To help the world transition to net zero, decommissioned oil and gas platforms can be repurposed into green energy hubs.

This includes offshore rigs for carbon capture and storage or storing and transporting hydrogen, a type of sustainable fuel that doesn’t emit carbon when it is burned. A report published on the World Economic Forum suggested using legacy oil platforms to produce green hydrogen, which is generated using renewable energy.

Scientists have said that resusing depleted oil and gas wells would allow operators to access geothermal heat in hot rock formations, eliminating upfront costs of drilling new wells and potentially making the technology more appealing to the industry.

Moreover, researchers have suggested that repurposing depleted oil and gas wells may significantly help mitigate potential environmental impacts of abandoned wells and allow operators to access geothermal heat in underground rock formations. It also provides new job opportunities in areas with rich energy industry traditions.

According to Arash Dahi Taleghani, professor of petroleum and natural gas engineering at Penn State, using existing wells can help maintain employment in the area while also allowing communities to be part of the energy future.

Shell Brasil Petroleo Ltd has reached a final investment decision (FID) with Modec Inc for a floating production storage and offloading (FPSO) vessel to be deployed at the Gato do Mato oil field, offshore Brazil.

Shell Brasil Petroleo Ltd has reached a final investment decision (FID) with Modec Inc for a floating production storage and offloading (FPSO) vessel to be deployed at the Gato do Mato oil field, offshore Brazil.

The partners have a purchase and sales agreement that allows Modec to cover operations and maintenance of the FPSO for a period of 20 years with Shell. This follows the front-end engineering design (FEED) contract in March 2024 that has already been delivered.

The new agreement makes Modec responsible for the design of the hull and all related topsides facilities for the FPSO before mooring it with the help of a Sofec Spread Mooring system. Once moored at a water depth of approximately 2,000m, around 200km South of Rio de Janeiro, FPSO Gato do Mato will be capable of producing 120,000 barrels of oil per day (bopd), as well as associated gas and water. The produced stabilized crude will be stored in the FPSO tanks, and the oil will be offloaded to shuttle tankers to go to market.

Modec's 19th project in Brazil and the second for Shell, the FPSO Gato do Mato will feature a new built, custom-made next generation hull, designed on the basis of a 25-year shelf life.

The FPSO Gato do Mato will be the 19th FPSO to be developed by MODEC for Brazil. It will be the second unit to be delivered directly to Shell by MODEC for operation in Brazil.

The FPSO agreement comes soon after Shell took the FID for Gato do Mato, a deep-water project in the pre-salt area of the Santos Basin, offshore Brazil.

The Gato do Mato Consortium includes Shell (operator with a 50% stake), Ecopetrol (30%), TotalEnergies (20%) and Pré-Sal Petróleo S.A. (PPSA) acting as the manager of the production sharing contract (PSC). It is said that the estimated recoverable resource volumes from the site can reach upto 370 mn barrels.

“Gato do Mato is an example of our ongoing investment in increasingly efficient projects,” said Zoe Yujnovich, Shell’s Integrated Gas and Upstream Director. “The project contributes to maintaining stable liquids production from our advantaged Upstream business, and expands our leadership as the largest foreign producer in Brazil as we continue working to provide for the world’s energy needs well into the future.”

The consortium anticipates that the Gato do Mato field will commence operations in 2029.

Cilck here to know more about Offshore Network's events in Latin America.

Aquaterra Energy, a leading provider of offshore engineering solutions, has secured a multi-million-dollar, multi-year contract with Intrepid Energy Limited (IEL) to supply a tailored subsea well intervention equipment package for a project in Nigeria

Aquaterra Energy, a leading provider of offshore engineering solutions, has secured a multi-million-dollar, multi-year contract with Intrepid Energy Limited (IEL) to supply a tailored subsea well intervention equipment package for a project in Nigeria

The turnkey well access system will enable IEL to conduct intervention operations across multiple mature oil wells, enhancing reservoir production.

The contract covers a complete seabed-to-surface intervention package, including Aquaterra Energy’s TRT tieback tooling for production bore and annular access, a lightweight well pressure control system, and an ISO 13628-7 qualified open water intervention riser with an integrated tensioning system. In addition to supplying the equipment, Aquaterra Energy will provide ongoing offshore engineering support throughout the project.

Designed for deployment from jack-ups and lift boats, the 7-3/8” lightweight well access solution offers a cost-effective and operationally efficient alternative to floating vessels, reducing intervention costs while maintaining safety and performance standards.

