Energy services provider Expro has landed a significant milestone with the 100th deployment of its cementation technology SeaCure; this time for a five-well subsea batch campaign in Australia.

An exclusive offering on cementing portfolio, SeaCure technology was originally developed by DeltaTek, which Expro acquired last year. While the acquisition widened Expro’s technology portfolio in the well construction cementing sector, it also unlocked global access for DeltaTek. Recently, Expro completed the acquisition of integrity and intervention specialist, Coretrax, as well.

SeaCure helped maintain the quality primary cementation of the conductors, eliminating major risks associated with cement slurry placement.

A proprietary stabbed-in inner string technique was involved in post-cementing circulation via the inner annulus until slurry curing was complete. This ensured reliable installation of the top holes.

Alistair Geddes, Expro’s Chief Operating Officer, said, "Reaching our 100th global SeaCure job is a testament to the dedication and expertise of our team, as well as the strength of our technology and solutions. We are proud of providing the platform for Tristam Horn and the legacy DeltaTek to expedite their growth journey and quest for providing innovative solutions to our clients.

“Ineffective cementation is one of the single biggest contributors to cost over-runs, poor life of well integrity and ultimate failure of well objectives. Expro’s robust Cure portfolio has been developed to solve many of the issues associated with cementing subsea wells with the aim of delivering first time ultimate cement placement. SeaCure is an example of Expro’s commitment to investing in innovation, developing new technologies and delivering value and excellence to our clients globally."

BiSN, a provider of permanent downhole sealing solutions, has opened a manufacturing facility in Perth, Australia in order to increase its operational capacity in the Asia-Pacific region as well as creating several local jobs.

The decision to make the investment was driven by the growing demand for Wel-lok technology in the region. According to Paul Carragher, founder and CEO of the company, it is another step in its global expansion and builds on successful campaigns with operators in Australia and the wider region. Carragher added, “The Perth facility is one part of our commitment to rapidly support operators, allowing them to deploy Wel-lok technology for all intervention and P&A sealing applications.”

The Perth facility features full heater and bismuth-based alloy production, two major components of Wel-lok technology, as well as final assembly. It also provides a focus for regional business development and a field operations base. It will also boast a demonstration room to allow operators to view and get hands-on with Wel-lok and other technologies offered by BiSN. This will facilitate a collaborative environment for planning P&A, intervention and completion solutions.

The opening of the facility will remove the barrier of lead times due to shipping from the US or UK which can be prohibitive for operators and their intervention needs. “By opening a facility in Perth, it allows us to be more responsive to the needs of operators in Australia,” said Adrian Weiss, BiSN Senior Vice President of Operations. “The new facility is a continuation of BiSN’s commitment to increasing our global capability. We have listened to our clients in this region, and we are responding to help them seal safer and protect forever.”

The announcement follows the appointment of a new Regional Business Development Advisor in the Australian city, revealed earlier this year. Andy Vigor, the new appointment, boasts extensive experience in the industry having held roles in the Middle East and Asia Pacific regions. Now with BiSN, he is supporting customers both in Australasia and throughout the wider region.

Vigor surmised, “With the geographical size of the Australasia and the Asia Pacific region, response time and the ever-increasing cost of logistics is critical to our customers. We can now provide customized, engineered products and solutions locally, which will assist BiSN in its efforts to achieve service excellence for all of our regional customers.”

The Offshore Well Intervention Australia 2023 Conference was carried out earlier this month as a host of industry experts and key stakeholders in the offshore community arrived in Perth for two days of engrossing seminars, presentations, panel discussion and (of course) extensive networking.

There were many highlights from the conference which provided an extensive ranging of talking points for those in attendance. A presentation by a NOPSEMA representative was an early point of interest which provided an insight into where the Australian regulator saw gaps in technology within the industry and what are the requirements for bringing new technology into the fold.

Attendees were also invited to hear how ExxonMobil has been creating a culture of innovation and improvement, where biases can be challenged and leadership teams are more receptive to new ideas. The ExxonMobil presenter noted and reviewed why this culture is so important and how it can help in upcoming campaigns as every participant’s ideas are valued, allowing for the continuous development of techniques and ideas to complete projects efficiently and effectively.

