Odfjell Technology, an integrated supplier of offshore drilling, well and engineering services, has achieved an industry-first for cleaning blowout preventers (BOPs) by reaching a 50% time reduction during a successful trial.

Odfjell Technology, over a test period of six months, revised the procedure for cleaning the BOP on the Johan Sverdrup platform in Norway by increasing the pump rate to allow more water flow into the BOP cavities to aid debris removal.

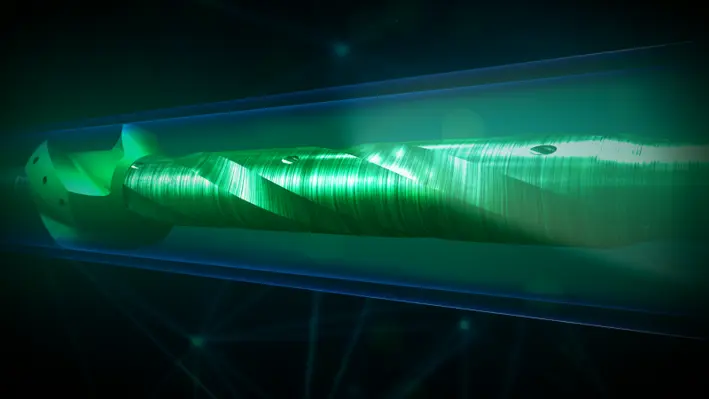

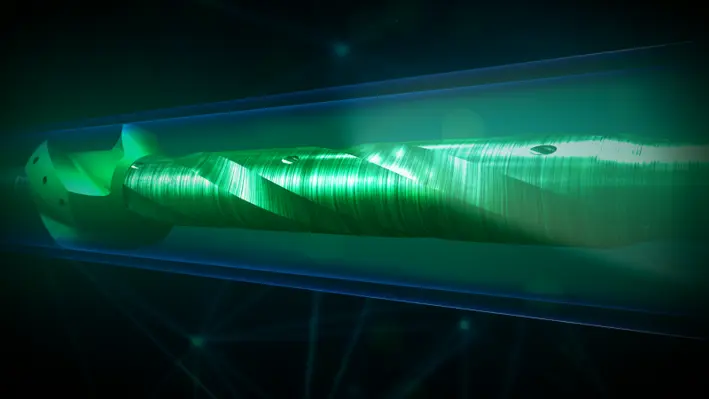

The annular and variable rams were flushed with two passes at the new recommended flow rates to remove debris, then the BOP stack was flushed at the same rate using Odfjell Technology’s RizeRdillo Advanced Jetting Tool. The flow rates went from 1,500 litres per minute (LPM) to 5,500LPM while flushing the annular and from 3,000LPM to 5,500LPM while flushing the BOP.

Results from the successful test period proved that no damage occurred to the BOP and annular with the recommended pump rates, and between six and 12 hours of time could be saved using this new procedure.

The RizeRdillo Advanced Jetting Tool allows for higher pump flow rates, enabling a larger volume of fluid with less pump pressure. This maximises riser cleaning efficiency to reduce operating costs and non-productive time.

Ian Low, Global Product Line Manager, Well Intervention at Odfjell Technology, commented, “By focusing on delivering world class expertise and technology which enables more efficient operations without compromise on safety, Odfjell Technology proves it is the partner of choice for customers time and again.

“Our ethos has been demonstrated by our expert teams achieving this impressive industry-first result for cleaning BOPs. BOPs are essential for safe and efficient well operations, and we are proud to deliver leading solutions to our customers to ensure BOPs are operating at optimal levels.”

The Norwegian oil and gas operator, DNO ASA, has reported that the wellhead platform production facilities have been removed from the Schooner field offshore the UK, signifying the last major offshore operation under DNO’s multi-year North Sea decommissioning campaign.

The Norwegian oil and gas operator, DNO ASA, has reported that the wellhead platform production facilities have been removed from the Schooner field offshore the UK, signifying the last major offshore operation under DNO’s multi-year North Sea decommissioning campaign.

