The Asia Pacific (APAC) offshore well intervention market is witnessing significant growth, given the advancements in technologies that are capable of boosting operational efficiency while reducing operator costs.

The future scope of the APAC Well Intervention Market points towards further expansion as exploration and production (E&P) activities in the region continue to thrive. The integration of automation and digitalisation in well intervention processes is expected to play a major role in driving market growth. Moreover, rising offshore production activities, especially in countries with untapped hydrocarbon reserves, are projected to offer lucrative opportunities for well intervention services.

Environmental regulations and a focus on sustainable production will also influence the adoption of advanced technologies and efficient well management practices. This evolving market landscape presents ample growth potential for stakeholders in the APAC Well Intervention Market in the years to come.

Removing abandoned offshore platforms are a major hassle, but converting these ageing infrastructure into reefs are an efficient and eco-friendly way to tackle this issue.

In the Asia-Pacific (APAC) region alone, there are more than 2,500 platforms that are awaiting decommissioning in the coming decade. Removing these huge structures not only take time, but is also likely to disrupt marine life. The rigs-to-reefs movement was introduced as a potential solution, with several countries in the APAC region including Thailand and Malaysia implementing these programmes successfully.

These platforms boost biodiversity by offering shelter, breeding grounds and feeding areas for marine organisms like fish, corals and invertebrates, with their metal frames in particular, being a key habitat to numerous marine communities.

Despite its advantages however, reefing does not come without risks. For example, several questions have been raised about the impact of these structures on natural marine patterns, migratory species and surrounding habitats. Moreover, regulators are often hesitant about adopting reefing programmes due to concerns surrounding long-term liability and public trust.

In order to tackle these issues, environmental agencies have there began monitoring these artificial reefs to keep a check on marine health. On the whole, reefing has received mixed reactions. While some have called this as a ‘creative problem-solving’ initiative, others have accused the oil and gas industry of using the technique as a way of stepping aside from taking environmental responsibility.

As reported by Earth.org, this approach however has a promising future, as it balances financial realities with sustainability.

Oilenco Ltd has announced the appointment of Paul Vettese as its new Business Manager for the Asia Pacific region.

Oilenco Ltd has announced the appointment of Paul Vettese as its new Business Manager for the Asia Pacific region.

Paul brings over 25 years of oil and gas experience to the role, including a decade spent leading sales teams for a global well intervention services provider in Asia Pacific. His extensive background makes him well-positioned to support Oilenco’s strategic growth and regional development plans.

Oilenco designs, engineers, and manufactures specialised downhole tooling to support oil and gas operations worldwide. Its comprehensive portfolio of well intervention solutions is designed to help operators reduce operational time and costs. The company’s innovative solutions are used globally across various offshore assets to enhance well access, intervention, and recovery operations.

In his role, Vettese will lead the development and execution of Oilenco’s business strategy across Asia Pacific. He will oversee the company’s regional direction and growth initiatives, drive new business opportunities, and strengthen relationships with existing clients throughout the region.

Blair McCombie, Operations Director, remarked, "The company is entering an exciting phase of growth, with clear ambitions to expand internationally. With Paul joining the team, we look forward to strengthening our presence across Asia Pacific and expanding our global footprint."

“Having spent the past decade leading sales across the Asia Pacific region, I’ve developed a deep understanding of the market dynamics, client expectations, and the technical challenges operators face. I’m excited to bring that regional insight and network to Oilenco, and to play a key role in expanding the company’s footprint by aligning our innovative solutions with the specific needs of customers throughout Asia Pacific,” added Paul.

Decommissioning activities have been limited in southeast Asia, with only a handful of countries being able to point to any decommissioning work in the last 20 years and the challenge has become tougher due to three key issues.

There is a general inconsistency regarding the approach to international conventions relevant of the decommissioning of offshore installations. International treaties do not have a force of law in every signitory country and the approach taken is inconsistent across the region. Domestically, the decommissioning requirements for southeast Asian nations may vary, depending on various factors. For example, in Indonesia, the implementation of Oil and Gas Law No 22 of 2001 meant that every production sharing agreement (PSC) must contain provisions with respect to post-operation obligations. Another example is Thailand, where the PSC contractor is expected to provide a security deposit, the value of which is approved by the Director General.

