Toshiba Energy Systems & Solutions Corporation (Toshiba ESS) will be supplying SEPCOIII Electric Power Construction Co., Ltd. with steam turbines and generators for the geothermal power plant equipment renovation of Units 1 through 3 at the 45MW Olkaria I geothermal power plant in Kenya.

Toshiba Energy Systems & Solutions Corporation (Toshiba ESS) will be supplying SEPCOIII Electric Power Construction Co., Ltd. with steam turbines and generators for the geothermal power plant equipment renovation of Units 1 through 3 at the 45MW Olkaria I geothermal power plant in Kenya.

The equipment will be shipped to the site by December 2025.

Said to be the oldest geothermal power plant in Kenya, Olkaria I has been in commercial operation by the Kenya Electricity Generating Company PLC (KenGen) since 1981.

The installation of the new steam turbines and generators will allow the units to achieve higher outputs with less steam, as each of them will increase considerably from 15MW to 21MW each. This will make a huge difference in meeting Kenya's growing demand for power. The development aligns with the Kenya Government's Vision 2030, which aims to boost the country's electricity generating capacity from renewable sources. Many new geothermal power plants are planned to tap into the 9GW geothermal potential in Kenya's Great Rift Valley region.

Toshiba ESS and KenGen are working closely since 2022 in providing operation and maintenance (O&M) services for geothermal power plants, and have plans to expand their service to developing countries beyond Kenya.

Shinya Fujitsuka, Director and Vice President of the Power Systems Division at Toshiba ESS, said, "I'm pleased that we can contribute to energy stability in Kenya by providing our equipment and services. Toshiba ESS will continue to provide optimal products and solutions to meet customer needs through its lineup of small to large geothermal steam turbines and generators with power outputs ranging from 1 MW to 200 MW. Aiming for the further clean energy indispensable for the realization of a sustainable society, we will contribute to the realization of a carbon neutral society by providing geothermal power plant services both in Japan and overseas."

The Offshore Well Intervention West Africa Webcast from Offshore Network shines the spotlight on a market with significant potential and unpicks the challenges holding it back.

The Offshore Well Intervention West Africa Webcast from Offshore Network shines the spotlight on a market with significant potential and unpicks the challenges holding it back.

Moderator Robert Daniels, Editor at Offshore Network, was joined by an expert panel of guests who joined the discussion from a myriad of locations across the region. This list of panellists willing to share their knowledge and experience included Obasi Isdore Chigozie, Well Intervention Specialist at Sterling Oil Exploration & Energy Production Co. Ltd; Albert Amewolah, Subsea Operations Engineering at Tullow Oil; and Isioma Agbadiba, Subsea Production Supervisor at Eni Nigeria.

At a time when the global oil and gas industry is grappling with the energy transition, the need to maintain production targets has remained imperative – despite COP28 calling for an eventual transition away from fossil fuels – in line with growing power demand. In West Africa, companies are now looking to do their part for the environment while also contending with the wider issues around electrification and the role fossil fuels will continue to play in the economic development of its nations.

It is against this backdrop that the panellists spoke on the role of offshore well intervention within this evolving environment – a method often depicted as the answer to enhancing production rates without incurring the sustainability hit of drilling new wells. Additionally, the market and its servers are receiving heightened attention due to the growing need for plug and abandonment activities as the world’s (and region’s) offshore wellstock increases in average age with every passing year.

Together, the industry experts explored such topics and answered where West Africa fits into this global trend? What are the factors unique to the region and that are shaping its future? And what must be done for more well intervention campaigns to be conducted there?

Click here to discover the full, free-to-view webcast.

And for any questions surrounding the topics covered or the upcoming OWI WA conference (running from 28-29 May in Lagos, Nigeria), reach out to:

Jack Heffernan - Project Manager

e:

t: +44 (0)20 3038 6926

Helix Energy Solutions Group has been awarded a deepwater well intervention contract by Esso Exploration and Production Nigeria (Esso).

Helix Energy Solutions Group has been awarded a deepwater well intervention contract by Esso Exploration and Production Nigeria (Esso).