Then, in a memorable panel discussion that was described by a later presenter as one of the most memorable on the subject he had ever seen, participants from CCS Energy, NOPSEMA, Asia Pacific Energy Solutions and CO2Tech sat down to provide their thoughts on the CCS market in Australia. In the session, the speakers provided a detailed insight into the challenges and opportunities posed by the CCS market in the region, what are the advantages and disadvantages of repurposing ageing wells for CO2 storage, and how regulatory pressures are shaping the environment. Read more about what was said in the session here: https://offsnet.com/content/australia/meeting-emission-reduction-targets-through-ccs

Stringing the two days together was a myriad of presentations from technology providers and service providers outlining how their solutions were ready to support Australia’s offshore community for its well intervention requirements. In this vein, on the exhibition floor stood the likes of TAM International, Oilenco, Impact Selector and WELLVENE ready to display their wares to the gathered delegates. The onsite representatives provided some thoughts to Offshore Network on how their organisation was perceiving the Australian market:

Alastair McGregor, Business Development Manager at TAM International, remarked, “For Australia I think there's a lot of potential growth. The legislative, government and regulatory bodies have perhaps worked against themselves somewhat and lobbyists have perhaps been able to derail some projects that actually didn't have a lot of risk but were perceived as high risk.

“However, we have definitely seen a massive uptick in the whole P&A space but also routine well intervention here. P&A is definitely a major part of what we do and plugs and packers are integral to some of the operations around P&A. We are also seeing a bit of an uptick in people understanding how to apply them in the drilling phase as well. But, overall, P&A is definitely a large scope of what we do and is a large area of growth for us here.

“We've attended a few OWI AUS now and this one has certainly been very engaging with regards to the attendees; people definitely want to connect and learn a bit more about each other. We like to participate at events like this because it allows us to talk to more people and engage with them individually. There has definitely been a lot of interest in having those conversations during this event and I think we have at least four or five new leads from this conference.”

Colin Mackie, Country Manager at WELLVENE, said, “The main changes over the last six years for our company in Australia has been utilisation of equipment that is tried and tested in remedial intervention and utilising them in the P&A space. There has been more focus from operators on robust barriers and making efficiencies in deploying those barriers, which is where we've been able to help. As you go through P&A operations you have to consider every possible obstacle you may encounter on these older wells and try and plan contingencies that are efficient yet allow for the unknown, the fact that we are a smaller and more flexible company allows us to provide solutions a lot faster when the unknown does occur, and have a short turnaround on equipment that is bespoke to that particular problem. I think that will remain a big part of what we do in Australia over the next 10 years as well as the building of core products.

“Major growth areas for us as a company over and above the P&A and remedial intervention market would be service, we have some new technologies that allow for significant efficiencies in the Intervention space, and we are keen to work alongside the operators and indeed the contracted service companies to improve the safety and overall efficiency of interventions going forward.

“As a company that is established in Australia already, OWI AUS allowed us to reconnect with some people that we don’t necessarily get to see on a regular basis that have flown in for the event and meet some of the overseas service companies that are coming in to try and introduce their products into our market. It has allowed us to share our story of growth in Australia over the last six years. Furthermore, it allows us to showcase our understanding of Australian market to the clients and operators that are here.”

David Fisher, Business Development Manager at Oilenco, commented, “Oilenco have a strong track record in the North Sea and have been completing abandonment workscopes in this space since 2018. As Australia is becoming increasingly active in this area, we recognise that our technologies are transferable to this market.

“The OWI AUS conference provided us with the opportunity to showcase not only our capabilities but for attendees to see first-hand some of the projects we have completed. From safety valve remedial projects for well intervention workscopes to creating well-barriers for multi-well campaigns for an abandonment workscope. But also, how we deal with the unexpected, creating bespoke solutions to solve parted tubing challenges as an example, and our ability to manufacture, design and engineer these solutions to meet the specific challenges our clients face. It also allowed us to demonstrate how we can become an extension to a project team, with early engagement sometimes being the difference between getting a solution and getting the right solution. When speaking with operators they recognise how our solutions can support their needs.

“From the work we have completed in Australia so far, the feedback we have been getting from clients is very positive, so we look forward to continuing to support this region.”

Steve Irvine, Region Manager Australia-New Zealand-PNG at Impact Selector International, surmised, “This last year has been pretty slow because there's been a lot of projects been pushed back due to various factors such as the regulator and the government just told him things back a bit. So it has been a bit slow but I think it appears that it is going to fruition next year and in the years ahead. This is because these plans will likely now get passed and the major operators are getting their EPs together and better than they have been. So I would say I am optimistic for the future in this region, especially in regards to P&A which appears will be the next big thing here with lots of projects kicking off for that. So that will certainly be a focus for us.

“OWI AUS 2023 was very much what we wanted to happen. The audience was very much in our own line of business, which is good and it has been a while since I've been to conference which has had the right people as this did.”

At the recently concluded Offshore Well Intervention Australia 2023 conference held in Perth, a panel of industry experts convened to explore the outlook for the CCS market in Australia.