Andrew McDowell, Delivery Director at Aquaterra Energy, stated, “Our expertise in offshore engineering allows us to develop tailored intervention solutions that address the operational challenges of subsea well access. This system has been engineered for efficiency, ease of deployment, and safety, helping IEL optimise intervention activities across Nigeria while reducing costs. By delivering a complete, integrated package, we are simplifying complex operations and enabling operators to maximise production potential.”

Engr Seun Alonge, CEO at Intrepid Energy Limited, added, “Working with Aquaterra Energy marks a significant step forward for our intervention operations in Nigeria. Their specialised technology enhances our ability to execute intervention programmes efficiently, maximising performance across our assets. By combining Aquaterra’s technical expertise with our deep understanding of the local operating environment, we’re confident this collaboration will enhance production outcomes and create lasting value for our operations in the region.”

The project is set to span multiple years, with Aquaterra Energy providing continuous technical support through a dedicated team of engineers.

George Morrison, CEO at Aquaterra Energy, commented, "Delivering reliable and efficient well access solutions for shallow water subsea operations is central to how we support offshore operators. This collaboration with IEL reinforces our commitment to providing cutting-edge engineering solutions that enhance efficiency and reduce operational costs. With West Africa playing an important role in the global energy sector, we’re proud to continue supporting its offshore industry with our expertise and innovative technologies.”

D&A GOM, the world’s leading decommissioning conference, is all set to open its doors on 8 April in Houston!

D&A GOM, the world’s leading decommissioning conference, is all set to open its doors on 8 April in Houston!

The two-day event, held in partnership with Promethean Energy at Norris Conference Centers, Houston City Center, will provide an unmissable opportunity to gain exclusive access to the latest operator case studies, decommissioning strategies, regulatory insights and best-in-class technology to create long-lasting partnerships for upcoming abandonment campaigns. Delegates will also be able to get together with more than 600 decommissioning decision makers at dedicated networking events.

Leading operators including Apache, bp, Chevron, HESS, LLOG exploration, Petrobras, Promethean Energy, Shell and Woodside will share their decommissioning insights, along with other leading industry experts.

With environmental factors coming to the fore, the event will kick off with an opening presentation on the circular economy and decommissioning, followed by a panel session on reefing processes in Texas, Louisiana, Mississippi and Alabama and presentations focusing on platform reuse and recycling. This will be followed by sessions focusing on aspects of planning and execution of decommissioning projects, a highlight being presentations focusing on the challenges, learnings and success factors of the Chevron Genesis Spar removal campaign.

As a forum for the sharing of international expertise, the event will feature international decommissioning case studies and overviews from the North Sea, Australia and Brazil. A highlight will be a panel session on pipelines, where senior managers and directors from Offshore Operators Committee, bp, Woodside and Appache will discuss global approaches to pipeline removal. This will be followed by a case study from Shell focusing on the relationship between circularity and decommissioning and how these concepts were applied in an offshore field in Brazil.

All the latest technology advances will be covered, from Oilfield Service Professionals’ modular, high-performance drillable technologies for enhanced wellbore isolation and remediation to Rotech Subsea’s state-of-the-art CFE tools and pipeline grabs and Welltec’s advanced wireline intervention tools.

“Last year demonstrated how critical this topic still is with the community as 500+ delegates joined us in Houston from all over the world, as we discussed the pertinent issues within decommissioning and abandonment. We are confident we can build on the successful 2024 conference by ensuring that lessons learned and critical case studies are discussed in 2025,” said Joseph Watson, Lead Project Manager.

Featuring 600+ delegates, 20+ operator delegations, more than 40 expert speakers, 35 decom tech demos, three breakout technical workshops and eight bespoke networking sessions, D&A GOM 2025 promises to be an unmissable event in the region’s oil and gas calendar.