The contract is for work offshore Nigeria in the Erha and Usan fields wherein Helix will provide its Q4000 well intervention vessel to cover fully integrated well intervention services from production enhancement to plug and abandonment.

Scotty Sparks, Helix’s Executive Vice President and Chief Operating Officer, commented, “We are pleased to announce this contract for the Q4000. We are eager to strengthen our relationship with Esso and to further establish our presence as the leader for well intervention services in West Africa.”

The project is expected to commence in September 2024, with the vessel expected to stay in Nigeria until 2025.

Thermoplastic composite pipe (TCP) provider Strohm has supplied TotalEnergies with a TCP jumper, which has been commissioned for a 1,600 m deepwater project in West Africa.

Thermoplastic composite pipe (TCP) provider Strohm has supplied TotalEnergies with a TCP jumper, which has been commissioned for a 1,600 m deepwater project in West Africa.

This installation has followed a rigorous testing programme, during which TotalEnergies qualified the Netherlands-based company's TCP jumper for permanent subsea applications. All pre-deployment inspections and tests were successfully passed, certifying it for its full life cycle on schedule.

The installation of Strohm’s 5.2” ID, 340 bar design pressure TCP Jumper in the Egina field was supported by a local Nigerian subsea services provider. The pipe’s lightweight properties allowed it to be transported by a small, multi-purpose vessel and installed by local contractors, greatly reducing carbon emissions and costs. Strohm personnel were mobilised offshore to assist in the installation process.

Martin van Onna, Strohm CEO, said, “We are immensely proud to see our first TCP Jumper for our highly valued client TotalEnergies installed and operational in West Africa. This success reaffirms TCP as an ideal deepwater solution and strengthens our leading position in the market.”

Strohm’s TCP provides a robust, corrosion free and field-proven solution for operators. TCP jumpers can be manufactured and shipped in long continuous lengths, stored onsite for long periods of time, cut to length when required and terminated within hours, with no change to its properties or lifespan. TCP for subsea jumpers as well as flowlines and risers have proven to reduce the CO2 footprint of pipeline infrastructures by more than 50%.

40 years since the launch of its first subsea test tree system, Expro, a leading energy services provider, has remained at the forefront of subsea landing string technology.

40 years since the launch of its first subsea test tree system, Expro, a leading energy services provider, has remained at the forefront of subsea landing string technology.

The first 10ksi subsea test tree assembly (SSTTA) was created for an exploration and appraisal well project for Hamilton Brothers in the North Sea in 1983. Several of its SSTTA technologies have been on a first to market basis and have helped to progress the sector’s capabilities over the years. Expro has now undertaken more than 3,000 subsea deployments in exploration and appraisal, completion, and intervention applications, and remains a global leader in large-bore SSTTA solutions.

Other subsea well access major milestones Expro has achieved over the years have included the introduction of the first 7 3/8” 10ksi horizontal tree completion landing string system; the launch of the industry’s first 6 ¾” high debris SSTTA system; the release of the first large bore 6 ¾” 10 ksi subsea electro hydraulic control system; unveiling the first 6 ¾” 10ksi dual bore and mono-bore subsea test tree offshore; revealing the first 15ksi 6 1/8” horizontal tree SSTTA and electro-hydraulic control system; and the development of 7 3/8” 10ksi high debris SSTTA.

The evolution of subsea test tree assemblies has allowed the company to expand into the open water well intervention market through the introduction of both riser-based and riser-less well intervention solutions. Such success and dedication to subsea well access application even earned the company the accolade of Intervention Champion of the Year at the recently-held OWI Global Awards 2023.

At the company is showing no signs of building on its successful history. In a bid to continue this history, it has sought to boost its subsea capabilities by acquiring PRT Offshore, the only company to offer a complete Hook-to-Hanger solution enabling comprehensive well completions, interventions, and decommissioning services from surface to subsea. The acquisition enables Expro to expand its portfolio of cost-effective, technology-enabled services in the North and Latin America region and accelerate the growth of PRT Offshore’s surface equipment offering into the Europe and sub-Saharan Africa and Asia Pacific regions.

