The riserless light well intervention (RLWI) market, valued at US$270.52mn in 2024, is projected to reach US$405.81mn by 2032, growing at a CAGR of 5.2%, according to Credence Research.

Key players shaping the market include Expro, ExxonMobil, Halliburton, Aramco, NOV, Emdad, Baker Hughes, Oceaneering, Hunting Energy, and Nortech. These companies focus on technological innovation, vessel upgrades, and digital integration to improve efficiency and safety in offshore interventions.

Within the service segment, logging and bottom hole surveys account for over 25% of total demand. These services are critical for evaluating reservoir conditions, identifying production zones, and ensuring accurate well diagnostics without costly drilling. Operators increasingly rely on advanced downhole logging tools for real-time data, which reduces non-productive time and optimises subsea operations.

By intervention type, light interventions dominate with over 40% market share, using wireline, slickline, or coiled tubing techniques for routine tasks such as inspection, cleaning, and data collection. These methods reduce operational costs and environmental risks, making them ideal for mature offshore fields. For example, Halliburton’s ClearTrac wireline tractor can traverse highly deviated wells while carrying payloads up to 1,000 lbs efficiently.

Offshore applications account for 65% of the market, driven by rising deepwater and ultra-deepwater exploration. RLWI provides cost-effective well maintenance without heavy rigs, maintaining production efficiency and safety. The growing number of aging subsea wells in North America further reinforces offshore interventions’ importance.

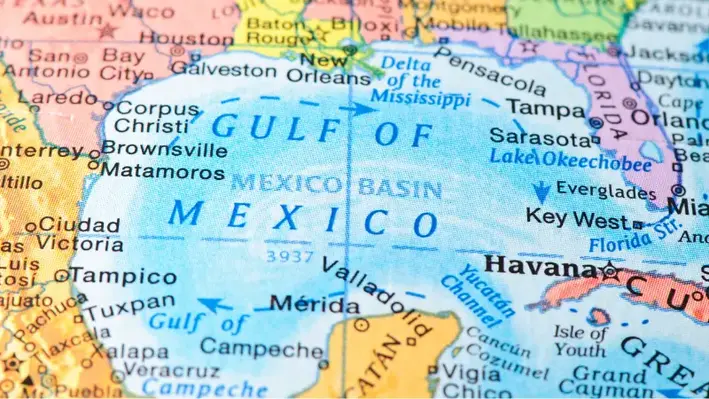

North America: Market leadership and offshore dominance

North America dominates the riserless light well intervention (RLWI) market with a 35% share, supported by extensive offshore activity in the Gulf of Mexico. The region benefits from advanced offshore infrastructure, mature subsea wells, and a strong presence of leading service providers. Operators focus on extending the production life of aging wells while maintaining cost efficiency, driving consistent demand for RLWI services. Regulatory support for safe intervention practices and investments in deepwater exploration further reinforce the region’s leadership. The combination of technological expertise and high offshore activity ensures North America remains a primary market driver.

To learn more about the RLWI market in other regions, visit Credence Research’s full report here

The Centre of Decommissioning Australia (CODA), the University of Western Australia (UWA) and the UK’s Teesside University’s Net Zero Industry Innovation Centre (NZIIC) have signed a memorandum of understanding (MoU) to collaborate on the establishment of a Western Australia Industry Transformation Hub.

The Centre of Decommissioning Australia (CODA), the University of Western Australia (UWA) and the UK’s Teesside University’s Net Zero Industry Innovation Centre (NZIIC) have signed a memorandum of understanding (MoU) to collaborate on the establishment of a Western Australia Industry Transformation Hub.

The proposed WA Industry Transformation Hub will unite academic expertise, industry leadership and government support to drive innovation in decarbonisation and local manufacturing.

It also marks the latest collaboration between Australia and the UK in the drive towards decarbonisation, which includes the decommissioning of ageing oil and gas infrastructure, among other areas.

The latest MoU brings together expertise from both sides to support Western Australia’s industrial transition to net zero, aligning with a number of Australian government priorities including decarbonisation and the LNG Jobs Taskforce.

“This hub’s focus advances the WA CCUS [carbon capture, utilisation and storage] Action Plan vision of establishing a world-leading CCUS industry to decarbonise heavy industries while supporting economic diversification,” said CODA’s chief executive, Francis Norman.

“It also supports the Made in WA agenda by building local advanced manufacturing capability and skilled jobs, keeping WA at the forefront of global market shifts through strong industry support and innovation infrastructure,” said Norman.

The new ‘hub’ will focus on three core research themes:

Industrial emissions reduction: targeting heavy industries such as oil and gas, mining and cement, developing and deploying CCUS technologies in collaboration with industrial centres like Kwinana and the Pilbara.