In each case, identifying the entity with liability for decommissioning is not a necessity. New legislation with respect to decommissioning may have an impact on the older concession agreements, PSCs or risk service agreements, subject to the terms of each relevant agreement, and whether the legislation has retrospective effect. In practice, they often lack clarity. There are a many such development agreements or arrangements between States or NOCs and oil and gas companies. However, there is no standard form of agreement; these are usually bespoke agreements, subject to different rules and covering different activities. Unless they are clear on decommissioning liabilities at the end of the JDA term, they would likely give rise to additional difficulties.

Since southeast Asia's oil & gas industry is immature when compared to other areas, there arise certain challenges that may not be the case in other areas. A lack of experience is often related to a lack of understanding of the decommissioning cost. Despite an operator or contractor contributing to a decommissioning fund, it is unlikely that the fund would be adequate.

To help the world transition to net zero, decommissioned oil and gas platforms can be repurposed into green energy hubs.

This includes offshore rigs for carbon capture and storage or storing and transporting hydrogen, a type of sustainable fuel that doesn’t emit carbon when it is burned. A report published on the World Economic Forum suggested using legacy oil platforms to produce green hydrogen, which is generated using renewable energy.

Scientists have said that resusing depleted oil and gas wells would allow operators to access geothermal heat in hot rock formations, eliminating upfront costs of drilling new wells and potentially making the technology more appealing to the industry.

Moreover, researchers have suggested that repurposing depleted oil and gas wells may significantly help mitigate potential environmental impacts of abandoned wells and allow operators to access geothermal heat in underground rock formations. It also provides new job opportunities in areas with rich energy industry traditions.

According to Arash Dahi Taleghani, professor of petroleum and natural gas engineering at Penn State, using existing wells can help maintain employment in the area while also allowing communities to be part of the energy future.

Borneo Oil Bhd, through its indirect subsidiary Borneo Oil (Sabah) Sdn Bhd (BOS), has been selected as a vendor by Petroliam Nasional Bhd (Petronas), Malaysia’s state-owned oil and gas giant, marking a significant step forward for local participation in Sabah’s energy sector.

Announced on 24 March, this development comes alongside a strategic collaboration with Intercontinental Strait Energy Technology Co Ltd (SETC), a leading Chinese drilling consultancy, to jointly bid for drilling and well intervention projects in the region.

The partnership, formalised 20 March, positions BOS and SETC—a Chengdu-based firm specialising in drilling optimisation, completion, and reservoir management—to compete for contracts that include consultancy, supervision, and services for drilling, workovers, stimulation, and real-time drilling monitoring. Borneo Oil emphasised SETC’s expertise as China’s largest drilling-management consultancy, highlighting the potential for this alliance to bolster Sabah’s oil and gas capabilities. This move aligns with Petronas’ broader efforts to ramp up operations in Sabah, a region critical to Malaysia’s energy ambitions.

Sabah, located on the northern tip of Borneo, is a cornerstone of Malaysia’s oil and gas industry, holding an estimated 1.5 billion barrels of oil (25% of the nation’s reserves) and 11 trillion cubic feet of gas (12% of total gas reserves). Petronas’ operations in Sabah centre on both sustaining production from mature fields and unlocking new potential through exploration and development. A key recent milestone is the signing of two production sharing contracts (PSCs) by Petronas Carigali Sdn Bhd (PCSB) for the SB412 and 2W blocks offshore Sabah. These blocks, encompassing nine fields, are part of the 2024 Malaysia Bid Round and leverage existing infrastructure like the Samarang Asam Paya and Erb West hubs.

While these PSCs focus on exploration and development, they set the stage for well intervention and maintenance—areas where vendors like BOS and partners like SETC could play a role. Petronas’ goal is clear: increase national production to two million barrels of oil equivalent per day (MMboe/d) to meet rising domestic demand, which hit 929,556 barrels per day in December 2023. Sabah’s deepwater and marginal fields are pivotal to this target, with intervention work like workovers and stimulations often required to optimise ageing assets.

Petronas’ ramp-up in Sabah extends beyond new blocks. The company’s Activity Outlook 2025-2027 forecasts 69 development wells in 2025 (up from 56 in 2024) and an average of 367 Facilities Improvement Plans (FIPs) annually through 2027. In Sabah, FIPs target rejuvenation and well maintenance—key intervention activities—for fields like Samarang, which produces 36,000 boe/d. This surge reflects Petronas’ response to natural decline and the need to maintain output, especially as Sabah’s mature fields age.