“At Expro, we’ve been first to the market with many of our subsea test tree assembly products and, as future technical challenges arise, we believe that with our customer-bespoke solution philosophy, we’ll continue to be at the top of the subsea test tree application,” remarked Graham Cheyne, Expro’s Vice President of Subsea Well Access.

“From starting in 1983 supporting operators in the Norwegian North Sea, we’ve become a global player in all parts of the world, supplying fully integrated technologies and services from surface to seabed – the hook to hangar concept. The subsea test tree market operates in the full well lifecycle – from exploration and appraisal through to abandonment and decommissioning while continually looking to improve our delivery and operational performance, and service quality to our global client base.

"Whilst leading in this market for over 40 years with many first to market technologies we are committed to delivering the new technology requirements of tomorrow in order to meet our customer needs whilst maintaining the high level of service quality and customer care.”

Global leader in oil and gas well integrity and production optimisation, Coretrax, has appointed Colin Graham as the company’s first Sales and Operations Manager for Africa as it plans for future expansion.

Graham joins the business with more than four decades of experience under his belt, including previous works completed in the North Sea, Middle East and Africa. In his previous role as Business Development Manager for the Middle East and Caspian at TAM international, he was responsible for driving new and existing business across the region, with a particular focus on well intervention, completions and drilling.

His new role will see him play a key role in strengthening Coretrax’ presence in Africa by building on the company’s existing relationships within the region. His appointment follows a number of substantial project wins for Coretrax in western and southern Africa.

Graham said, “I’m very proud to be joining the team at Coretrax to enhance existing operations and actively expand the business’ footprint across Africa. The region is so vast, and no two fields are the same, so the breadth of Coretrax’s technology allows us to support every stage of the well lifecycle for both onshore and offshore projects. I am eager to share the opportunities that these technologies present to the energy industry in Africa and with the companies operating in the region.”

John Fraser, CEO at Coretax, commented, “As we continue to grow our business on a global scale, Colin will be a huge asset to the Coretrax team. His operational experience and expertise in well intervention and integrity will be extremely valuable to our existing customers in Africa and optimise well performance, and actively address operator challenges.

“Africa has been a key focus area for the business, and we have significant experience supporting major projects in Ghana, the Ivory Coast, Mauritania, Tanzania and Angola with a strong aim to increase our operations. We look forward to extending the delivery of our technology and high quality customer service to enable valuable time and cost savings to our customers.”

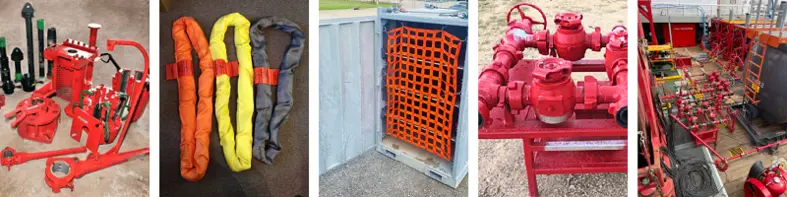

Gulfstream Services Inc. (GSI), an oilfield rental services company, has formed a partnership with Kontinental Energy Services (KES) to provide rental tool equipment and services for jobs in the African oil and gas industry.

Bobby Bond, GSI Chief Executive Officer, remarked, “We are excited about being aligned with the management of KES and bringing quality equipment and solutions to the African continent. Our 45 years of industry experience, solid reputation and solutions-based approach is something we feel will ensure our success going forward.”

The partnership will facilitate a more robust approach for providing the right tools to get jobs completed to the highest level of quality, safety and performance for energy services companies and international, major, national and independent oil and gas companies across the continent.

Bond added, “We believe the growth potential in the Eastern Hemisphere will be robust for many years. This partnership, along with our recent expansions into Asia Pacific and the Middle East show our commitment to this part of the world.”