Together, they considered the ambitious goal of significant emissions reduction by 2030 and how the industry can overcome the time constraints by implementing CCS projects, what opportunities exist or could be put in place to facilitate industry stakeholder collaboration, and how can the industry share knowledge to accelerate CCS adoption and address common challenges effectively.

In the session, Diego Vazquez Anzola, CCS Specialist at APES Energy Evolution, explained, “Acceleration can indeed benefit from industrial and governmental collaboration. Collaboration is important and necessary, but it is not indispensable.

“There are those who point at regulations, or sometimes the lack of them, as the reason for the slow progress of CCS projects in Australia. Australia has the opportunity to not reinvent the wheel and analyse closely the history of other successful projects in other jurisdictions. The few successful commercial scale CCS projects around the world, in or nearing execution, were matured in various timeframes. However, those projects with the most compressed maturation timelines have common denominators, which, contrary to the general belief, are not particularly technical.

“The acceleration of CCS projects around the world has been attained by prioritising simplicity in storage development planning, with phased and calculated strategies for growth and scalability. Furthermore, acceleration has been truly attained by having first a clear understanding of the value generating models, with clear strategies on revenue generation and maximisation. This is indispensable.

“It is when commercial models are clear that industrial collaborations thrive – with a solid strategy towards job creation and workforce re-skilling and with regulators incentivising an environment of knowledge sharing and communication that naturally results in simpler and more streamlined approval processes.

“In summary, industrial and governmental collaboration and knowledge sharing would indeed be beneficial for acceleration. However, commercial clarity is what enables true collaboration towards acceleration.”

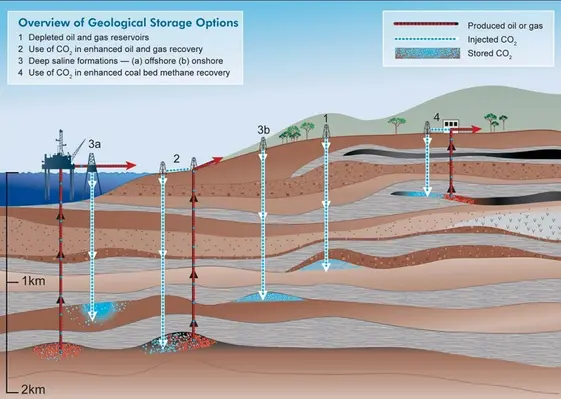

Adding his voice here, Jason McKenna, CCS Strategic Advisor at CO2Tech/CO2CRC, commented, “If I had to choose one word to describe the goal of achieving significant GHG emissions reductions by 2030, it would be ‘challenging’. In Australia, the LNG and gas industries are likely to be the first movers as the capture component is already built in to the CCS value chain. The rate limiting step for significant emissions reductions is likely to be the development of cost-effective large-scale capture technologies for the hard-to-abate sectors. In terms of storage, depleted fields may offer reduced project development timelines in comparison to green-field saline aquifers by avoiding the need for lengthy appraisal programmes and the possible re-use of existing infrastructure.

“Currently, there seems to be more of a competitive rather than a collaborative environment amongst the oil and gas companies in terms of access to geological storage. There is the possibility for the Australian CO2 storage capacity to be ‘over-subscribed’ at the moment due to the number of gazetted GHG permits. It would be disappointing to see a number of individual small-scale CCS developments fail the commerciality test (i.e $/tonne) to the detriment of more commercially efficient hub-scale collaborative CCS developments.

“Another area of collaboration to facilitate timely project development timelines is early and regular engagement with stakeholders, particularly NOPTA and NOPSEMA. CCS is an emerging industry globally and regulators will likely have more confidence to provide timely project approvals if they feel informed and engaged at key project milestones.”

Ageing Wells for CO2 Storage

On exploring the advantages and disadvantages of repurposing ageing wells for CO2 storage, Vazquez Anzola continued, “It is well known that engineers prefer to build from scratch rather than modify existing tools, machines or gadgets. Well engineers around the world concur that newly built wells result in the most effective and safest designs.

“On the other hand, general perception dictates that reutilising infrastructure, including aged oil and gas wells, is the simplest and the most cost efficient solution for CO2 storage development plans that can be matured in the shortest time frame. This is not always the case, and it is rarely the case for scalable CO2 storage hubs.

“Although injecting CO2 in depleted fields is a valid option for commercial scale CCS projects, especially in early phases for CO2 storage hubs, this does not come without technical challenges and can result in extremely complex and/or expensive solutions.