Circular economy: supporting the Made in WA agenda, the hub will promote advanced manufacturing, industrial waste recycling and life-cycle design to grow WA’s circular economy.

Knowledge exchange: a joint governance model will embed international collaboration, with NZIIC and WA industry representatives guiding strategic direction to ensure alignment with the state’s Diversify WA priorities.

Each of the MoU partners brings unique strengths to the collaboration: CODA’s extensive Australian and international decommissioning networks, UWA’s track record of supporting Australian industry with applied research, and NZIIC’s strong research base and industrial partnerships in the UK.

Professor Hélène de Burgh-Woodman, Pro Vice Chancellor (Research Training) at UWA said: “The international network established by this MoU will provide a springboard to deliver innovation not just in net zero technologies themselves, but in their process of discovery.”

Earlier in the year, another UK-Australia MoU saw Global Underwater Hub (GUH) and Subsea Innovation Cluster Australia (SICA) team up to pursue subsea opportunities, including decommissioning, across both hemispheres.

The Gulf of Mexico’s decommissioning specialisit Promethean Energy has successfully completed a multi-client campaign in the South Timbalier lease area for the plugging and abandonment of an orphaned well on a storm-damaged platform.

The Gulf of Mexico’s decommissioning specialisit Promethean Energy has successfully completed a multi-client campaign in the South Timbalier lease area for the plugging and abandonment of an orphaned well on a storm-damaged platform.

The high-risk project (thanks to extensive hurricane-related structural damage) was completed sans incidents and under budget, reinforcing Promethean’s com8ittment to retiring ageing offshore infrastructure while supporting the broader goals of the BSSE’s orphaned well programme.

The project entailed reinstating well control barrier on an orphan well and completing abandonment activities. Structural instabilities, deteriorated well barrier, hydrocarbon leaks and subsurface complexities posed significant risks to the operation, yet through phased execution, proactive risk mitigation and an experienced team, the project was completed incident-free.

The initial inspection of the well was conducted in May 2025, revealing extensive damage including a missing boat landing, the heliport having been torn away, the wellhead access deck was no longer intact, and the main deck support column was detached from the stabbing guide.

The well was also venting gas from the production casing downstream of the gate valve. Drone surveys and high-res imagery uncovered severe structural compromise at a jacket leg weldment, and the desk leg had been forcibly displaced into the jacket leg, exceeding material deformation limits. The pile-to-jacket connection on the leg has also completely failed. The data and stability assessments indicated a high-risk of structural collapse.

Despite the high risks, the operator successfully executed the decommissioning project using a combination of advanced inspection tools, methodical engineering reviews and meticulous planning. The site has been secured without environmental harm.

Astro Offshore, part of the Adani Group, has taken another significant step in expanding its offshore fleet with the en bloc acquisition of five additional DP2 vessels.

Astro Offshore, part of the Adani Group, has taken another significant step in expanding its offshore fleet with the en bloc acquisition of five additional DP2 vessels.

This move increases the company’s total fleet size to 49, including 15 DP2 units, five of which feature diesel-electric technology.

The newly acquired vessels include four platform supply vessels (PSVs), two powered by diesel-electric systems, and one advanced 86-metre multipurpose supply vessel fitted with a 160-tonne crane. This purchase builds on the company’s recent addition of two modern PSVs and further strengthens Astro’s ability to deliver flexible, future-ready solutions across key offshore regions.

Industry observers see the acquisition as a strategic effort to expand Astro’s reach in West Africa while enhancing its operational capacity and geographical flexibility. By investing in diesel-electric vessels, the company underlines its commitment to smarter, cleaner, and more efficient offshore operations. Three of these advanced vessels form part of the latest deal, while two more sister vessels, Sagitta and Sculptor, are expected to join the fleet in the coming weeks.

Mark Humphreys, CEO of Astro Offshore, said,“This latest acquisition further enhances our global presence in the offshore sector and reaffirms our commitment to meeting both the current and future needs of our valued clients. The en-bloc transaction underscores our ambition to operate one of the world’s youngest and most efficient fleets. We are excited to bring this new tonnage into service and look forward to supporting our customers on a truly global scale.”

Astro explains that these acquisitions mark a crucial step in deepening its relationships with end users, offering assets capable of supporting long-term charters with both national and international oil companies. The inclusion of additional PSVs and continued investment in its workboat fleet positions the company to play a more active role in production support and to meet the evolving demands of offshore operators worldwide.

With its strengthened fleet, Astro Offshore continues to align its operations with global energy market needs, focusing on efficiency, reliability, and environmental responsibility.

OceanPact has signed a four-year contract with Petrobras worth R$310mn to charter the Ilha de Santana platform supply vessel.

OceanPact has signed a four-year contract with Petrobras worth R$310mn to charter the Ilha de Santana platform supply vessel.