Further boosting local involvement, Petronas celebrated vendor growth in Kota Kinabalu on 23 January, with the Sabah government. Four Sabahan vendors, including those tied to “Integrated Well Continuity Services,” secured contracts for well interventions, abandonments, and workovers. This follows a trend of increasing local contract awards, which jumped from US$141mn (RM613 million) in 2021 to over US$460mn (RM2 billion) recently, with ambitious 2025-2027 targets to double Sabahan OGSE (Oil & Gas Services and Equipment) contracts and boost local job awards by 50-100%.

FourPhase, a specialist in solids and production performance within the oil and gas sector, has introduced The Observer, an advanced tool for real-time data capture and optimisation.

FourPhase, a specialist in solids and production performance within the oil and gas sector, has introduced The Observer, an advanced tool for real-time data capture and optimisation.

Already deployed in five operations across the Gulf of Mexico and the Norwegian Continental Shelf, the solution will soon be integrated across all FourPhase operations, enabling full-scale remote monitoring. As operators increasingly shift towards data-driven smart operations, the real-time insights provided by The Observer are proving invaluable.

Addressing key industry challenges

The Observer is designed to tackle three critical industry challenges: minimising downtime through data-driven decision-making, enhancing equipment maintenance efficiency, and accelerating the shift to remote operations. The system continuously captures real-time data to generate a live operational feed within FourPhase’s control centre while simultaneously populating online dashboards accessible to customers globally.

A key strength of The Observer is its robust security architecture. Adhering to a zero-trust security model, it complies with ISO 27001, 27017, and 27701 standards. The system establishes a secure connection to onshore operations via Starlink or similar technologies, providing a protected data transmission channel between offshore sites and onshore centres.

"Coupled with onsite remote operations, these capabilities are enabling a step-change improvement in offshore sand management. This opens up new opportunities for production optimisation and autonomy that were previously not possible," remarked FourPhase CEO Øyvind Heradstveit.

Leveraging a decade of data

Since 2013, FourPhase has been gathering solids management data, using it to simulate operational scenarios. By applying insights from real-world experiences rather than relying purely on theoretical calculations, the company has achieved an uptime exceeding 99.5% over the past decade. This extensive database allows for more accurate operational planning and improved performance predictions.

"As the energy industry operates with multiple, often competing, data-sharing standards, we’ve developed The Observer as a universal solution, integrating over 300 languages and protocols rather than locking into a single standard. This allows for real-time monitoring across diverse equipment—including Multiphase Flow Meter, the DualFlow Desander, Acoustic Sand Detectors, and client plant data—all simultaneously. The goal is to capture and process data instantly, empowering operators with real-time insights to make informed decisions," explained Jørgen Bruntveit, COO/CTO.

"Many competitors claim real-time monitoring, yet their systems often suffer from minute-long delays and cumbersome designs—some as large as a server rack. The Observer delivers true real-time monitoring in a form factor small enough to hold in one hand," added Bruntveit.

Although real-time condition monitoring and data-driven optimisation are now standard in many production-related workflows, sand management has largely remained dependent on labour-intensive legacy methods. This reliance has slowed the adoption of autonomous and low-manning platforms. By investing significantly in remote monitoring technology, FourPhase has closed this gap, ensuring The Observer enables full oversight across its entire fleet, including desanders.