“Traditional oil and gas professionals need to soon understand the concept of ‘permanent storage’ when commerciality of CCS projects is directly dependent on demonstrating to authorities, regulators, shareholders, and the market in general, that every molecule that has been injected is expected to remain sequestered for centuries. A small percentage of leakage after 100 or 200 years or more is considered acceptable in various jurisdictions. The general expectation is that by then, CO2 sequestration would not be as necessary to tackle global warming as it is today.

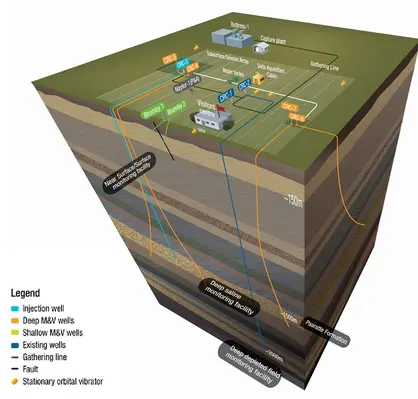

“As a consequence of these radically different timeframes, risks of loss of containment and mitigation plans embedded in the much needed Measure, Monitoring and Verification (MMV) plans of any CO2 storage project directly affect the design and material selection of future P&A campaigns, as well as all steps required for transforming other infrastructure for CO2 manipulation, conditioning and transportation.

“In a nutshell, initial scale and future scalability of the future CO2 storage hub determines whether or not depleted fields are suitable options. Long term containment risks need to be managed in a cost-efficient but also pragmatic fashion founded on a thorough understanding of these containment risks, their likelihood and their consequence severity.

“However, even when legacy wells are not re-used as CO2 injectors or monitors, they may need to be abandoned more adequately as they will eventually be exposed to the CO2 pressure and/or saturation plumes. The challenge reaches its peak when some of the riskiest legacy wells abandoned years ago following traditional O&G standards, might not even be accessible for adequate re-abandonment. Costs but most importantly containment risks determine whether or not a specific storage site is adequate to the required CO2 injection scale. This is of particular importance in depleted fields.

Picking up this thread, McKenna added, “The perceived advantages of using legacy petroleum wells (and legacy petroleum facilities for that matter) are reduced project timelines and reduced cost (CAPEX). However, this perception may be a false economy as retrofitting a brownfield development may not deliver on these perceived benefits and may pose increased safety risk. Furthermore, the operational efficiency (up-time) and OPEX costs (well interventions and facility maintenance) for brownfield developments may offset and negate any commercial benefit over a greenfield CCS development. There is the added risk of extended monitoring periods post-injection to achieve site closure and relinquish liability for the storage site. A key technical risk I foresee for legacy wells is related to the thermal shock the wells may experience from Joules-Thomsen cooling effects when high pressure CO2 is injected into pressure depleted reservoirs or when a CO2 injection well is shut-in and there is a pressure drop in wellbore.

“There also seems to be somewhat of a double standard developing between greenfield versus brownfield CCS developments. Well designs for greenfield developments are generally being built with several layers of redundancy to ensure well integrity over geological time. In contrast, well integrity issues related to legacy wells which were designed for a completely different purpose may be seen through ‘rose coloured’ glasses by some operators.”

Regulatory and environmental pressures

Across all the issues discussed at OWI AUS, a common thread throughout was the impact of regulatory and environmental pressures and this held true when it came to CCS. On reaching this topic, the panellists sought to understand how these were reshaping and influencing the CCS landscape and what strategies operators can adopt to proactively address the concerns in their future campaigns.

Providing his perspective here, Vazquez Anzola noted, “Communication is key. The operator should provide the regulator with a holistic perspective of how their CCS projects would not only help their own decarbonisation plans, but also how they fit into a deeper and wider plan that not only results in net-zero or even negative emissions, but is directly linked to value generating models that would positively impact the community.

“A key role of the regulator is to ensure that no industrial activity causes irreversible harm to natural resources, flora and fauna as well as human life.

“When the operator genuinely seeks guidance from the regulator to enable a project that visibly generates value (and revenue) for everybody, all pieces start falling into place and true collaboration enables quality projects adhering to the highest safety and environmental standards.”

Continuing the discussion, McKenna added, “With respect to NOPTA approvals, there is an additional approval required for CCS projects in comparison to petroleum developments. This relates to approval from the Responsible Commonwealth Minister (RCM) for any Key GHG Operations (ie seismic surveys, geotechnical surveys and drilling wells). The guidance provided for these approvals is three months for NOPTA review and one month for RCM approval. If the GHG activity overlaps an existing petroleum title, the GHG Operator is required to demonstrate there will not be a ‘A Significant Risk Of A Significant Adverse Impact’ (SROASAI) on a discovered or undiscovered petroleum resource or an associated increase in costs to develop the resource.