DNO’s Chief Operating Officer, Chris Spencer, said, “We have conducted these operations in a safe, cost-efficient and environmentally responsible manner, coordinating five tier-one contractors and displaying our capabilities as a full life-cycle offshore operator.”

The heavy lift was conducted using the Heerema Marine Contractors’ Thialf semi-submersible crane vessel. The 1,200 tonne platform deck was lifted aboard the vessel on 17 May, while the jacket was removed on 23 May after the piles had been cut three metres below the seabed. The deck and jacket have been transported to the Hoondert Yard in the Netherlands for dismantlement and recycling.

Energy services provider, Expro, has announced a five-year well intervention and integrity contract with TotalEnergies EP Uganda for the multi-well Tilenga project.

Energy services provider, Expro, has announced a five-year well intervention and integrity contract with TotalEnergies EP Uganda for the multi-well Tilenga project.

Expro’s ability to provide an innovative environmental solution was a key component for securing the contract worth more than US$30mn for slickline services. The solution supported the client’s carbon reduction objectives, as well as coincided with Expro’s commitment to national recruitment in line with a local development plan set up in collaboration with TotalEnergies and the Petroleum Authority of Uganda (PAU).

Work will begin in Q2 2023, with Expro initially supporting drilling activity followed by production optimisation, integrity and well workover support. The company has designed four well intervention units to deliver a single operational solution for slickline and braided line in a cased hole environment across the life of the well. The solution is designed to reduce equipment footprint and equivalent CO2 emissions, while delivering improved efficiency.

Iain Farley, Expro’s Regional Vice President for Europe and sub-Saharan Africa, said, “We are delighted to further develop our relationship with TotalEnergies through work on this key project, which reinforces Expro’s ability to partner in frontier field developments in support of energy security.

“Expro’s solution was designed and engineered with the specific needs of this project in mind, taking into account the environmental sensitivities of the location and the need to support the project’s overall environmental and social objectives. It builds on our current operations in East Africa and on many years of successful delivery on key projects in locations such as Algeria, Saudi Arabia, Mozambique and Egypt.”

Helix Alliance, the Louisiana-based subsidiary of Helix Energy Solutions Group, has been awarded a 39-well decommissioning contract for the Gulf of Mexico shelf.

Helix Alliance, the Louisiana-based subsidiary of Helix Energy Solutions Group, has been awarded a 39-well decommissioning contract for the Gulf of Mexico shelf.

Owen Kratz, Helix’s President and Chief Executive Office, said, “This award demonstrates Helix’s position as the preeminent company for full-field decommissioning in the Gulf of Mexico shelf, along with our other services supporting the full life cycle of offshore fields, following the expansion of our industry-leading decommissioning services with our acquisition of Alliance last year.”

The scope of work includes the plug and abandonment of 39 wells, 15 pipelines and seven structures. Helix Alliance plans to utilise the EPIC Hedron heavy lift derrick barge for structure removals, lifeboats for P&A activities, the Triton Explorer dive support vessel for pipeline abandonments and multiple Helix Alliance OSVs throughout the campaign.

BiSN, a global provider of Wel-lok sealing solutions, has achieved a remarkable milestone by reaching 400 commercial deployments of its Wel-lok technology, a patented technology enabling bismuth-based seals that are more reliable, durable, and cost-effective than traditional sealing methods.

It was only 13 months ago that BiSN reached 300 commercial deployments of Wel-lok technology. According to the company, the rise in deployment since then has been part of a wider, exponential demand growth over the past three years among operators for both plug and abandonment and well intervention. As a result, 2022 represented the busiest commercial year for BiSN and Q1 of 2023 has already been record setting.

BiSN has now deployed into major areas such as North America, Europe, Africa, the Middle East, Asia, and Australia. Within these regions, the company has run commercial deployments in 17 countries, most recently in Mozambique. Building on this success, BiSN now harbours plans to continue its global reach while continuing to foster productive and collaborative relations with global operators.

