpark tool produced the same result in just 10% of the time and led to an aggregate increase of 60% in oil production across the two wells.

Parker noted that the technology can be used to clear blockages across the wellbore – be that in the productive zone or the completion equipment further up – any part that has the capacity to create somewhere for debris to start building up the BlueSpark tool is effective at treating the disruption. It is also not restricted by the kind of debris that is obstructing the well, and anything from waxes, calcium carbonate or even iron sulphides can be treated. With other intervention methods you often need deeper diagnostics to ascertain what chemicals are required, for example, but all Blue Spark Energy operators need to confirm is if there is debris and where – they are not concerned with what it looks like or what it is.

To emphasise this, Parker added, “In the North Sea at an unmanned installation the operator encountered a barium sulphate scale build up in the tubing and across the surface controlled subsurface safety valve (SCSSV). Operators were unable to use conventional methods due to scale build up restrictions above the SCSSV and were therefore required to shut-in the well and set up a plug as a barrier below the SCSSV. We were able to take out a small wireline mast and within 24 hours place the technology across the SCSSV, remove the debris and put the well back into production. This was a 3500bpd producer in danger of being shut which we were able to rapidly treat without causing any damage.”

Multiple applications

In addition to cleaning screens and gravel packs in oil production, the BlueSpark tool has also been deployed for usage in other applications such as water source wells or improving geothermal efficiency, proving its versatility across the energy sector. In another case in the North Sea, Parker showed how the technology was used to improve the efficacy of decommissioning wells by removing debris to allow for a rigless type of decommissioning as opposed to section mill or something more complicated.

This technology, as Parker continued, is particularly suited when deployed by wireline tractor, and is compatible with all wireline industry equipment – if a perforating gun can be run off the wireline unit so can the BlueSpark tool. It is very transportable, able to be transferred in a helicopter for example, and is deployed in pairs to de-risk operating time. It also has an incredibly small environmental footprint, without using chemical fluids, explosives and requiring only a small amount of energy. Although the pulses are released at high power, due to the low energy used, there is no risk of damaging any equipment.

Saving money as well as the environment

After the webinar, Parker spoke to Offshore Network to shed more light on this innovative new technology and which markets the company is targeting in the future.

Parker said, “The process people are talking about a lot at the moment is the electrification of a lot of carbon intensive processes. The BlueSpark tool can become that intervention device that leads in the electrification of conventional well intervention techniques. There is no risk of creating a situation worse than you had before, no safety hazards, and finally you are reducing the carbon footprint of your intervention operations.”

Aside from the environmental and safety benefits, the BlueSpark technology also offers significant financial incentives as well. Parker added, “The costs savings mainly come from operators not having to move a rig or heavy equipment, and the ability to intervene quickly. It costs less to transport, there are less people required to move it, and it’s very fast to set up (there is no wellbore preparation). Looking from a fiscal perspective you are probably looking at being able to save more than 50% over using a conventional technique to accomplish the same result. We have case studies where we have saved customers days of operating time and millions of dollars.”

The story so far

Parker took some time to reflect on Blue Spark Energy’s journey so far which, at times, has been quite frustrating. He said, “The physics is basically high school physics, the engineering was not, so it took some time to build the tool robust, durable and slimmer to access more wellbores, but we finally had a commercial model in 2013 which we started to take around the world.”

“Unfortunately this is where you run up against the inherent conservativeness of the industry itself. From 2013 to 2018 we really faced that from a lot of operators who, broadly speaking were interested in new technology but really struggled to introduce it as it is radically changing their intervention, not changing a small part of it such as introducing a type of chemical. It took us a few years to get some customers to where they were comfortable making that change.”

Currently Blue Spark Energy has quite a large capacity, after deploying to more projects and manufacturing more assets to meet demand. It has ongoing projects in Nigeria, Denmark, Norway, the UK, Malaysia and the Middle East and, to date, has completed over 600 projects across the world working with a variety of clients such as Exxonmobil, Chevron, Shell, Equinor and more. Across the thousands of well descents attempted by the technology, it boasts a 99.6% operating efficiency and rarely creates downtime for customers. As there is a small amount of equipment and capex required to perform an operation, it is a relatively easy fleet to maintain. Additionally, as there are no complicated moving parts and the supply chain is quite simple, it is an extremely scalable business.

Looking ahead

Turning to the future, Parker commented, “Covid had an impact on business, 2020 was not our best year but it was our second best year. Now there is a tremendous backlog of wells that require maintenance and people want to do it rapidly and effectively, so we are envisioning a big uptake in activity in the short term. We think it is an opportunity for a lot of customers to see the benefit of this technology.”

Parker continued, “We want to continue to operate in logistically challenged regions, that is the easy argument. In some regions such as Africa, the Middle East, and Far East it is hard to get equipment to these locations, so why not try something radically different that is easy to get there.”

“The second dimension is we are still discovering additional applications. People are coming to us and asking, can we do it for this or use it for this purpose and we are continually refining the technology. So while there is a geographic spread there is also some technical growth we are seeing as well. Being able to help the decommissioning process, for example, to more effectively cut off any methane leaks in the future is exciting, as it is a big topic which at the moment has tremendous costs for operators. We are starting to get some real interesting air time in that space.”

Welltec has announced the agreement of a long-form contract (LFC) with Saudi Aramco which, following an extensive approval process, will see Welltec deliver completion products and services across the Saudi Aramco portfolio in any environment.

“Welltec began installing WAB metal expandable packers for Saudi Aramco in 2014 as part of a technology trial, and the award of a LFC demonstrates how far we’ve progressed since then,” said Kevin Wood, Well Completions Sales Director for Welltec Middle East.

Wood added, “Confirmation of this award represents a major step in our partnership with Saudi Aramco which also enables us to continue along the path of exemplary service quality in the execution of completions. With more products being qualified through Saudi Aramco this year, and the addition of an in-country Welltec manufacturing facility, it’s greatly appreciated that Welltec have been recognised through this award.”

More to come?

The approval procedure for this agreement has been extensive and thorough, and such a high standard of qualification brings with it the benefit of an expedited process for the establishment of future agreements between the two companies.

Hani Sagr, Area Vice President for Welltec Middle East, explained, “The LFC is the highest level of contract in the Saudi Aramco procurement processes. It provides the best possible foundation for the provision of our technology and services to Saudi Aramco, enabling us to continue growing our partnership as well as our overall presence in the region.”

“The qualification process included a number of site visits, inspections and audits, with full and detailed reports covering the entire Welltec organisation with particular focus on our manufacturing process,” added Sagr, who also noted that it was in December 2018 when proceedings began in earnest.

“This is not only an excellent recognition of the great teamwork between Welltec and Aramco, it also highlights our commitment to the IKTVA programme geared towards in-Kingdom value creation,” Sagr concluded.

The combination of this award and the continued expansion of in-house manufacturing at local level serves as an excellent platform for the future and continued growth in neighbouring countries. The agreement also comes in a strong period for Welltec which has seen an admirable financial period in the face of Covid-19, the penning of deals with companies such as Petronas, and a change of executive who has promised to expand the company’s business potential to new heights. To read more on Welltec’s progress, click here.

Page 2 of 3