“To facilitate timely approval of a Key GHG Operation, it is preferable for the overlapping petroleum titleholder to agree in writing that there is no significant risk posed by the GHG activity. However, if such agreement cannot be achieved, the RCM can form an independent view of the SROASAI assessment. This additional approval and the requirement to engage with overlapping titleholders has the potential to increase project development timelines. There is also the possibility that CCS proponents may have to declare force majeure if they cannot obtain RCM approval to undertake the activities related to their permit commitments. The unfamiliarity of the regulator to approve a Declaration Of Identified Storage Formation (DISF) and subsequent Injection License may increase uncertainty in project timelines for early adopters of CCS technology.

“Brownfield developments may suffer from project delays related to achieving approval of safety cases to from NOPSEMA to re-use legacy petroleum infrastructure. In terms of environmental approvals, the recent litigation against NOPSEMA approvals for petroleum activities poses similar risk for CCS activities. Furthermore, the CCS industry may be seen by activists as extending the life of the fossil fuel industry.

“I agree with Diego that communication is pivotal. A strategy of early and regular engagement with stakeholders who have high interest and high influence is Stakeholder Management 101. Education will also be a key enabler for the public acceptance of CCS technology.”

Relatively stable oil prices and a growing global oil demand is creating favourable dynamics for the oil and gas community in the near-future, however uncertainty is rife over how long this will last as the race to meet the Paris Agreement 2050 target intensifies.

While this is raising questions over further drilling activity offshore Australia, it is suggesting a promising future for the country’s well intervention market as operators seek to squeeze the last drops of oil out of existing assets and perform end-of-life work in preparation for the substantial decommissioning task ahead. At the same time, the offshore carbon capture and storage space is garnering significant interest and marks another tantalising frontier that is receiving Government backing.

Read Offshore Network’s full report to understand the background and nuances of Australia’s offshore well intervention market as well as the potential challenges (such as labour shortages and vessel availability) which threatens to stifle it.

Esso Australia, a subsidiary of Exxonmobil Australia, has entered into an agreement with Helix Energy Solutions to charter the Helix Q7000 semisubmersible vessel to support decommissioning activity across the Gippsland Basin.

Esso Australia, a subsidiary of Exxonmobil Australia, has entered into an agreement with Helix Energy Solutions to charter the Helix Q7000 semisubmersible vessel to support decommissioning activity across the Gippsland Basin.

The vessel will join Esso Australia’s growing fleet, with its roster of mobile offshore assets now including Rig 22, the HWT600 and a DOF Subsea Multi-Purpose Support Vessel.

Dylan Pugh, ExxonMobil Australia’s Chair, said, “The Helix Q7000 is a welcome addition to our extensive fleet of vessels and rigs currently operating across the Gippsland Basin. It is the forth mobile offshore asset we have added to our decommissioning fleet, and marks the first time we will be using a light well intervention vessel for subsea work locally.

“We are committed to sourcing the right assets for the work we are completing, given the variety of fields we have operated for over 50 years. Our priority is to remain safe, whilst using fit for purpose solutions which ensure we are meeting our decommissioning requirements.”

The Helix Q7000 is set to support decommissioning activities in Bass Strait from the end of 2023.

Well-SENSE, a downhole sensing specialist, has deployed its FiberLine Intervention (FLI) technology at a large carbon capture and storage (CCS) facility, in an industry-first application.

FLI has already been well-proven in a variety of seismic, acoustic and temperature monitoring applications in the oil and gas sector and has just completed its first geothermal well survey for Eden Geothermal in Cornwall.

The fibre-optic monitoring system has since been deployed for a leading integrated energy operator in Australia and marks the first time that fibre has been used to survey live CCS wells and reservoirs.

The new application in the carbon sequestration sector provides a safe, low-risk monitoring solution in a highly corrosive CO2 environment where traditional intervention solutions are often detrimentally affected.

The energy operator employed FLI in a field trial to study well integrity, CO2 flow characterisation and plume movement within the reservoir. FLI’s distributed temperature sensing (DTS) enabled assessment of the reservoir zones, while its distributed acoustic sensing (DAS) simultaneously acquired vertical and passive seismic data.

Annabel Green, CEO at Well-SENSE, commented, “Our FiberLine Intervention system was selected by this leading operator, to be evaluated as a potential alternative to the use of wireline production logging tools. Our system’s advantages include its extremely compact rig-up, much lighter surface pressure control equipment which uses a static rather than a dynamic seal and a simpler deployment method compared to conventional techniques. FLI also uses a bare fibre that is impervious to the corrosive effect of CO2, which helped to make this intervention possible.