Currently, Wel-lok technology has been commercially applied to 11 different applications, including water shut off, cement repair, packer repair, and plug and abandonment. The company has stated that it will continue to refine and develop Wel-lok technology for a variety of well intervention, completion, and plug and abandonment applications.

Paul Carragher, CEO and Founder of BiSN, remarked, “We are thrilled to have achieved this important milestone of 400 commercial deployments. It is a testament to the value and effectiveness of Wel-lok technology and could not be achieved without the commitment of the full BiSN team. As demand continues to rise across all active regions, BiSN is expanding to meet that demand by opening facilities now in Australia and Brazil.”

Archer has announced the award of a five-year contract for the provision of coiled tubing and pumping services with Perenco UK Limited in the United Kingdom.

The contract, with an estimated value of up to US$50mn, contains two options of one year each and commenced 3 May 2023 in direct continuation of company's previous contract with Perenco.

Dag Skindlo, CEO of Archer, commented, “We are extremely proud to announce this long-term coiled tubing and pumping contract. This commitment reflects our client’s confidence in our ability to maintain safe operations and continue our strong service delivery performance.

“Archer announced the acquisition of the Baker Hughes UK Coiled Tubing business early in 2023 and assumed operations from 4 April. We have successfully transitioned the business and have a dedicated Archer Coiled Tubing team of 50 experienced and skilled employees performing safe and efficient services in the UK.

“We look forward to continuing growing the Archer service offering in the UK and bringing value to our clients’ P&A, workover, and intervention programmes.”

Odfjell Technology, an integrated supplier of offshore drilling and well operations, and well service equipment including project and engineering services, has deployed its innovative rigless plug and abandonment (P&A) unit for a geothermal pilot project in Tromsø, Norway.

The downhole conditions for further testing and development of a underground heat storage concept were successfully established by using equipment and operational principles from the offshore oil and gas industry.

In co-operation with Xrig and Halliburton, Odfjell Technology played a key role in the planning and execution of this project for Kvitebjørn Varme, the company operating the district heating facility in the city of Tromsø. The overall aim for the project was to progress an underground heat storage concept developed by Ruden AS, which won the innovation prize at ONS in 2022.

Creating a network of subsurface fractures between a centre injector well, along with surrounding production wells placed in a circle around the injector, was the purpose of the project. All wells had been pre-drilled down to 300 m depth and Odfjell Technology’s P&A unit was used to deploy a hydraulic stimulation assembly, sand jetting and fracturing the formation every 5-7 m from 270 to 70 m depth.

Following the establishment of fractures, significant flow communication was confirmed between the injector well and the various producers by performing an injection test, meaning ideal downhole conditions were achieved for further testing the Ruden AS heat storage concept.

With this fracture system in place, Kvitebjørn Varme can now use the excessive heat produced from its plant during summer to warm up water, continuously circulating hot water down the injector well, into the fracture network and up through the producer wells. Heat is then transferred from the hot water to the formation, heating up the rock over time. During winter, cold water will be circulated into the same heated fracture system, transferring the stored heat to the cold water. Hot water is then produced from the production wells, ready to be distributed directly into the district heating network.

Elisabeth Haram, Executive Vice President Well Services at Odfjell Technology, commented, “Odfjell Technology uses its heritage of 50 years in the oil and gas industry to play a leading role in the energy transition. This very exciting and strategically important pilot geothermal project clearly shows how our technology and experience can be applied across the energy mix, and what collaboration and competence sharing between the oil and gas industry leaders and new industry partners in the energy sector can achieve.

“Our full rigless P&A unit offering for offshore SR and P&A operations will launch in the next four to six months. We look forward to working with customers and partners to implement this at scale across the world.”

Expro has secured a new contract with Harbour Energy for a well abandonment campaign as part of the decommissioning project for the Balmoral area, in the UK Continental Shelf.