For further information see the website at https://events.offsnet.com/DA-GOM-2025#/ or get in touch with Joseph Watson at

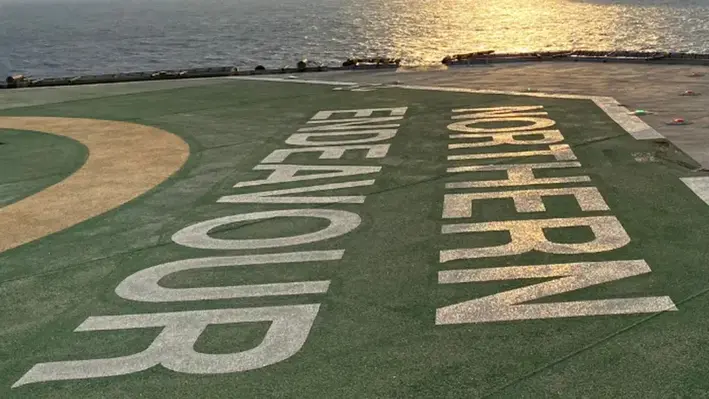

Australia’s 2025 federal budget, unveiled this week, reinforces the government’s commitment to decommissioning, including the completion of the Northern Endeavour project.

Australia’s 2025 federal budget, unveiled this week, reinforces the government’s commitment to decommissioning, including the completion of the Northern Endeavour project.

Offshore decommissioning has been considered a growing and expensive issue in the Gulf of Mexico.

Several analyses conducted to estimate the costs of decommissioning infrastructure in the federal waters of the Gulf of Mexico have shown that it would amount to an estimated US$40bn to US$70bn. According to a 2024 report by the Governmental Accountability Office (GAO), out of a total of 8,000 wells and 1,600 oil and gas platforms, nearly 2.700 wells and 500 platforms are overdue for decommissioning. To be considered overdue, a platform needs to be unoperational on an active lease for more than 10 years or left standing with an inactive lease for well over a year. In case of the latter, the lease may have either expired, been relinquished or terminated.

Shallow and deep water wells are the two main types of wells located in the Gulf of Mexico. While shallow-water wells were initially developed by large oil companies, they were later sold to smaller companies over the years, that lacked the financial resources of major oil companies. Being of minimum economic value, shallow-water wells are often at a high risk of being abandoned by their operators. On the other hand, deepwater wells are newer and relatively more complex that shallow-water wells. Being larger and deeper makes them higher in economic value. Therefore, decommissioning these wells during their end-of-life stage is costlier when compared to shallow-water wells.

According to a report by Ocean Conservancy, decommissioning a deepwater well costs a whopping US$24mn, while a shallow-water well costs only around US$660,000. Currently, there are more than 1,600 active deepwater wells in the Gulf of Mexico, with the cost of decommissioning these wells estimated to exceed US$34bn. Considering subsea pipelines that are often left discarded on ocean floors, the exact cost of their removal has not been estimated, but is expected to have a high cost similar to deepwater well decommissioning.

Solstad Offshore has secured another contract with Subsea7 for its subsea construction vessel Normand Subsea.

Solstad Offshore has secured another contract with Subsea7 for its subsea construction vessel Normand Subsea.

This new contract extends the partnership between the two companies for at least another two years, with potential for further expansion. The contract is now in place and set to commence from 1 January, 2026.

Normand Subsea, a versatile inspection, maintenance and repair (IMR) vessel, has been on contract with Subsea7 since 2009. In July last year, Subsea7 exercised the 2025 optional charter period for the vessel, meaning the current contract is firm until 31 December, 2025, with no further expansion options. Under the new contract, the vessel will continue to serve Subsea7 for another two years, including three yearly options.

Baker Hughes has announced a major multi-year contract with Petrobras for fully-integrated completions systems.

Baker Hughes has announced a major multi-year contract with Petrobras for fully-integrated completions systems.

The award followed an open tender and will leverage Baker Hughes’ innovative technology portfolio and extensive experience in Brazil to optimise production across multiple deepwater fields.

A range of technologies have been specifically tailored to meet the needs of Petrobras’ offshore developments. The completions technologies will be combined with conventional upper and lower completions solutions to provide remote operations capabilities and multizone control which limits water and gas breakthroughs, reducing the risk of costly interventions.

Amerino Gatti, Executive Vice President, Oilfield Services & Equipment at Baker Hughes, said, ““Deepwater, high pressure wells require an unmatched level of reliability, and our completion technologies have proven themselves in these harsh environments […] Through continual innovation, improvement and testing, and in close collaboration with Petrobras, the Baker Hughes team has pioneered new ways to help develop Brazil’s natural resources safely and efficiently for decades to come.”

Through the agreement Petrobras will utilise Baker Hughes’ new SureCONTROL Premium interval control valve (ICV), which provides enhanced reliability in the high flowrates of Petrobras’ offshore fields. The technology allows operators to respond remotely to evolving well conditions across multiple zones in real time.