“Several challenges were overcome efficiently, including the requirement to leave the fibre in the well for four days with exposure to strong fluid cross flows, the requirement for immediate Cloud data transfer from the wellsite to the operator’s technical centre and servicing a remote wellsite near live infrastructure. We are delighted that operations were performed incident free with no major NPT events and that our unique technology provided valuable, high-quality data from multiple wells.”

At D&A AUS 2022, Craig Costello from ASX Listed (T3K) TEK-Ocean Energy Services, provided an in-depth exploration of the company’s work within the abandonment space, explaining how it has inspected, refurbished, revalidated and recertified vintage well intervention equipment and assisted in decommissioning vintage oil and gas wells.

Speaking about wells and well intervention equipment, he presented cases of petroleum production companies with vintage subsea wells. He added that some of those wells were past their design lives and have integrity issues – both known and unknown problems. “The construction and production of these wells provided jobs for many decades. But it’s now time for these legacy wells to be plugged and abandoned, safely and efficiently,” he added.

In many cases, the required intervention equipment isn't readily available via OEMs – often because it has been retired. So this legacy vintage equipment, when it is available, requires revalidation, recertification, refurbishment and adaptation to the specifics of the project, Craig explained. Much of the legacy equipment is said to be redundant tooling.

There's an expectation from those who have worked on these wells for many years and from the broader community that the wells are abandoned safely and in a timely manner. “Increasingly, we're seeing NOPSEMA publishing directions and notices in regard to the decommissioning of wells, setting deadlines, and publishing information papers on decommissioning.”

Moving on, he presented three case studies to the audience, the first being the abandonment of some subsea wells by a semi-sub rig – Esso’s Blackback abandonment in the Gippsland basin; second was another subsea well set from a jackup rig: Esso’s Seahorse & Tarhwine abandonments; and lastly the Intervention Riser System assessment on Laminaria Corallina.

He informed that there were a lot of common themes for the three projects, one of them being that these are vintage subsea wells, with both known or otherwise unknown issues due to the lack of communication with the wells.

In all these cases, TEK-Ocean was able to provide alternative means to monitor the wells and barriers in both open water and drilling riser configurations.

Other common threads on these projects were:

• Intervening on wells past the original nominal design lives

• The vintage legacy equipment requiring revalidation, recertification and refurbishment

• Integrity issues on the wells

• Planning, innovative solution ideation and engineering.

Focusing on the first case study – the Blackback well abandonments – Craig said there were 20-year-old wells that had been shut for almost 10 years without any communications. “They have been lost from the Mackerel platform. So they didn't know the status of those wells. TEK-Ocean was selected as the lead subsea provider for that project for a turnkey solution to abandon the wells, requiring innovative approaches to get communications back to these vintage subsea control modules,” Craig added.

Hence, the scope of supply that TEK-Ocean provided for the solutions included sourcing equipment, conducting risk assessments and implementing a barrier philosophy for operational phases. The customer had supplied the vintage tree running tool and TEK Ocean recertified that.

“Re-establishing communications on these wells was a project in itself. Several pre-rig campaigns were executed to survey the assets, confirm the subsea interfaces functionality and to reduce the cost of the programme. This included ROV inspections, testing, opening and closing valves, cleaning, and debris removal."

Craig said establishing communications on those wells did take some effort as several of them that had not been attended to in a very long time and the equipment wasn’t readily available. “So TEK-Ocean was tasked with carefully assembling together a working system from three partial and broken systems that were available, with limited support and documentation from the OEM. This was successfully achieved.”

Craig informed that the Blackback wells were first attempted to be killed in 2010 via a bullhead operation from the Mackerel platform that was successful in two of the wells but it was later found that one had some internal leaks. “TEK-Ocean was not involved in the original bullhead operations but in the light of diagnostics, it was found that there was pressure on the wellhead above the master valves. Also, in 2015, communications were lost, so those investigations were a part of the 2019 campaign. The customer supplied a tree running tool, a 1980s vintage piece of equipment required for recertification and refurbishment. This recertification was achieved via crosschecking materials, part numbers, compatibility and suitability.”

One risk assessment flagged up that only one tree running tool had been provided. This was identified as a single point of failure and required de-risking because multiple runs of the tree running tool were going to be required. De-risking was achieved via a saver- sub approach that was designed, manufactured and project managed by Tek-Ocean for an integrated solution.