The contract, valued at more than US$20mn, will utilise Expro’s Subsea Well Access technology with a combination of open-water and in-riser applications deployed from a semi-submersible rig.

Expro’s ability to supply a lightweight open-water system will help to mitigate loading issues during the subsea well access intervention part of the overall abandonment campaign. The company’s open-water and in-riser bore selector technology, which eliminates the use of a dual bore riser for the entire abandonment campaign, is designed to deliver significantly reduced system deployment and retrieval times with lower maintenance costs.

To overcome key technical requirements from the customer, Expro devised an innovative technological solution based on a new build lightweight intervention system, incorporating its unique subsea ball valve technologies. Expro’s existing API 17G standard high debris ball valve was recently qualified to provide a single ball cut and seal on coil tubing. This ball valve technology will be re-packaged into bespoke open water riser housings to provide the lightweight solution required.

The solution developed for this award expands Expro’s subsea well access portfolio and allows Expro to now supply the client with all the subsea well access tooling required for the abandonment campaign on the Balmoral area, for horizontal and vertical Xmas Trees.

Colin Mackenzie, Expro’s Vice President of Europe and Sub-Saharan Africa, commented, “We are proud to have secured this award by offering an innovative approach to meet the needs of this important customer. We believe that our leading-edge technology continues to deliver safe, reliable and environmentally secure subsea well access in support of major projects around the world. We are delighted to further extend the scope of our partnership on this campaign which reinforces our position as a key enabler within the plug and abandonment market.”

TechnipFMC has been awarded a significant contract by Equinor to provide riserless light well intervention (RLWI) services on the Norwegian Continental Shelf.

The two-year contract (valued between US$75 and US$250mn as per TechnipFMC’s definition of significant) runs from 2024 to 2025, with options to extend for each of the three subsequent years. TechnipFMC will provide production enhancement, production data, and pre-plug-and-abandonment services to Equinor using the RLWI method.

RLWI enables well interventions from a monohull vessel, eliminating the need for a riser and the rig required to connect the riser to the subsea well. Instead, remotely operated Well Control Systems are used to facilitate operations on the seabed. This reduces cost and complexity, increases efficiency, and accelerates the timeframe for increased production.

Jonathan Landes, President, Subsea at TechnipFMC, commented, “TechnipFMC has been providing RLWI services to Equinor since 2006. Over that period, the average duration of an intervention has been reduced by nearly two-thirds thanks to improvements in process and technology, aided by the collaborative relationship with Equinor’s dedicated RLWI team. It is a pleasure to continue developing that relationship as we help our client meet demand for energy.”

Elemental Energies has added to its extensive portfolio through the acquisition of Norwell Engineering (North Sea Well Engineering).

This is the second acquisition for Elemental Energies in just five months after it acquired Vysus Senergy Wells, a subsidiary of Vysus Group in December 2022. These are part of a series of strategic acquisitions to cement its position as the leading wells-focused energy consultancy.

The latest deal will increase the company’s total workforce from 75 to 105. Current clients will continue to be supported by the same long-term engineering specialists.

Elemental Energies’ Chairman, Martyn Fear, commented, “Norwell Engineering is a fantastic addition to our business. Their unrivalled experience in delivering major wells projects around the world further strengthens our capability and expands the opportunities to partner with operators, EPCs and other service companies. Their team has delivered more wells than any other independent consultancy, and decommissioned more wells than any of their peers. This impressive track record and reputation for excellence combined with our own extensive in-house capabilities now gives us a competitive edge on a global scale.”

Iain Adams, Managing Director of Norwell Engineering, added, "I’m extremely proud of our team at Norwell Engineering. Over the last three decades we have delivered many industry firsts and been behind multiple flagship projects from drilling wells in world record water depths to delivering more than 500 project managed wells globally since 1989. As we look to the future and how our world-leading expertise can support the transition of the energy sector through decommissioning and to low carbon, joining Elemental Energies is a natural fit and we look forward to integrating our teams to provide best-in-class, independent engineering and project management across oil & gas, decommissioning, CCUS and geothermal projects.”