Petrobras will deploy a number of Baker Hughes’ technologies, including the SureSENS QPT ELITE downhole gauges, SureSENS B-Annulus monitoring system, SureTREAT chemical injection system, Sure-Set flow control system, Orbit Premium barrier valves, a gas lift system, REACH subsurface safety valves, DeepShield subsurface safety valves, Premier packers, screens and gravel pack system.

Delivery of the completions technologies will begin in late 2025.

Borneo Oil Bhd, through its indirect subsidiary Borneo Oil (Sabah) Sdn Bhd (BOS), has been selected as a vendor by Petroliam Nasional Bhd (Petronas), Malaysia’s state-owned oil and gas giant, marking a significant step forward for local participation in Sabah’s energy sector.

Announced on 24 March, this development comes alongside a strategic collaboration with Intercontinental Strait Energy Technology Co Ltd (SETC), a leading Chinese drilling consultancy, to jointly bid for drilling and well intervention projects in the region.

The partnership, formalised 20 March, positions BOS and SETC—a Chengdu-based firm specialising in drilling optimisation, completion, and reservoir management—to compete for contracts that include consultancy, supervision, and services for drilling, workovers, stimulation, and real-time drilling monitoring. Borneo Oil emphasised SETC’s expertise as China’s largest drilling-management consultancy, highlighting the potential for this alliance to bolster Sabah’s oil and gas capabilities. This move aligns with Petronas’ broader efforts to ramp up operations in Sabah, a region critical to Malaysia’s energy ambitions.

Sabah, located on the northern tip of Borneo, is a cornerstone of Malaysia’s oil and gas industry, holding an estimated 1.5 billion barrels of oil (25% of the nation’s reserves) and 11 trillion cubic feet of gas (12% of total gas reserves). Petronas’ operations in Sabah centre on both sustaining production from mature fields and unlocking new potential through exploration and development. A key recent milestone is the signing of two production sharing contracts (PSCs) by Petronas Carigali Sdn Bhd (PCSB) for the SB412 and 2W blocks offshore Sabah. These blocks, encompassing nine fields, are part of the 2024 Malaysia Bid Round and leverage existing infrastructure like the Samarang Asam Paya and Erb West hubs.

While these PSCs focus on exploration and development, they set the stage for well intervention and maintenance—areas where vendors like BOS and partners like SETC could play a role. Petronas’ goal is clear: increase national production to two million barrels of oil equivalent per day (MMboe/d) to meet rising domestic demand, which hit 929,556 barrels per day in December 2023. Sabah’s deepwater and marginal fields are pivotal to this target, with intervention work like workovers and stimulations often required to optimise ageing assets.

Petronas’ ramp-up in Sabah extends beyond new blocks. The company’s Activity Outlook 2025-2027 forecasts 69 development wells in 2025 (up from 56 in 2024) and an average of 367 Facilities Improvement Plans (FIPs) annually through 2027. In Sabah, FIPs target rejuvenation and well maintenance—key intervention activities—for fields like Samarang, which produces 36,000 boe/d. This surge reflects Petronas’ response to natural decline and the need to maintain output, especially as Sabah’s mature fields age.

Further boosting local involvement, Petronas celebrated vendor growth in Kota Kinabalu on 23 January, with the Sabah government. Four Sabahan vendors, including those tied to “Integrated Well Continuity Services,” secured contracts for well interventions, abandonments, and workovers. This follows a trend of increasing local contract awards, which jumped from US$141mn (RM613 million) in 2021 to over US$460mn (RM2 billion) recently, with ambitious 2025-2027 targets to double Sabahan OGSE (Oil & Gas Services and Equipment) contracts and boost local job awards by 50-100%.

Conventional plugs can often fail to provide an effective solution when a well environment gets challenging.

Conventional plugs can often fail to provide an effective solution when a well environment gets challenging.

This is where comes the high expansion bridge plug (HEX) with its capacity to expand enough to overcome narrow restrictions to reach and successfully seal off larger wellbore diametres. It's far-reaching range makes it a versatile and reliable downhole tool that can function in crucial offshore situations, from zonal isolation, well intervention to well abandonment activities.

No matter what casing size in question, elastomeric or metallic HEX bridge plugs are durable to tackle advanced expansion with heighetened strength for pressure resistance. Downhole positions that determine the mode of operation allow to accordingly select a sealing mechanism, be it elastomeric or metal-to-metal seals. The plug is then directed towards the targetted depth using conveyance methods, such as wireline, coiled tubing, or slickline. The approach to activate the plug expansion is determined by its design, involving hydraulic pressure, mechanical setting or electrical activation, as relevant. Operators can rest assured of unintended fluid migration between wellbore zones, thanks to the solidity of the seal created out of the expanded HEX plug. They are sturdy enough to keep certain areas away from the other so that the flow can be stopped.