The ship will be used for logistics and emergency response support for Petrobras along the Brazilian coastline.

Earlier this year OceanPact announced new contracts with Petrobras worth R$650mnto charter three oil spill response vessels to be used in operations off the Brazilian coast to provide emergency readiness in the event of environmental incidents.

Currently, OceanPact has a fleet of 28 vessels made up of oil spill response, ROV support, platform supply, research, multi-purpose support and anchor handling tug supply vessels, as well as othering a largest inventory of offshore emergency response equipment in Latin America.

Woodside has welcomed the Australian Government’s final decision to grant environmental approval for the North West Shelf Project extension.

The operator’s Executive Vice President and Chief Operating Officer Australia, Liz Westcott, said, “This final approval provides certainty for the ongoing operation of the North West Shelf Project, so it can continue to provide reliable energy supplies as it has for more than 40 years.

The Australian Government approval includes conditions that require additional monitoring and management of air emissions to protect the Dampier Archipelago National Heritage Place.

Thus far, the North West Shelf Project has supplied more than 6,000 petajoules of domestic gas, powering homes and industry in western Australia. If used just for household electricity, this is enough to power homes in a city the size of Perth for 175 years.

Heavy lifting giant Sarens has outlined its role in the dismantling of the South Angsi Alpha offshore platform in Malaysia.

Heavy lifting giant Sarens has outlined its role in the dismantling of the South Angsi Alpha offshore platform in Malaysia.

The dismantled platform, weighing around 4,000 tons, is the largest ever dismantled and reused in Malaysia, with part of its structure already located on the seabed, where it will serve as a support for the creation of artificial reefs.

Sarens, working on behalf of Marine Masters, used 16 units of 450/650 ton strand jack combinations to lower the Mobile Offshore Application Barge (MOAB) onto the barge on which the topside was loaded, in what is now the first task of this type carried out by the group’s Asia Pacific (APAC) team.

This was the first time Sarens APAC had worked on a decommissioning task using a strand jack solution, the company noted in a statement, so a significant amount of preliminary study was required to meet all the necessary requirements to meet the safety standards of the process, while ensuring that no downtime occurred.

Located in Block PM 305, approximately130 km from Terengganu, off the coast of West Malaysia, the South Angsi Alpha platform was in service from August 2005 until its closure in September 2019.

The floating storage and offloading vessel was decommissioned almost a year later, in March 2020, while the two-phase wells plugging and abandonment campaign was completed in August 2022.

“Once the main platform had been lowered, the topside, the 13 conductors and their four support legs were separated,” the Sarens statement noted.

“The topside was transported to the coast at the Labuan Shipyard, where the loose elements were unloaded.”

The platform's substructure was then sunk to the seabed, at a depth of approximately 70 metres, where it will now serve as a structure for the creation of artificial reefs.

Petrofac has secured an extension to its contract with ONEgas West, reinforcing its presence in the Southern North Sea market.

The deal, issued on 15 September 2025, continues Petrofac’s long-running service role across ONEgas West’s portfolio, including support for the Clipper South complex, Leman Alpha assets, Bacton Terminal, and OneGas barge operations.

John Pearson, chief operating officer of Petrofac’s Asset Solutions and Energy Transition Projects, noted that the company has supported these assets since 2020, positioning it as an embedded member of the delivery team with the ability to assist in production enhancement and field life extension.

This extension builds on a similar EPC contract awarded in March 2024, when Petrofac won a two-year brownfield EPC extension with ONEgas West, which is operated by NAM and owned by Shell UK. The renewed scope underscores ONEgas West’s confidence in Petrofac’s teams in Great Yarmouth and Aberdeen, valued for their operational knowledge and delivery.

As the industry faces pressures including energy transition goals and tighter regulation, contracts like this become strategic. Supporting key infrastructure such as terminals, complex offshore installations, and barge operations helps ensure continuity of supply and contributes to operational resilience.

For Petrofac, this deal strengthens its standing in one of its primary markets and demonstrates its capability to deliver both maintenance and enhancement in challenging offshore settings.

“Having supported these assets since 2020, Petrofac is embedded within the delivery team and is uniquely placed to support production enhancement and field life extension,” said Pearson.

“The North Sea remains one of Asset Solutions’ core markets and this award demonstrates confidence held in our team and the value they drive. We look forward to continuing this relationship, delivering safe and reliable operations.”

UK's Serica Energy has revised its 2025 production guidance following maintenance challenges and scheduled subsea work on fields tied to the Triton FPSO.

The Triton Floating Production Storage and Offloading (FPSO) vessel is operated by South Korea's Dana Petroleum.