Elemental Energies is currently working on a number of energy projects including a landmark carbon capture and storage project for the INEOS-led Greensand project, a number of major decommissioning campaigns in both the UK and Middle East, and multiple deepwater field development projects.

Established in 1989, Norwell Engineering has become the go-to wells specialist for large-scale and challenging projects. It has built a reputation supporting governments, regulators and the largest IOCs in delivering expert, independent advice. It has also built a leading reputation in decommissioning, completing its first dedicated well decommissioning project in 1996 and currently acting as project managers for both wells and facilities decommissioning on the UAQ field decommissioning campaign, offshore UAE.

Michael Dafforn, Director of Elemental Energies, remarked, “Elemental is committed to engineering the energy transition, and the expert team from Norwell Engineering will form an integral part of our ambition to build the leading independent consultancy for wells projects, across upstream, decommissioning and low carbon around the world.

“The Norwell team has earned an enviable reputation for successfully managing the largest and most challenging wells projects for clients around the world over the past 34 years, and we are delighted to welcome their wealth of expertise, team and clients to the company.”

Saipem has been awarded two new offshore contracts, one for an Engineering, Procurement, Construction and Installation (EPCI) project in the Black Sea and one for decommissioning activities in the North Sea, with the total value amounting to approximately US$850mn.

Saipem has been awarded two new offshore contracts, one for an Engineering, Procurement, Construction and Installation (EPCI) project in the Black Sea and one for decommissioning activities in the North Sea, with the total value amounting to approximately US$850mn.

The first contract was assigned by Turkish Petroleum OTC for the second phase of the Sakarya FEED and EPCI Project, and entails the engineering, procurement, construction and installation of a 16” pipeline, 175 km long at 2,200 m water depth in the Turkish Black Sea Waters. The offshore operation will begin in summer 2024 and will be conducted by Saipem’s flagship vessel, Castorone.

The other contract has been assigned by EnQuest Heather Ltd. for the decommissioning of the existing Thistle A Platform located in the UK sector of the North Sea. Saipem’s activities will include the engineering, preparation, removal and disposal of the jacket and topsides, with possible extension to further subsea facilities. The services will be carried out by the Saipem 7000, one of the largest semi-submersible heavy-lifting vessels currently in the world.

Fabrizio Botta, Saipem Chief Commercial Officer, said, “These important awards demonstrate Saipem’s excellent competitive positioning in the Offshore Engineering & Construction market a sector that is experiencing a full expansion momentum of which Saipem is ready to seize the opportunities.

“The contract awarded in the Black Sea is a confirmation of Siapem’s prominent positioning and of its long-standing relationship with the clients. The North Sea contract, finally, is a further example of Saipem’s capabilities in a segment where the combination of innovative engineering, unique assets and safe operations is crucial.”

Helix Energy Solutions’ Q7000 vessel has berthed in Port Taranaki to carry out a crew exchange and load up on supplies before heading to complete the third stage of the Tui oil field decommissioning campaign, which is set to take approximately three months to complete.

Helix Energy Solutions’ Q7000 vessel has berthed in Port Taranaki to carry out a crew exchange and load up on supplies before heading to complete the third stage of the Tui oil field decommissioning campaign, which is set to take approximately three months to complete.

Port Taranaki’s head of commercial, Ross Dingle, said the port was pleased to support the project, having also provided berthing services and laydown facilities for the first two stages.

Port Taranaki is working with New Plymouth-headquartered energy consultancy, Elemental Group, which is providing project management assistance of New Zealand operations for Helix Energy Solutions.

Nick Jackson, Elemental Group Director, said, “All up, there will be a team of more than 100 on the Q7000, over half being Kiwis and Aussies in operations roles working alongside the Helix crews, as well as several specialist roles, such as wireline and cementing.

“We’re excited to be a part of the project. I worked on some of the original Tui exploration wells, so it’s nice to be involved in restoring the mauri of the area.”

Page 69 of 118