The suite of rental tools and equipment include (but not limited to):

• A complete line of high-pressure standard services, H2S Services Chiksan Equipment;

• Low pressure piping and hoses;

• Cargo boxes, baskets and custom designed racks for operators and services companies;

• Restraint system to restrict movement of temporary flow iron in the event of an unplanned release of pressure;

• Full-service 3rd party iron management programme that helps keep customer-owned asset pumping at peak performance;

• Cementing, coil-tubing; HWO and flowback support packages;

• Spool & gate valves.

KES and GSI are also planning to build workstation hubs in Africa for proactive maintenance of equipment and training of all service technicians in respective countries. The first of these will be built in Congo/Angola and will support activities in the nations as well as in Namibia, South Africa, Gabon and Equatorial Guinea.

"We are confident in the partnership with KES to expand our footprint in Africa, and we anticipate GSI to bring much innovation and technology to service operators throughout those areas with our full array of rental services and equipment," concluded Bond.

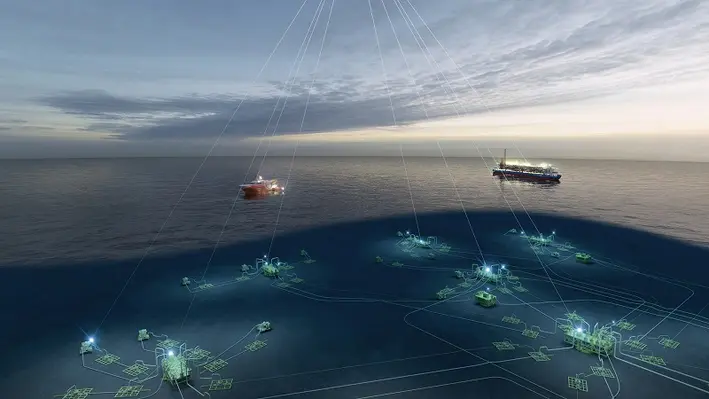

The proposed joint venture between SLB, Subsea7 and Aker Solutions has taken the next step to being realised following regulatory approval by antitrust authorities in Brazil.

With the signing off from the Brazilian authorities, all regulatory approvals and clearances have now been obtained, including those required in Angola, Mozambique, Australia, Norway and US, making the Q4 2023 closing more likely.

The joint venture has been pursued in order to help customers unlock reserves, reduce time to first oil, lower development costs and achieve decarbonisation goals in their projects. The companies will pool their deep reservoir domain and engineering expertise, extensive subsea production and processing technology portfolios, manufacturing scale and capabilities, and comprehensive suite of life-of-field solutions for clients around the world. This has this been described as a “milestone in subsea production economics” by the companies.

Following this announcement, the parties have stated they will continue to work to satisfy the remaining conditions for closing and aim to do so as practicably possible in Q4 2023.

According to Rystad Energy, the well intervention market is receiving a healthy boost as oil and gas companies look to increase their output.

The research and business intelligence company claimed that spending on interventions is projected to jump by almost 20% in 2023 to total US$58bn and this is just the start of a surge in the coming years.

The intervention rate is forecast to reach 17% in 2027 which would total about 260,000 wells globally.

Breaking this down, Rystad showed that more than US$11bn of the total expenditure will be directed to the wireline & perforating segment, while together, intervention units and oilfield chemicals sectors will represent 35%. In addition, the sum of the investments in coiled tubing, water management, and intervention tools is expected to close 2023 surpassing US$20bn.

Regionally, onshore interventions in Asia, South America, and Africa will lead the 9% growth in activities related to intervention during 2024, a year expected to be significant for the well intervention market. North America is projected to account for 64% of the total oil and gas wells ready for intervention in 2027, whereas Asia and South America will reach their maximum in 2026, with respectively 41,413 and 9,703 wells.

Jenny Feng, Supply Chain Analyst at Rystad Energy, explained, “As oil demand picks up in the second half of this year, operators will look to ramp up production from existing fields, and well interventions will be a vital piece of the puzzle. As a quick, efficient, and cost-effective method of maximizing existing resources, interventions are going to be a hot topic in the years to come.”