Serica Energy said production guidance has been reduced to between 29,000 and 32,000 barrels of oil equivalent per day (boepd), down from a previous range of 33,000–35,000 boepd.

Operator Dana Petroleum notified Serica of a temporary reduction in output from the Triton FPSO due to a vibration issue within the compression trains.

Production is currently running at a significantly reduced rate but is expected to return to normal levels by the end of September once repairs are completed.

Production net to Serica from the Triton FPSO exceeded 25,000 boepd in August. Once both compressors are operational, output will be boosted further, supported by additional production from the EV02 well on the Evelyn field.

Dana has also scheduled subsea intervention work on the Bittern field for November 2025 to address an emerging infrastructure vulnerability.

Originally expected in 2026, the three-week scope will now halt production not only from Bittern but also from the Evelyn and Gannet fields, temporarily reducing Serica’s output by more than 20,000 boepd.

Despite the setbacks, Serica highlighted that production ramp-ups earlier this year had lifted wider portfolio output to more than 55,000 boepd in mid-August, before the maintenance-related constraints began.

DOF Group, a Norwegian vessel owner, has secured a new contract in the Asia Pacific (APAC) region for mooring hook-up services.

DOF Group, a Norwegian vessel owner, has secured a new contract in the Asia Pacific (APAC) region for mooring hook-up services.

The contract scope includes DOF’s complete suite of in-house services, such as project management, engineering, procurement, and logistics support. For this project, the Skandi Hercules, a 109.6-meter vessel, will be utilised for mooring and subsea installation services.

Offshore execution is scheduled for the first quarter of 2026, with an estimated vessel utilisation of around four weeks. The total contract value is capped at $15 million, which DOF classifies as a smaller-sized contract.

The Skandi Hercules had previously provided similar services offshore West Australia. In addition to this contract, DOF Group recently announced a long-term commitment in the APAC region. This commitment involves a construction support vessel (CSV) for subsea construction, inspection, repair, and maintenance (IRM), as well as remotely operated vehicle (ROV) services for depths of up to 3,000 metres. The contract, awarded by an international operator, is set to commence in January 2026 for a one-year duration, with options for further extensions.

This new contract reinforces DOF’s growing presence and capabilities in the APAC market.

Australia’s Department of Industry Science and Resources has released a request for tender (RFT) on the AusTender platform for a lead contractor to deliver Phase 2 of the Northern Endeavour decommissioning programme.

Australia’s Department of Industry Science and Resources has released a request for tender (RFT) on the AusTender platform for a lead contractor to deliver Phase 2 of the Northern Endeavour decommissioning programme.

Phase 2 of the Northern Endeavour programme includes permanently plugging and abandoning nine wells in the Laminaria and Corallina oil fields in a planned two-stage process.

Stage 1 will involve project management, engineering, logistics, regulatory approval, subcontracting and procurement activities to: design and plan to permanently plug and abandon the wells; develop a Stage Gate Review Pack outlining a pricing model with detailed budget, risk profile and Performance Management Framework; and achieve Registered Operator status and monitor and maintain the Laminaria Corallina oil fields.

Stage 2 will include: permanently plugging and abandoning the wells; project management, engineering, procurement and field monitoring; meeting all regulatory requirements, including a National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA) approved Safety Case.

The Department intends to hold four industry briefing sessions for interested parties, each covering a different topic of the programme including commercial, technical, regulatory and financial aspects of the RFT.

The briefings are set to begin during the week of 22–26 September 2025.

Closing date for the submission of bids is 1 December 2025.

The flagship Northern Endeavour decommissioning project is already underway amid initial Phase 1 work at the site, which is located in the Timor Sea, approximately 550 km northwest of Darwin, Australia.

Subsea7 has confirmed the award of a significant project under its long-term agreement (LTA) with Aramco, targeting offshore infrastructure in Saudi Arabia.

Subsea7 has confirmed the award of a significant project under its long-term agreement (LTA) with Aramco, targeting offshore infrastructure in Saudi Arabia.

The scope of the contract covers engineering, procurement, construction, and installation (EPCI) of 106 kilometres of infield and export pipelines. It also includes modifications to existing topside structures and associated hook-up activities.

Project engineering and management will commence immediately from Subsea7’s offices in Saudi Arabia and the UAE, with offshore execution planned across 2027 and 2028.

David Bertin, Senior Vice President for Subsea7’s Global Projects Centre East, said, “This project marks another important milestone and reinforces our long-term strategic engagement with Aramco. We look forward to working closely with the client to deliver this project safely, efficiently, and to the highest standards.”

This award highlights Subsea7’s continued presence in the Middle East and its strategic alignment with Aramco’s offshore development initiatives. The project strengthens regional operations and demonstrates Subsea7’s capability to deliver complex offshore energy solutions in partnership with key clients.

Page 18 of 118