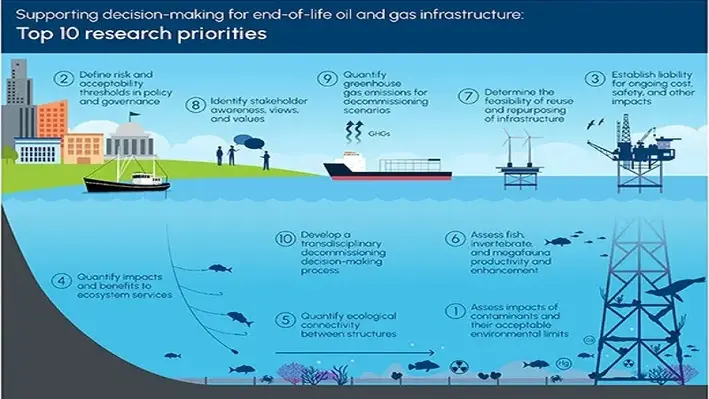

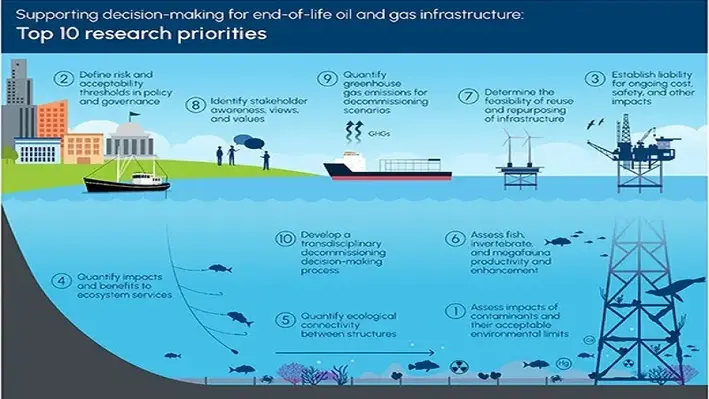

Depending on the scenario, decommissioning oil and gas infrastructure can have potential negative impacts both on the economy and environment.

Depending on the scenario, decommissioning oil and gas infrastructure can have potential negative impacts both on the economy and environment.

The top 10 research priorities were highlighted in a 2023 resarch paper which aid in making informed decommissioning decisions and enhance our understanding of its detrimental impacts.

Several contaminants are released into the environment during the decommissioning process. These include residual chemicals and reservoir constituents that can have significant negative impacts on marine life. As part of the risk assessment framework, all contaminants need to be carefully identified and assessed. Understanding the long-term, site-specific consequences of these contaminants is key to adequately assess risks from various decommissioning options including full removal, partial removal and leave in-situ decommissioning options.

A majority of risks associated with offshore decommissioning activities lack well defined baselines to measure potential impacts. In order to identify parameters that can be measured and monitored, a baseline needs to be predetermined, without which, the acceptability of decommissioning options cannot be assessed.

Due to a lack of knowledge and inconsistent or deficient regulatory guidance, the ongoing costs within current decommissioning decision-making processes are often overlooked. Liability frameworks should therefore be defined to determine the cost of full removal of structures, making remaining items safe, and returning the seabed to its pre-activity state. Costs involving alternative approaches such as the relocation of structures to a reefing location are also calculated by the industry.

To adequately assess and compare the social, technical and economic impact of decommissioning, the ecosystem services that are gained or lost from different decommissioning options need to be determined. While few marine-based environmental impact assessments (EIAs) are currently being integrated with ecosystem services, there has been limited success attributed to data gaps and the values have been ineffectively captured by ecosystem services. Hence, alternate schemes such as the Intergovernmental Platform for Biodiversity and Ecosystem Services (IPBES) and Nature's Contributions to People have been developed.

The long-term presence of offshore structures can have a positive and negative influence on ecological diversity, productivity and connectivity. For example, the presence of oil and gas structures in marine ecosystems can have negative consequences on the natural migration pathways of species that might be altered by the emission of sound, vibrations and light from structures. On the other hand, presence of these offshore infrastructures can also extend foraging opportunities of certain mobile species such as Australian fur seals. Long-term monitoring data should therefore be collected throughout the lifecycle of these installations to appropriately understand their impact on populations and connectivity.

Production and attraction mainly refer to whether fish are attracted to an artificial structure or whether it enhances fish production. When a new structure is installed, fish are rapidly attracted to the structure which can redistribute existing production. In some cases, fish production can significantly increase when infrastructures are installed in predominantly sandy, oligotrophic habitats since they provide additional hard substrata that can potentially increase the carrying capacity of organisms that utilise such habitats. Assessments should consider the duration of these structures in place and the extent of connectivity between fish populations on the structures and the broader ecosystem.

A range of research questions need to be addressed to assess the feasibility of re-using or re-purposing offshore structures. Firstly, it is important to understand the process of degradation of different materials beyond their initial design life. Secondly, the evolution of different seabed sediments and their impact on the stability and integrity of decomissioned offshore infrastructure need to be considered. Thirdly, the technology required to contain hazardous substances, monitor their impact on the ocean environment, pursue re-cycle, re-purpose and re-use opportunities for recovered infrastructure needs to be understood. Lastly, performing testing and validation is crucial to achieving confidence of the sector and inclusion in industry standards.