While that serves zonal isolation, HEX bridge plugs can also assure permanent isolation of adandoned sections of a wellbore, which ensures environmental safety and regulatory compliance. On the other hand, it can also create temporary barrier to address casing leaks or unwanted fluid challenges in cases of well integrity issues or restoring well performance. Well testing is a crucial part of well intervention that requires operators to safely check pressure controls, and they can rely on HEX bridge plugs for this.

Houston-based oilfield technology company called SLB has to its name a hi-ex retrievable bridge plug which operates in the set-and-retrieve format and is rated up to 4,000 psi and 250 degF. It is specifically designed for through tubing applications, which comes with SLB's segmented-ring technology that boosts internally to create a gas-tight seal.

To know more about the global well intervention scene, click here.

Reelwell AS has secured a strategic equity investment from Odfjell Technology, which has acquired a 10% stake in the company. The investment will support the continued growth and advancement of Reelwell’s DualLink digital pipe technology.

Reelwell AS has secured a strategic equity investment from Odfjell Technology, which has acquired a 10% stake in the company. The investment will support the continued growth and advancement of Reelwell’s DualLink digital pipe technology.

As part of this agreement, the existing collaboration between Reelwell and Odfjell Technology has been extended for five years, with the option to extend for an additional five one-year terms. This partnership aims to combine Reelwell’s DualLink digital platform and modem capabilities with Odfjell Technology’s offshore expertise in equipment deployment, maintenance, and logistics.

Earlier in the year, Reelwell announced a multi-year contract with Vår Energi ASA for the provision of its DualLink-powered digital drill pipe technology. This marked the first collaboration under the cooperation agreement between the two firms. Manufacturing and assembly are currently in progress at Reelwell’s Sola facility, with project execution scheduled to begin in late 2025. Under this contract, Reelwell will oversee the complete delivery of the DualLink technology, while Odfjell Technology will supply the required drill pipe components and accessories and manage various maintenance aspects.

Jørgen Peter Rasmussen, Executive Chairman of Reelwell, stated, "We welcome Odfjell Technology to our investor group as a strong industrial partner, and I am pleased to welcome Elisabeth Haram as a new Non-Executive Director on our board. Reelwell and Odfjell Technology will work closely together to deliver DualLink services to our clients. This is great news for the industry."

Elisabeth Haram, Executive Vice President Well Services at Odfjell Technology, added: “We look forward to working closely with Reelwell to enhance sustainable drilling practices and expand the use of DualLink across new markets.”

Houston-based oilfield technology company Baker Hughes' Prime Compact Puncher is one of the finalists for the 2025 ICoTA Global Intervention Technology Award, the winners for which will be declared towards March end during the SPE/ICoTA Well Intervention Conference and Exhibition.

Houston-based oilfield technology company Baker Hughes' Prime Compact Puncher is one of the finalists for the 2025 ICoTA Global Intervention Technology Award, the winners for which will be declared towards March end during the SPE/ICoTA Well Intervention Conference and Exhibition.

The other nominations include TorcCollector by E Plug AS, riserless coiled tubing in a live subsea well from RLWI vessel by TechnipFMC, high resolution dual caliper and slim multielement cement and corrosion tool combination by SLB, and Wellgrab by Welltec.

The Prime Compact Puncher is an advanced electro-mechanical puncher technology that gives way through spaces between two strings of downhole tubing. The puncher comes with an orientation module that directs it to the high side of a pipe where flow is optimal. There it can punch multiple circulation holes at the same depth level, boosting fluid consistency during circulation.

While it's an autonomous process operating on the basis of inputted parameters, an engineer can still maintain manual supervision if and when required. When it comes to well security, the puncher's anchor system goes on alert mode in cases of power loss, shutting down automatically and tools safely pulled out of the holes.

The punch head and anchor kits can be customised on the basis of the pipe size, and the drilling-bit comes in either 25 mm or 12 mm in OD, creating up to 0.792 inches of flow per punch.

The model's feedthrough wiring supports the deployment of additional technology below enabling single-run, multi-function solutions e.g. punch and cut in a single run.

To know more about the global well intervention scene, click here.

Page 35 of 118