Moving to the second case study, he showed Seahorse & Tarhwine, which is in slightly shallower water in the Gippsland basin with 46 metres of water, and the abandonments were performed from a jack up rig. These vintage wells were drilled in the early 80s and then completed later that decade, but had been shut for five or six years, so they hadn’t been checked for quite some time. “The scope of supply in this case was a full subsea project management service again, using TEK-Ocean ISO accredited integrated management system, including all aspects of project management and engineering. The project execution plan was prepared including rig interfacing, barrier and emergency shutdown philosophies. Again, there was a TEK-Ocean managed pre-rig ROV campaign, including subsea cleaning, testing, to de-risk the rig campaign,” he added.

TEK-Ocean supplied and repaired all the equipment, again except for the tree running tool. In this project, the intervention riser system used was the TEK-Ocean dual bore riser system and this can operate down to 200 metres.

It was again a tight preparation and delivery schedule for this project. However, TEK-Ocean was able to mobilise in good time ahead of the required date set by the customer again with HSE performance and an operation during the peak COVID lockdown period in Victoria.

The third case study was the recent inspection and condition assessment of 1990s vintage Laminaria Corallina IRS. The inspection and condition assessment were carried out for both the upcoming suspension of the wells and for the future abandonment.

While concluding, Craig said that TEK-Ocean has a deep and broad knowledge of installed infrastructure throughout Australia particularly in the Carnarvon & Gippsland basins and that the company can support across all different project types. “These case studies demonstrate the recent projects that have been done in the last couple of years for major operators in the Gippsland Basin. We can help you achieve your cost and schedule goals on subsea well abandonments, and help you maintain a strong HSE performance record. TEK-Ocean is now recognised as a leading Australian company in the decommissioning space.”

Shelf Subsea have announced that the Southern Star, DPIII Saturation Diving Vessel, has arrived in New Zealand waters to commence work on phase 2 of the Tui decommissioning project.

The New Zealand Ministry of Business, Innovation and Employment (MBIE) awarded the contract to Shelf Subsea for the removal of the subsea infrastructure from the Tui Oil Field (phase 2 of the decommissioning process). This is the next step in the decommissioning of the field after the disconnection and demobilisation of the FPSO Umuroa was completed in May 2021.

The Southern Star, a 112m vessel with a 150t AHC crane, 1000m of back deck and installed WROVs. It arrived in New Zealand after encountering some poor weather, which was easily overcome.

Shelf Subsea noted that it is the most advanced DSV operating in the Asia Pacific region and comes with Port and Starboard SPHLs for greater driver safety and more efficient operations in blow-on, blow-off scenarios. As demonstrated on the journey over, the vessel handles exceptionally well in challenging weather conditions providing a stable platform for subsea intervention work.

The New Zealand Ministry of Business, Innovation and Employment (MBIE) has entered into an agreement with Helix Offshore Services Limited, a subsidiary of Helix Energy Solutions Group, for the plugging and abandonment (P&A) of the wells in the Tui Oil Field.

This is part of Phase 3 of the Tui Oil Field decommissioning.

“Helix was awarded the contract after a competitive procurement process to select a supplier that met MBIE’s objectives of a robust technical solution, flexibility in timing, competitive pricing and a commitment to working with iwi and local stakeholders,” said MBIE Tui Project Director, Lloyd Williams.

“Helix is widely recognised internationally as one of the largest and most capable contractors for well intervention and abandonment, and we are looking forward to working with them to complete the final phase of the decommissioning."

“Helix’s proposed vessel to carry out the work, the Q7000, is a state-of-the-art unit which is optimised for well decommissioning and features specialised equipment required to complete the work safely and efficiently,” added Williams.

Wharehoka Wano, CEO of Te Kāhui o Taranaki Trust, remarked, “We are very pleased the project has secured a highly competent contractor for Phase 3. This gives us every confidence as Taranaki Iwi and the hapū of Ngāti Kahumate, Ngāti Tara, Ngāti Haupoto and Ngāti Tuhekerangi as kaitiaki, to fulfil and maintain our responsibility and obligation of ensuring the mouri of our environment and cultural resources are protected and enhanced for future generations.”

The disconnection and demobilisation of the FPSO Umuroa, the first phase of the decommissioning of the Tui Oil Field, was completed in May 2021. In October 2021 the contract for the second phase of the decommissioning process, the removal of the subsea infrastructure, was awarded to Shelf Subsea Services Pte Limited. It is anticipated this phase of the work will be carried out in the summer of 2021/22 or alternatively in the summer of 2022/23.

MBIE has submitted an application for marine consents with the Environmental Protection Authority (EPA) for the removal of the subsea infrastructure and the plugging and abandoning of the Tui wells. An independent board of inquiry is considering MBIE’s application.

Subject to EPA granting the marine consents, it is anticipated the plugging and abandonment work will be carried out from late 2022.