A review of stakeholder values regarding the benefits of offshore instrastructure identified both risks and opportunities. These involve a combination of social and economic values that are shaped by their knowledge frames. Since there is no one-size-fits-all, further research is required to understand the factors that influence the perceptions and attitudes of stakeholders towards decommissioning.

Although the decommissioning process contributes minimally to greenhouse gas (GHG) emissions in comparison to its full cycle, it still needs to be evaluated in regard to its total contribution to the global goal of reaching net zero emissions by 2050. It is also important to highlight the positive contributions of these structures such as the carbon sequestration potential of marine ecosystems formed around these structures in situ. Qualitative analysis of all sources of GHG emissions sequestered should also be considered. A combination of all these analyses would result in a net-carbon footprint being identified for each decommissioning option.

While classifying research priorities into disciplines is necessary to assess their impact, they are also in most cases, found to be transdisciplinary in nature.

The offshore well intervention market in the Asia-Pacific region is experiencing steady growth, driven by increasing investments in oilfield optimisation and advanced intervention technologies.

The offshore well intervention market in the Asia-Pacific region is experiencing steady growth, driven by increasing investments in oilfield optimisation and advanced intervention technologies.

According to a report by Future Market Insights (FMI), the global downhole tractor market is expected to expand from US$4,033.6mn in 2025 to US 7,088.4mn by 2035, at a 5.8% CAGR.

Rising demand for downhole tractors

The growing complexity of offshore drilling operations in the region has heightened demand for downhole tractors, particularly in deepwater and horizontal well applications. Countries like China, Australia, and Malaysia are leading investments in offshore exploration, requiring efficient well-intervention solutions.

Technological advancements driving growth

Technological advancements, such as real-time monitoring and AI-driven automation, are enhancing the efficiency of downhole tractors. "The growing need for efficient well intervention and technological advancements will continue to drive the downhole tractor market’s expansion. The increasing application of these tools in complex drilling operations and emerging oilfields, especially in key regions, positions the market for sustained growth over the next decade," said Nikhil Kaitwade, Associate Vice President at Future Market Insights (FMI).

With increased investment in offshore well optimization, the Asia-Pacific region is poised to play a critical role in shaping the future of downhole intervention technologies.

For more insights please visit here

Brunei Shell Petroleum (BSP) has awarded Serikandi Hilong Sdn Bhd, a joint venture between Serikandi Oilfield Services (Serikandi) and Hilong Marine Engineering (Hilong), a significant contract for decommissioning services offshore Brunei.

Brunei Shell Petroleum (BSP) has awarded Serikandi Hilong Sdn Bhd, a joint venture between Serikandi Oilfield Services (Serikandi) and Hilong Marine Engineering (Hilong), a significant contract for decommissioning services offshore Brunei.

In a LinkedIn article published by the consortium, the contract is for the Engineering, Preparation, Removal and Disposal (ERRD) of redundant structures. Serikandi says the project “prioritises resource reclamation, ecosystem revitalisation, and economic growth aligning with global sustainability goals.”

Serikandi states the that by leveraging its local expertise with Hilong’s technology proficiency, the collaboration will deliver safe, efficient and environmentally responsible decommissioning services.

Revi Bhaskaran, CEO of Serikandi Group, said, “This milestone reflects our commitment to environmental preservation and operational excellence. Collaborating with Hilong enables us to expand our capabilities while supporting regional decommissioning expertise.”

Jeffery Gu, Executive Deputy President of Hilong Group, commented, “We are honoured to contribute to Brunei’s first major decommissioning project. Together with Serikandi, we will ensure successful delivery while upholding the highest safety and environmental standards.”

The offshore oil and gas industry is experiencing a transformative wave, driven not only by innovations in downhole technologies but also by its increasing adoption of digitalisation.

The offshore oil and gas industry is experiencing a transformative wave, driven not only by innovations in downhole technologies but also by its increasing adoption of digitalisation.

Across the globe, digital technologies and digitised data are reshaping industries, and oil and gas is no exception. Solutions leveraging IoT technologies, data analytics, and digital twins are enabling operators to harness information more effectively. These advancements are improving productivity and unlocking significant cost savings.