In terms of offshore markets, 618 assets are highly attractive for intervention. Norway and Australia stand out with 36% and 25%, respectively, while the UK has 91 wells likely to be involved in intervention activities.

Baseload Capital, an investment entity dedicated to advancing geothermal energy deployment globally, has announced its second strategic investment from energy technology company Baker Hughes.

Together, the partners will look to expand global geothermal project development and position the resource as a high-impact, clean energy source for global markets; catalyse market growth by facilitating the implementation of new commercial and development models; and advance next-generation technologies from the pilot stage through to commercial scale.

Alexander Helling, Baseload Capital CEO, remarked, “Developing long-lasting, strategic and co-beneficial partnerships is vital to driving innovation and scaling up geothermal power. Baker Hughes' second round of investments exemplifies the importance of leveraging assets and expertise across the energy sector for a swift transition to a global renewable energy mix.”

Ajit Menon, Vice President of Geothermal Energy, Oilfield Services and Equipment at Baker Hughes, added, “Baker Hughes is dedicated to driving lower carbon solutions through strategic investments in key growth areas. Our collaboration with Baseload Capital represents a truly innovative alliance in the geothermal market, leveraging the unique strengths of both companies to rapidly expand installed geothermal capacity.”

Oilenco Ltd has announced the appointment of David Nicoll who has joined the company as Business Development Manager for sub-Saharan Africa (SSA) in order to reinforce Oilenco’s focus on overseas well intervention markets.

Oilenco Ltd has announced the appointment of David Nicoll who has joined the company as Business Development Manager for sub-Saharan Africa (SSA) in order to reinforce Oilenco’s focus on overseas well intervention markets.

David, known to his network as Davie, will bring 25 years’ worth of experience to the company, with more than 16 years working across a variety of downhole intervention roles. He commented, “I’ve spent the last nine years travelling all over SSA learning about this market. As a leader in well intervention and abandonment within the UK, Oilenco are uniquely positioned to deliver best-in-class solutions that are ideally suited to the SSA market.”

In his role, Davie will be responsible for bringing Oilenco products and solutions to this evolving market, developing the Oilenco brand in the sub-Saharan region and establishing the company as the provider of choice for downhole tool solutions.

Davis will make his debut as Business Development Manager next week at the Offshore Network Well Intervention West Africa Conference on 20 and 21 June.

“I am delighted to be joining such an innovative team, at an exciting time for the company. With a real focus on growth not only in Africa, but in other regions, I look forward to bringing Oilenco’s reputation as a first-class downhole tooling provider to the market,” Davie said.

Energy services provider, Expro, has announced a five-year well intervention and integrity contract with TotalEnergies EP Uganda for the multi-well Tilenga project.

Energy services provider, Expro, has announced a five-year well intervention and integrity contract with TotalEnergies EP Uganda for the multi-well Tilenga project.

Expro’s ability to provide an innovative environmental solution was a key component for securing the contract worth more than US$30mn for slickline services. The solution supported the client’s carbon reduction objectives, as well as coincided with Expro’s commitment to national recruitment in line with a local development plan set up in collaboration with TotalEnergies and the Petroleum Authority of Uganda (PAU).

Work will begin in Q2 2023, with Expro initially supporting drilling activity followed by production optimisation, integrity and well workover support. The company has designed four well intervention units to deliver a single operational solution for slickline and braided line in a cased hole environment across the life of the well. The solution is designed to reduce equipment footprint and equivalent CO2 emissions, while delivering improved efficiency.

Iain Farley, Expro’s Regional Vice President for Europe and sub-Saharan Africa, said, “We are delighted to further develop our relationship with TotalEnergies through work on this key project, which reinforces Expro’s ability to partner in frontier field developments in support of energy security.

“Expro’s solution was designed and engineered with the specific needs of this project in mind, taking into account the environmental sensitivities of the location and the need to support the project’s overall environmental and social objectives. It builds on our current operations in East Africa and on many years of successful delivery on key projects in locations such as Algeria, Saudi Arabia, Mozambique and Egypt.”

Page 4 of 9

Copyright © 2026 Offshore Network