Interventek, a subsea engineering business, has launched a new API 17G qualified, in-riser subsea landing string system, named the ‘Revolution-7’.

The landing string is an advanced, 7-inch nominal, 10,000psi rated system incorporating Interventek’s unique Revolution safety valve – proven to provide superior shear-and-seal performance. The system also includes Interventek’s PowerPlus technology, which is a unique arrangement of a locally integrated, gas-accumulated power source.

The landing string incorporates lower and upper subsea test tree valves, a latch, a retainer valve and lubricator valve. A slick joint, shear sub and project specific adaptors enable space out in the BOP and interface with the tubing hanger running tool and landing string tubulars. The system components are integrated via pre-loaded connections which provide high operational performance and fatigue resistance.

The Revolution-7 landing string is market-ready and the first systems have already been dispatched to a customer.

The company believes the system is a stand-out solution, offering industry qualification to the highest standard, combined with advanced shear-seal valve technology, rapid failsafe gas-accumulated actuation, plus a range of technical, functional and cost benefits. The valve performs both cutting and sealing functions, using separate internal components, in a single rotation, reducing the need for the usual secondary valve to provide a post-cut seal.

With fewer, simpler components, the landing string system is compact and lightweight, but stronger and more fit-for-purpose. Supply lead time, redress and maintenance are faster, which in turn reduce project and lifetime costs. The system is suitable for deployment in all BOPs and its modular nature allows additional or alternative valve functions to be incorporated.

Gavin Cowie, managing director at Interventek, said, “Historically, operators requiring subsea landing string services have relied on a handful of tier one, integrated service companies that have their own fleet of proprietary systems. We work with both the operators and service companies to supply our advanced safety valves as system upgrades, where enhanced performance and functionality is demanded.

“In developing our offering, we are now delighted to be able to supply a complete subsea landing string system to a variety of customers in this market. We see a large and collaborative opportunity in providing cost-competitive and technically advanced solutions, to improve safety and operational efficiency for the wider industry.”

For subsea well completion, intervention, workover or decommissioning operations, a landing string is deployed from a floating vessel, via a marine riser, to enable safe and environmentally secure operations. The landing string system includes a subsea test tree which provides the capability to close in the well, cut any medium in the bore and disconnect in the event of an emergency.

The shear-and-seal Revolution valve technology used in the in-riser system is also compatible with open water, tree-on-tree abandonment and surface applications. Interventek is also working towards the provision of a subsea control system to complement their advanced landing string package.

Cowie added, “Our technology is modular and universal, allowing it to be scaled up or down in its configuration and capability, and integrated with other third-party equipment. We can offer simplified landing string systems, spanner joint systems, ultra-deep water systems and high-pressure, high-temperature systems depending on the field application.”

EXCEED, an industry-leading specialist in delivering well management and performance improvement solutions to the energy sector, has announced the launch of EXCEED Australia, as it eyes the country’s burgeoning decommissioning sector and a revitalised offshore market.

The company continues to implement an unwavering strategy of international expansion with its fifth overseas entity, which builds upon recent expansion into Mexico and Norway

Brad Girdwood has been nominated to steer the ship, after his appointment as Operations Manager, Australia. He brings 30+ years’ local and international experience to EXCEED Australia.

Girdwood commented, “In the pipeline for some years, the time is now right for EXCEED to make its mark upon the region. In particular, significant legislative developments surrounding the decommissioning of Australia’s offshore and onshore assets have accelerated the sector’s timeline. Honed in the North Sea, EXCEED’s spectrum of decommissioning capability provides this evolving US$40.5bn market with critical experience and expertise.”

In with ICON

EXCEED’s entry into the local decommissioning and well management market is bolstered by the advent of a collaborative relationship with Perth-based oil and gas services provider, ICON Engineering.

EXCEED Managing Director, Ian Mills said, “ICON’s impressive track record in delivering unrivalled innovative, practical turnkey solutions to the offshore field development industry in both facilities and in support of drilling operations is entirely congruent with our approach across all stages of the well lifecycle.

“Since 2010, EXCEED has built upon its well management service through the development and implementation of efficient intervention and abandonment programmes, expertly executed in full compliance with all North Sea regularity requirements. Initially, our joint objective with ICON is to provide the emerging Australian decommissioning sector with the end-to-end project service it requires, with full focus upon compliance, safety and efficiency.”

To hear more about the blossoming opportunities presented by the Australian offshore market, be sure to attend OWI AUS, in Perth 23-24 November. To find out more information follow this link: https://www.offsnet.com/owi-aus/conference-brochure

Page 1 of 2