According to SLB, many companies are leveraging digitalisation to enhance their portfolios. SLB, for instance, uses its Intervention Advisor Software to manage risks, cut value chain costs, and improve production. The software offers diagnostic, remediation, and prevention methods tailored to optimise operations and reduce costs per barrel. Additionally, SLB’s recently announced partnership with Geminus AI introduces a physics-informed AI model builder, allowing for real-time optimisation across various outcomes, including operational expenditure reduction, increased productivity, and carbon emissions minimisation. “Geminus’ capability to fuse AI methods with physics-based simulation data will empower customers to quickly and easily create hybrid models of their operating assets that can be optimised in real time against numerous outcomes, such as opex reduction, increased productivity, and carbon emissions minimisation,” remarked Rakesh Jaggi, President, Digital and Integration, SLB.

In the second half of 2023, Silverwell Technology announced it had secured a major contract in Southeast Asia to deploy its digitally intelligent artificial lift (DIAL) system across multiple wells. According to the company, DIAL integrates in-well monitoring with surface analytics and automation to optimise gas-lifted fields remotely, even in challenging environments. Silverwell added that, across a three-year contract, the technology would be deployed in difficult conditions and expressed hopes that its successful completion would encourage broader adoption in the region.

The development of digital tools, especially around data interpretation, is being closely watched in the industry. According to Utama, “Improving the interpretation of logging data with new technology will enable oil companies to make better decisions for their well, especially around abandonment.”

The continued evolution and adoption of digitalisation remain a focal point for the offshore oil and gas sector, driving innovation and efficiency across operations.

In Asia, regulatory change driven largely by environmental concerns has continued apace, notably with the ASEAN Council on Petroleum (ASCOPE) issuing decommissioning guidelines for oil & gas facilities.

In Asia, regulatory change driven largely by environmental concerns has continued apace, notably with the ASEAN Council on Petroleum (ASCOPE) issuing decommissioning guidelines for oil & gas facilities.

Industry sources estimate that around 800 offshore platforms in the Asia Pacific region will enter decommissioning by 2027, at a predicted cost of some US$100 bn. While English law remains a popular choice to govern Asia Pacific decommissioning contracts, it faces stiff competition from other systems.

The dispute resolution clause of BIMCO’s DISMANTLECON form of contract envisages a choice between English, Singapore and US maritime (or New York) law. Historically, English and Singapore law have followed each other closely. However, the common law of penalties is the latest area in which divergence has emerged, with the Singapore Court of Appeal declining to follow the UK Supreme Court’s Cavendish Square decision when examining liquidated damages and forfeiture clauses in oil and gas contracts. Choice of law therefore, has real consequences for businesses engaged in decommissioning.

Net zero also has a profound impact on decommissioning. Despite the Strategy’s change of name, the MER objective remains in place. This is no “keep it in the ground” strategy. What has altered is the way assets are managed in the context of recovery of oil and gas. The updated OGA Strategy is unlikely in itself to accelerate the pace at which assets come forward for decommissioning, beyond the consequences of falling demand (and perhaps prices) flowing from the government’s overall policy of reducing fossil fuel dependence in the downstream economy. Rather, elements of the OGA Strategy may slow the pace of decommissioning.

The Central Obligation is supplemented by a number of detailed provisions on re-use of assets not only for CCS projects but also, 'where appropriate', for 'projects relating to hydrogen supply'. 15 to 17 of the OGA Strategy, headed 'Decommissioning', require relevant persons to demonstrate, before planning decommissioning of infrastructure, that 'all viable options' for its continued use, 'including for reuse or re-purposing for CCS' have been 'suitably explored'. Note the word 'including': potential re-use is not confined to CCS but could also include hydrogen and other clean energy uses such as offshore wind. So, even where an asset cannot continue in economic petroleum use, OPRED may reject a decommissioning programme where the whole or part of the structure may viably support clean energy development.

The OGA may also use its licensing powers to ensure cooperation between asset owners and others, including parties seeking to invest in alternative uses. Postponement of decommissioning will sometimes, but not always, be welcome news to asset owners. UKCS M&A transactions and other contracts will typically be priced on assumptions about the useful life of an asset and the timeframe within which the costly process of decommissioning is expected to take place. Insistence by OGA or OPRED on prolonging the life of an asset with a view to reuse may result in parties discovering they have overpaid into a security arrangement, or finding themselves compelled to negotiate elaborate cost apportionments with incoming investors. Unravelling or altering already complex contractual arrangements to accommodate these changes may prove legally and financially problematic.

Page 5 of 14

Copyright © 2026 Offshore Network